Cerium-tin-based composite oxide catalyst for catalytic purification of nitrogen oxide and preparation method thereof, and application of cerium-tin-based composite oxide catalyst for catalytic purification of nitrogen oxide

A technology for composite oxides and nitrogen oxides, which is applied in the field of preparation of cerium-tin-based composite oxide catalysts and rare earth-based composite oxide catalysts for catalytic purification of nitrogen oxides, and can solve problems such as poor hydrothermal stability and narrow operating temperature window problem, to achieve the effect of wide operating temperature window, high NOx conversion rate, and good resistance to high temperature hydrothermal aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

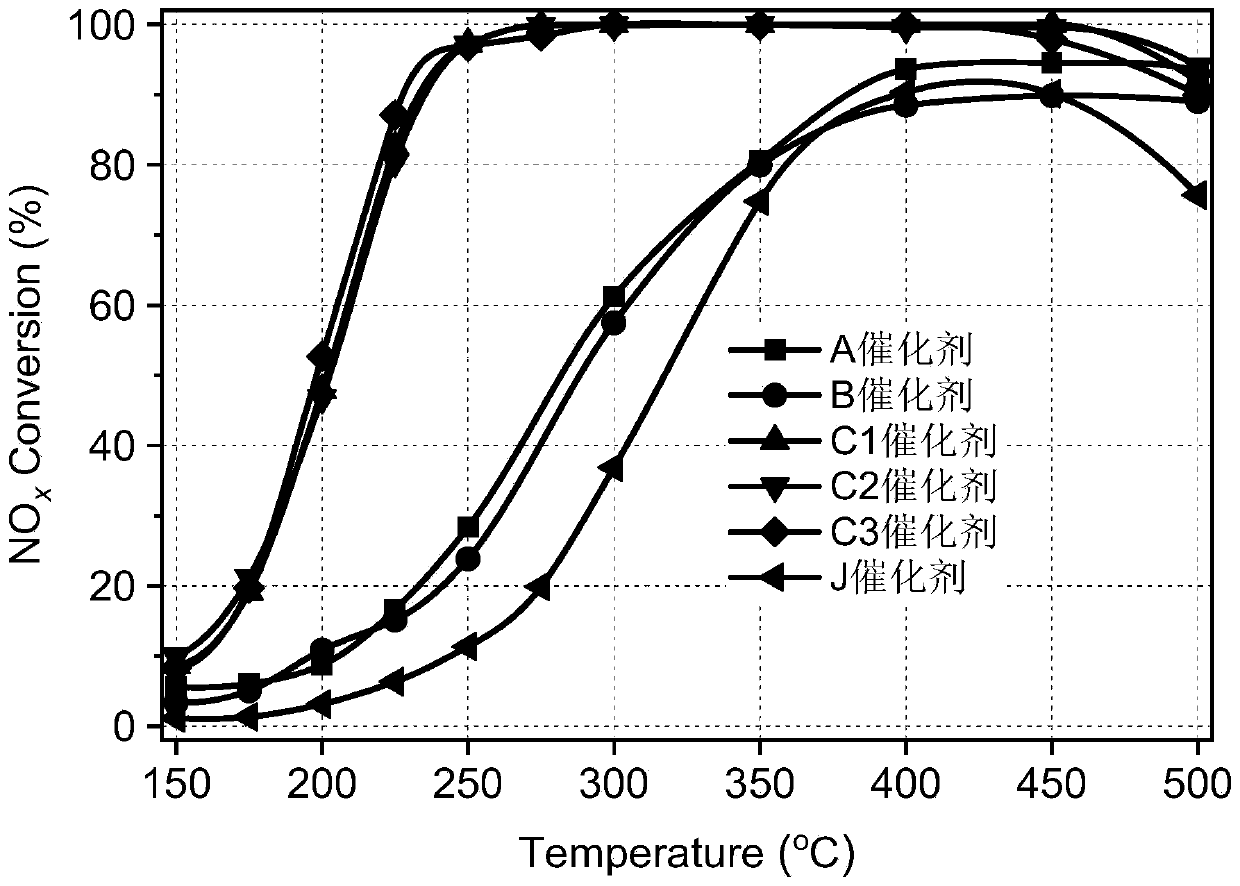

[0089] This embodiment provides a cerium-tin-based composite oxide catalyst, the preparation method of which is as follows:

[0090] Dissolve ammonium metatungstate, cerium nitrate, and tin chloride in deionized water in turn, prepare a solution with a Ce:Sn:W molar ratio of 1:0.8:0.6 (the molar ratio of W and Sn is 0.75:1) and mix well , add 30mL ammonia water to the solution, and continuously stir at 25°C for 12h, then perform suction filtration and washing, put the filter cake in an oven and dry at 100°C overnight, and finally pass through a muffle furnace at 800°C in air Calcined for 3h to obtain the target catalyst.

