A zirconium-doped vanadium-based oxide catalyst, preparation method and use thereof

A zirconium oxide and catalyst technology, applied in the field of zirconium-doped vanadium-tungsten-titanium oxide catalysts, can solve problems such as poor high-temperature stability, and achieve the effects of excellent high-temperature stability and excellent N2 generation selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

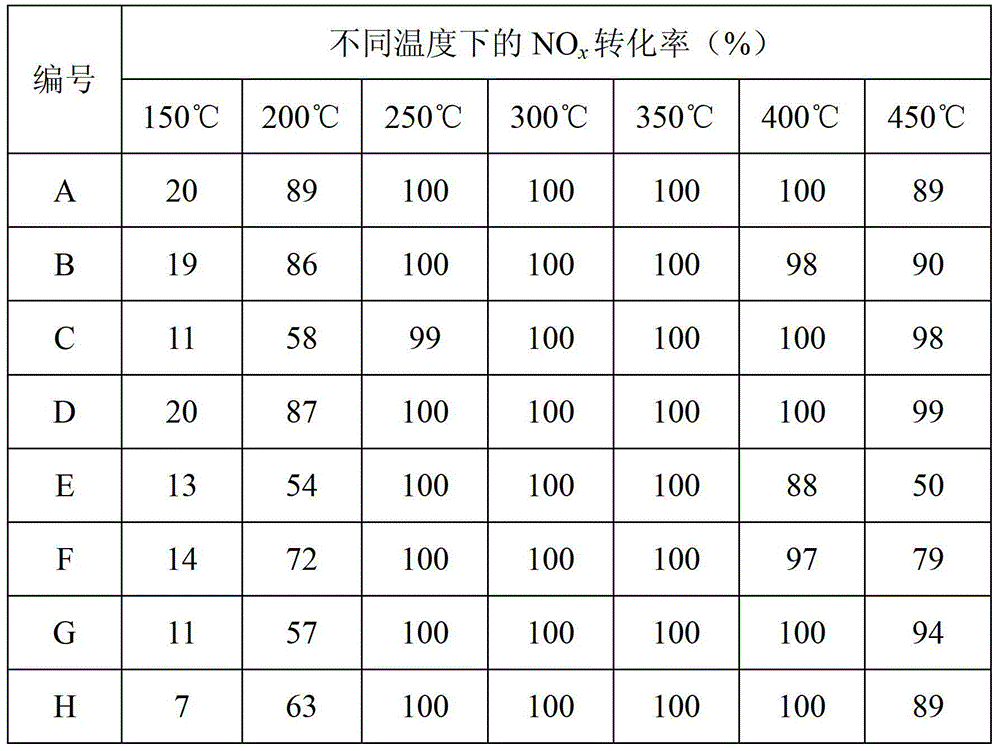

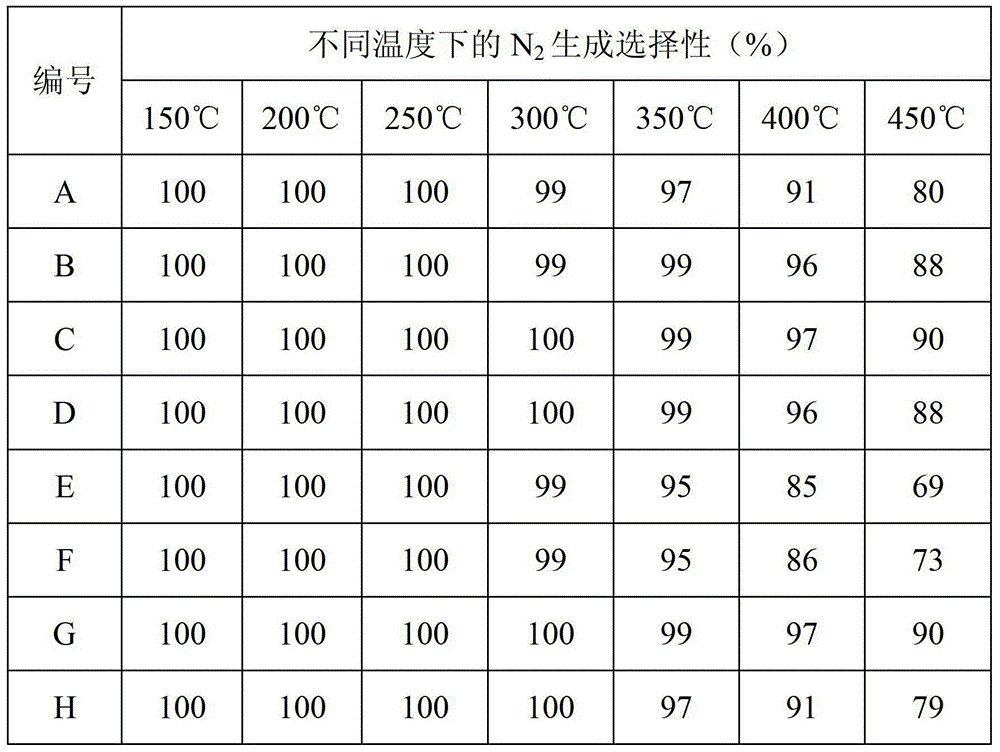

[0038] Dissolve 0.964g ammonium metavanadate in oxalic acid solution (mass ratio of ammonium metavanadate to oxalic acid is 1:2), make 750ml mixed solution, mix well, add 25g titanium tungsten powder (10% WO 3 -TiO 2 ), fully stirred for 1 h, and then the mixed slurry was rotatably evaporated until the water was fully volatilized, dried at 100 °C for 12 h, and finally roasted at 550 °C for 3 h to obtain 3% V 2 o 5 / 10% WO 3 -TiO 2 catalyst.

[0039] Grind and sieve the prepared catalyst, and take 40-60 mesh for later use, which is called catalyst A.

Embodiment 2

[0041] 0.964g ammonium metavanadate (NH 4 VO 3 ) was dissolved in oxalic acid solution (the mass ratio of ammonium metavanadate to oxalic acid was 1:2), and 1.74g of zirconium nitrate pentahydrate (Zr(NO 3 ) 4 ·5H 2 O), prepared into 750mL mixed solution, mix well, add 25g titanium tungsten powder (10%WO 3 -TiO 2 ), fully stirred for 1 h, and then the mixed slurry was rotatably evaporated until the water was fully volatilized, dried at 100 °C for 12 h, and finally roasted at 550 °C for 3 h to obtain 3% V 2 o 5 -2%ZrO 2 / 10% WO 3 -TiO 2 catalyst.

[0042] Grind and sieve the prepared catalyst, and take 40-60 mesh for later use, which is called catalyst B.

Embodiment 3

[0044] Other conditions are as embodiment 2 constant, change zirconium nitrate pentahydrate add-on to be 4.36g, obtain 5% V 2 o 5 -2%ZrO 2 / 10% WO 3 -TiO 2 catalyst. Grind and sieve the prepared catalyst, and take 40-60 mesh for later use, which is called catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com