Patents

Literature

59results about How to "Wide operating temperature window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium-zirconium-tungsten composite oxide catalyst as well as preparation method and usage thereof

ActiveCN103240079AWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumNitric oxide

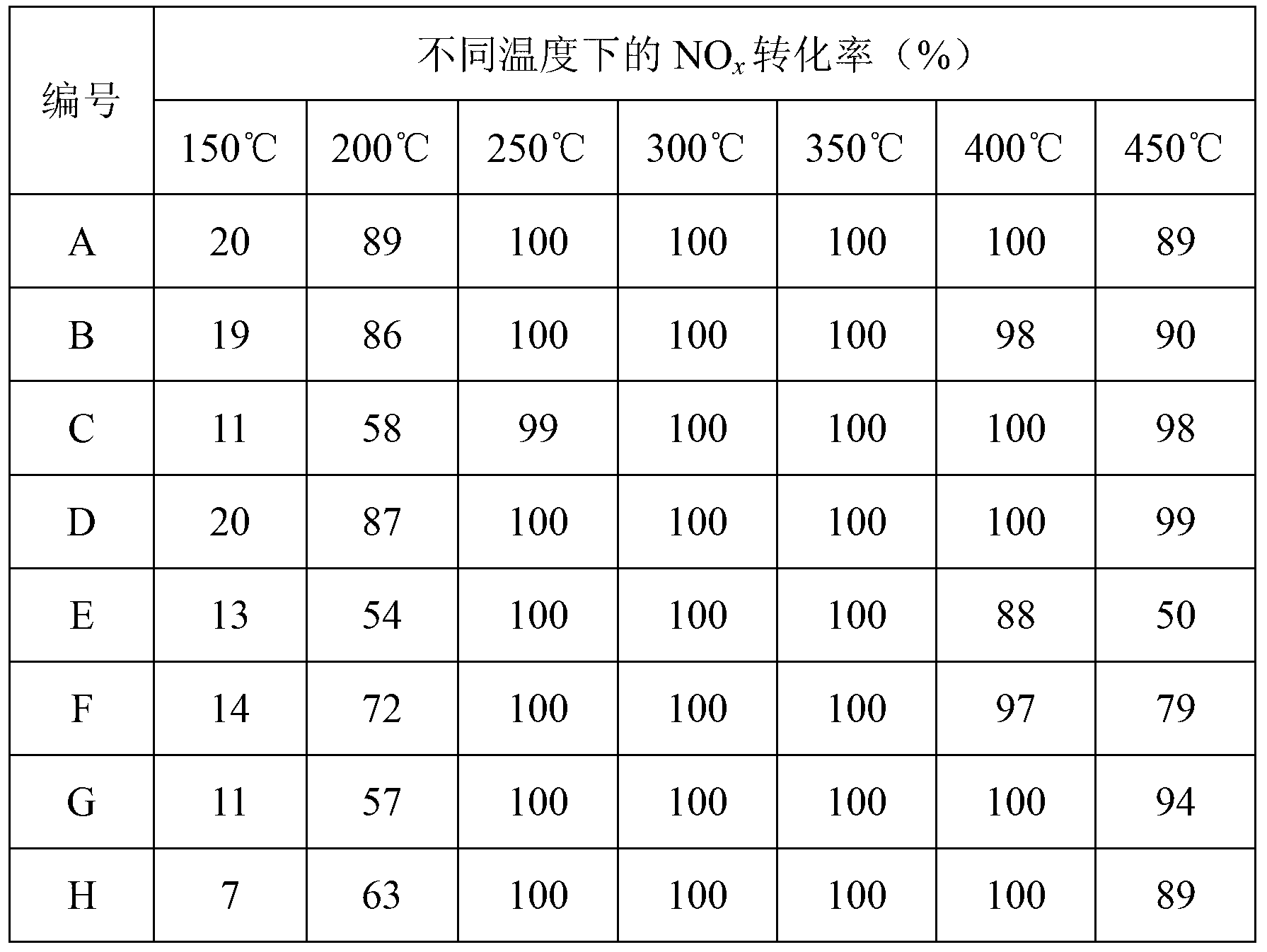

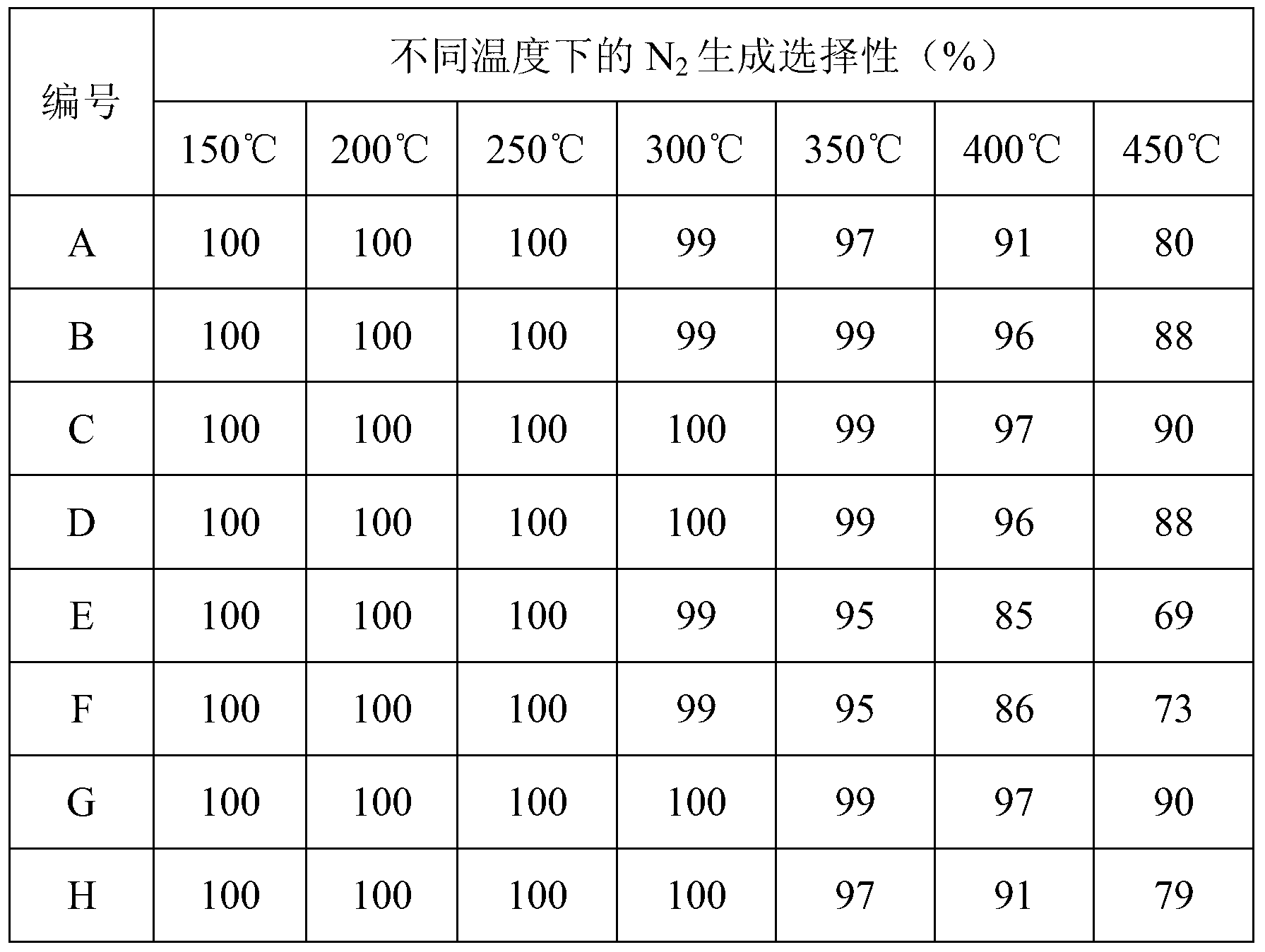

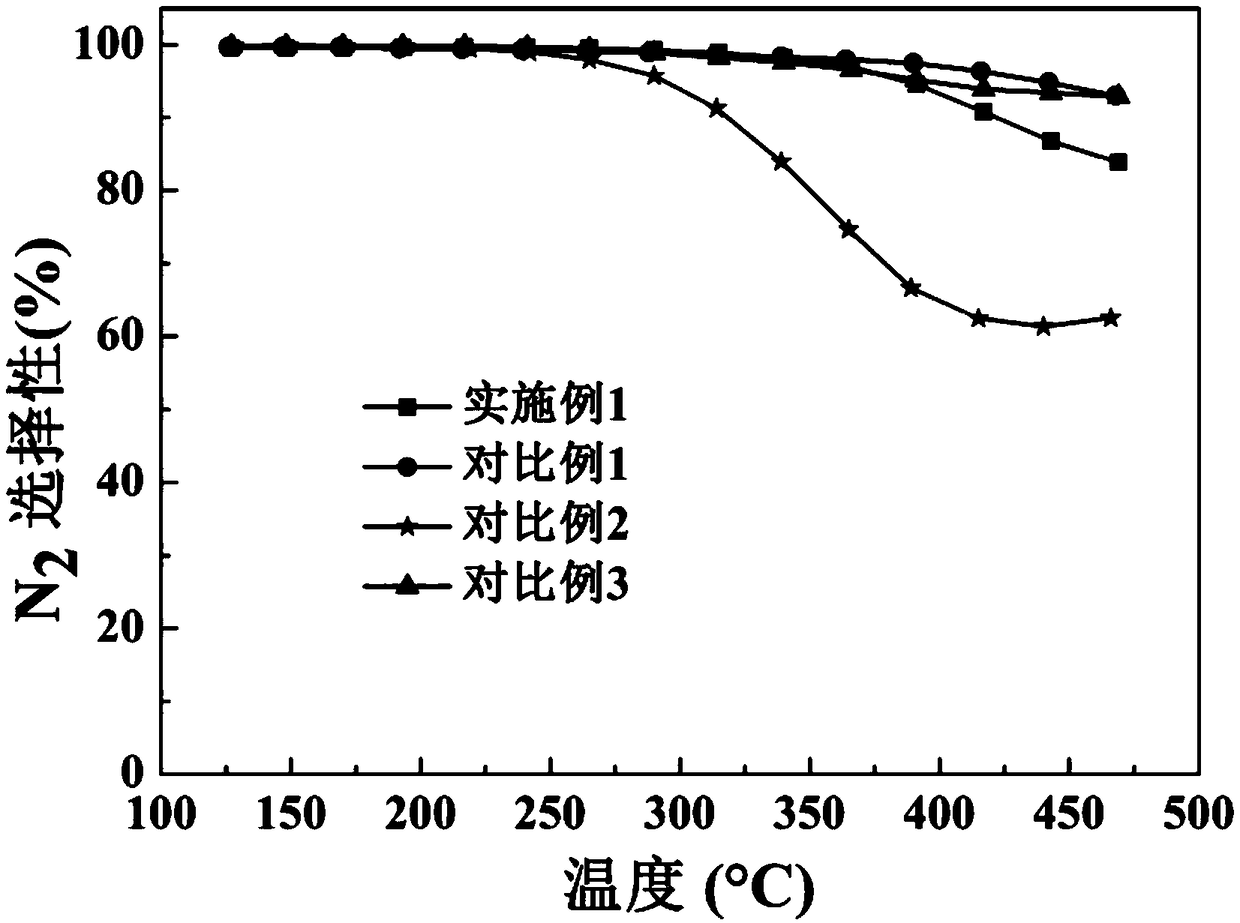

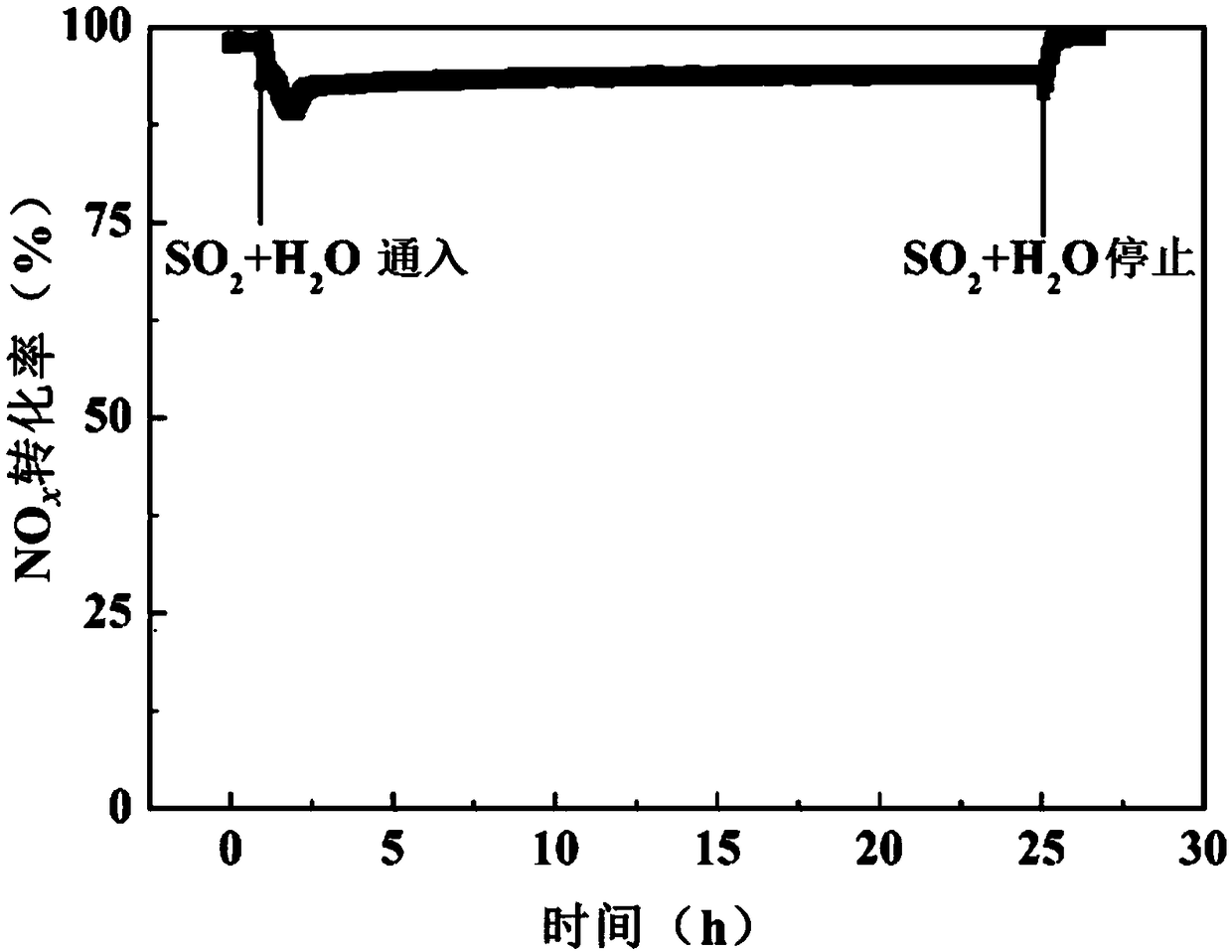

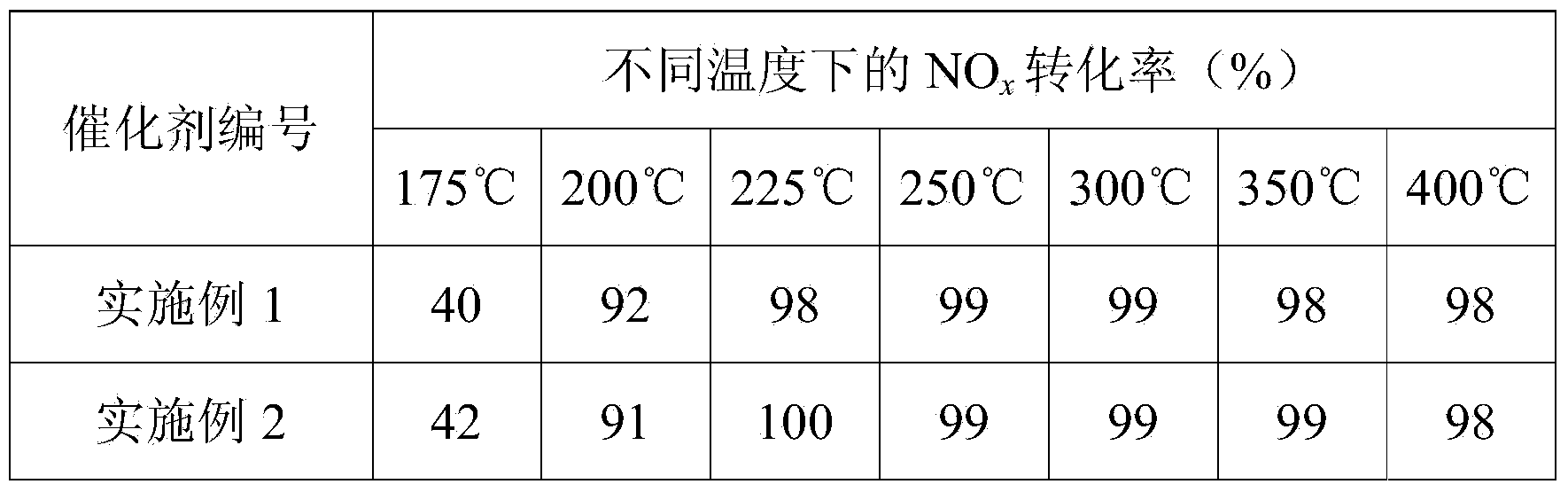

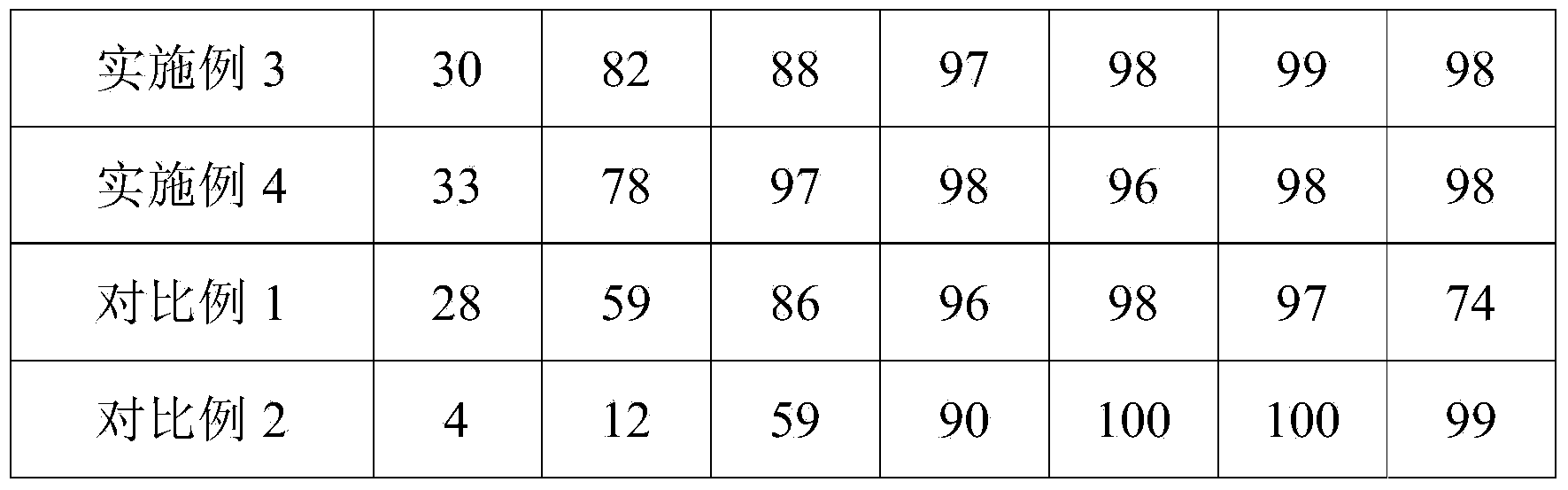

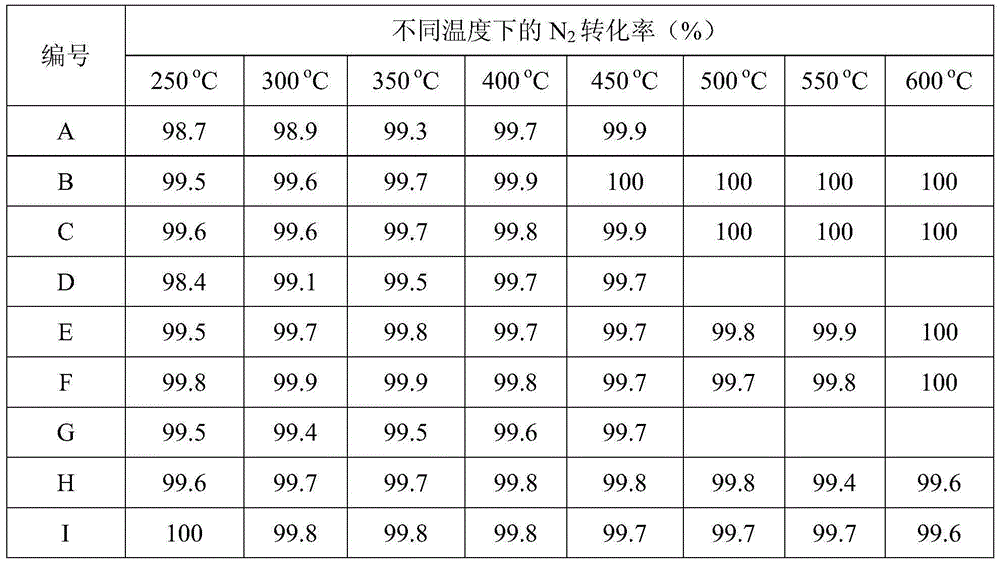

The invention relates to a cerium-zirconium-tungsten composite oxide catalyst used for carrying out selective catalytic reduction on nitric oxide by ammonia, as well as a preparation method and usage thereof. The catalyst is a composite metal oxide formed by three types of metal including cerium, zirconium and tungsten. The catalyst adopts non-toxic and harmless raw materials; the cerium-zirconium-tungsten composite