Patents

Literature

40results about How to "Excellent high temperature aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

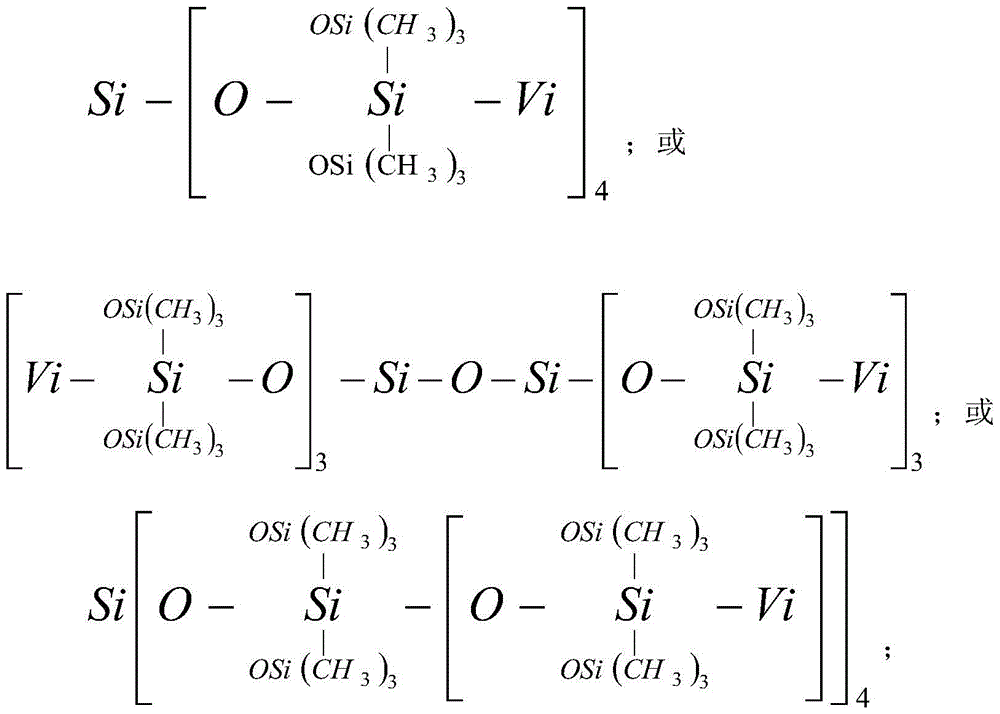

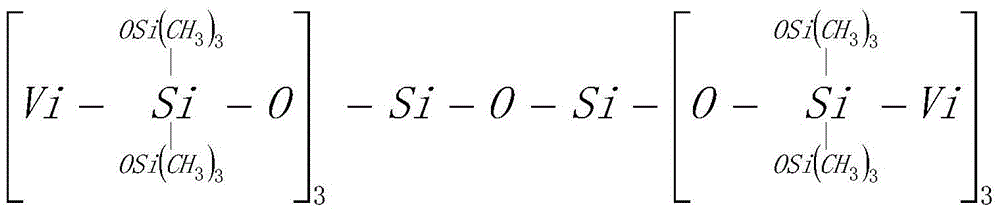

High-temperature resistance organic silicon adhesive

ActiveCN104974711AImprove high temperature resistanceEasy to operateNon-macromolecular adhesive additivesCross-linkAging resistance

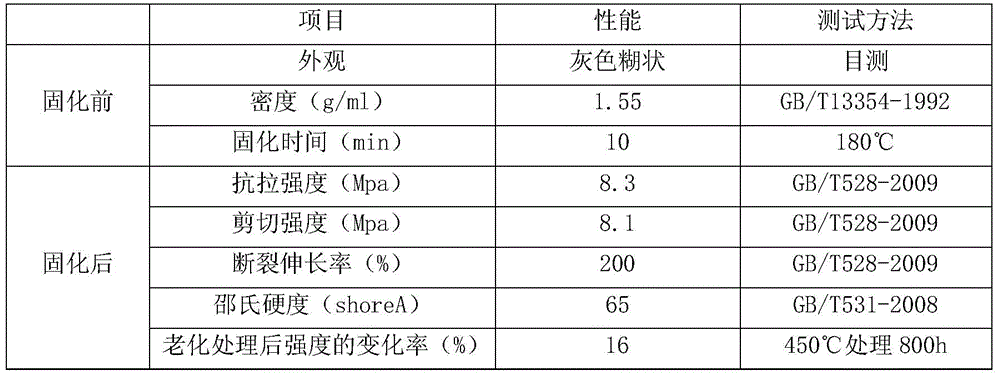

The present invention relates to a high-temperature resistance organic silicon adhesive and a preparation method thereof, wherein the adhesive comprises, by weight, 100 parts of vinyl-terminated polyorganosiloxane, 10-30 parts of a reinforcing resin, 10-30 parts of a toughening resin, 2-5 parts of an antioxidant, 2-5 parts of a tackifier, 3-20 parts of a cross-linking resin, 0.005-0.1 part of a catalyst, 0.2-0.5 part of an inhibitor, 30-150 parts of a thermal conduction filler, and 3-20 parts of a temperature resistance filler. According to the present invention, the adhesive adopts the single component package so as to easily and conveniently use, no gelating or curing phenomenon is generated after storing for 12 months in the normal temperature environment, the curing can be completed by placing for 5-30 min at the temperature of 120-300 DEG C, the good high temperature aging resistance is provided after the curing, the normal temperature shear strength is reduced by less than 20% after the aging treatment for 800 h at the temperature of 450 DEG C, and the adhesive can be used for the adhesion and the curing of the heat generating ceramic in the PTC ceramic heat generating assembly and the stainless steel.

