Vanadium-modified iron-based activated carbon catalyst, preparation method and application thereof

A technology of activated carbon and catalyst, which is applied in the field of low-temperature iron-vanadium activated carbon catalyst, which can solve the problems of poor selectivity and sulfur resistance, susceptibility to sulfur poisoning, poor hydrothermal stability, etc., and achieves low price, reduced preparation cost, and operating temperature window wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

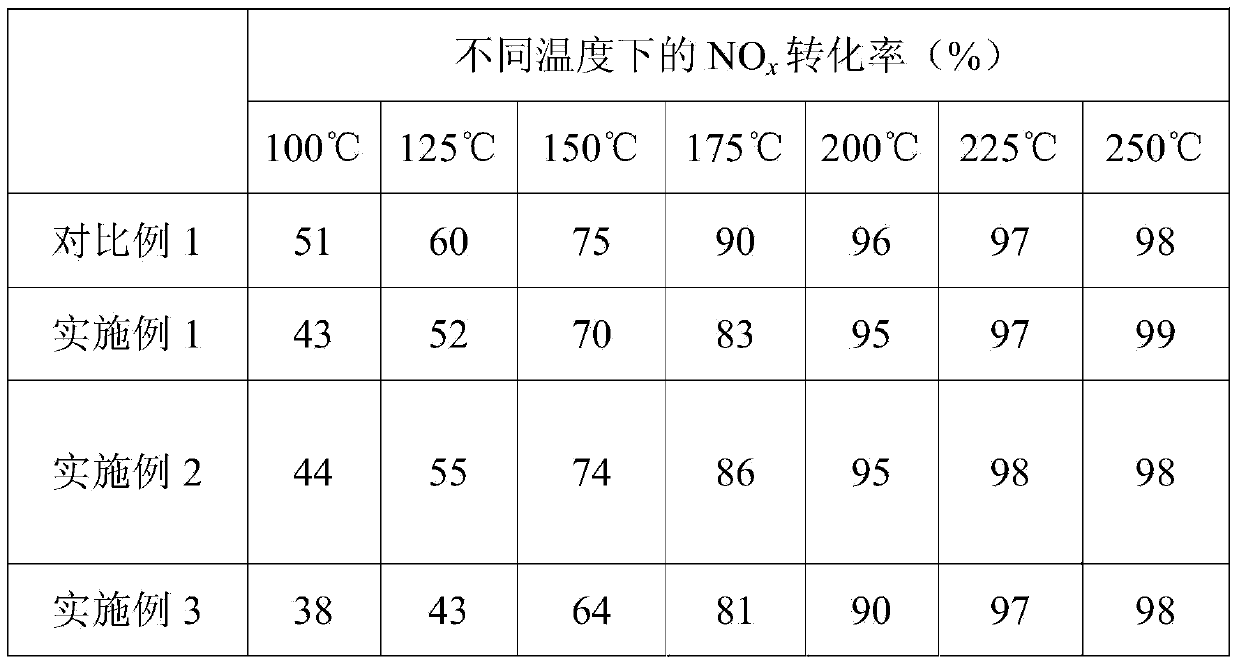

Examples

Embodiment 1

[0030] A vanadium-modified iron-based activated carbon catalyst, the active components of the catalyst are iron oxide and vanadium pentoxide, the carrier is activated carbon, the mass percentage of the iron oxide accounted for activated carbon is 3%, and the vanadium pentoxide accounts for The mass percentage of activated carbon is 0.3%.

[0031] The preparation method of the iron-based activated carbon catalyst modified by vanadium as described above, the method is a co-impregnation method, comprising the steps of:

[0032] (1) Use nitric acid to oxidize the surface of activated carbon;

[0033] (2) In the presence of oxalic acid, the mixture of ferric nitrate, ammonium metavanadate and oxidized activated carbon was stirred at room temperature for 2 hours, evaporated to dryness at 60°C by a rotary evaporator, dried at 110°C for 12 hours, and then placed in a tube Calcined at 500°C for 5 h in a nitrogen atmosphere in a type furnace to obtain a vanadium-modified iron-based act...

Embodiment 2

[0035] A vanadium-modified iron-based activated carbon catalyst, the active components of the catalyst are iron oxide and vanadium pentoxide, the carrier is activated carbon, the mass percentage of the iron oxide accounted for activated carbon is 3%, and the vanadium pentoxide accounts for The mass percentage of activated carbon is 0.5%.

[0036] The preparation method of the iron-based activated carbon catalyst modified by vanadium as described above, the method is a co-impregnation method, comprising the steps of:

[0037] (1) Use nitric acid to oxidize the surface of activated carbon;

[0038] (2) In the presence of oxalic acid, the mixture of ferric nitrate, ammonium metavanadate and oxidized activated carbon was stirred at room temperature for 2 hours, evaporated to dryness at 60°C by a rotary evaporator, dried at 110°C for 12 hours, and then placed in a tube Calcined at 500°C for 5 h in a nitrogen atmosphere in a type furnace to obtain a vanadium-modified iron-based act...

Embodiment 3

[0040] A vanadium-modified iron-based activated carbon catalyst, the active components of the catalyst are iron oxide and vanadium pentoxide, the carrier is activated carbon, the mass percentage of the iron oxide accounted for activated carbon is 3%, and the vanadium pentoxide accounts for The mass percent of activated carbon is 0.7%.

[0041] The preparation method of the iron-based activated carbon catalyst modified by vanadium as described above, the method is a co-impregnation method, comprising the steps of:

[0042] (1) Use nitric acid to oxidize the surface of activated carbon;

[0043] (2) In the presence of oxalic acid, the mixture of ferric nitrate, ammonium metavanadate and oxidized activated carbon was stirred at room temperature for 2 hours, evaporated to dryness at 60°C by a rotary evaporator, dried at 110°C for 12 hours, and then placed in a tube Calcined at 500°C for 5 h in a nitrogen atmosphere in a type furnace to obtain a vanadium-modified iron-based activate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com