oxide catalyst which can adapt to high space velocity reaction condition and has the characteristics of being excellent in catalytic activity, high in N2 generation selectivity, wide in operating temperature window and the like can be prepared by using a simple and practicable method; and the cerium-zirconium-tungsten composite oxide catalyst is suitable for a nitric oxide catalytic purification device used for a moving source represented by diesel exhaust and a fixed source represented by flue gas of a coal-fired power plant.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

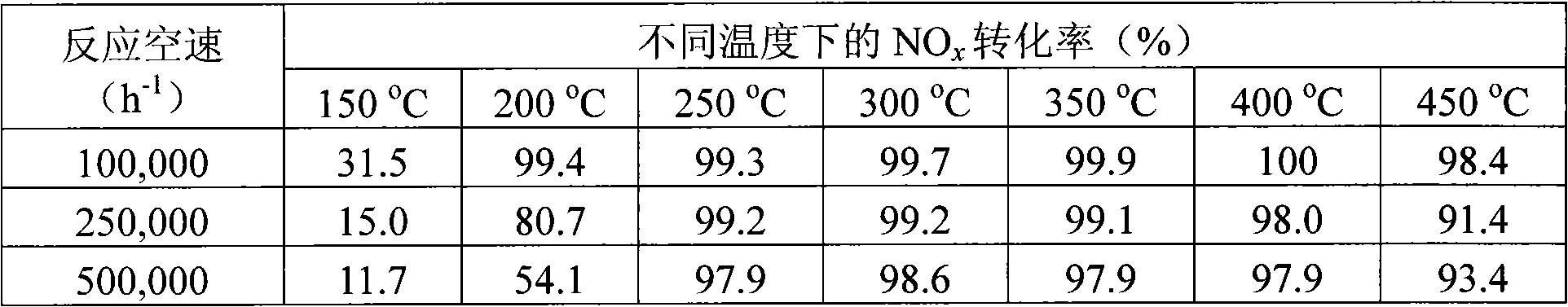

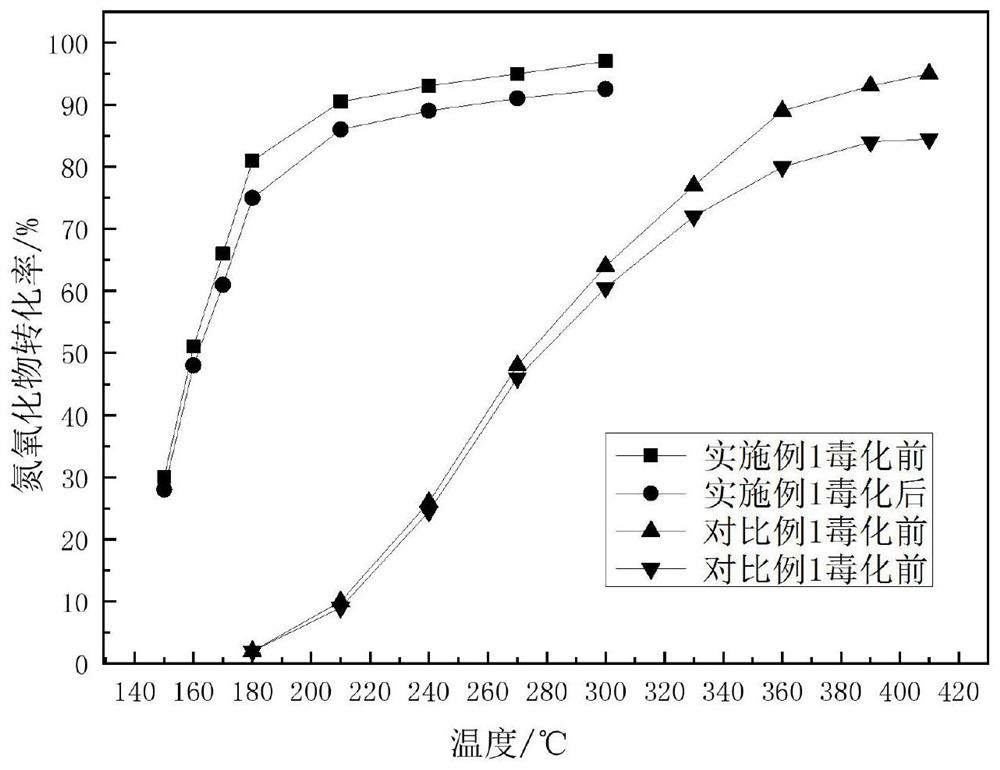

CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

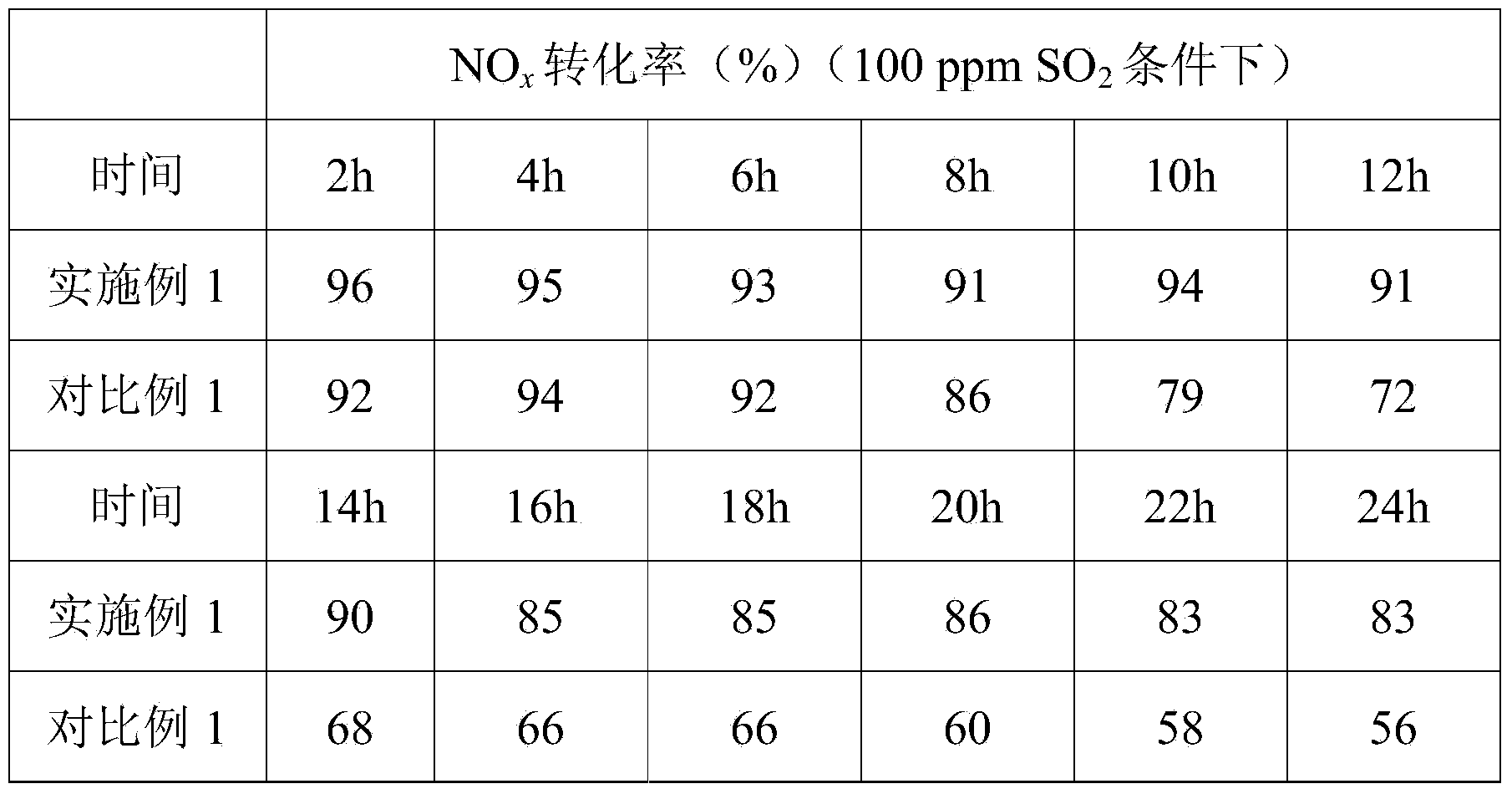

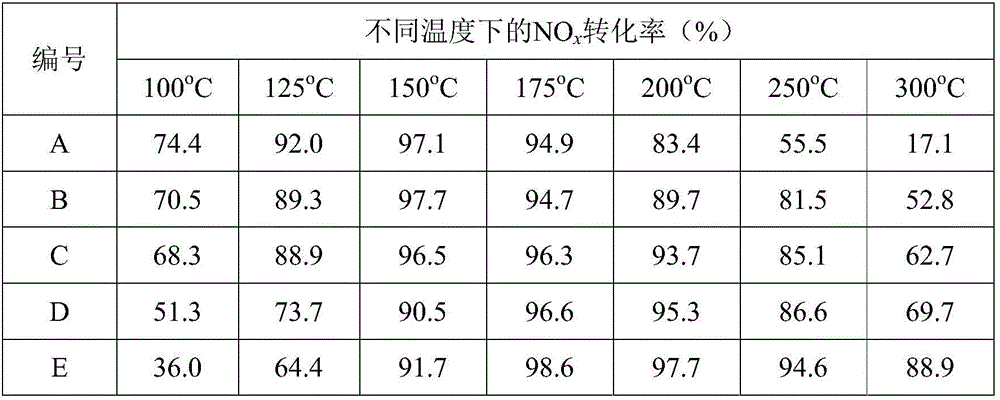

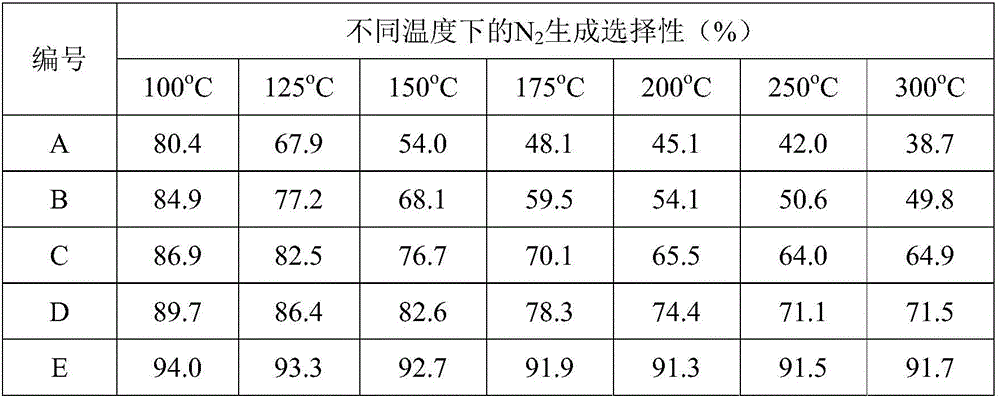

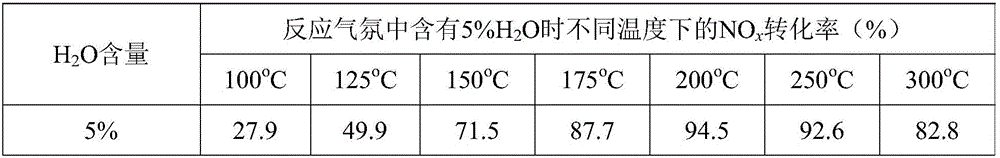

ActiveCN102240543AImprove anti-sulfur poisoning performanceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurWorking temperature