Owner:武汉双键新材料股份有限公司 +1

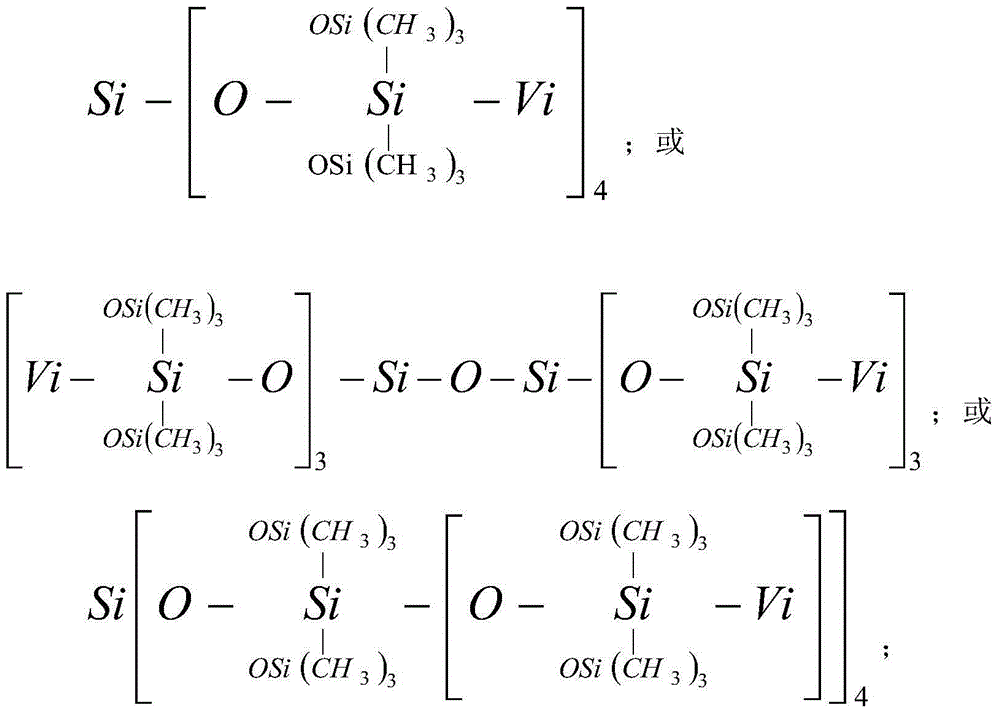

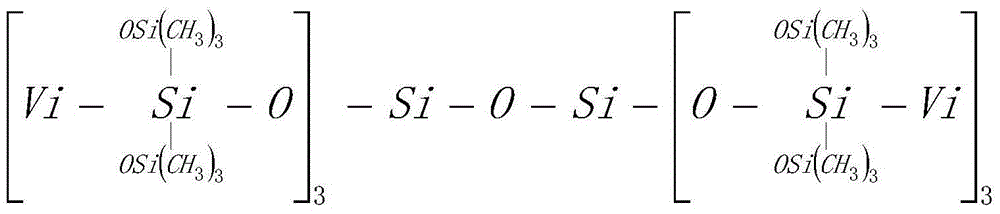

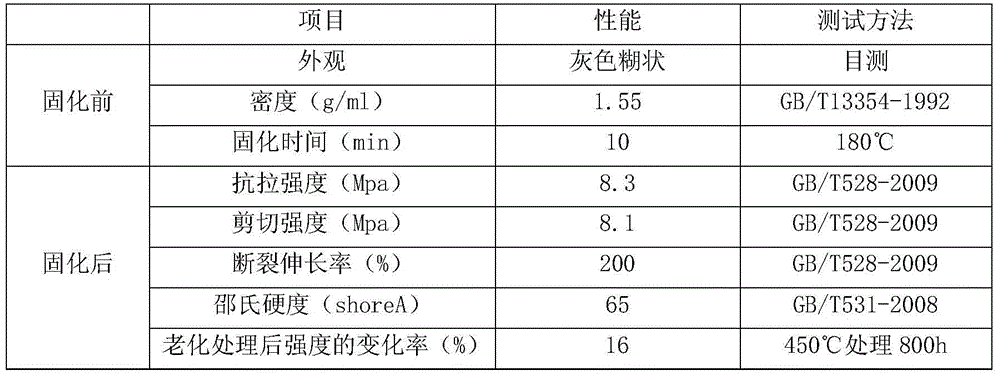

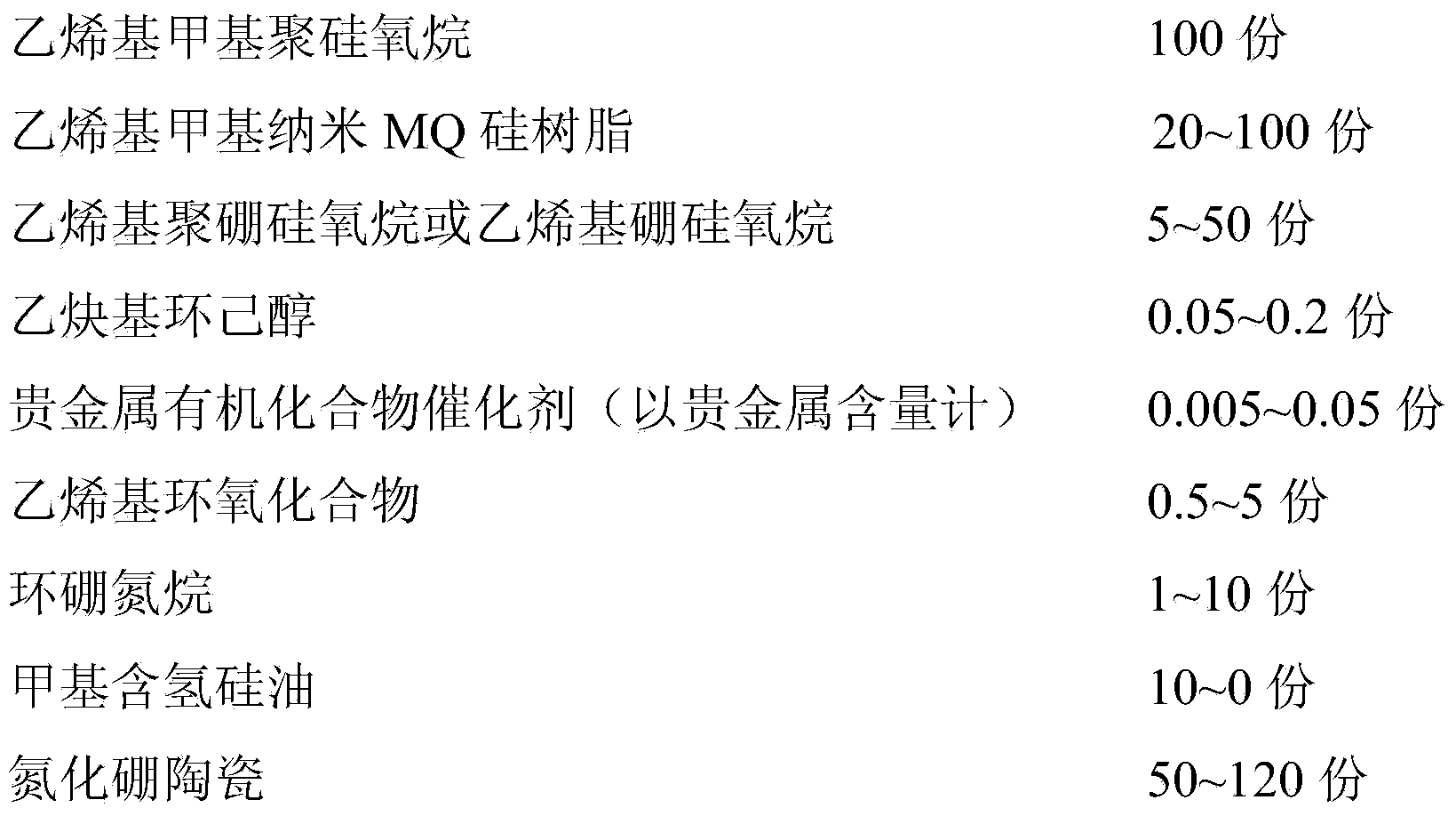

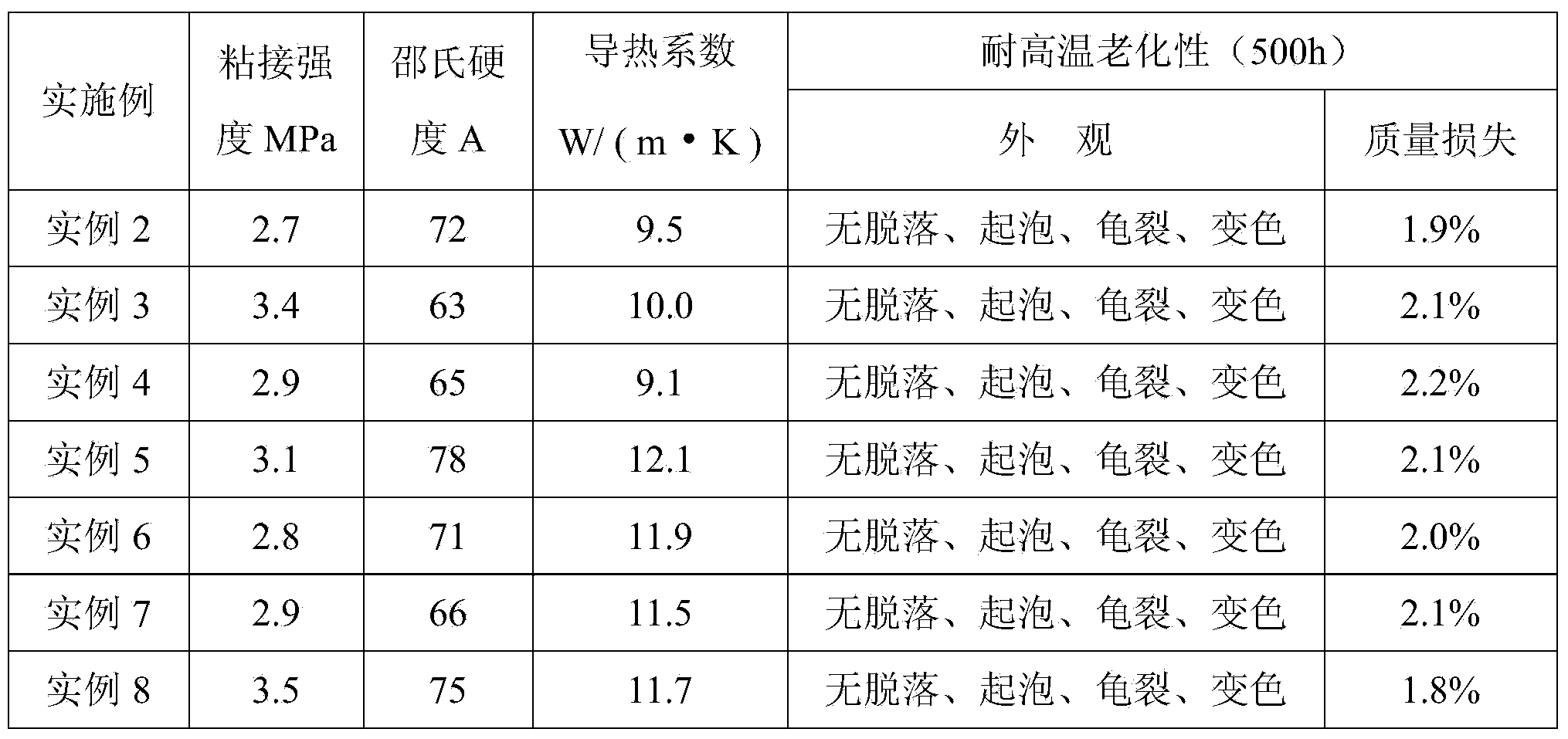

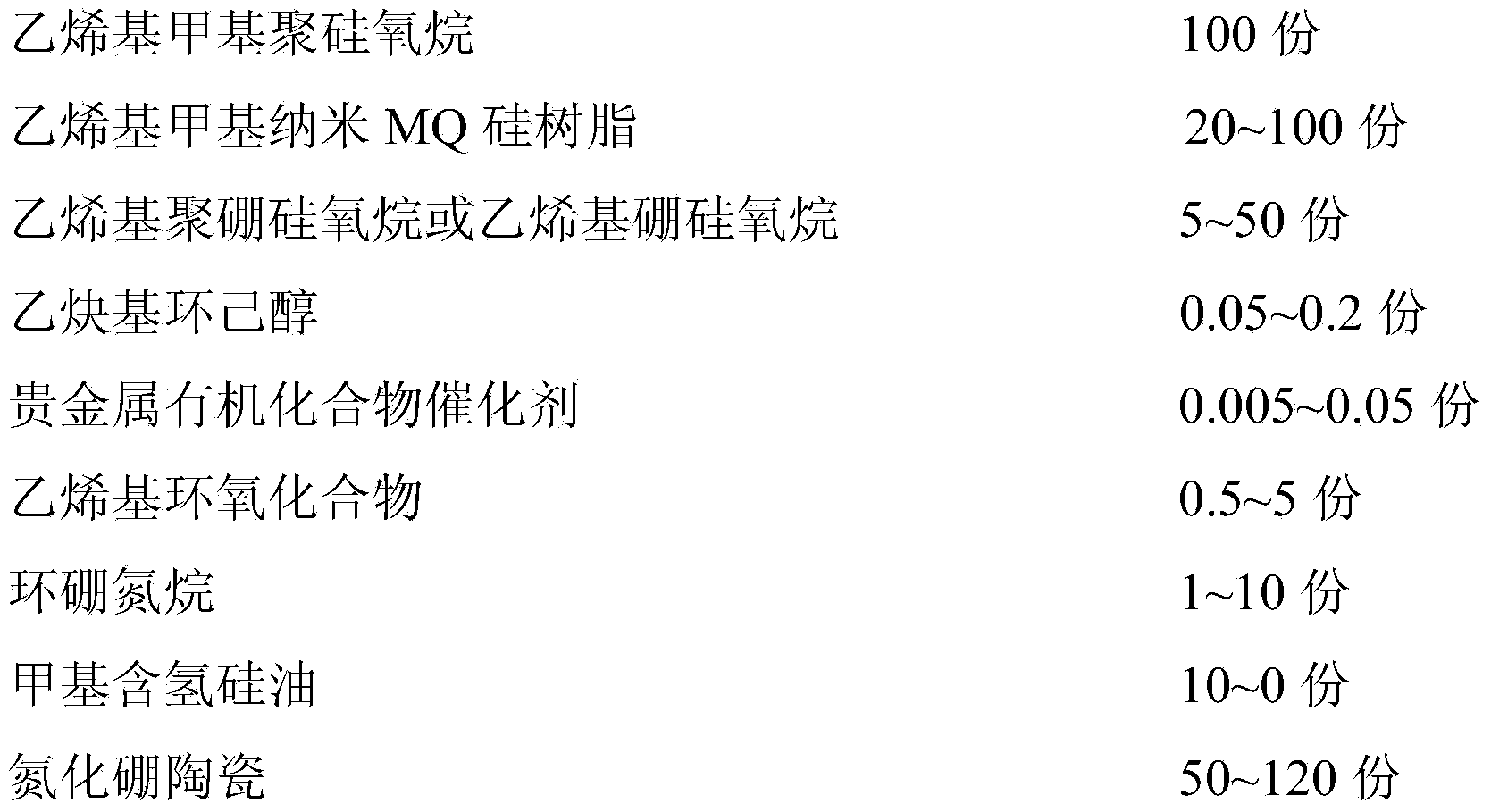

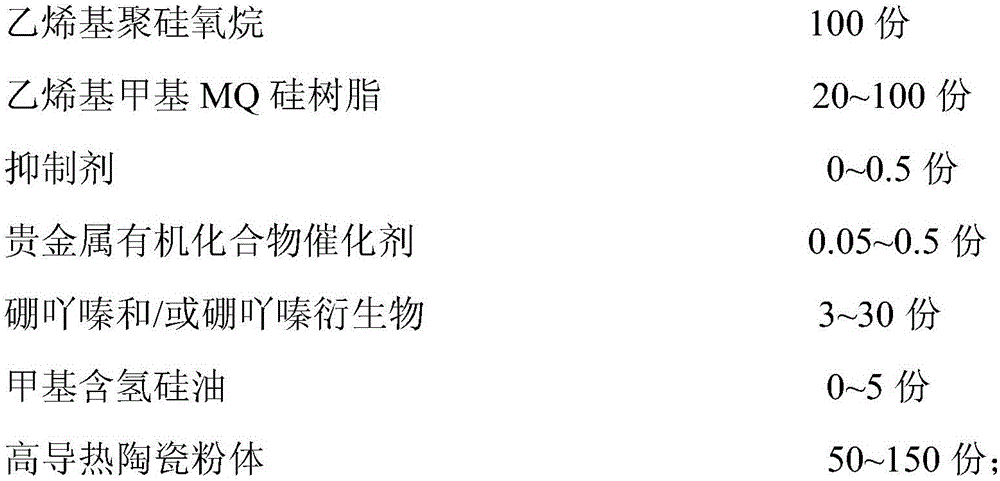

High-heat-conductivity boroheteropolysiloxane potting adhesive and preparation method thereof