[0091] The prepared catalyst was ground and sieved, and the particle size of the obtained catalyst was between 40 and 60 mesh, and the catalyst was called catalyst A.

Embodiment 2

[0093] This embodiment provides a cerium-tin-based composite oxide catalyst, the preparation method of which is as follows:

[0094] Other conditions remained unchanged as in Example 1, and the precipitant ammonia water was replaced with 40 g of urea, and the precipitation temperature was set at 90° C. to obtain catalyst B.

Embodiment 3

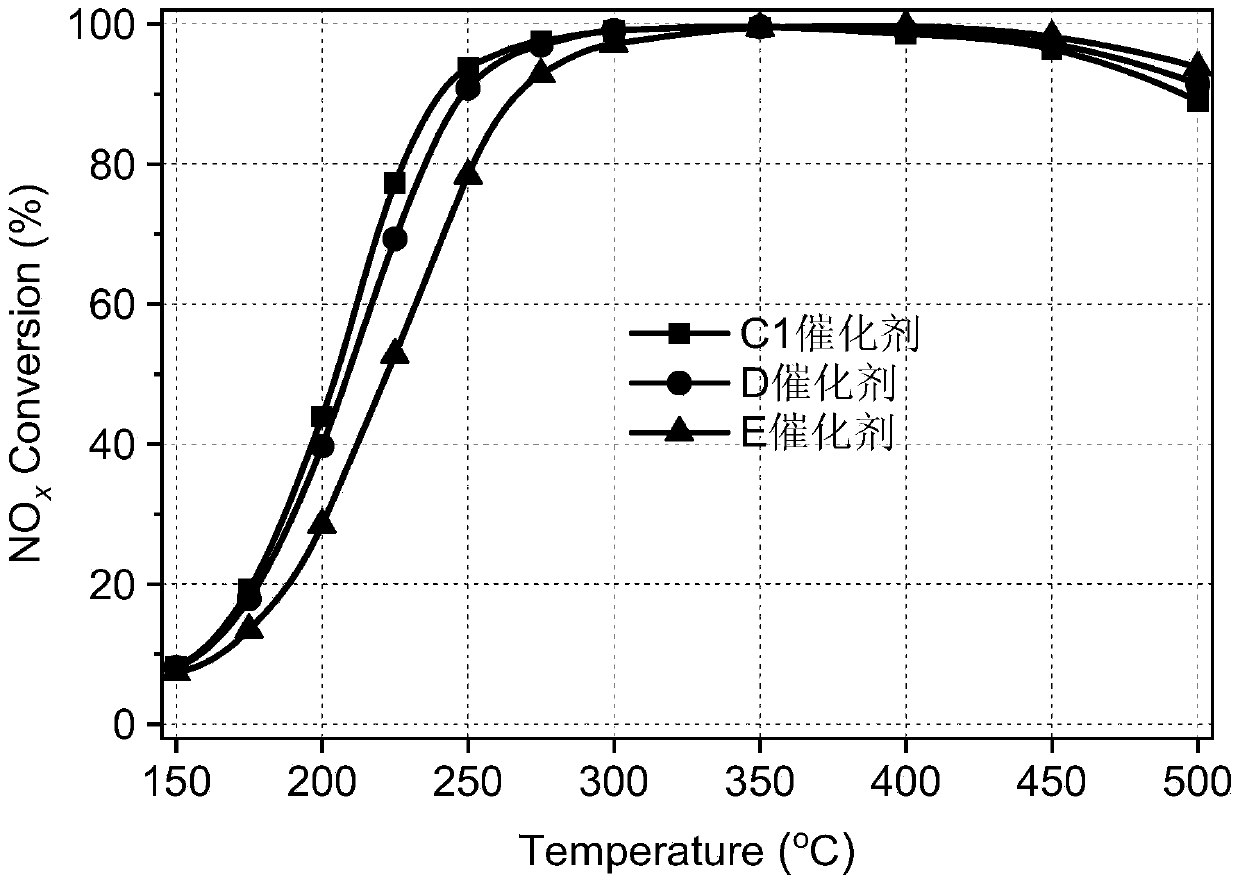

[0096] This embodiment provides a cerium-tin-based composite oxide catalyst, the preparation method of which is as follows:

[0097] Other conditions remained unchanged as in Example 1, but the Ce:Sn:W molar ratio was changed to 1:2:0.5 (the molar ratio of W to Sn was 0.25:1), and catalyst C1 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com