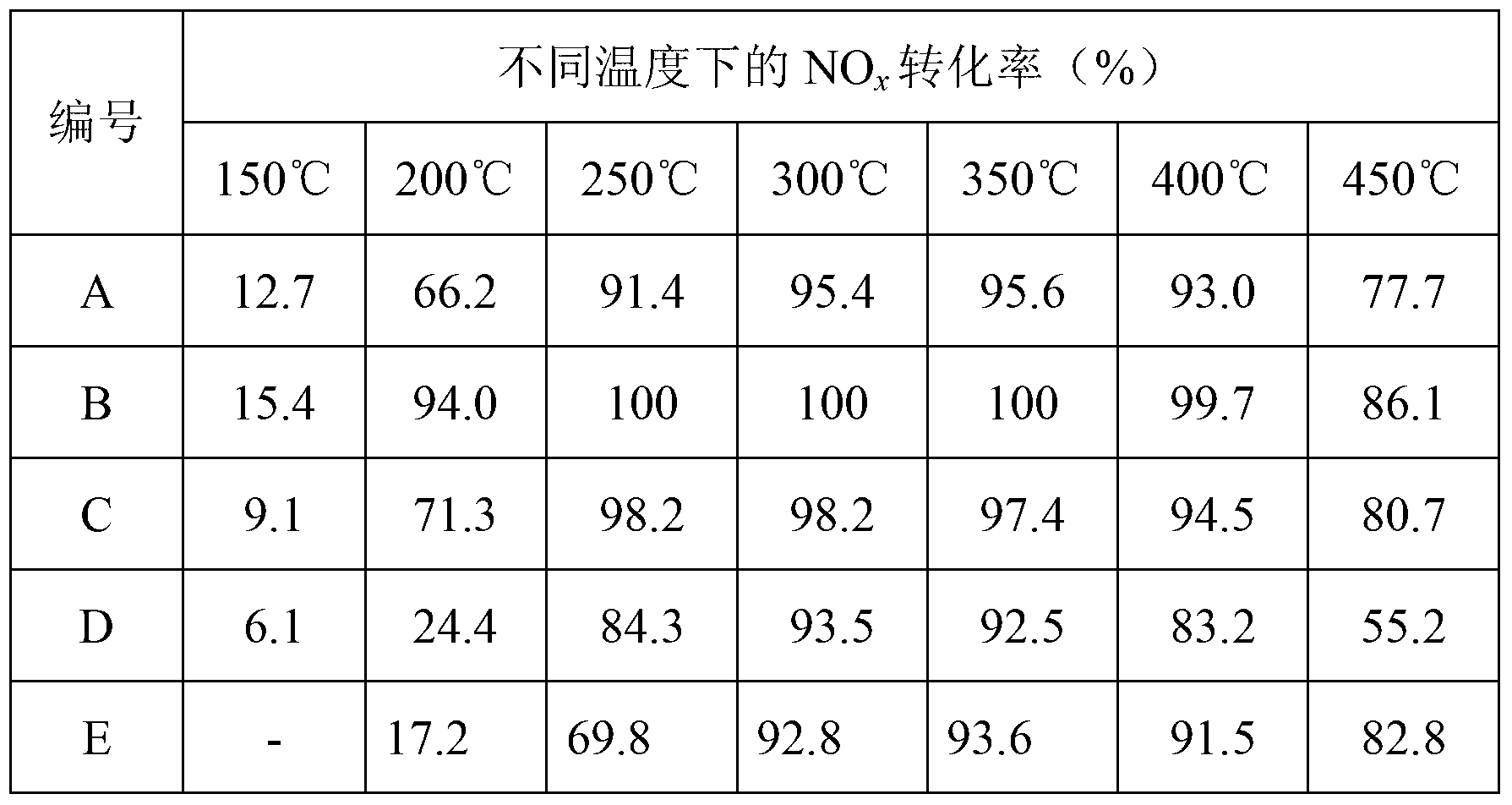

The invention discloses a CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and a preparation thereof and belongs to the field of nitric oxide post-processing purification. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier; an active coating is loaded on the carrier; a modifying coating is loaded on the active coating; the cordierite carrier has a skeleton carrying function; the active coating of the catalyst mainly has a function of activating NOx and NH3; and the modifying coating mainly has functions of storing NH3, avoiding deep oxidation of NH3 on the surface of the catalyst when the catalyst is used at a high temperature and increasing the sulfur poisoning resistance of the catalyst. The preparation process of the catalyst is simple and can be easily industrialized. A working temperature window of the optimized catalyst can reach 250-450 DEG C, and denitration efficiency is above 80%. The catalyst has the significant advantage of being nontoxic and has excellent heat stability and excellent SO2 poisoning resisting property.

Owner:TSINGHUA UNIV +1

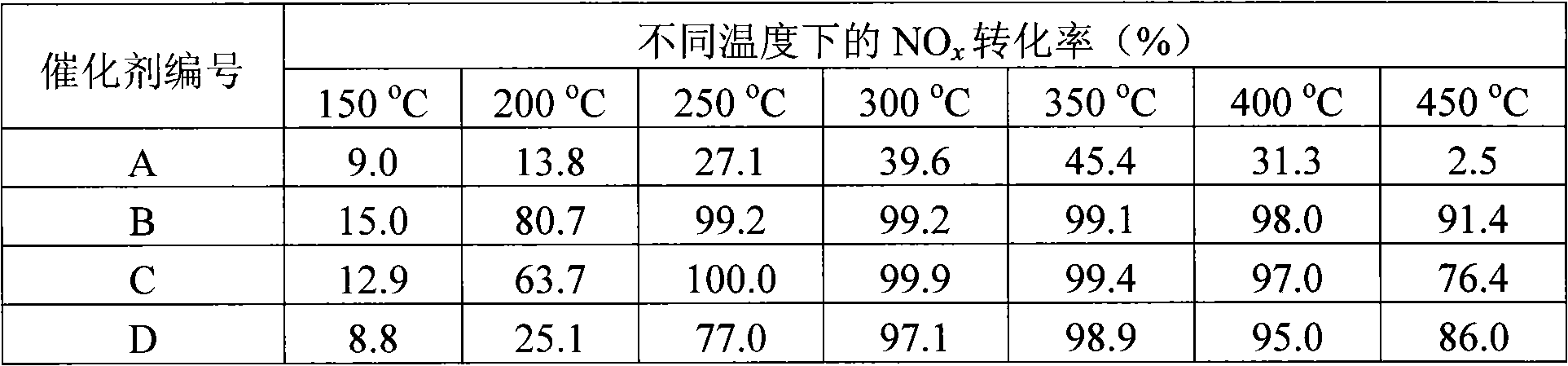

Cerium-based composite oxide catalyst for catalyzing and purifying nitric oxide

ActiveCN102000560AExtended service lifeWide operating temperature windowInternal combustion piston enginesHeterogenous catalyst chemical elementsCeriumNitric oxide

The invention relates to a cerium-based composite oxide catalyst for ammonia selective catalytic reduction of nitric oxide and a preparation method thereof. The catalyst of the invention is a metal composite oxide catalyst comprising any one or more transition metals of cerium, tungsten, molybdenum and ferrum. The preparation method of the catalyst is an even precipitating method and comprises the following steps of: preparing the needed cerium salt and salt corresponding to any one or more transition metals into a mixed solution; with excessive urea as a precipitant, continuously stirring for 8-15 hours under the condition of the temperature of 90-95 DEG C; and then sucking for filtering, washing, drying and calcining to obtain the cerium-based composite oxide catalyst. In the invention, the cerium-based composite oxide catalyst which has the characteristics of high catalytic activity, excellent N2 generating selectivity, wide operating temperature window, adaption of high-air speed reaction condition, and the like is prepared by adopting a non-toxic and harmless raw material through a simple and easy method, and the cerium-based composite catalyst is suitable for a moving source nitric oxide catalytic purification device represented by the tail gas of a diesel vehicle and a fixed source nitric oxide catalytic purification device represented by the smoke of a coal fired power plant.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

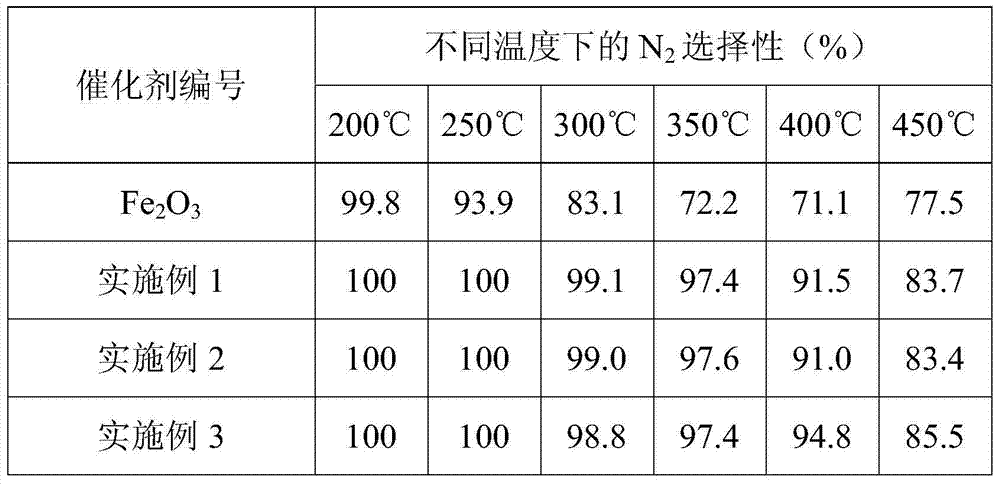

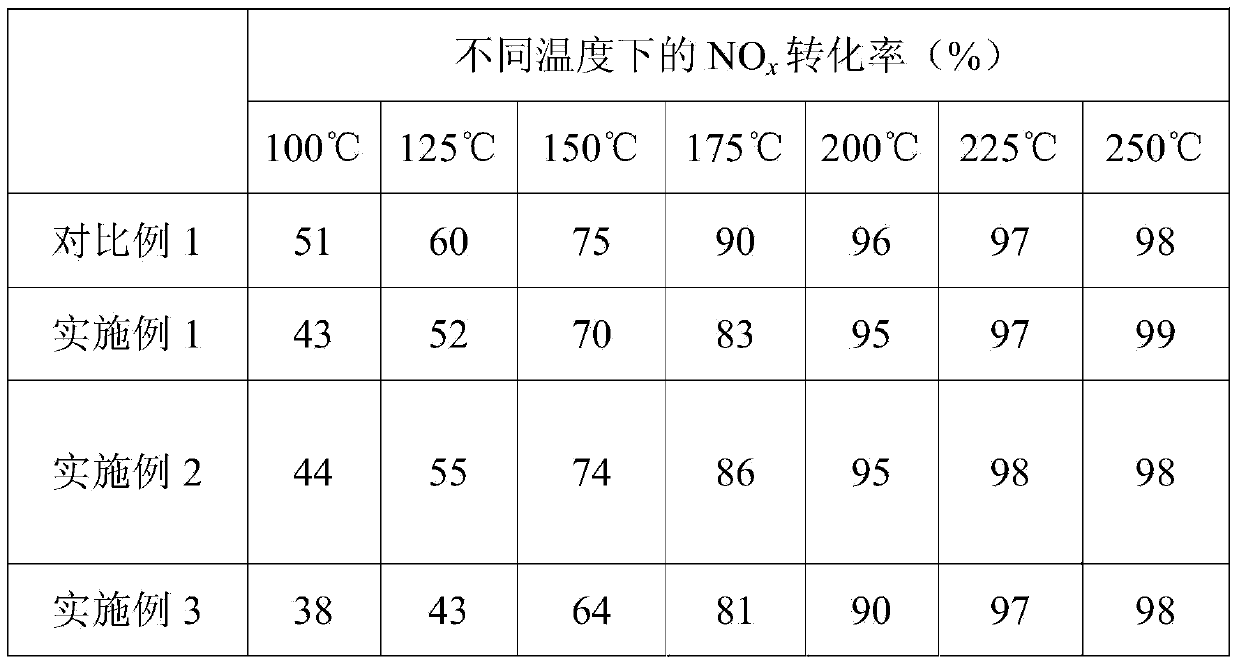

SCR (selective catalytic reduction) nitrogen oxide catalyst, and preparation method and application thereof

ActiveCN102764645AWide operating temperature windowGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOperating temperatureComposite oxide

The invention relates to an SCR (selective catalytic reduction) nitrogen oxide catalyst, and a preparation method and application thereof, belonging to the field of catalysis. The SCR nitrogen oxide catalyst is a composite oxide catalyst composed of manganese and at least one transition metal. The SCR nitrogen oxide catalyst is prepared from non-poisonous raw materials through a method which is simple and easy to operate, and has the advantages of wide operating temperature window, good low-temperature activity and excellent N2 generation selectivity. Thus, the catalyst is very suitable for the purification of nitrogen oxide in flue gas from coal-fired power plants representative of stationary sources.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Transition metal doped cerium and titanium compound oxide catalyst for selective catalytic reduction of nitric oxide by ammonia

ActiveCN102302930ACause harmWide operating temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumSodium hydroxide

The invention relates to a transition metal doped cerium and titanium compound oxide catalyst for selective catalytic reduction of nitric oxide by ammonia, and a preparation method thereof. The catalyst in the invention is a transition metal (iron, tungsten and molybdenum) doped cerium and titanium compound oxide catalyst. The preparation method of the catalyst is a co-precipitation method, which comprises the following steps of: preparing mixed solution from cerium salt, titanium salt and salt corresponding to one or more transition metals of iron, tungsten and molybdenum, and continuously stirring for 3 to 15 hours at the temperature of between 50 and 150 DEG C by using one of ammonia water, sodium hydroxide, sodium carbonate, ammonium bicarbonate or urea; and filtering, washing, baking and calcining. In the invention, the adopted raw materials are non-toxic and harmless, the preparation method is simple and easy, the prepared catalyst has the characteristics of high catalytic activity, excellent N2 generation selectivity, broad operation temperature window, high space velocity reaction condition adaptability and the like, and is suitable for mobile sources represented by tail gas of diesel vehicles, as well as stationary source nitric oxide catalytic purification device represented by flue gas of coal fired power plants.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Double-perovskite metal oxide catalyst and preparation method thereof

InactiveCN104707617AEasy accessLow costGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsCoprecipitationOxide

The invention discloses a double-perovskite metal oxide catalyst. The formula of the double-perovskite metal oxide catalyst is LaSrFeMo1-xCoxO6, wherein x is greater than or equal to 0.1 and less than or equal to 1. The invention discloses four methods, that is, a coprecipitation method, a gel-sol method, a reversed-phase microemulsion method and a hard template method in all to prepare a series of double-perovskite metal oxide catalysts. As nitrate, ammonium carbonate, citric acid, glucose and the like are taken as raw materials, the double-perovskite metal oxide catalyst is wide in raw material source, easy to prepare and low in cost; under conditions of specific reaction steps and process parameters, a complete double-perovskite crystal form is formed through specific high-temperature roasting, the whole preparation method is simple, and the yield is relatively high.