ActiveCN104031603ALow shrinkageImprove shrinkageNon-macromolecular adhesive additivesModified epoxy resin adhesivesEpoxyAdhesive

The invention belongs to the field of potting materials, and discloses a high-heat-conductivity boroheteropolysiloxane potting adhesive and a preparation method thereof. The potting adhesive is composed of the following components in parts by mass: 100 parts of vinylmethyl polysiloxane, 20-100 parts of vinylmethyl nano MQ silicon resin, 5-50 parts of vinyl polyborosiloxane or vinyl borosiloxane, 0.05-0.2 part of acetylenyl cyclohexanol, 0.005-0.05 part of noble metal organic compound catalyst, 0.5-5 parts of vinyl epoxy compound, 1-10 parts of borazine, 10-0 part of methyl hydrogen-containing silicon oil and 50-120 parts of boron nitride ceramic. The high-heat-conductivity boroheteropolysiloxane potting adhesive has the advantages of high heat conductivity, favorable sealing property, high bonding force, favorable elasticity, water and moisture resistance, electric insulation, shock absorption, high temperature resistance and excellent aging resistance, and has wide application prospects in packaging of high-power electronic information components, semiconductor communication and illumination components and other components.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

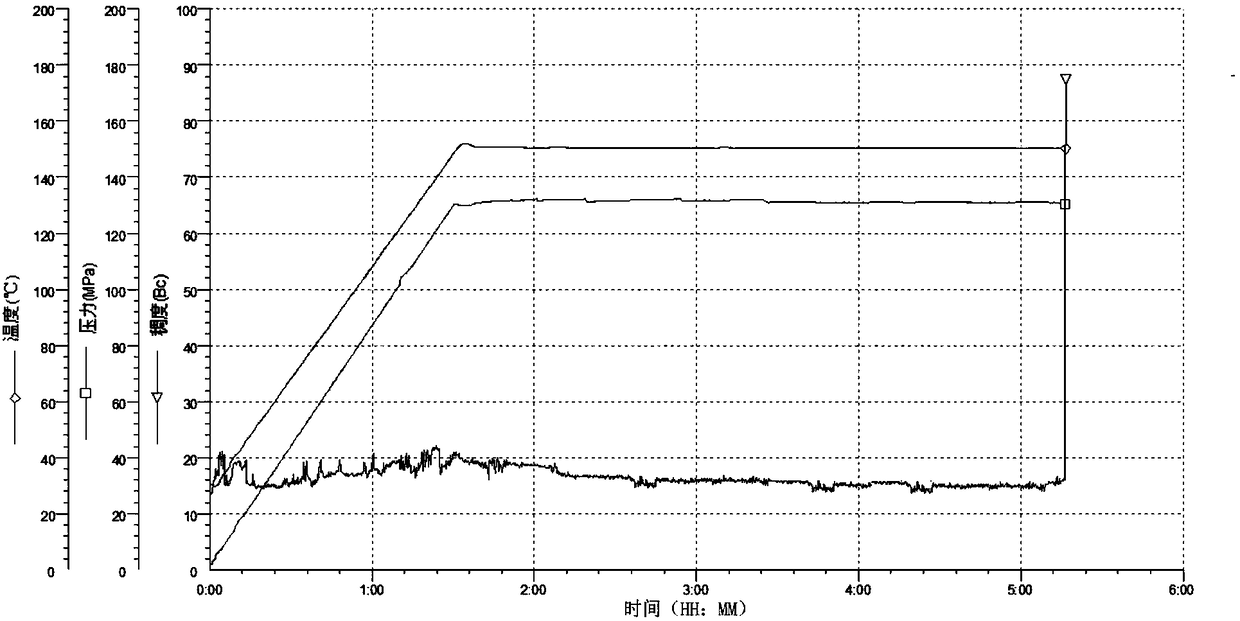

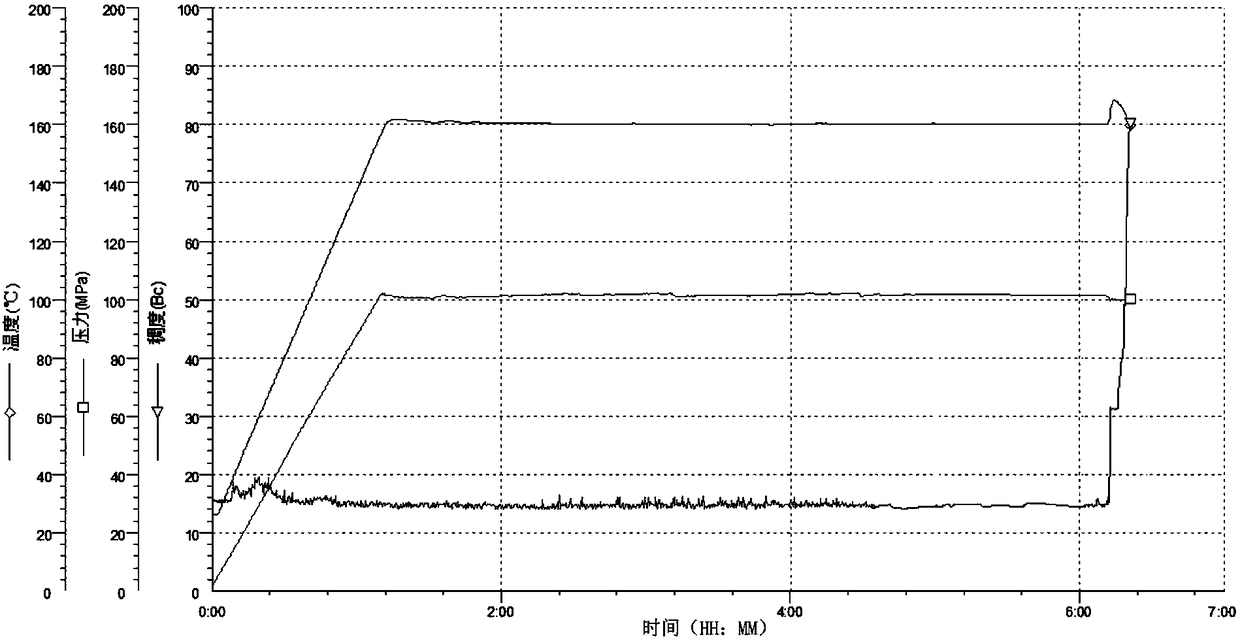

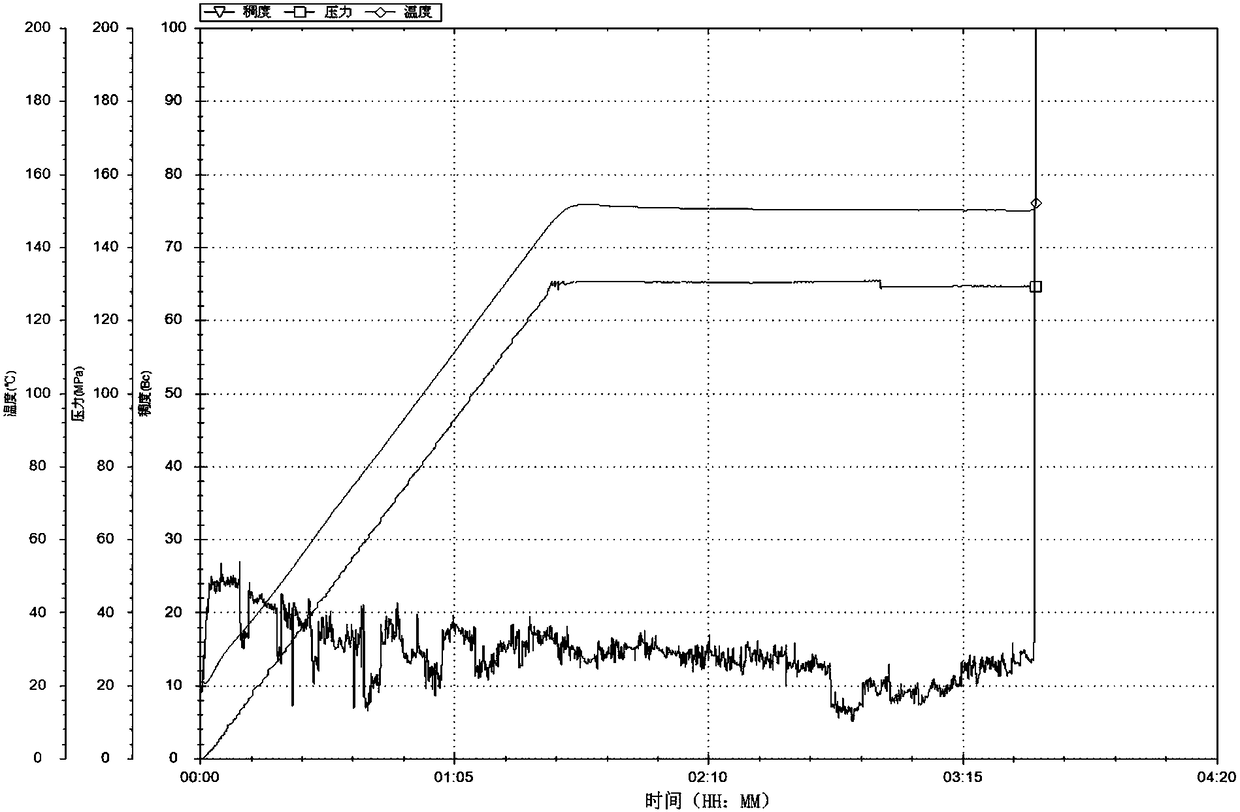

High temperature-resistant and gas channeling-resistant cement system and preparation method thereof

The invention relates to the field of petroleum drilling engineering, and especially relates to a high temperature-resistant and gas channeling-resistant cement system and a preparation method thereof. The high temperature-resistant and gas channeling-resistant cement system comprises, by weight, 100 parts of cement, 60 parts of composite silicon powder, 1-1.5 parts of inorganically toughened fibers, 1.5-3 parts of a fluid loss agent, 0.3-0.7 part of a dispersant, 6-10 parts of a latex gas channeling inhibitor, 1-1.2 parts of a latex stabilizer, 6-10 parts of nano-liquid silicon, 2.5-8 parts of a high temperature retarder, 1-1.5 parts of an antifoaming agent and 65-90 parts of water. The preparation method of the high temperature-resistant and gas channeling-resistant cement system comprises the following steps: (1) uniformly mixing the cement, the silicon powder and the inorganically toughened fibers in proportion; (2) uniformly mixing the fluid loss agent, the dispersant, the latex gas channeling inhibitor, the latex stabilizer, the nano-liquid silicon, the high temperature retarder, the antifoaming agent and the water in proportion; and (3) slowly adding the mixture obtained instep (1) into a mixture obtained in step (2), and performing rapid stirring by a stirrer.

