Fe-modified nano manganese oxide/MIL-125 (Ti) catalyst and preparation method thereof

A nano-manganese and oxide technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost and high energy consumption, and reduce the Reaction temperature and poisoning, deposition inhibition, excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

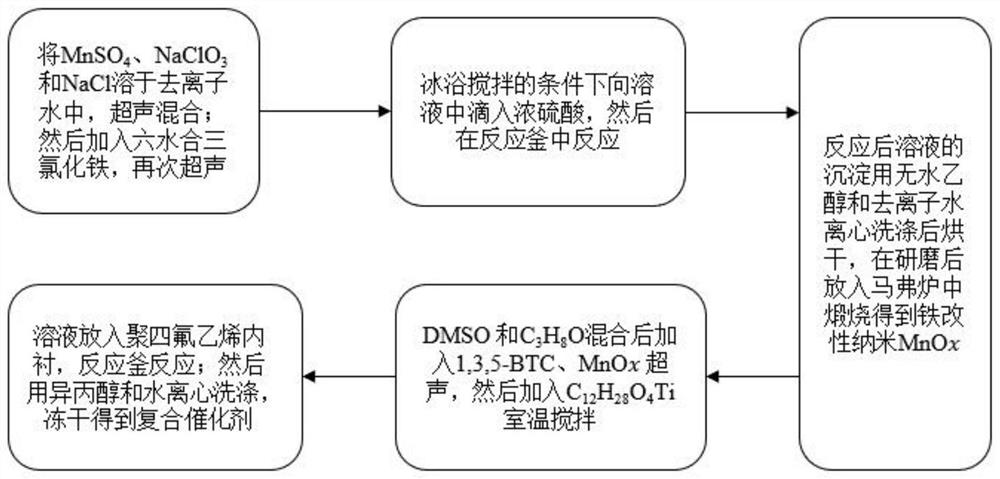

[0024] Step 1: Add 0.01mol of MnSO 4 , 0.025mol of sodium chlorate NaClO 3 Dissolve 2.925g of NaCl in 50ml of deionized water, and mix well by ultrasonication for 5min; then add 0.135g of ferric chloride hexahydrate, and ultrasonicate again for 10min. Then, 8 ml of concentrated sulfuric acid was slowly dropped into the mixture under constant stirring in an ice bath to form a clear solution. After the dropwise addition was completed, it was put into a reaction kettle and reacted at 120° C. for 8 hours.

[0025] Step 2: After 8 hours, the precipitate of the solution was washed by centrifugation with absolute ethanol, and then with deionized water; and then dried in an oven at 70°C. After drying, it was put into a mortar and ground, then calcined in a muffle furnace at 400°C for 10 minutes, and then heated to 600°C at a rate of 8°C / min for 2h to obtain iron-doped modified nano-MnOx.

[0026] Step 3: Mix 42.5ml of DMSO and 15.3ml of C 3 h 8After O mixing, add 4.2 g of trimesi...

Embodiment 2

[0028] Step 1: Add 0.008mol of MnSO 4 , 0.032mol of sodium chlorate NaClO 3 Dissolve 4.69g of NaCl in 50ml of deionized water, and mix well by ultrasonication for 5min; then add 0.216g of ferric chloride hexahydrate, and ultrasonicate again for 10min. Then, 8.6 ml of concentrated sulfuric acid was slowly added dropwise with constant stirring in an ice bath to form a clear solution. After the dropwise addition was completed, it was put into a reaction kettle and reacted at 150° C. for 5 hours.

[0029] Step 2: Same as Step 2 in Example 1.

[0030] Step 3: Mix 56.7ml of DMSO and 11.5ml of C 3 h 8 After O mixing, 8.4g of trimesic acid (1,3,5-BTC) and 1.8g of modified nano-MnOx were added to the mixed solution, and the solute was evenly distributed by ultrasonication for 20min; then 1.5ml of tetraisopropyl titanic acid was added Ester (C 12 h 28 o 4 Ti), stirred at room temperature for 20 min. After stirring, the solution was transferred to a polytetrafluoroethylene linin...

Embodiment 3

[0032] Step 1: Add 0.01mol of MnSO 4 , 0.032mol of sodium chlorate NaClO 3 Dissolve 3.5g of NaCl in 50ml of deionized water, and mix well by ultrasonication for 5min; then add 0.2g of ferric chloride hexahydrate, and ultrasonicate again for 10min. Then, 9 ml of concentrated sulfuric acid was slowly added dropwise with constant stirring in an ice bath to form a clear solution. After the dripping is completed, put it into the reaction kettle and react at 140°C for 5.5h.

[0033] Step 2: Same as Step 2 in Example 1.

[0034] Step 3: Combine 50ml of DMSO and 14ml of C 3 h 8 After O mixing, add 6.3g of trimesic acid (1,3,5-BTC) and 1.5g of modified nano-MnOx into the mixed solution, and ultrasonically 20min to make the solute evenly distributed; then add 2ml of tetraisopropyl titanate (C 12 h 28 o 4 Ti), stirred at room temperature for 20 min. After stirring, the solution was transferred to a polytetrafluoroethylene lining, and reacted at 170° C. for 5 hours in a reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com