Owner:CHUZHOU UNIV

Zirconium-doped vanadium-based oxide catalyst, and preparation method and application thereof

ActiveCN103252232AWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoal plantNitrogen

The invention relates to a zirconium-doped vanadium-based oxide catalyst for selectively catalyzing and reducing the nitrogen oxide through ammonia, and a preparation method thereof. The catalyst is a metal oxide catalyst which is formed by loading zirconium and vanadium oxide onto the surface of titanium tungsten powder. Through the zirconium doping method, the catalytic properties such as high-temperature stability of the traditional vanadium-based catalyst and the N2 (nitrogen) generation selectivity can be greatly improved, the prepared zirconium-doped vanadium-based oxide catalyst is suitable for a nitrogen oxide catalytic purifying device adopting the diesel exhaust as a representative movable resource and the smoke of a coal plant as a representative fixed source.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Heteropoly-acid-doped cerium oxide SCR denitration catalyst, preparation method therefor and application of catalyst

InactiveCN106582739AExtended service lifeLarge specific surface areaPhysical/chemical process catalystsDispersed particle separationGlass fiberSulfur

The invention discloses a heteropoly-acid-doped cerium oxide SCR denitration catalyst. The heteropoly-acid-doped cerium oxide SCR denitration catalyst is characterized in that heteropoly acid is Keggin-type phosphotungstic acid HPW, and the doped amount of the heteropoly acid is 5wt% to 15wt%. According to the catalyst, anatase TiO2 serves as a carrier, a mixture of cerium oxide CeO2 and the Keggin-type phosphotungstic acid HPW loaded to the carrier serves as an active component, and the catalyst is represented as CeO2-HPW / TiO2. The catalyst contains the following ingredients by content: 65wt% to 85wt% of TiO2 and glass fibers, 5wt% to 20wt% of CeO2 and 5wt% to 15wt% of HPW. The invention further discloses a preparation method for the catalyst and an application of the catalyst. The catalyst has relatively high catalytic oxidation-reduction power and acidic sites and achieves relatively high catalyst reaction activity at relatively low reaction temperatures, so that the low-temperature denitration efficiency and sulfur resistance are effectively improved.

Owner:LONGYAN ZIJIN INNOVATION RES INST

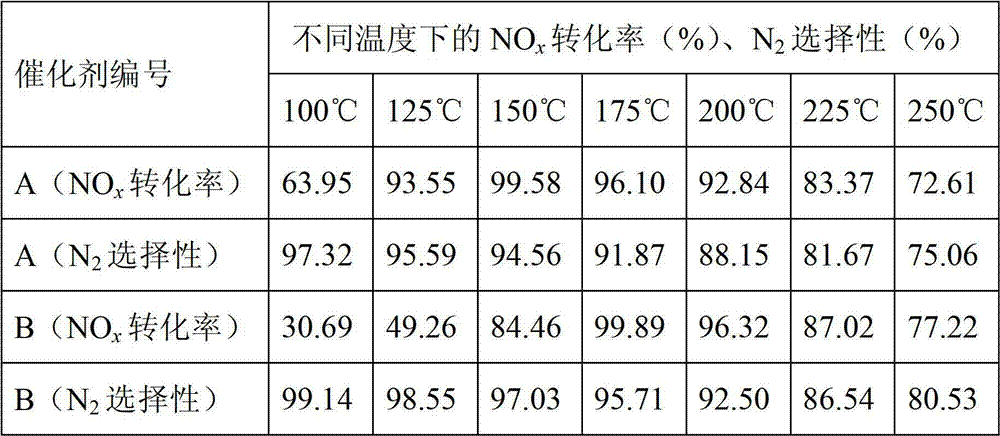

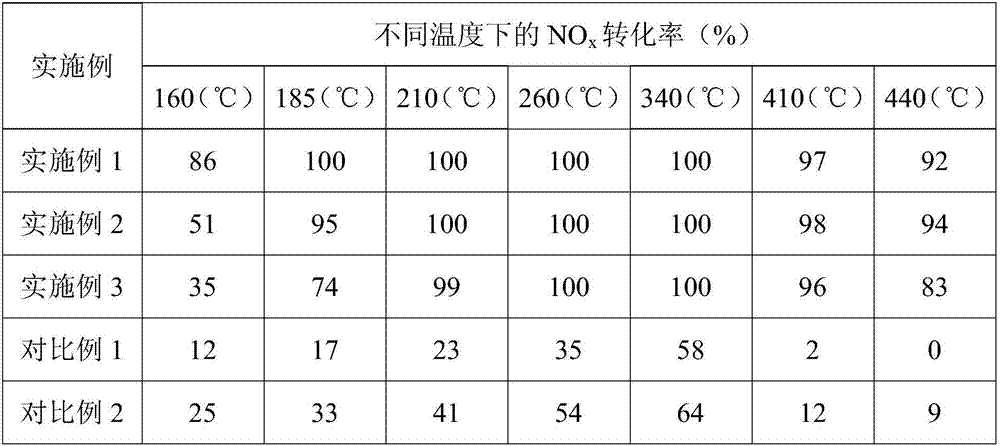

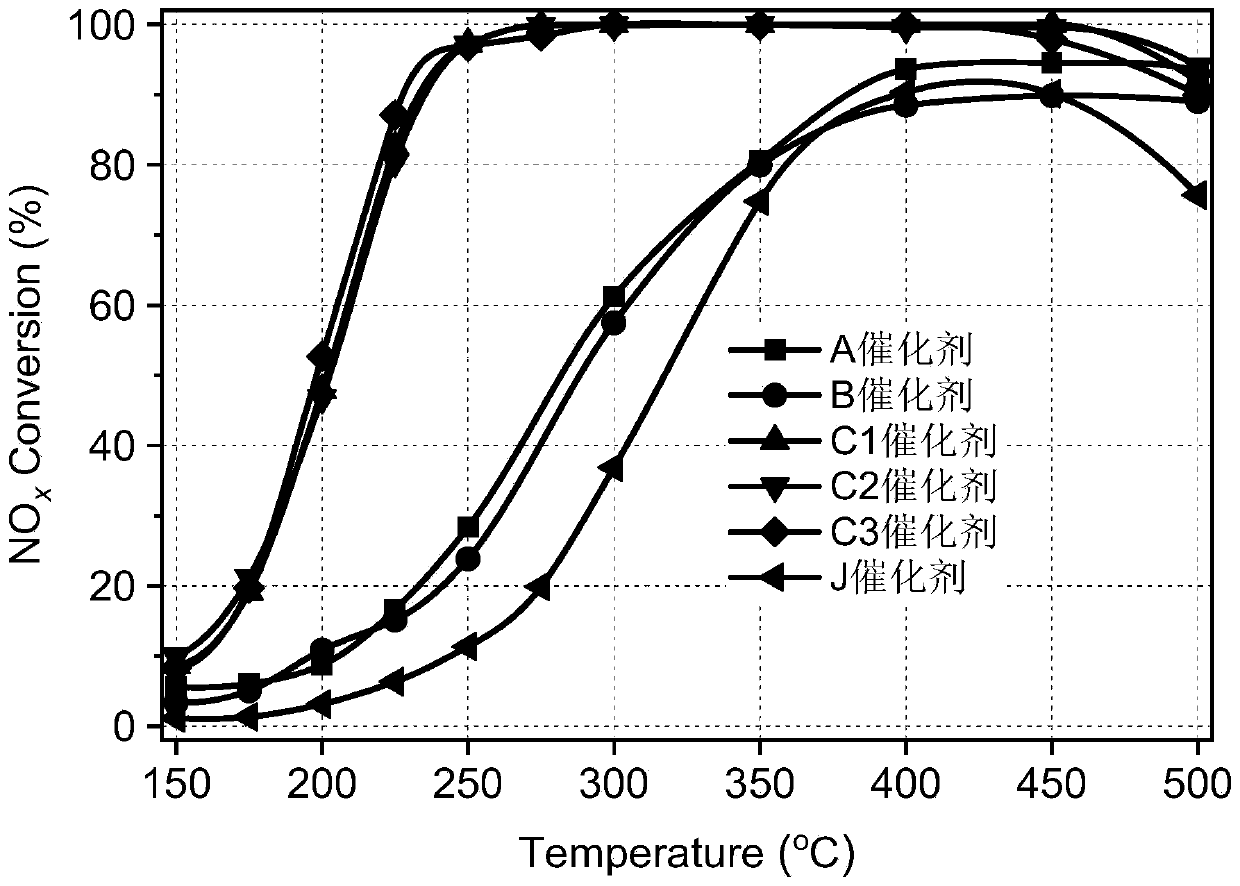

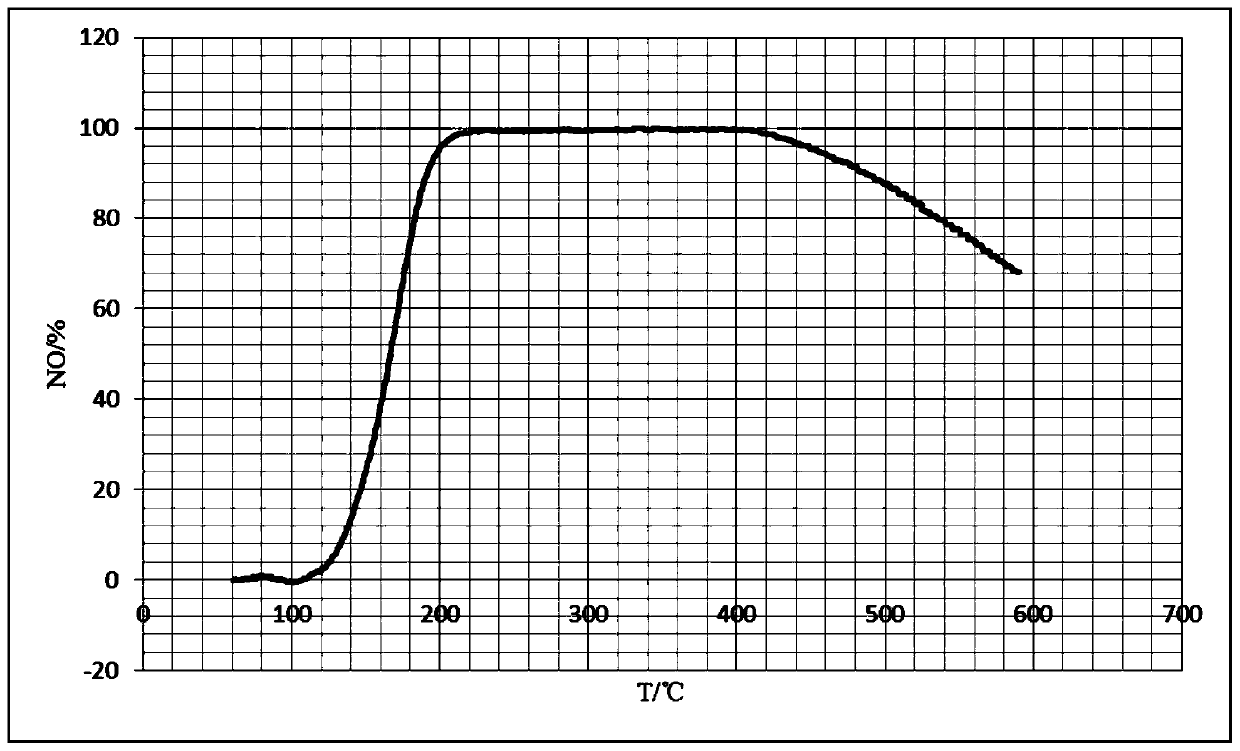

Cerium-based catalyst loaded with transition metal as well as preparation method and purpose thereof

ActiveCN107398266AIncrease acidityHigh catalytic activityGas treatmentDispersed particle separationCeriumActive ingredient

The invention provides a cerium-based catalyst loaded with transition metal as well as a preparation method and a purpose thereof. For the cerium-based catalyst loaded with transition metal, a catalyst carrier is CeO2; active ingredients are transition metal oxides loaded on the carrier; through being metered by that the mass of the CeO2 carrier is 100 percent, the mass of the transition metal oxides is 5 to 20 percent. The cerium-based catalyst loaded with transition metal provided by the invention has the NOx purification efficiency being near 100 percent in the temperature range of 200 to 440 DEG C; the operation temperature window is wide. The preparation method is simple; the prepared cerium-based catalyst loaded with transition metal can be used for NOx catalytic purification in the NH3-SCR process.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