Owner:CHINA PETROLEUM & CHEM CORP

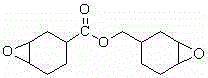

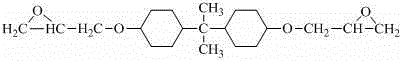

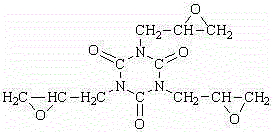

High-temperature-resistant ultraviolet-resistant epoxy resin prepolymer and preparation method thereof

InactiveCN105384914AImprove high temperature aging resistanceImproves UV resistancePolyolAntioxidant

The present invention discloses a high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer comprising the following components: 20-50wt% of epoxy resin, 40-60wt% of an anhydride curing agent, 1-15wt% of a polyol, 0.1-2wt% of a coupling agent and 0.1wt%-5wt% of an antioxidant; a preparation method of the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer is as follows: after the epoxy resin and the antioxidant are evenly mixed, the anhydride curing agent and the coupling agent are added, when the reaction system is cooled to 40 DEG C-80 DEG C, the polyol is added for ring opening reaction with anhydride to obtain a carboxylic compound, and the carboxyl compound is reacted with the epoxy resin to obtain the epoxy resin prepolymer. Advantages of the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer are that: the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer has excellent high-temperature aging resistance and ultraviolet resistance, and the preparation method is simple, raw materials are easily available, the process is controllable, industrial production is easy, and the high-temperature-resistant ultraviolet-resistant epoxy resin prepolymer can be widely used in electronic device packaging materials, coatings and adhesives and other field.

Owner:WUXI CHUANGDA ELECTRONICS

Special high-density polyethylene compound for automobile windshield washer and preparation method thereof

InactiveCN103709483AImprove ESCR performanceESCR performance improvementLow-density polyethyleneLinear low-density polyethylene

The invention provides a special high-density polyethylene compound for an automobile windshield washer and a preparation method thereof. The special high-density polyethylene compound for the automobile windshield washer is characterized by consisting of 59-100wt% of HDPE (High-Density Polyethylene), 0-30wt% of LLDPE (Linear Low-Density Polyethylene), 0-10wt% of ESCR (Environmental Stress Crack Resistance) synergist and 0-1wt% of heat stabilizer. The special high-density polyethylene compound for the automobile windshield washer disclosed by the invention has excellent ESCR performance as well as good mechanical properties and heat resistance. As proved by detection, the tensile strength (at 23 degrees centigrade) is not smaller than 24 MPa, the elongation at break is not smaller than 600%, the vicat softening temperature (10N) is not smaller than 120 degrees centigrade, and ESCR (GB / T1842-C) is not smaller than 200 h.

Owner:SHANGHAI KINGFA SCI & TECH

Rail transit rubber cable sheath material, its preparation method and application

InactiveCN102336946AImprove fire performanceGood flexibilityInsulated cablesInorganic insulatorsVulcanizationAluminium hydroxide

The invention belongs to the cable manufacturing field and specifically provides a heatproof low smoke halogen free flame retardant rail transit rubber cable sheath material which can resist temperature from minus 55 DEG C to 125 DEG C. The rail transit rubber cable sheath material is prepared by the following steps of: mainly selecting polar ethene-vinyl acetate rubber and nonpolar high-molecular silicone rubber materials as basic rubber, adding its corresponding vulcanization system, adding a frame retardant aluminium hydroxide and a zinc borate flame retardant, a zinc stabilizing agent, an ultralow temperature resistant sebacic acid phthalate plasticizer, a silane coupling agent and the like, so as to prepare the low smoke halogen free flame retardant rail transit rubber cable sheath material. The material provided by the invention can resist ultralow temperature of minus 55 DEG C for a long time, can also resist high temperature of 125 DEG C, can resist mineral oil and fuel oil, and has good flame retardance. The material provided by the invention accords with the requirement of the ultralow temperature resistant rail transit controlling cable and can bring convenience for rail transit locomotive cable users.

Owner:浙江万马股份有限公司

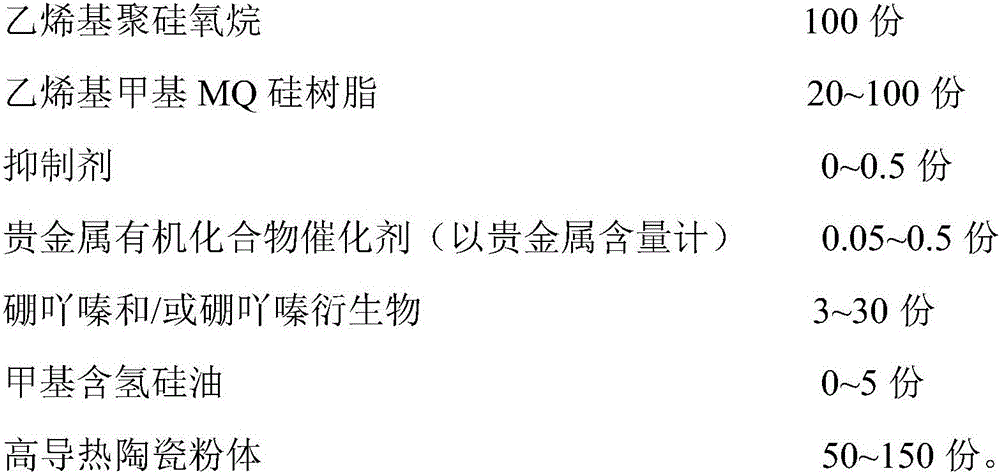

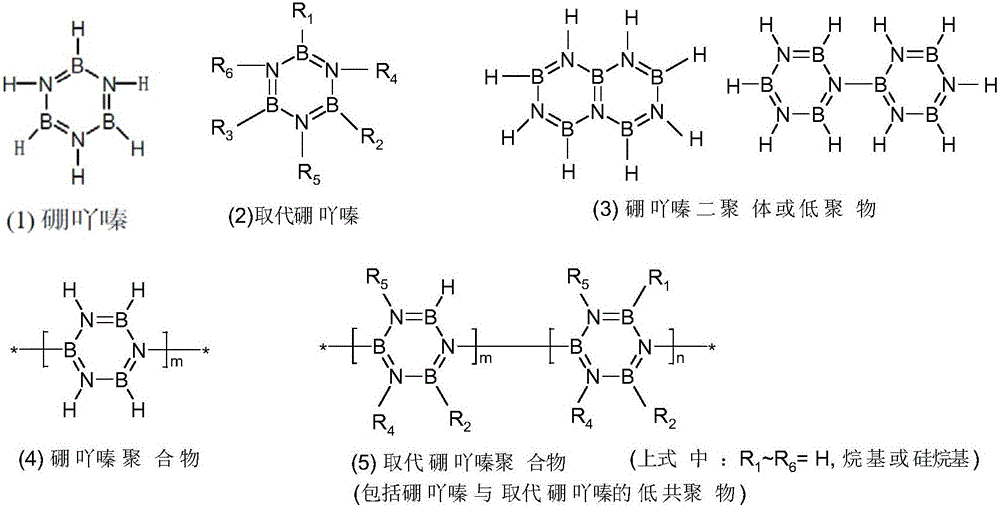

High-thermal-conductivity high-temperature-resistant polysiloxane ceramic composite material, as well as preparation method and applications thereof

ActiveCN103951983AImprove thermal conductivityIncrease elasticityHeat-exchange elementsAviationCeramic composite

