A boiler coal feeding device for improving coal combustion efficiency

A coal feeding device and boiler technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of inconvenient maintenance or use, complicated structure, etc., and achieve the effects of easy maintenance, simple device structure, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

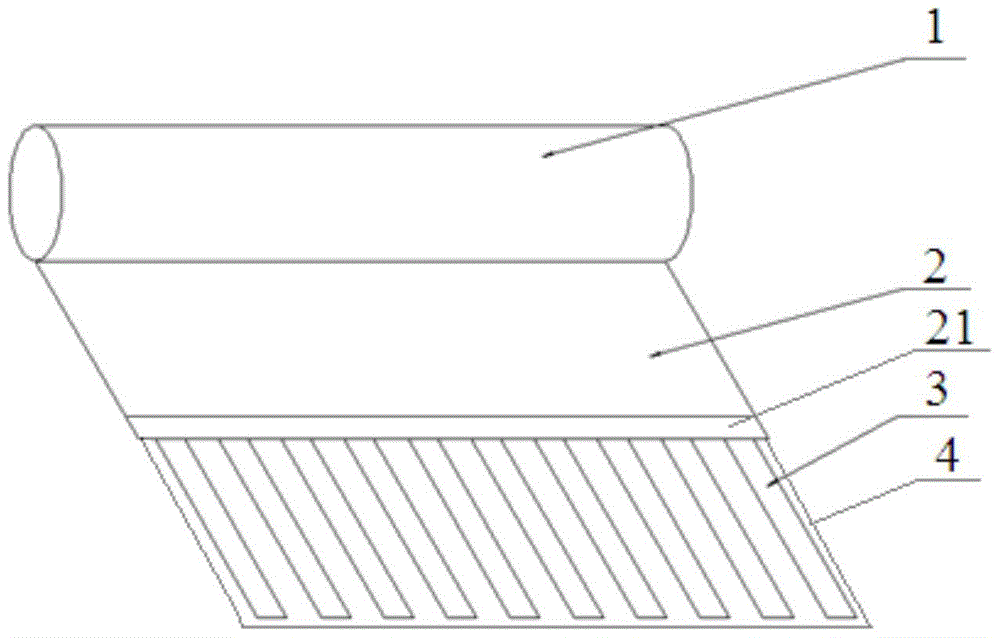

[0017] A boiler coal feeding device that improves coal combustion efficiency, such as figure 1 As shown, it is set above the grate of the boiler, including a coal hopper, and a roller 1 is arranged in the coal hopper, and the roller 1 is arranged at the exit of the coal hopper, and an elastic baffle 2 is arranged under the roller 1, and the elastic baffle 2 are arranged obliquely, and an elastic component that drives the elastic baffle 2 to bounce up and down is provided below the elastic baffle 2, and the elastic component is a spring. A sub-sieve assembly is arranged below the elastic baffle 2, the upper end of the sub-sieve assembly overlaps with the lower end of the elastic baffle 2, and the lower end of the sub-sieve assembly is located above the grate.

[0018] The sieve assembly includes an upper sieve plate 3 and a lower receiving plate 4, the upper sieve plate 3 is a flat plate with vertical grooves spaced thereon. The lower floor receiving plate 4 is a complete plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com