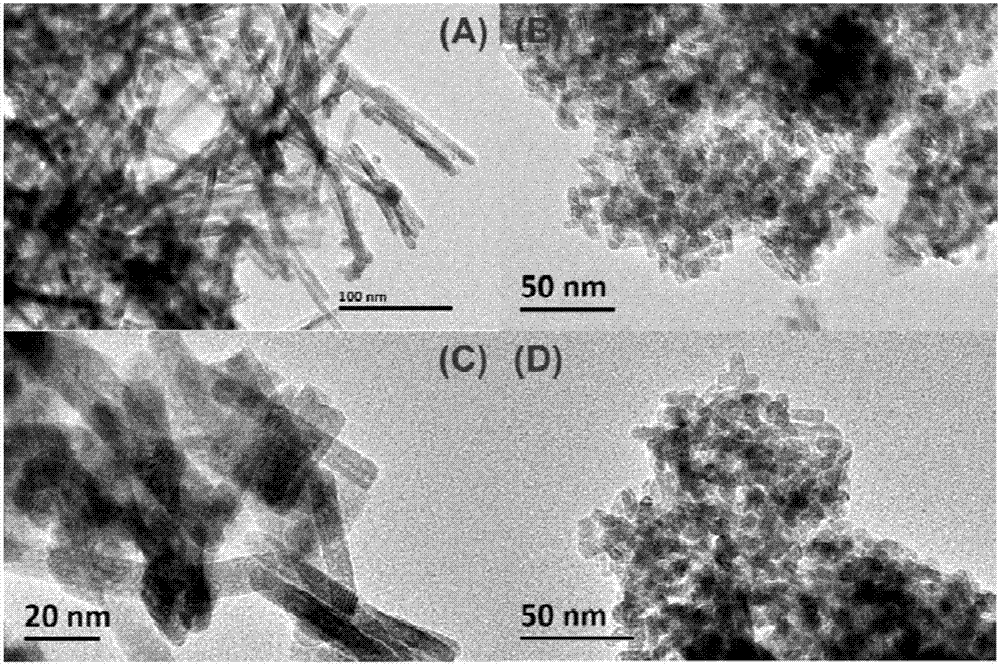

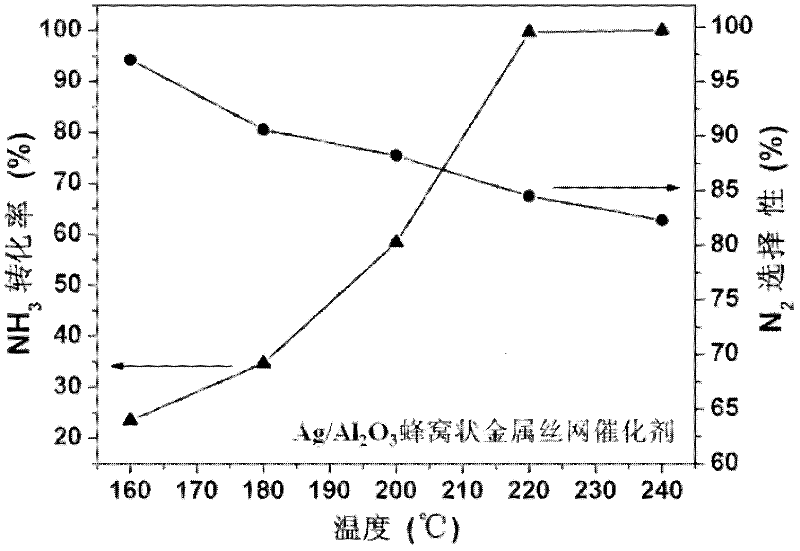

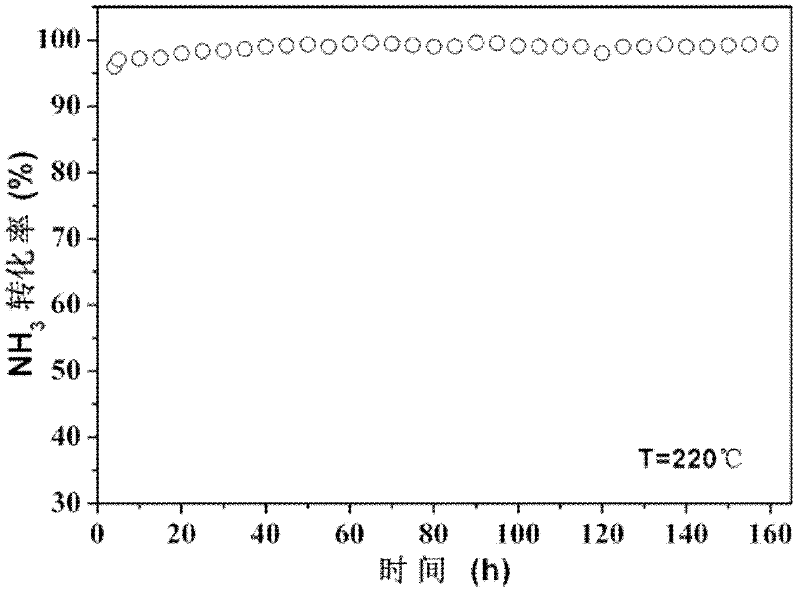

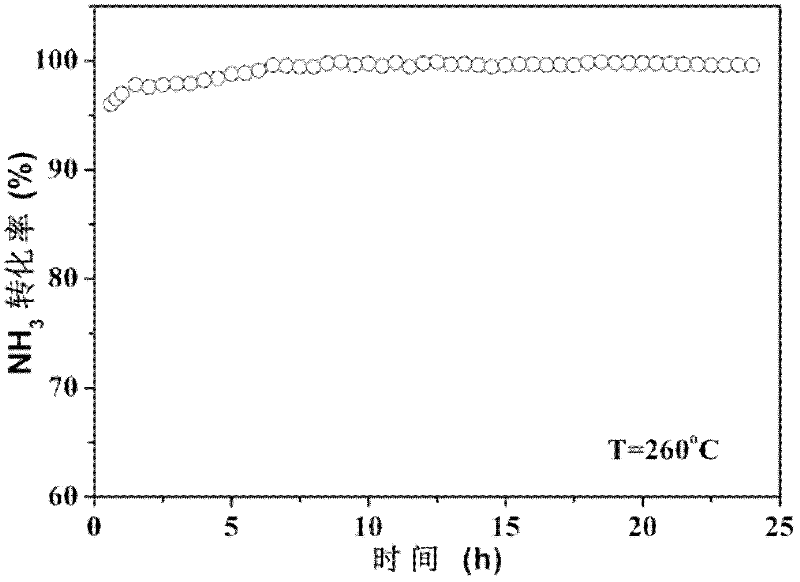

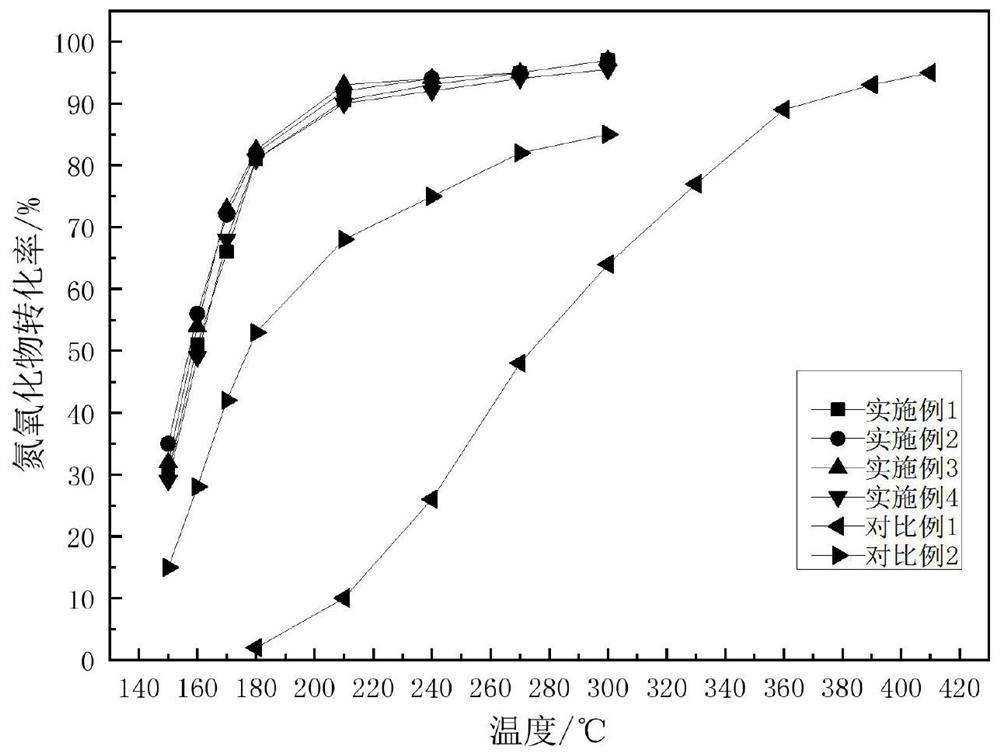

Preparation method and applications of monolithic catalyst used for catalyzing and purifying ammonia-containing waste gas

InactiveCN102357361AImprove stabilityEasy to prepareDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsInorganic oxideHigh selectivity

The invention relates to a preparation method and applications of a monolithic catalyst used for catalyzing and purifying ammonia-containing waste gas. The monolithic catalyst consists of two parts, namely a honeycomb-shaped metal wiremesh carrier and a catalytic active component, wherein the honeycomb-shaped metal wiremesh carrier material is a FeCrAl stainless steel wiremesh; and the catalytic active component consists of a metal active component and an inorganic oxide carrier; the metal active component is one or more of Ag, Cu, Fe and Mn; and the inorganic oxide carrier is one or more of Al2O3, TiO2, SiO2, ZrO2 and CeO2. The monolithic catalyst has a three-dimensional permeating structure and properties such as higher heat transfer coefficient and mass transfer coefficient and lower pressure drop, is suitable for the installations of various reactors and can be directly applied in the industrial field. For example, the Ag / Al2O3 honeycomb-shaped metal wiremesh catalyst can be used for completely converting NH3 at 220 DEG C and have higher selectivity to N2 (>80%); and the catalyst has high stability and wide operating temperature window and is insensitive to the change of space velocity.

Owner:DALIAN UNIV OF TECH

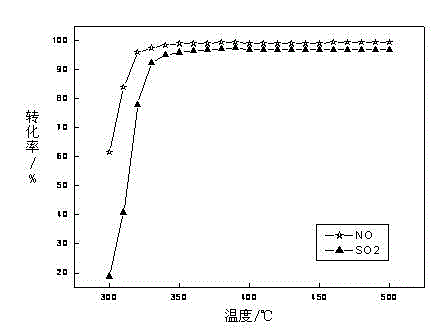

Simultaneous desulfurization and denitration catalyst and preparation method thereof

InactiveCN102974359AHigh activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a simultaneous desulfurization and denitration catalyst and preparation method of the simultaneous desulfurization and denitration catalyst. The desulfurization and denitration catalyst is composed of 60-80 parts by weight of carrier activated carbon (AC), 2-40 parts by weight of active ingredient neodymium oxide (Nd 203) and 0-20 parts by weight of promoter cobalt monoxide (CoO), wherein the total parts by weight of the activate ingredient and the prompter is 2-40. Detailed preparation method is explained in an introduction book. The simultaneous desulfurization and denitration catalyst and preparation method of the simultaneous desulfurization and denitration catalyst has the advantages of being wide in catalyst source, easy to obtain, easy in a preparation and regeneration method, high in catalyst mechanical strength, small in erosion, high in using efficiency of raw materials, suitable for mass production, high in catalyst activity, wide in operation temperature range, capable of being tested in a simulation test for a long time within a temperature range from 350 DEG C to 500 DEG C, and capable of acquiring a desulfurization denitration rate over 90 percent.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

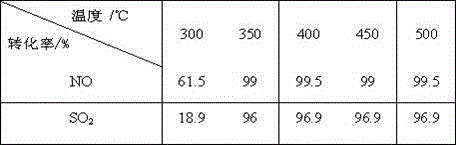

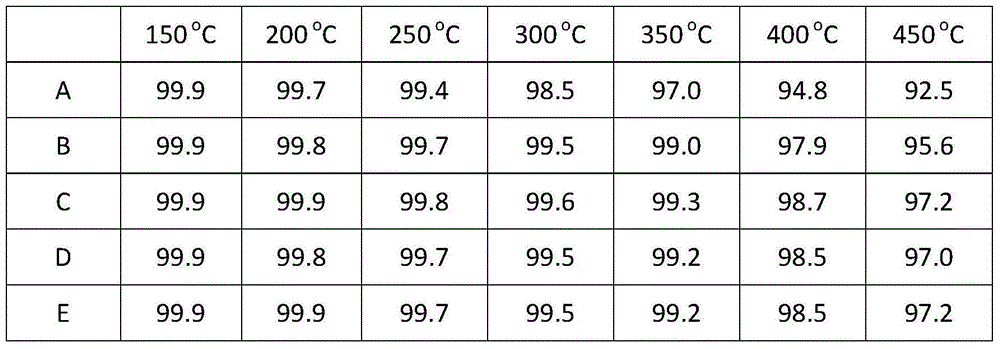

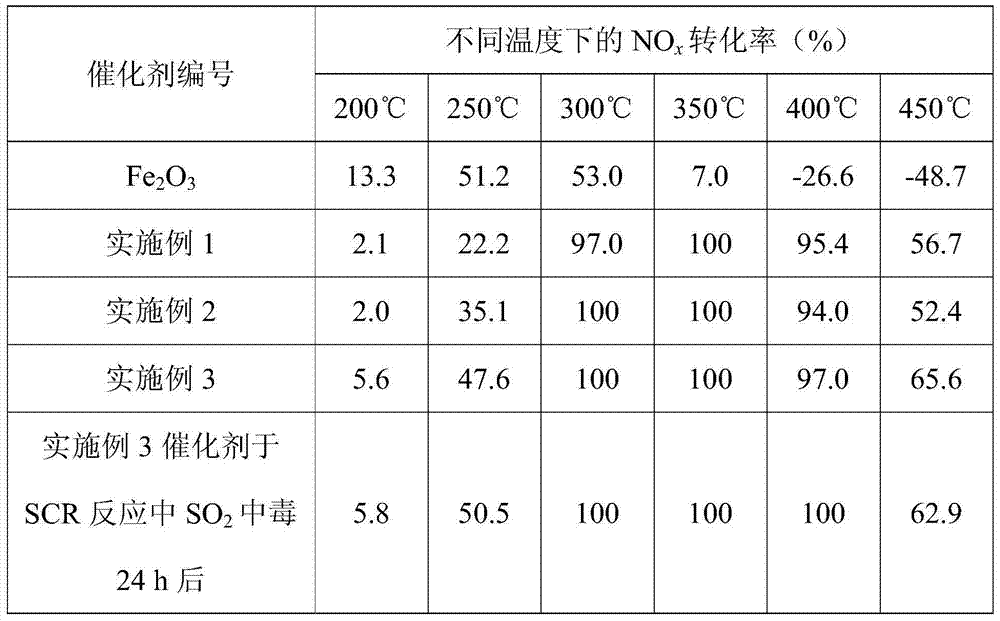

Tungsten oxide surface modified Fe2O3 catalyst as well as preparation method and application thereof

ActiveCN103170346AWide operating temperature windowImprove purification efficiencyNitrous oxide captureDispersed particle separationChemical compositionSurface modification

The invention relates to a tungsten oxide surface modified Fe2O3 catalyst comprising the following chemical compositions: WOx / Fe2O3(x=2-3), wherein the mass percent of WOx in the catalyst is 1-10 wt.%. The invention further discloses a method for preparing the catalyst. The NH3 selective catalytic reduction activity of surface non-modified Fe2O3 material into NOx (NH3-SCR) is extremely low, the operation temperature window is extremely narrow, and a large amount of N2O side product is generated, but the NH3-SCR catalyst activity and the N2 generation selectivity are remarkably improved after WOx surface modification. The tungsten oxide surface modified Fe2O3 catalyst as well the preparation method and the application thereof are suitable for catalytic elimination of stationary source and mobile source NOx.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

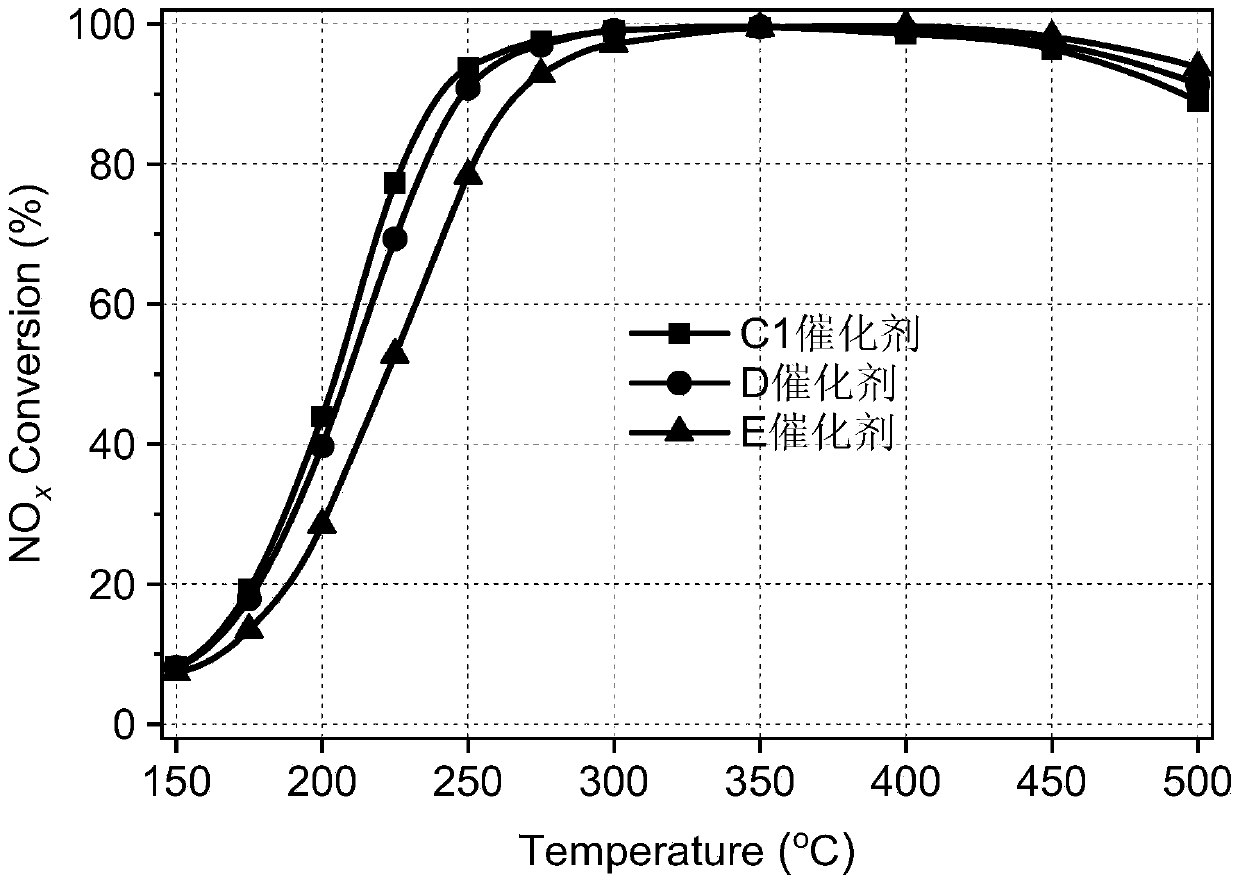

Tungsten titanium composite oxide supported cerium oxide catalyst, preparation method as well as application of catalyst