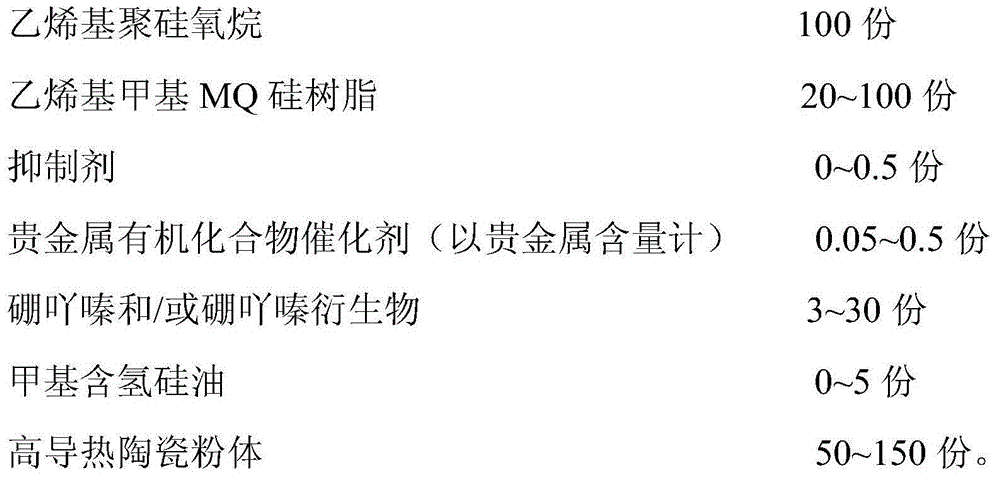

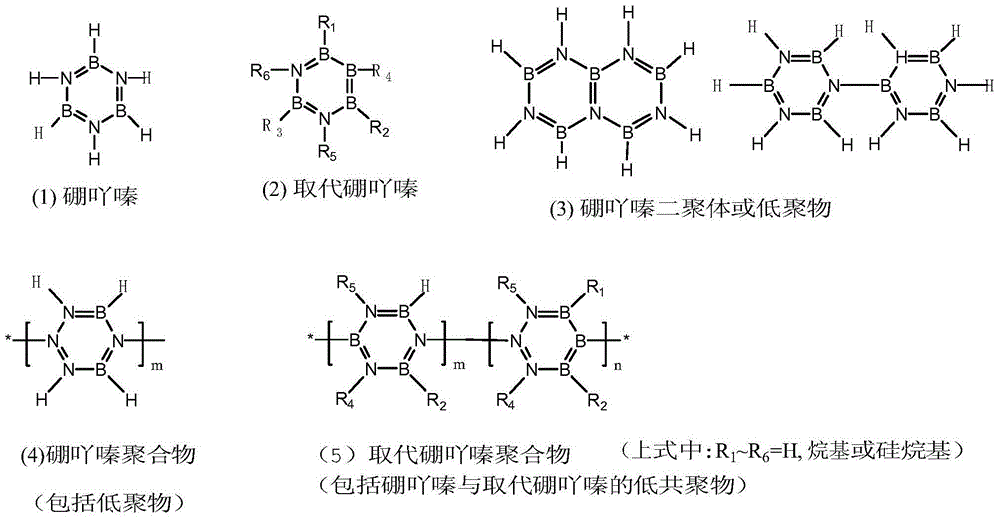

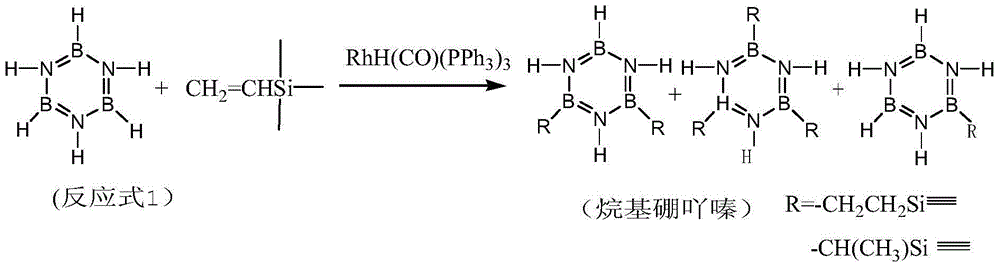

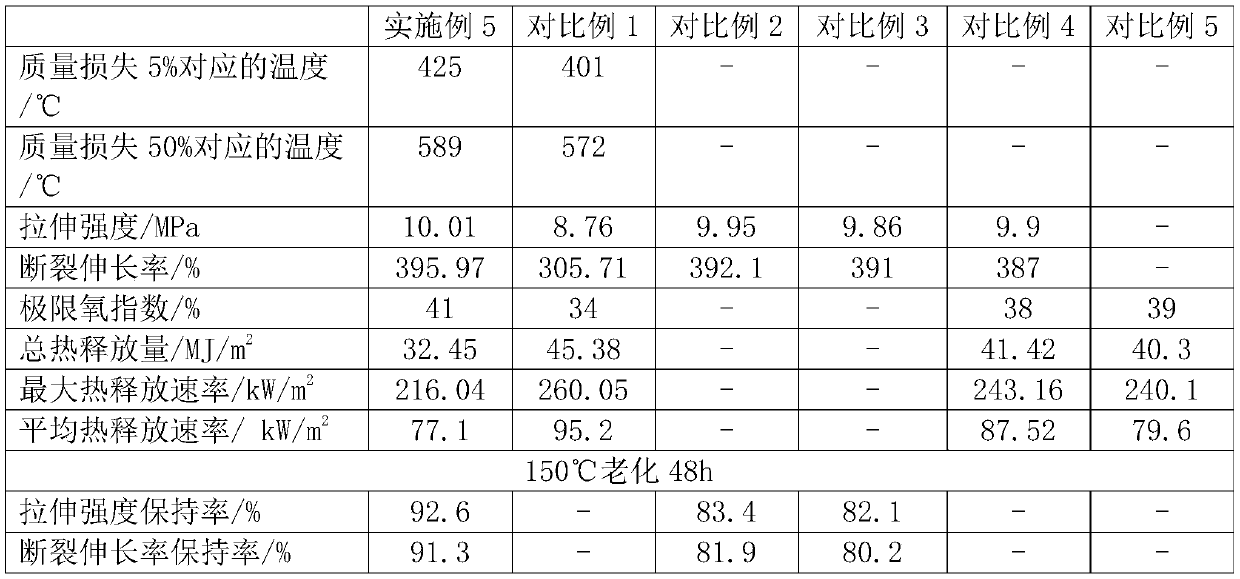

The invention discloses a high-thermal-conductivity high-temperature-resistant polysiloxane ceramic composite material, as well as a preparation method and applications thereof. The composite material comprises the following components in parts by mass: 100 parts of vinyl polysiloxane, 20-100 parts of vinyl methyl MQ silicone resin, 0-0.5 part of inhibitor, 0.05-0.5 part of precious metal organic compound catalyst, 3-30 parts of borazine and / or borazine derivatives, 0-5 parts of methyl hydrogen silicone oil and 50-150 parts of high-thermal-conductivity ceramic powder. The high-thermal-conductivity high-temperature-resistant polysiloxane ceramic composite material is high in thermal conductivity coefficient, good in elasticity, waterproof, damp-proof, insulating, can absorb absorption, and has excellent high temperature ageing resistance, thus having wide application prospects in the fields of aviation, aerospace, electronics, electrics and communication and illumination and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Double-layer co-extrusion insulation irradiation crosslinking halogen-free low-smoke flame-retardant power cable with long service life

ActiveCN110534249APromote environmental protectionImprove high temperature resistanceInsulated cablesPower cablesPolymer scienceInsulation layer

The invention discloses a double-layer co-extrusion insulation irradiation crosslinking halogen-free low-smoke flame-retardant power cable with a long service life. The power cable comprises a conductor, a fireproof layer wrapping the conductor, a double-layer co-extrusion insulation layer wrapping the fireproof layer and an outer protection layer wrapping the double-layer co-extrusion insulationlayer. The outer protection layer is prepared from an ethylene propylene diene monomer composite material; the ethylene propylene diene monomer composite material is prepared from the following raw materials: ethylene propylene diene monomer, silicone rubber, white carbon black, bentonite, talcum powder, zinc oxide, stearic acid, a vulcanizing agent, ammonium polyphosphate, aluminum hydroxide, microencapsulated red phosphorus, melamine pyrophosphate, pentaerythritol, an accelerant and an anti-aging agent. The double-layer co-extrusion insulation irradiation crosslinking halogen-free low-smokeflame-retardant power cable with a long service life provided by the invention is good in flame retardance and smoke suppression, excellent in heat resistance and aging resistance and long in servicelife.

Owner:ANHUI CABLE

SSZ-13 molecular sieves, production, SCR catalyst and production

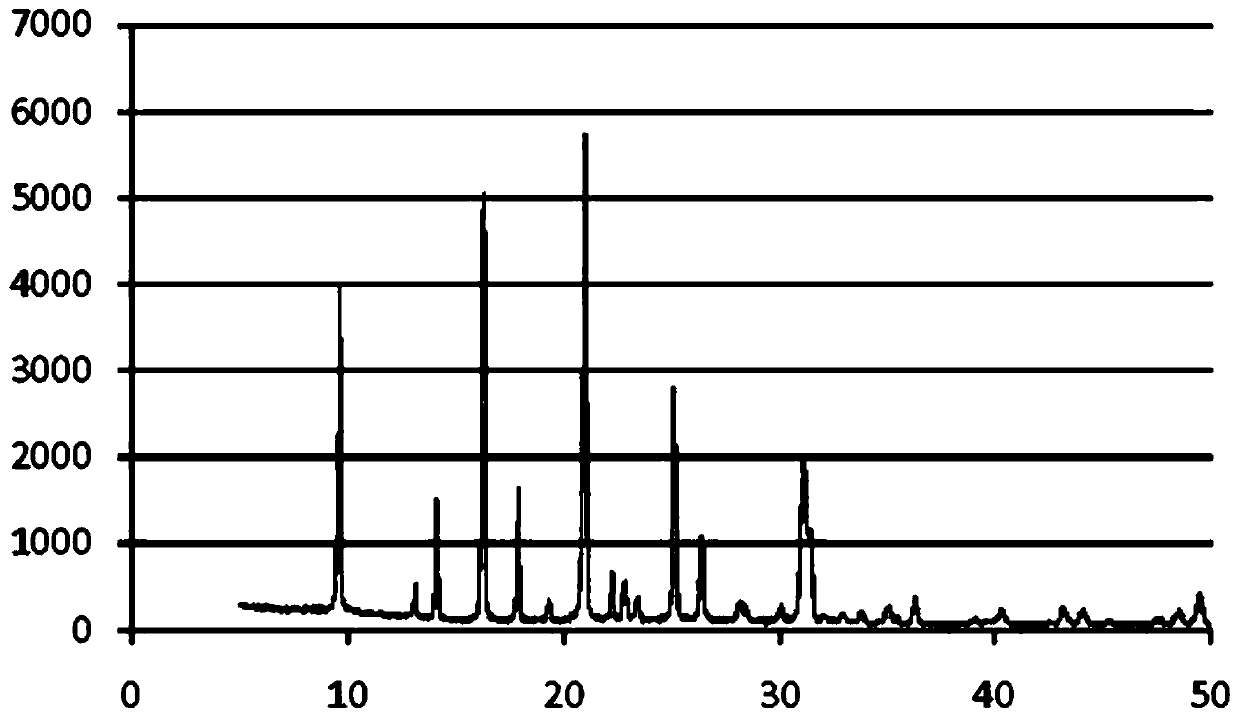

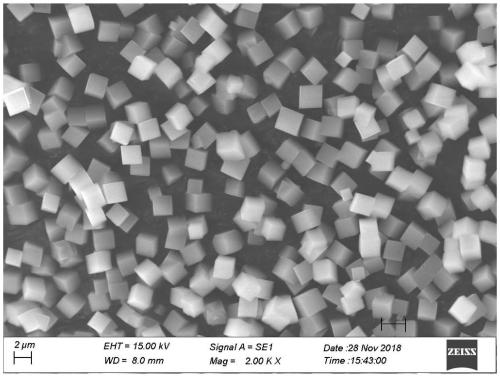

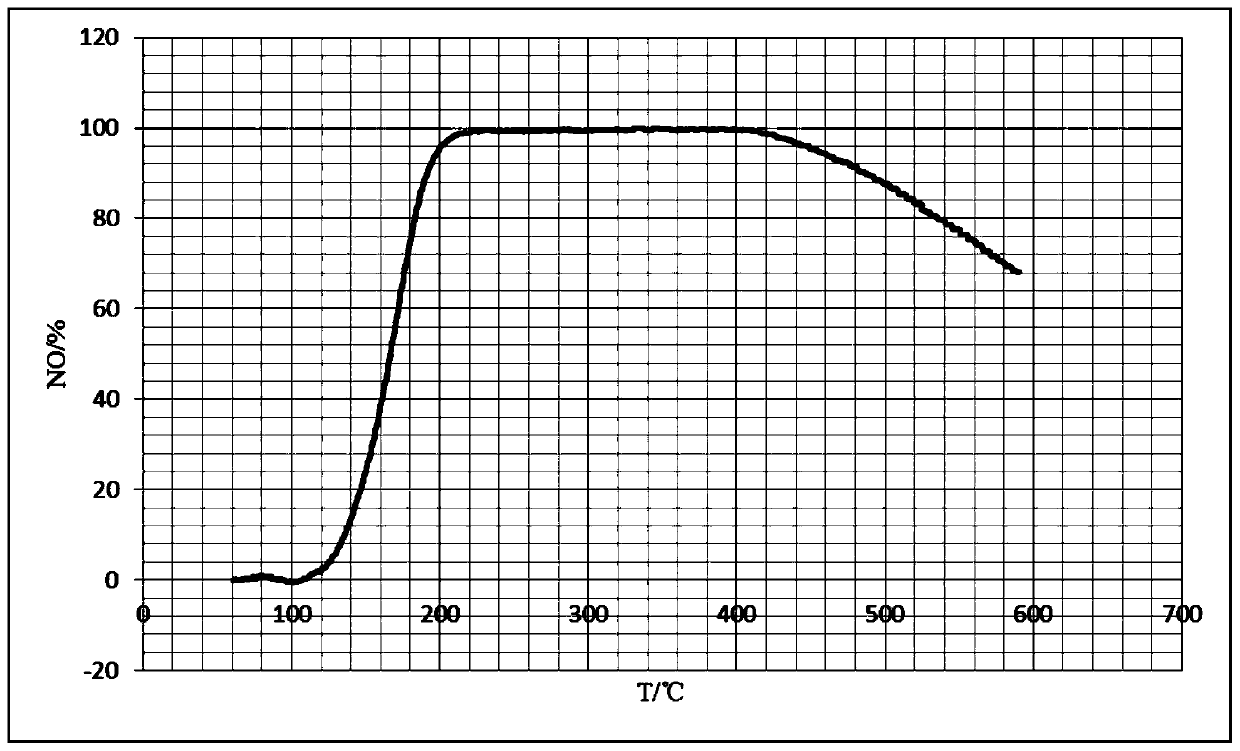

ActiveCN110407223AStable structureExcellent high temperature aging resistanceMolecular sieve catalystsCrystalline aluminosilicate zeolitesHydrogenAmmonium hydroxide

The invention relates to the technical field of catalysis, in particular to SSZ-13 molecular sieves, production, an SCR catalyst and production. A production method of the SSZ-13 hydrogen-type molecular sieves comprises the steps of (1) mixing an aluminium source, a template composition, a silicon source and an alkaline aqueous solution, and carrying out a gelation reaction to obtain gel; and (2)conducting crystallization, calcination and ammonium exchange on the gel to obtain the SSZ-13 hydrogen-type molecular sieves. The template composition comprises N,N,N-trimethylbicyclo[2,2,2]octane-2-ammonium hydroxide and at least one additional template.

