Cerium and titanium supported vanadium catalyst, and preparation method and use thereof

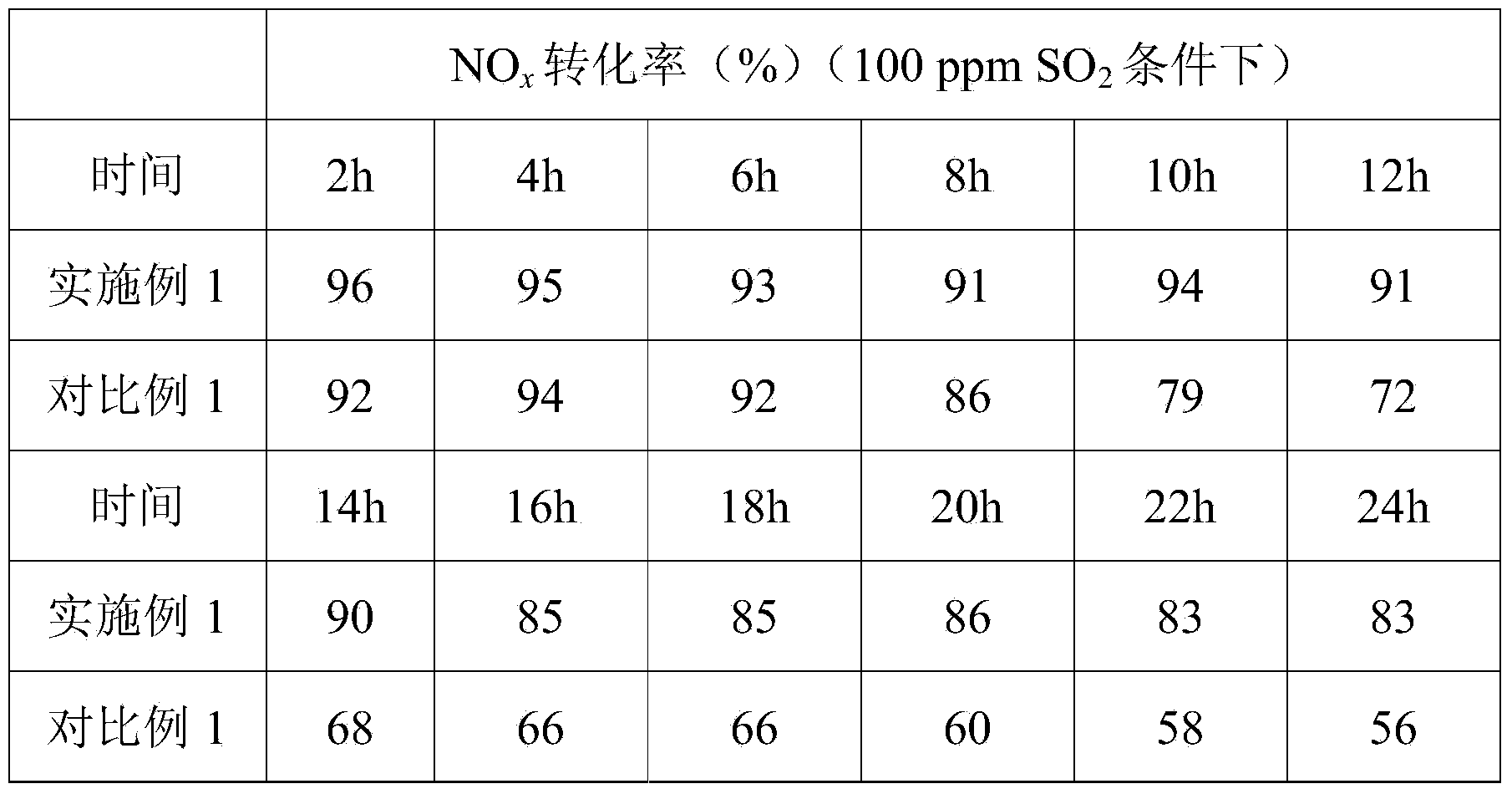

A catalyst, cerium-titanium technology, applied in the fields of cerium-titanium supported vanadium catalyst, preparation and application, can solve the problem of not mentioned anti-SO2 poisoning performance, etc., achieve excellent anti-SO2 poisoning performance, good NH3-SCR activity, active group highly dispersed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of cerium titanium loaded vanadium catalyst, described catalyst is made of Ce 1 Ti 1 o x carrier and the V loaded on the carrier 2 o 5 The active components consist of Ce 1 Ti 1 o x The mass of the carrier is 100wt%, and the V 2 o 5 Active ingredient The active ingredient was 2.8 wt%.

[0042] The preparation method of catalyst as described above comprises the steps:

[0043] (a) Using cerium nitrate as the Ce source, titanium sulfate as the Ti source, and urea as the precipitating agent, make a mixed solution of titanium sulfate and cerium nitrate, then add excess urea precipitant to it, and continuously stir under the condition of 90 °C water bath After 12 hours, the Ce and Ti ions were co-precipitated completely, and the precipitate was filtered and washed, and then the filter cake was dried in an oven at 100°C for 12h, and finally roasted in a muffle furnace at 400°C for 3h in an air atmosphere to obtain Ce 1 Ti 1 o x carrier;

[0044] (a) In the...

Embodiment 2

[0046] Except step (1) firing temperature is 500 ℃, other are the same as embodiment 1.

Embodiment 3

[0048] Except step (1) firing temperature is 600 ℃, other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com