InactiveCN103846083AWide operating temperature windowGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystComposite oxide

The invention discloses a cerium based oxide catalyst for ammonia selective catalytic reduction nitric oxide, a preparation method as well as application of the catalyst. The catalyst is prepared by the following steps: carrying out controllable regulation on the pH value in the preparation process; forming a metal oxide catalyst CeO(i)x( / i) / WO(i)y( / i)-TiO2 and cerium oxide CeO(i)x( / i) by fractional precipitation, and uniformly dispersing on the surface of a tungsten titanium composite oxide WO(i)y( / i)-TiO2. The cerium based oxide catalyst which has the characteristics of excellent low-temperature catalytic activity, high N2 generation selectivity, wide operation temperature window, capability of being adaptive to high-airspeed reaction conditions and the like is prepared from nontoxic and harmless raw materials by a simple and feasible method, and is suitable for nitric oxide catalytic purification devices with mobile sources represented by tail gas of a diesel vehicle and fixed sources represented by flue of coal burned power plants.

Owner:NANJING UNIV OF SCI & TECH

Cerium oxide catalyst for catalyzing and purifying nitric oxides, preparation method and application

InactiveCN105233814AWide operating temperature windowImprove catalytic performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumFlue gas

The invention discloses a cerium oxide catalyst for catalyzing and purifying nitric oxides, a preparation method and an application, wherein the cerium oxide catalyst for catalyzing and purifying the nitric oxides is a metal oxide catalyst CeOx@ZrO2-TiO2, cerium oxides (CeOx) are uniformly dispersed on the surfaces of composite titanium-zirconium oxides (ZrO2-TiO2). The cerium oxide catalyst for catalyzing and purifying the nitric oxides uses non-toxic harmless raw materials, is prepared through a simple and easy method, has the characteristics of excellent catalytic activity, high N2 generation selective and wide operation temperature window and the like, can be suitable for mobile sources using diesel exhausts as representatives and nitrogen oxide catalytic purification devices of fixed sources using coal burning power plant flue gas as representatives.

Owner:NANJING UNIV OF SCI & TECH

Simultaneous desulfurization and denitration catalyst

InactiveCN102974358AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention relates to a simultaneous desulfurization and denitration catalyst which comprises a carrier with a mass percent of 70-99.9 percent, active ingredient praseodymium oxide with a mass percent of 0.1-3.0 percent and nickel oxide or cobalt oxide prompter with a mass percent of 0-15 percent. The simultaneous desulfurization and denitration catalyst is prepared by an acknowledged isopyknic method and has the advantages of being wide in source, easy to acquire, low in cost, and easy in a preparation and regeneration method as the simultaneous desulfurization and denitration catalyst is manufactured from activated carbon, activated coke or activated carbon fibers, and being large in a catalyst specific surface area, high in activity, good in stability, and wide in operating temperature range from 300 DEG Cto 500 DEG C and capable of acquiring a desulfurization denitration rate over 90 percent, simultaneously eliminating carbon monoxide (CO) in flue gas by using CO as reducing agent, acquiring by-product elemental sulfur, free from secondary pollution, wide in application range and suitable for industry popularization.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

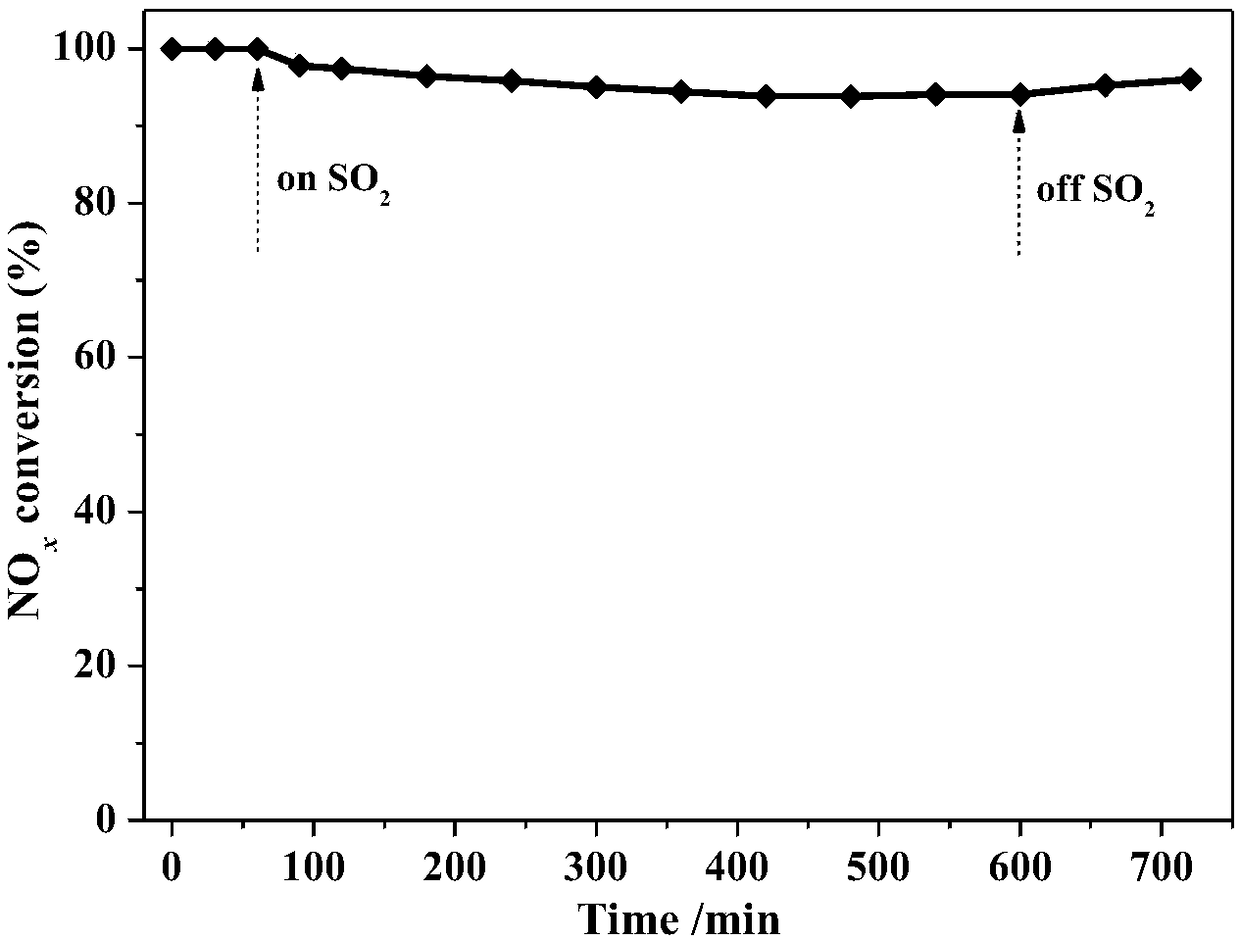

Catalyst for surface sulfation of ferric oxide, as well as preparation method and application thereof

InactiveCN103785420ALow priceEfficient redox processPhysical/chemical process catalystsDispersed particle separationSulfationBlack ferric oxide

The invention discloses a preparation method of a catalyst for surface sulfation of ferric oxide. The method comprises the following steps: (1) preparing ferric oxide; (2) performing sulfation treatment on the surface of the ferric oxide to obtain a ferric oxide catalyst of which the surface is sulfated. The ferric oxide catalyst with the enhanced surface acidity and the proper oxidation-reduction capacity is synthesized for the first time through performing sulfating process on the surface of the ferric oxide, so that the NOx purification activity of middle and high temperature sections in NH3 selectively reducing NOx (namely NH3-SCR) reaction is obviously improved, an operation temperature window is obviously broadened, and the catalyst has the extremely excellent SO2 poisoning resistance performance and is very applicable for catalytic elimination of a stationary source and a mobile source NOX.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

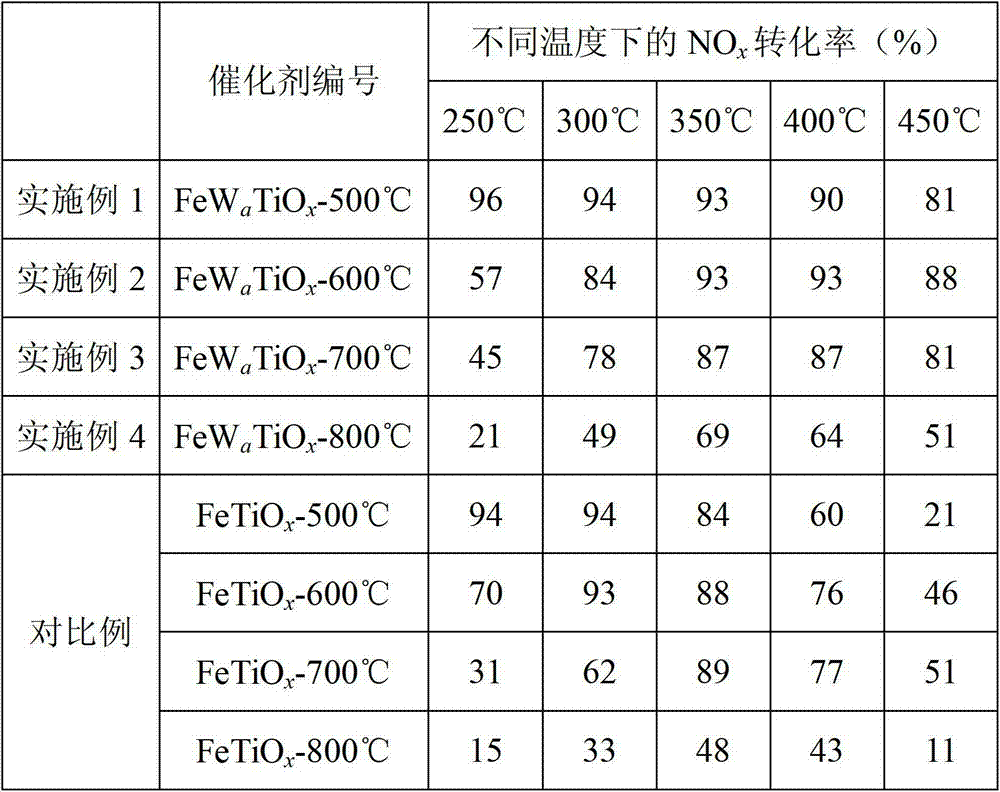

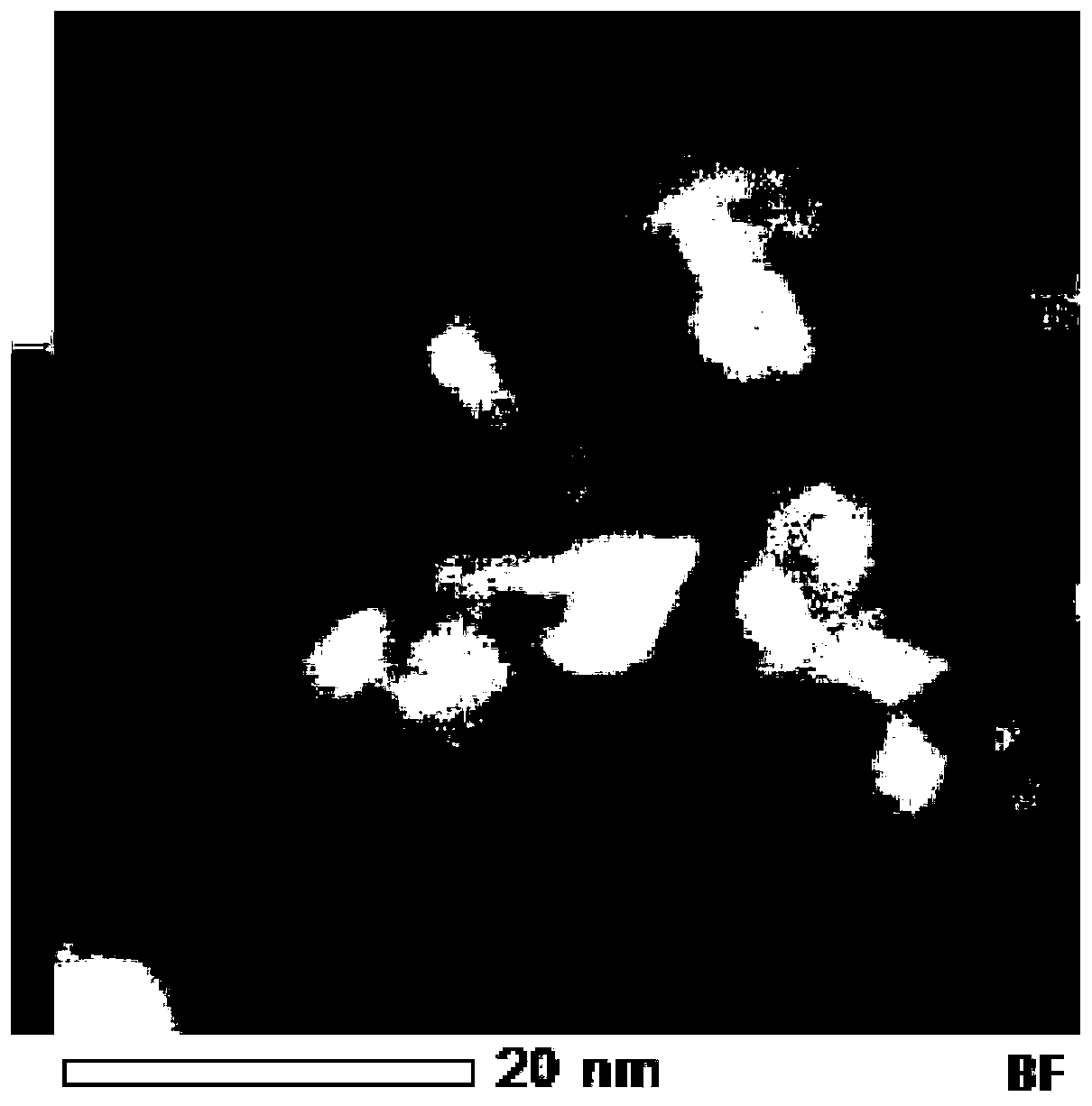

Iron-tungsten-titanium composite oxide catalyst, and preparation method and purpose thereof