Owner:合肥派森新材料技术有限公司

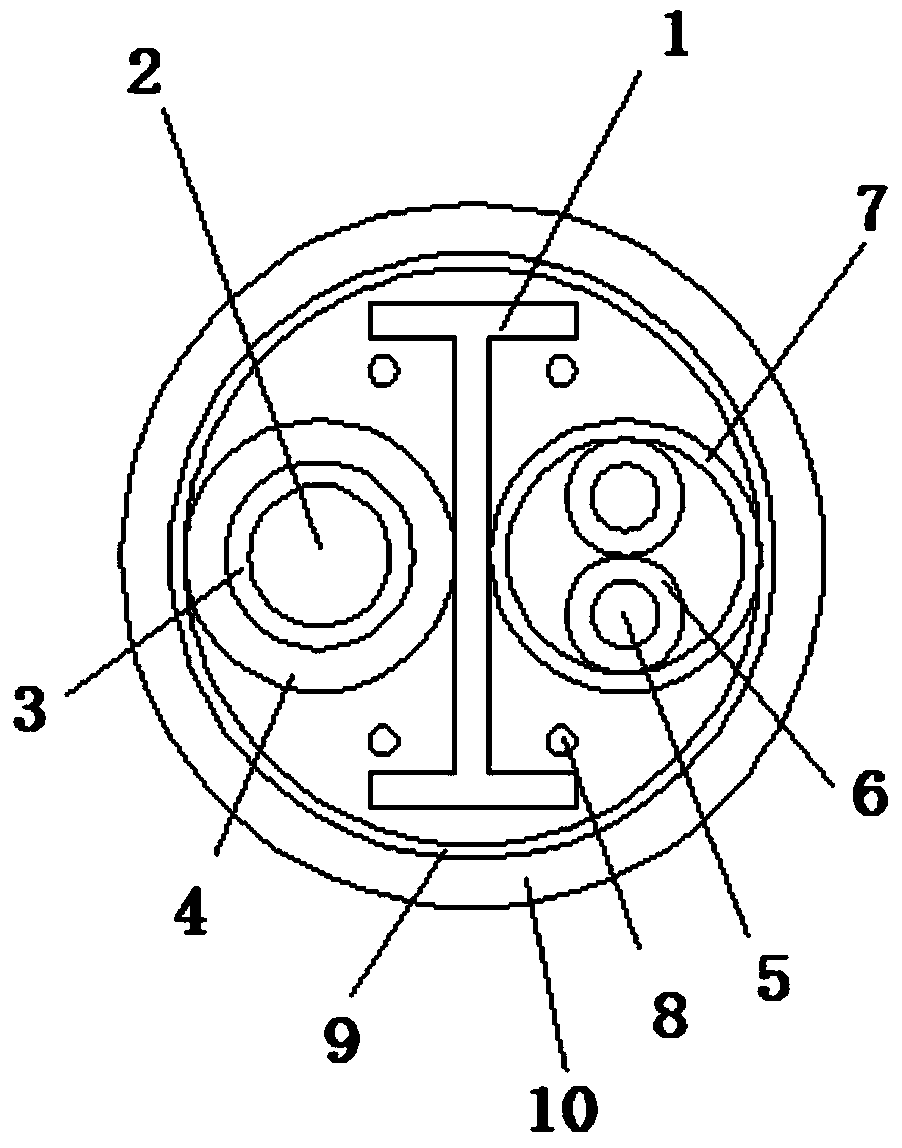

High-temperature resistant radio-frequency cable

InactiveCN103928096AIngenious ideaGood flexibilityInsulated cablesInsulated conductorsElectrical conductorThermoplastic elastomer

The invention discloses a high-temperature resistant radio-frequency cable which comprises an H-shaped nylon framework. A main wire core is arranged on the left side of the nylon framework, a control wire core is arranged on the right side of the nylon framework, the main wire core comprises a main conductor wrapped by a thermoplastic elastomer and a copper wire woven shielding layer, the control wire core comprises two control conductors wrapped by silicon rubber insulating layers, and the two control conductors are stranded and then wrapped by a copper strip woven shielding layer. The main wire core, the control wire core, the nylon framework and a plurality of tensile steel wires are stranded to form a cable core, and the cable core is wrapped by an aluminum alloy wire woven armor layer and a sheath layer in sequence.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

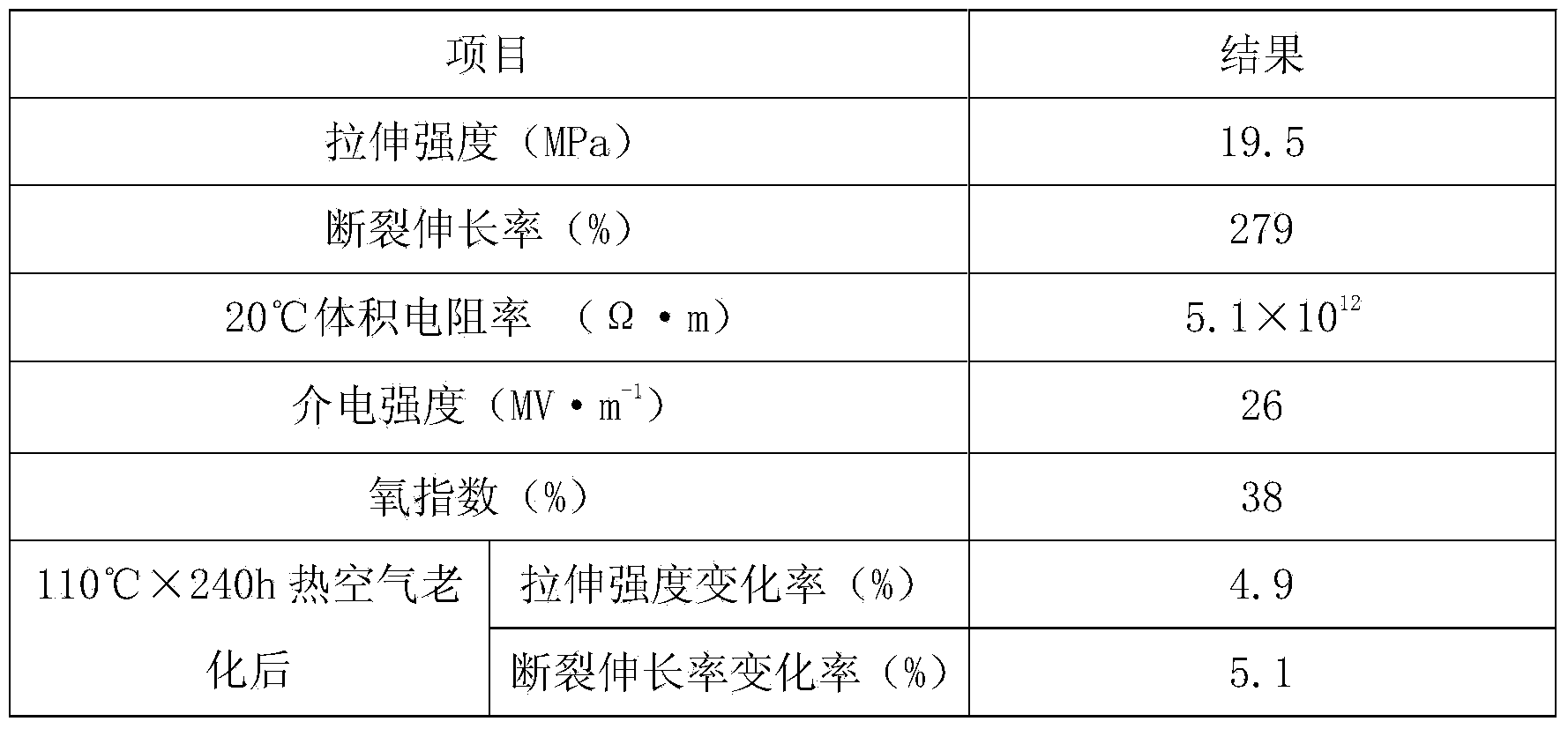

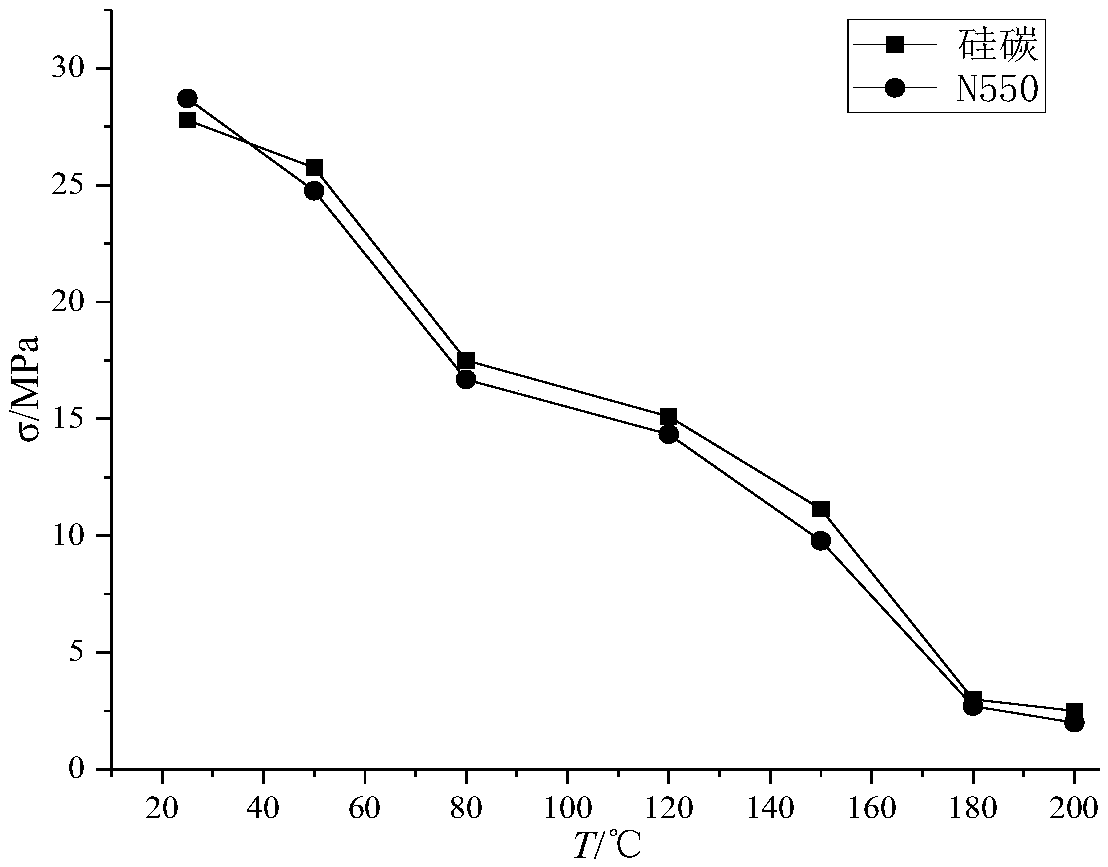

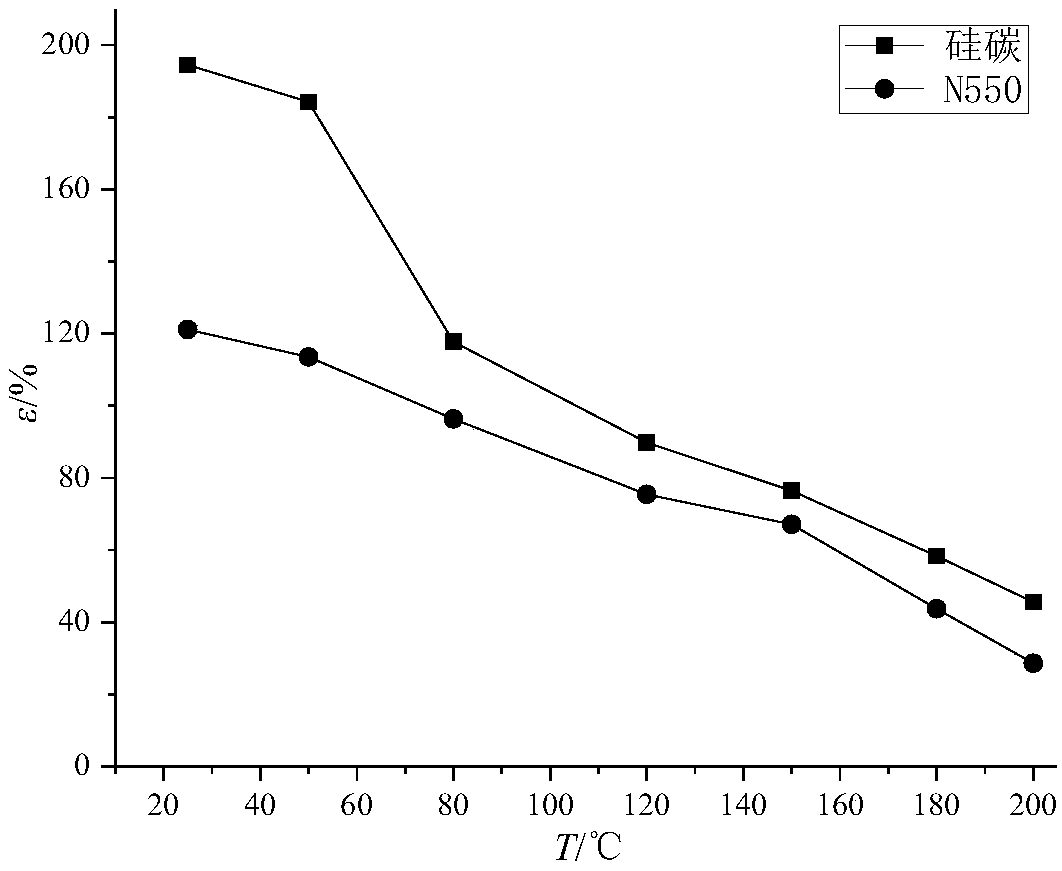

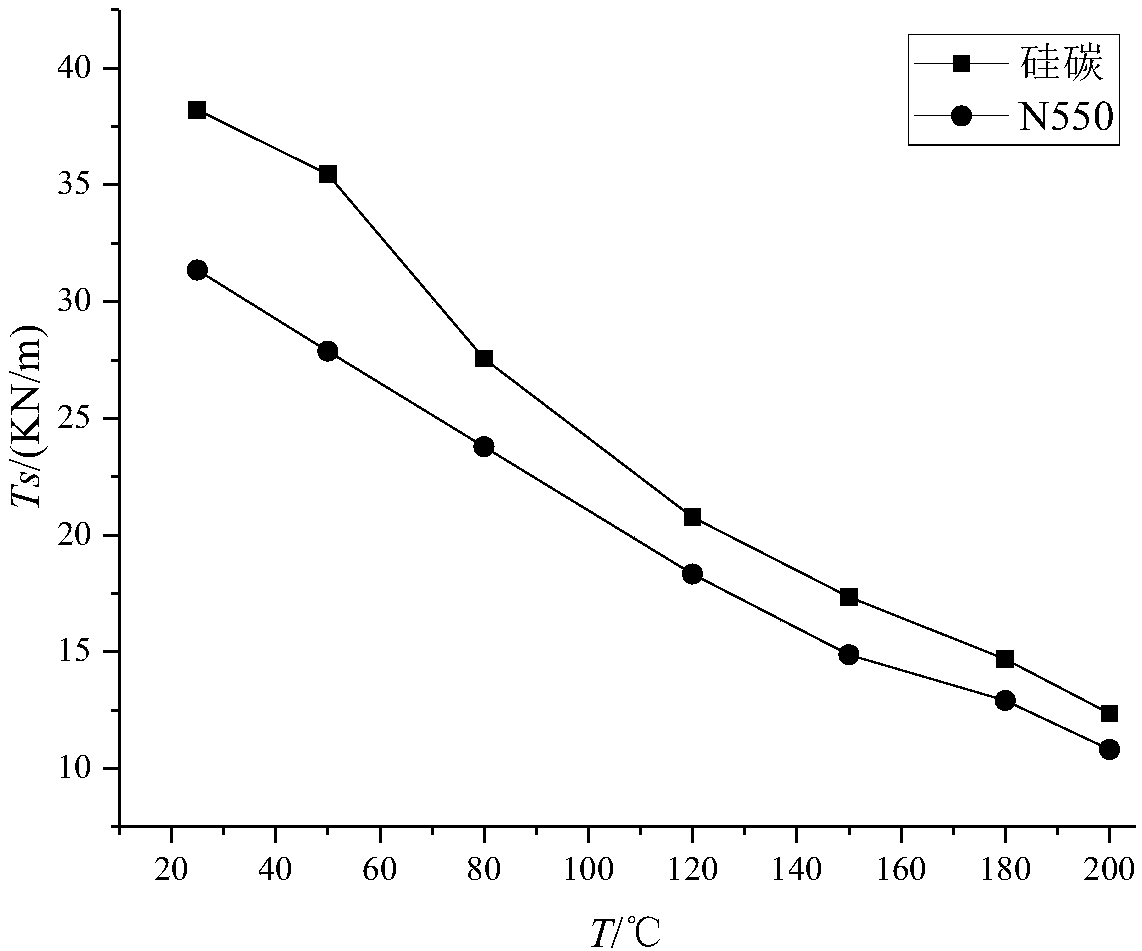

Anti-aging HNBR/silicone carbon rubber composite material, preparation method thereof and obtained packer

ActiveCN109251382AGood mechanical propertiesExcellent high temperature aging resistanceNitrile rubberAging resistance

The invention provides an anti-aging HNBR / silicone carbon rubber composite material, a preparation method thereof and an obtained packer, which belong to the technical field of a functional material.The composite material has excellent mechanical properties and aging resistance, and the packer prepared by the composite material can be used for a long time under high temperature oil exploitation conditions, and can still exhibit remarkable mechanical properties after aging for 30 days. The composite material includes 100 parts of supersaturated hydrogenated nitrile rubber, 40 to 50 parts of biomass silicon carbon, 3 to 7 parts of a reaction reinforcing agent, 30 parts of mixed carbon black, 2 to 5 parts of an anti-aging agent, 3 to 8 parts of an auxiliary agent, 3 to 8 parts of an odorlessfree radical initiator, 0.5 to 2.0 parts of a softener, and 2 to 6 parts of an accelerator. The composite material can be used in the preparation of the packer in an oil and gas reservoir exploitation process.