ActiveCN103028420AGood dispersionOvercome CorrosivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationComposite oxide

The invention relates to iron-tungsten-titanium composite oxide catalyst. The catalyst has the chemical composition of FeWaTiOx, wherein a is greater than 0 and less than or equal to 1.6. The invention further discloses a preparation method of the catalyst, which comprises the following steps: (1), preparing the solutions of Fe source, W source and Ti source in the presence of oxalic acid, and mixing the solutions of Fe source, W source and Ti source to obtain a mixed solution; and (2), adding excessive urea precipitation agent into the mixed solution to ensure that ions can be fully deposited, and carrying out suction filtration, washing, drying and baking to obtained sedimentation products to obtain the iron-tungsten-titanium composite oxide catalyst. Compared with iron-tungsten-titanium composite oxide catalyst without adulteration, the iron-tungsten-titanium composite oxide NH3-SCR catalyst has an obviously improved high-temperature thermal stability, and is easier to apply to catalysis and decontamination of NOx in heavy duty diesel exhaust.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Cerium-tin-based composite oxide catalyst for catalytic purification of nitrogen oxide and preparation method thereof, and application of cerium-tin-based composite oxide catalyst for catalytic purification of nitrogen oxide

ActiveCN110947377ALower surface energyWide operating temperature windowGas treatmentHeterogenous catalyst chemical elementsPtru catalystNitrogen oxides

The invention relates to a cerium-tin-based composite oxide catalyst for catalytic purification of nitrogen oxide and a preparation method thereof, and application of the cerium-tin-based composite oxide catalyst for catalytic purification of nitrogen oxide. The catalyst has the following chemical composition: cerium tin oxide and oxide of M, wherein M is selected from any one or a combination ofat least two of P, Ti, Zr, V, Mn, Fe, Cu, Al, Si, Ni, Hf, Nb, Ta, Cr, Mo, W or Re. Non-toxic and harmless raw materials are adopted, the cerium-tin-based composite oxide catalyst which has the characteristics of high catalytic activity, high hydrothermal stability, excellent N2 generation selectivity, the wide operation temperature window, adaptability to high space velocity reaction conditions and the like is prepared by adopting a simple and feasible method. The cerium-tin-based composite oxide catalyst is suitable for a moving source represented by diesel vehicle tail gas and a fixed sourcenitrogen oxide catalytic purification device represented by coal-fired power plant flue gas.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Layered structure cerium based oxide catalyst, preparation method and application thereof

InactiveCN105664917AWide operating temperature windowHigh selectivityGas treatmentHeterogenous catalyst chemical elementsCeriumNitrogen oxide

The invention discloses a cerium based oxide catalyst for catalytic purification of nitrogen oxides and a preparation method thereof. The catalyst is a layered structure CeOx / MoO3-TiO2 catalyst formed by step-by-step uniform precipitation based on controllable adjustment of a pH value in the preparation process. According to the invention, non-toxic and harmless raw materials are employed to prepare the cerium based oxide catalyst with the characteristics of excellent catalytic activity, high N2 generation selectivity, wide operation temperature window and the like through a simple and practicable method. The catalyst is suitable for nitrogen oxide catalytic purification devices adopting a diesel vehicle exhaust represented mobile source and a coal-fired power plant flue gas represented stationary source.

Owner:NANJING UNIV OF SCI & TECH

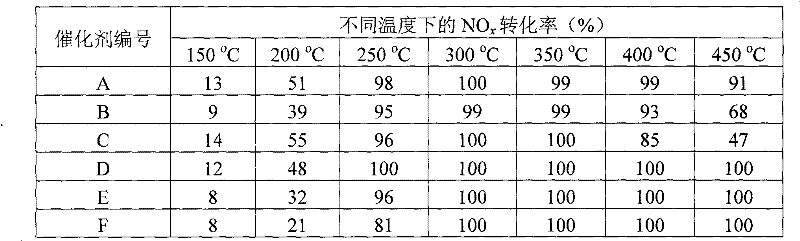

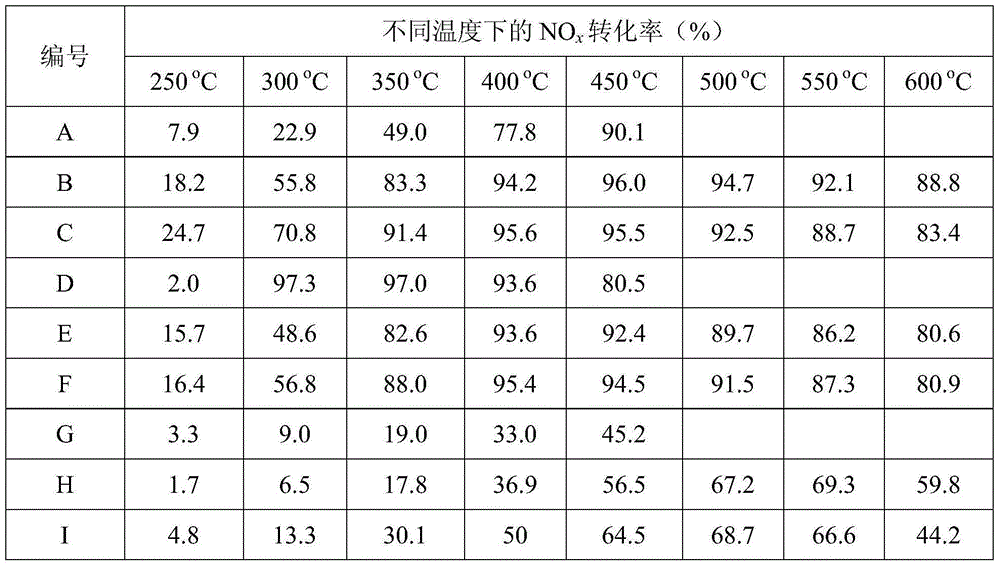

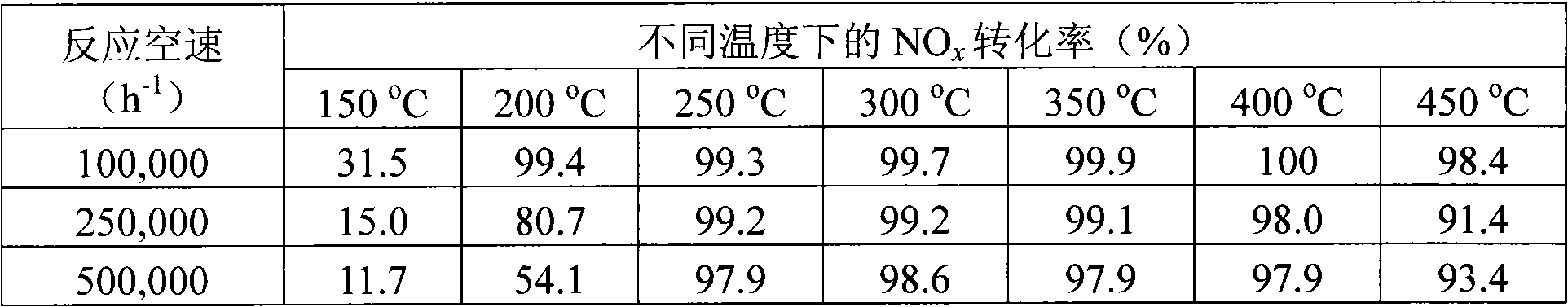

Transition metal oxide composite catalyst, preparation method thereof and application of catalyst

InactiveCN109351358AWide operating temperature windowImprove denitrification efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOxide compositeComposite oxide

The invention provides a transition metal oxide composite catalyst, a preparation method thereof and an application of the catalyst. The catalyst comprises a transition metal oxide active component and a carrier, and the transition metal oxide comprises an iron and vanadium composite oxide. According to the catalyst, iron is led in a vanadium and titanium denitration catalyst, the operating temperature of the catalyst can be widened to 200-450 DEG C by the aid of interaction between the iron and the vanadium and combination between an active site and an acid site of the carrier, denitration efficiency is improved, the conversion rate of NOx within the temperature range reaches 80% or more, generating selectivity of N2 is good, stability, sulfur resistance and water resistance of the catalyst can be enhanced, and the catalyst is low in cost, simple and easy in preparation process and wide in application range.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

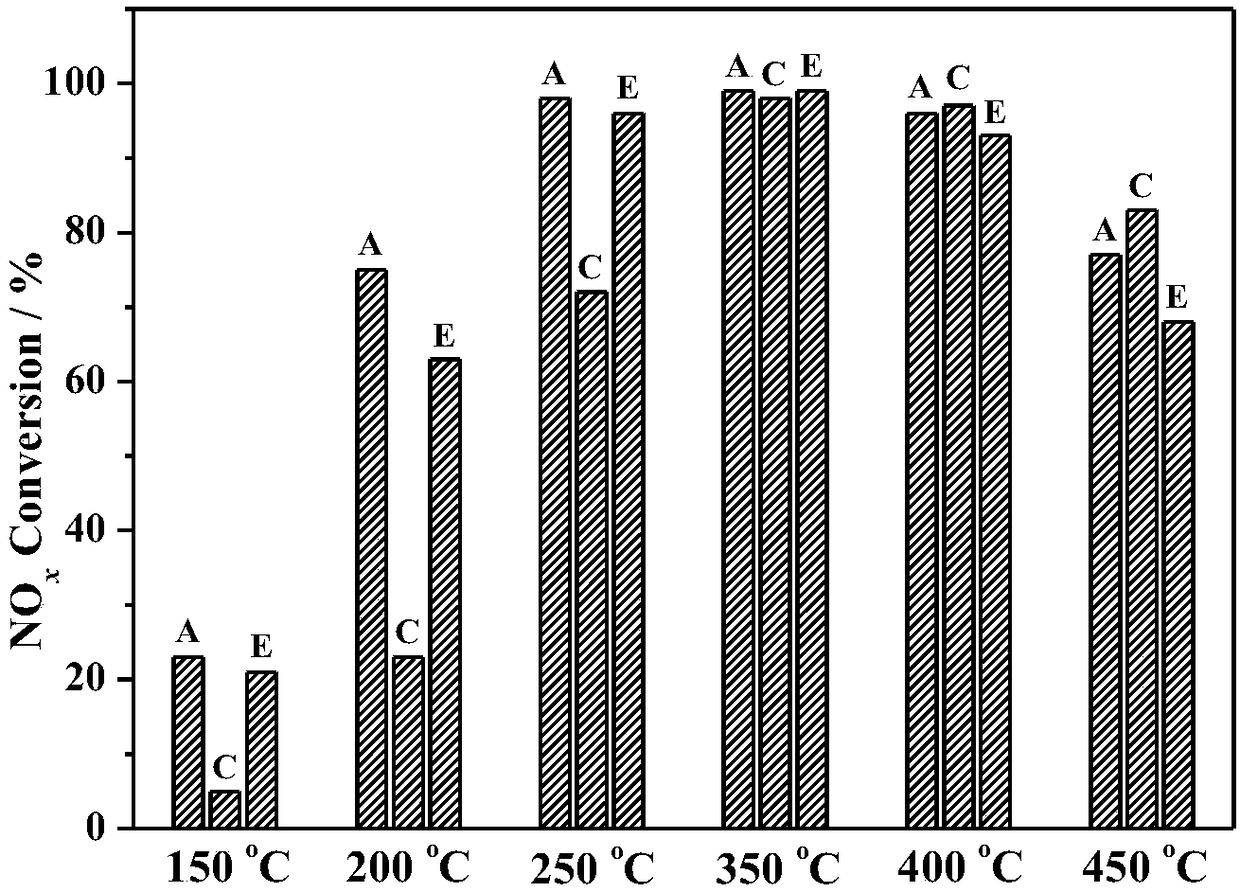

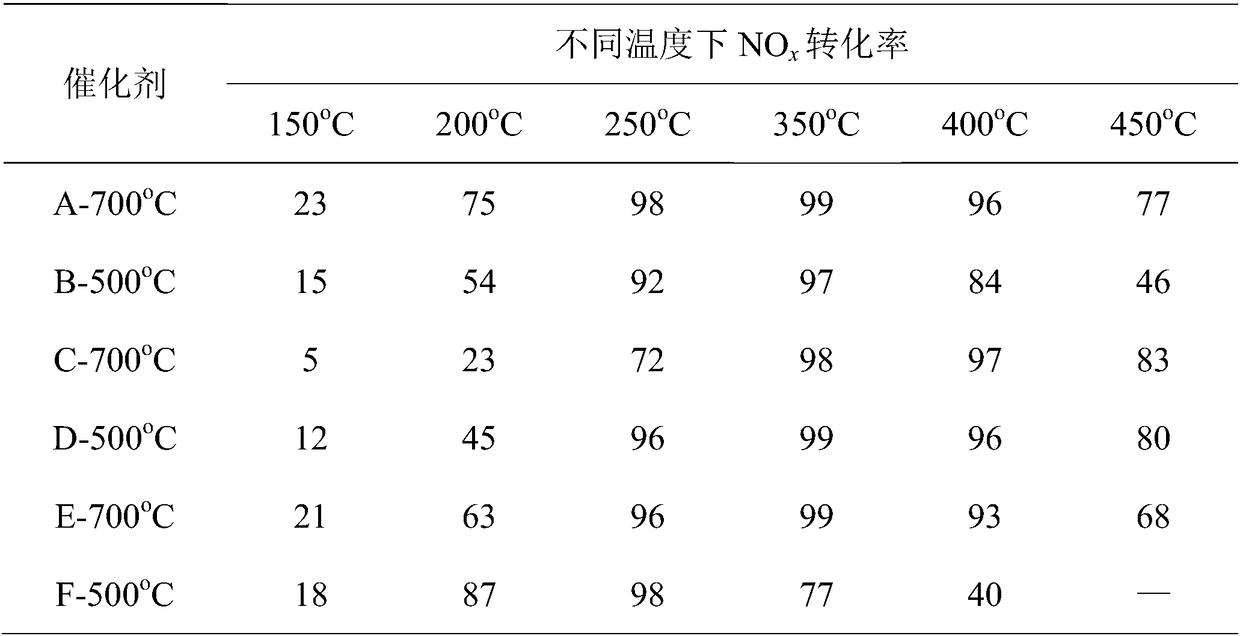

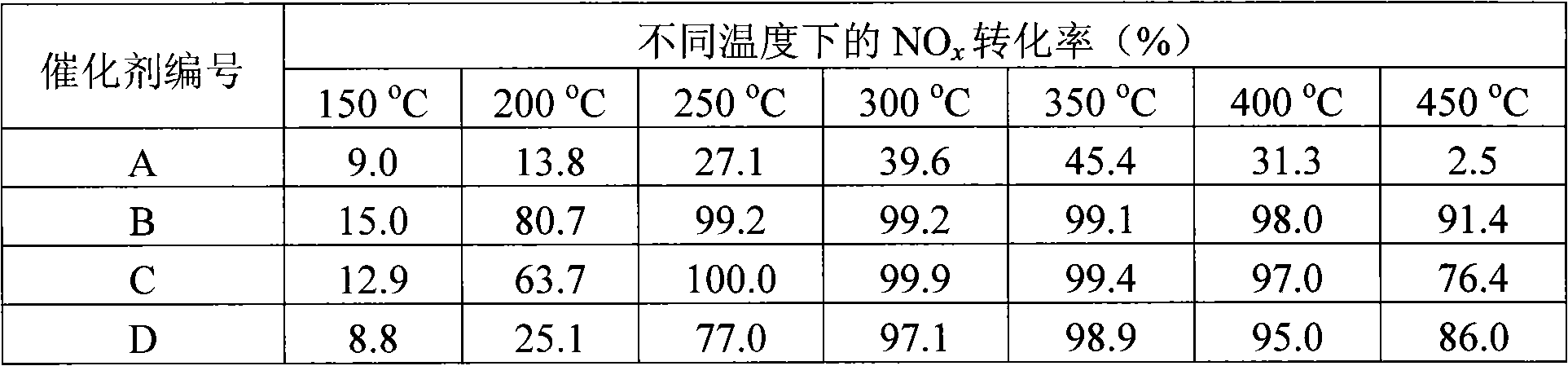

Cerium and titanium supported vanadium catalyst, and preparation method and use thereof

ActiveCN103816889AGood dispersionNH

<sub>3</sub>

-Good SCR activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentCerium

The invention discloses a cerium titanium supported vanadium catalyst. The catalyst is composed of a CeaTibOx support and a V2O5 active component supported on the support, a ratio of a:b is 0.5:1-2:1, and the weight of the V2O5 active component accounts for 1-10% (except 3%) of the weight of the CeaTibOx support. The NOx purifying efficiency of the catalyst is close to above 100% at 200-400DEG C, and the catalyst has a very good NH3-SCR activity, a greatly widened operation temperature window and an excellent SO2 poisoning resistance, and can be used for catalyzing the NOx purification in an NH3-SCR process.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparing method of silver-based sepiolite oxynitride catalytic reduction catalyst

InactiveCN104399456AHigh activityWide operating temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsFiltration

The invention relates to a preparing method of a silver-based sepiolite oxynitride catalytic reduction catalyst, and belongs to the field of environmental protection material preparation. The preparing method of the silver-based sepiolite oxynitride catalytic reduction catalyst comprises the following steps: adding 1.5 mol / L of a hydrochloric acid solution into sepiolite, soaking at the room temperature, stirring for 72 h, carrying out suction filtration, washing until no chloride ion is detected, drying the obtained sample for 24 h at the temperature of 80 DEG C, roasting for 4 h at the temperature of 250 DEG C, and thus obtaining acid-modified sepiolite; and vacuumizing the modified sepiolite, then impregnating with a certain amount of an AgNO3 solution, vigorously stirring for 4 h at the room temperature, drying with a 75 DEG C water bath, tabletting, crushing and sieving, taking a 20-40 mesh powder, transferring into a Muffle furnace, firing for 4 h, and thus obtaining the silver-based sepiolite oxynitride catalytic reduction catalyst. The process is simple; the prepared silver-based sepiolite oxynitride catalytic reduction catalyst has the characteristics of higher activity, wide working temperature window, heat and humidity resistance stability and the like, and the oxynitride conversion rate reaches a maximum value of 81.0% when the catalytic temperature rises to 320 DEG C.

Owner:XIAN HUALU ENVIRONMENTAL PROTECTION EQUIP

Manganese-based oxide catalyst with wide temperature window and preparation method thereof

InactiveCN106492788AWide operating temperature windowGood water and sulfur resistanceGas treatmentHeterogenous catalyst chemical elementsNitrogen oxidesSulfur

The invention discloses a manganese-based oxide catalyst for catalytic purification of nitrogen oxide and a preparation method thereof. The preparation method comprises the following steps: preparing a Mn3CeW0.3Ox composite oxide by using a uniform precipitation method and then carrying out roasting so as to obtain the (MnOx)3-CeO2-(WO3)0.3 oxide catalyst. According to the invention, the manganese-based oxide catalyst with the characteristics of a wide temperature window, excellent resistance to water and sulfur, high N2 generation selectivity, high-temperature resistance, heat stability and the like is prepared from nontoxic and harmless raw materials by using the simple and easily practicable method; and the prepared manganese-based oxide catalyst is applicable to a nitrogen oxide catalytic purification apparatus with flue gas of a coal-fired power plant as a representative fixed source and tail gas of a diesel car as a representative movable source.

Owner:NANJING UNIV OF SCI & TECH

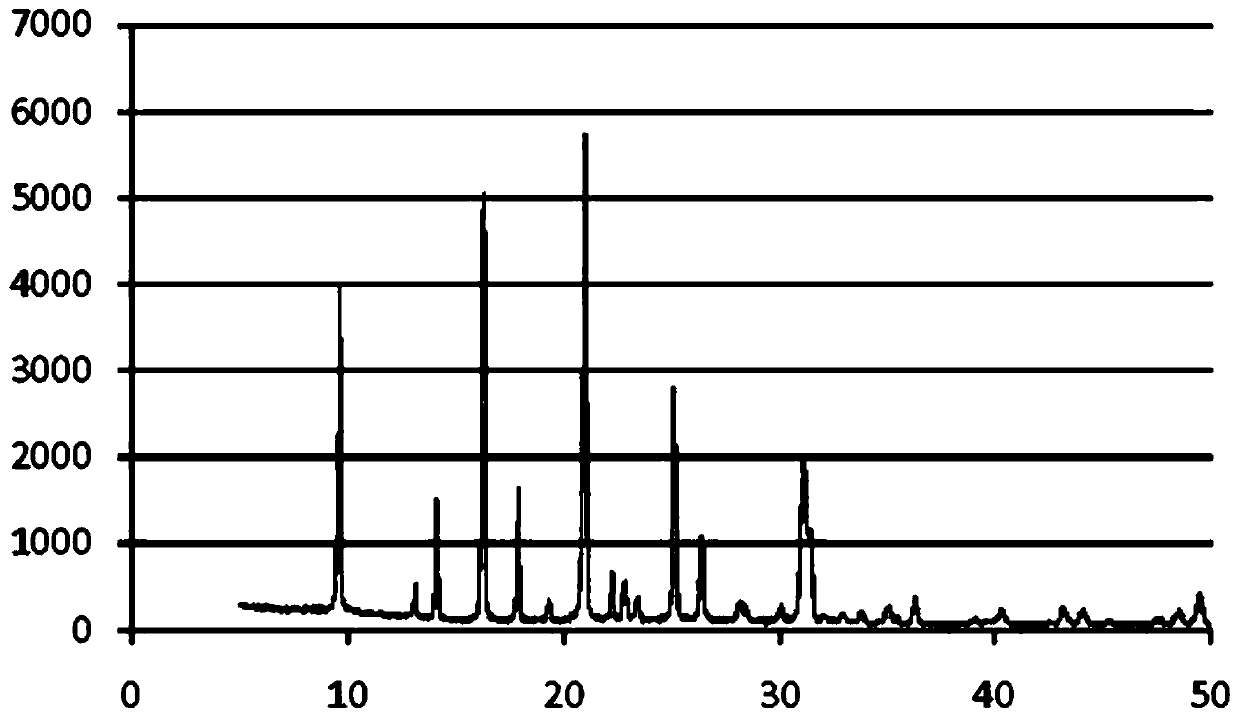

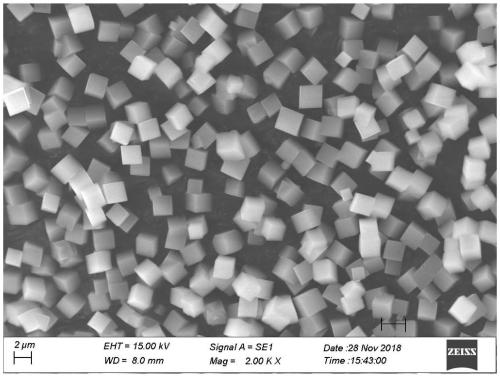

SSZ-13 molecular sieves, production, SCR catalyst and production

ActiveCN110407223AStable structureExcellent high temperature aging resistanceMolecular sieve catalystsCrystalline aluminosilicate zeolitesHydrogenAmmonium hydroxide

The invention relates to the technical field of catalysis, in particular to SSZ-13 molecular sieves, production, an SCR catalyst and production. A production method of the SSZ-13 hydrogen-type molecular sieves comprises the steps of (1) mixing an aluminium source, a template composition, a silicon source and an alkaline aqueous solution, and carrying out a gelation reaction to obtain gel; and (2)conducting crystallization, calcination and ammonium exchange on the gel to obtain the SSZ-13 hydrogen-type molecular sieves. The template composition comprises N,N,N-trimethylbicyclo[2,2,2]octane-2-ammonium hydroxide and at least one additional template.

Owner:合肥派森新材料技术有限公司

Uniform-load cerium-based molecular sieve catalyst, preparation method and application thereof

InactiveCN105233858AWide operating temperature windowExcellent SCR activityMolecular sieve catalystsDispersed particle separationCeriumComposite oxide

The invention relates to a uniform-load cerium-based molecular sieve catalyst, a preparation method and application thereof and discloses a cerium-based oxide catalyst for nitrogen oxide catalytic purification, a preparation method and application thereof. The catalyst is a metal oxide catalyst CeOx@ZrO2-TiO2, and CeOx is evenly dispersed to the surface of a zirconium titanium composite oxide ZrO2-TiO2. The uniform-load cerium-based molecular sieve catalyst is made of non-toxic and harmless raw materials. The cerium-based oxide catalyst which is excellent in catalytic activity, high in N2 generating selectivity and wide in operating temperature window is prepared through the simple and practical method, and the uniform-load cerium-based molecular sieve catalyst can be suitable for a nitrogen oxide catalytic purification device for a mobile source with diesel vehicle exhaust as a representative and a fixed source with coal-fired power plant exhaust as a representative.

Owner:NANJING UNIV OF SCI & TECH

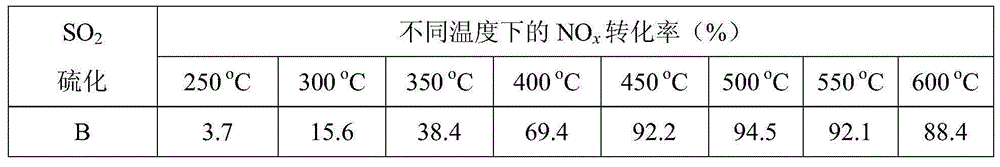

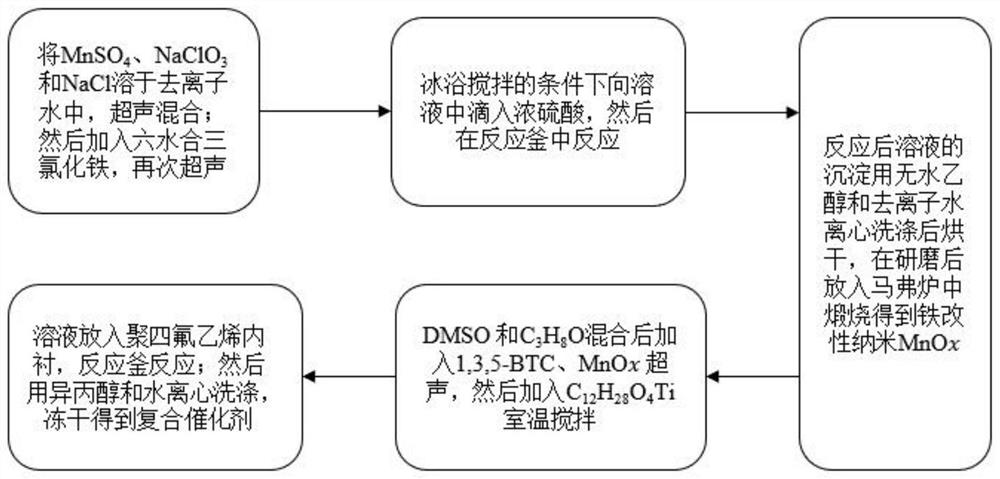

Fe-modified nano manganese oxide/MIL-125 (Ti) catalyst and preparation method thereof

ActiveCN111617807AImprove conversion rateRich variable valenceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationHydration reactionPtru catalyst

The invention belongs to the technical field of composite material preparation, and particularly relates to a Fe-modified nano manganese oxide / MIL-125 (Ti) catalyst and a preparation method thereof. The preparation method comprises the following steps: A, ultrasonically mixing MnSO4, NaClO3 and NaCl in deionized water; adding ferric trichloride hexahydrate for ultrasonic treatment; then dropwise adding concentrated sulfuric acid into the solution under the condition of ice bath stirring, and reacting in a reaction kettle; B, centrifugally washing the precipitate with absolute ethyl alcohol anddeionized water, drying, grinding, and calcining in a muffle furnace to obtain iron modified nano MnOx; C, after DMSO and C3H8O are mixed, adding 1, 3, 5-BTC and nano MnOx for ultrasonic treatment, and then dropwise adding C12H28O4Ti during stirring at the room temperature; putting the solution into a reaction kettle to react; and finally, centrifugally washing with isopropanol and water, and freeze-drying to obtain the composite catalyst. The composite catalyst provided by the invention can effectively reduce the conversion temperature of nitrogen oxides, improve the toxicity resistance andprolong the service life of the catalyst.

Owner:ZHEJIANG ZHIYUAN ENVIRONMENTAL TECH CO LTD

Iron cerium tungsten ternary composite oxide with high heat stability as well as synthesis and application thereof

InactiveCN108246304ASimple preparation processSimple equipmentInternal combustion piston enginesHeterogenous catalyst chemical elementsWater bathsCerium

The invention discloses iron cerium tungsten ternary composite oxide with high heat stability as well as synthesis and application thereof. The preparation method of a catalyst is a urea homogenous precipitation method, and comprises the following steps: salt corresponding an iron source, a cerium source and a tungsten source into a urea solution, continuously stirring for 6 to 36 hours under thecondition that the water bath temperature is 80 to 110 DEG C, centrifuging, drying and roasting to prepare the catalyst. When the catalyst prepared by the method is applied to ammonia selective catalytic reduction of nitric oxide, the catalyst has the characteristics of wide operating temperature window, high heat stability and the like, is suitable for a diesel engine automobile nitric oxide catalytic purification device, and has wide actual application prospect.

Owner:DALIAN UNIV OF TECH

Vanadium-modified iron-based activated carbon catalyst, preparation method and application thereof

InactiveCN103769114AExcellent low temperature NH <sub>3<</sub> High activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSilicon-controlled rectifierActivated carbon

The invention discloses a vanadium-modified iron-based activated carbon catalyst which comprises active components which are ferric oxide and vanadium pentoxide. Activated carbon serves as a carrier; the mass percentage of the vanadium pentoxide in the activated carbon is larger than 0 percent and smaller than or equal to 1 percent. The vanadium-modified iron-based activated carbon catalyst obtained by adding vanadium is excellent in low-temperature NH3-SCR (silicon controlled rectifier) activity and SO2 poisoning resistance; an operation temperature window is wide. Under 150 DEG C, the NOx purification efficiency of the catalyst is over 70 percent; under 175 DEG C, the NOx purification efficiency is over 80 percent; furthermore, under 200 DEG C, the catalyst is high in SO2 poisoning resistance.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

A manganese vanadium composite oxide catalyst for the selective catalytic reduction of nitrogen oxides by ammonia

ActiveCN103623814BGood activity at low temperatureWide operating temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPhysical chemistryNitrogen oxide

The invention relates to a manganese vanadium composite oxide catalyst used for selective catalytic reduction of nitrogen oxides by ammonia. The invention prepares a composite oxide catalyst with the characteristics of high low-temperature catalytic activity, high nitrogen selectivity, and wide operating temperature window through a simple and easy method, and is suitable for nitrogen oxides in stationary source flue gas represented by coal-fired power plants purification treatment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Cerium-based composite oxide catalyst for catalyzing and purifying nitric oxide

ActiveCN102000560BExtended service lifeWide operating temperature windowInternal combustion piston enginesHeterogenous catalyst chemical elementsCeriumNitric oxide

Disclosed is a Ce-based composite oxide catalyst for selective catalytic reducing nitrogen oxides with ammonia, which comprises Ce oxide and at least one oxide of transition metal except Ce. The Ce-based composite oxide catalyst is prepared by a simple method which uses non-toxic and harmless raw materials, and it has the following advantages: high catalytic activity, and excellent selectivity for generating nitrogen etc. The catalyst can be applied in catalytic cleaning plant for nitrogen oxides from mobile and stationary sources.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com