Owner:QINGDAO UNIV OF SCI & TECH

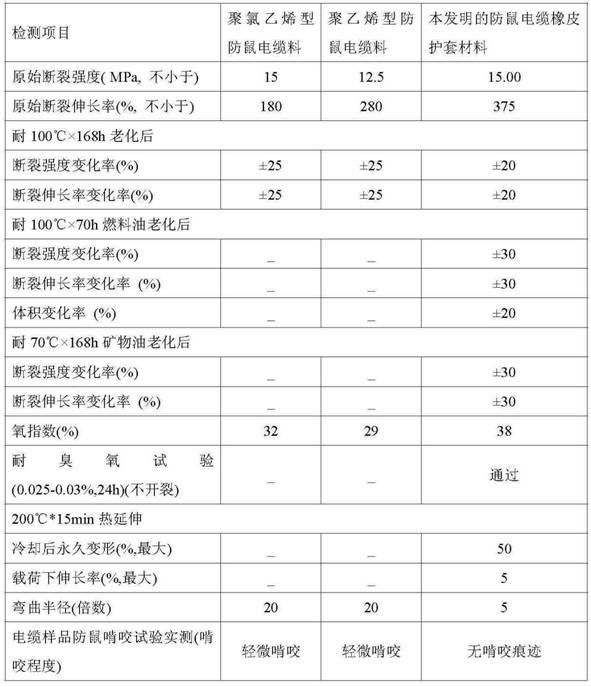

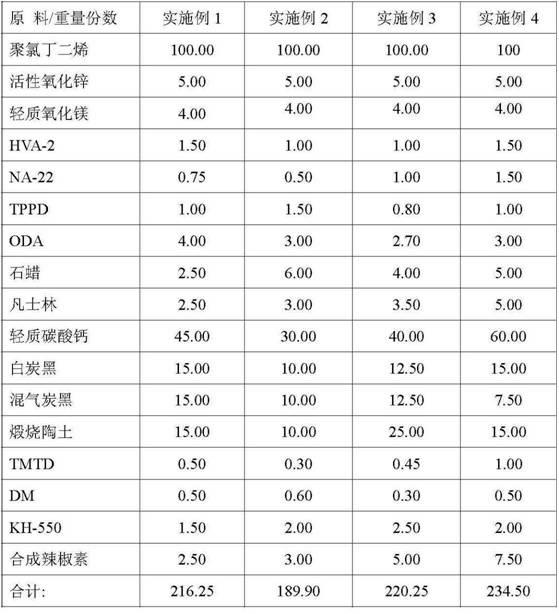

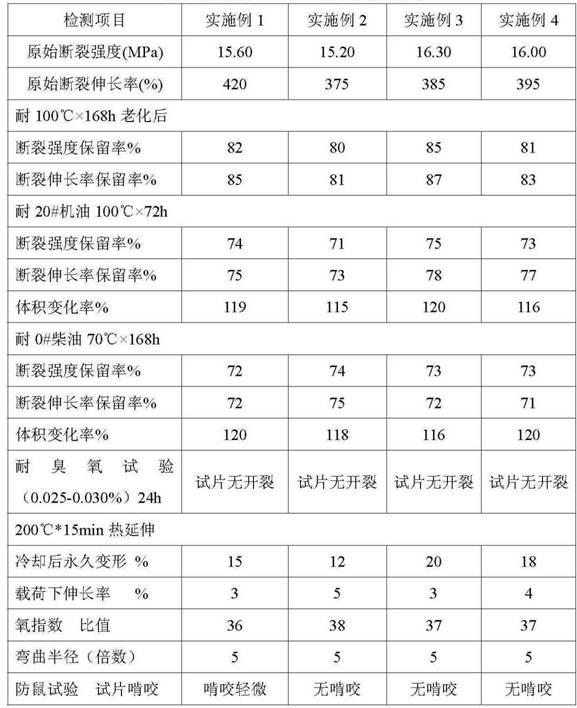

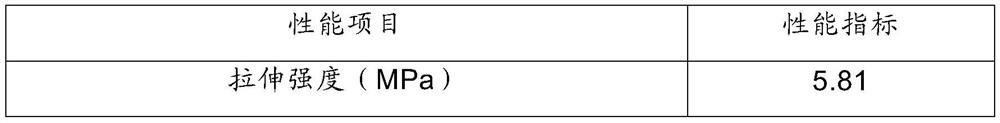

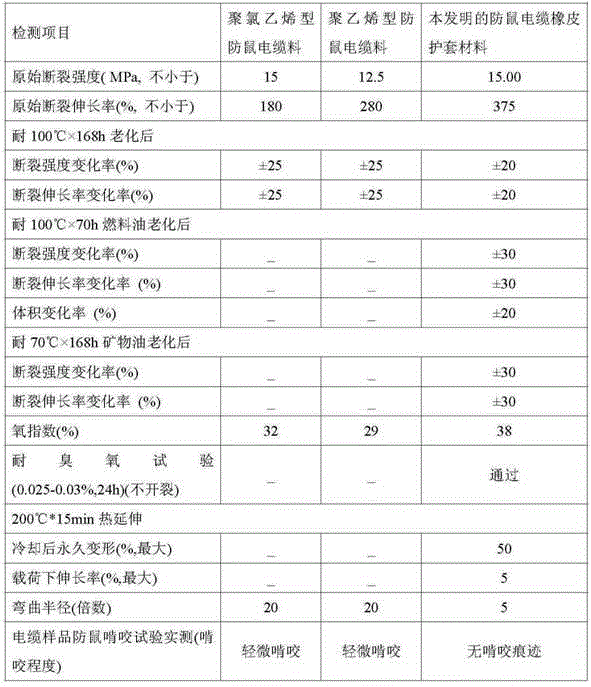

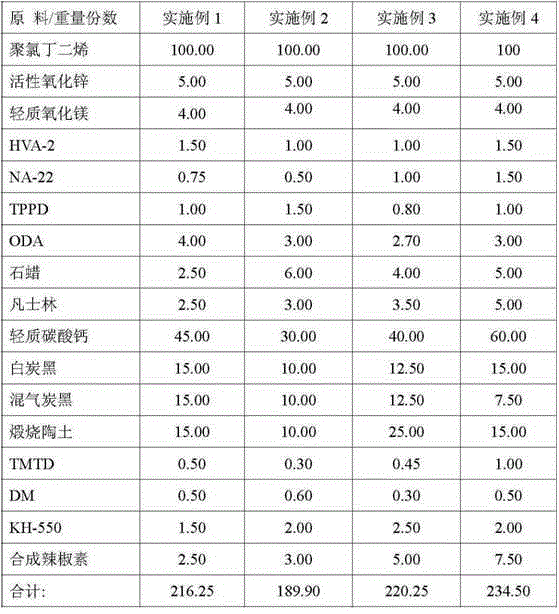

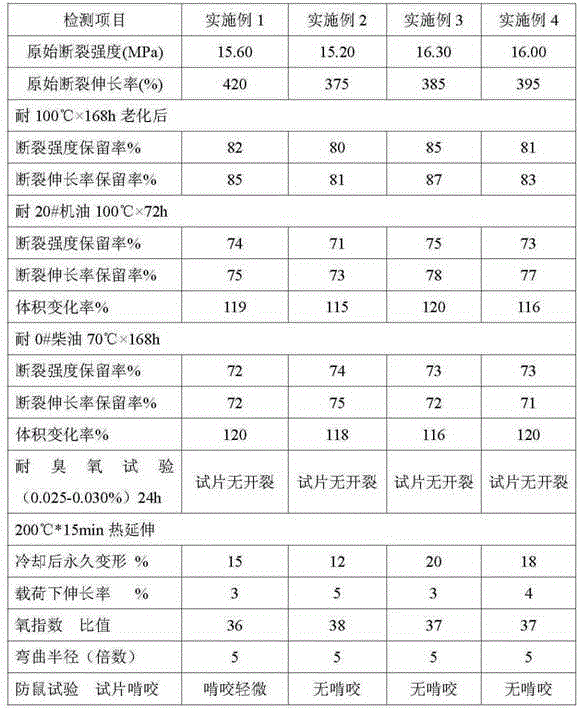

Ratproof cable rubber sheath material as well as preparation method and application thereof

InactiveCN102311565AHigh strengthImprove mechanical propertiesInsulated cablesInsulated conductorsVulcanizationPhysical chemistry

The invention belongs to the manufacturing field of cables, particularly relates to a ratproof cable rubber sheath material which is mainly prepared from the following raw materials in part by weight: 100 parts of polychloroprene, 5 parts of zinc oxide, 1.5-3 parts of vulcanization accelerator, 0.75-1.5 parts of scorch retarder, 3.5-5 parts of antiager, 4 parts of magnesium oxide, 30-60 parts of calcium carbonate, 30-50 parts of reinforcing filler, 1.5-2.5 parts of silane coupling agent, 5-10 parts of operating agent and 2.5-7.5 parts of synthetic capsaicin. The ratproof cable rubber sheath material provided by the invention has the characteristics of better flexibility, oil resistance, weather resistance, inflaming retarding and the like, and not only meets the requirements of field and users on rubber cable rat bite prevention, but also brings convenience for the users.

Owner:浙江万马股份有限公司

Mixed rubber used for automotive wiring harness pipes, and preparation method thereof

The invention discloses a mixed rubber used for automotive wiring harness pipes, and a preparation method thereof. The mixed rubber comprises, by weight, 60 to 80 parts of methyl vinyl Phenyl Polysiloxane rubber, 30 to 50 parts of methyl vinyl silicone rubber, 10 to 20 parts of white carbon black, 5 to 15 parts of argil, 5 to 15 parts of stearic acid, 1 to 10 parts of an enclosed type isocyanate curing agent, 5 to 15 parts of hexamethyldisilazane, and 1 to 8 parts of vinyltriethoxysilane. The mixed rubber used for automotive wiring harness pipes possesses high tensile strength, tearing strength, and hardness; hardness change is 2 DEG or lower, and elongation at break is 10% or lower after 24h of high temperature aging at 200 DEG C, and excellent high temperature aging resistance is achieved.

Owner:昕中和成都胶业有限公司

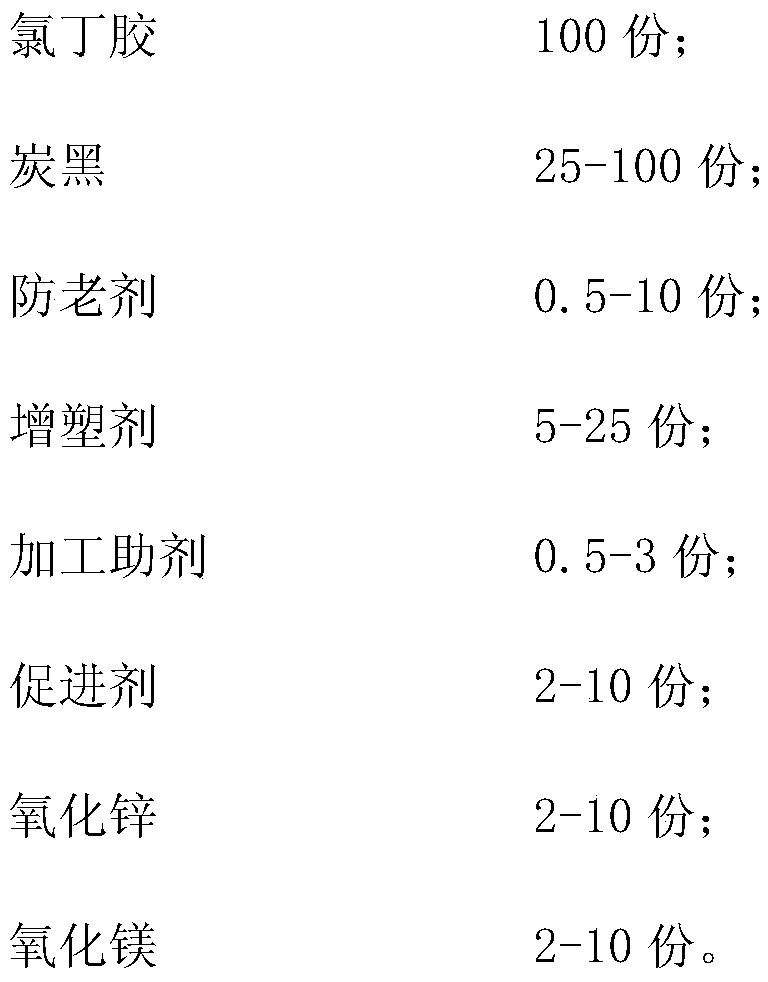

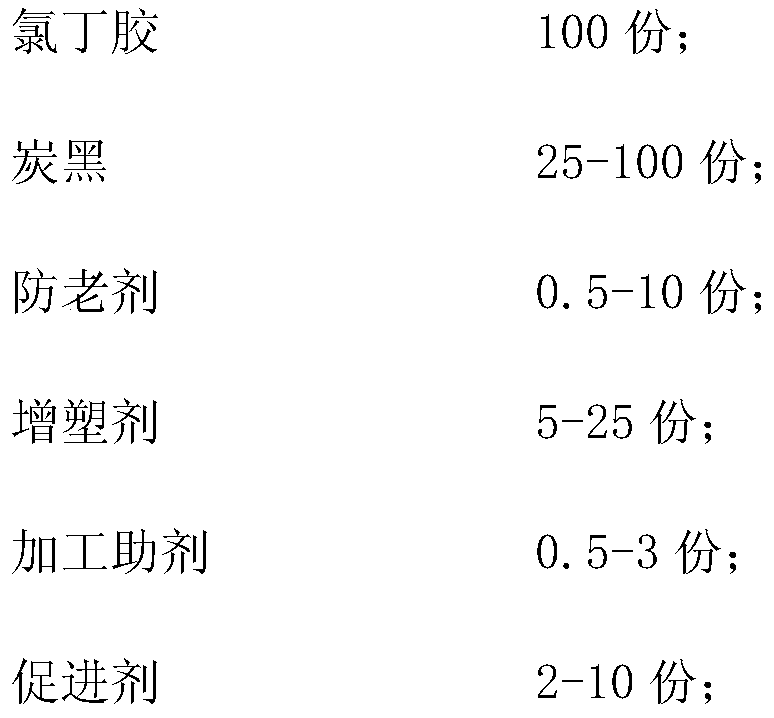

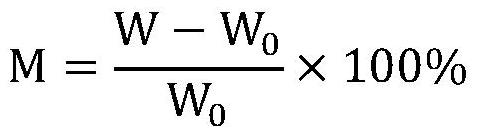

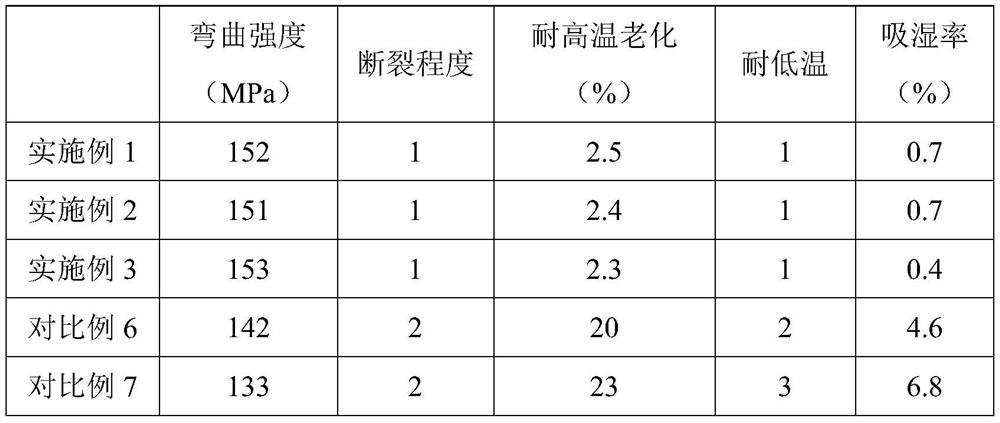

High-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip and preparation method thereof

PendingCN111423642AImprove thermal stabilityImprove thermal characteristicsRubber materialPolymer science

The invention discloses a high-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip and a preparation method thereof. The high-temperature-aging-resistant chloroprene rubber windshield wiper rubber strip comprises chloroprene rubber, carbon black, an anti-aging agent, a plasticizer, a processing aid, an accelerant, zinc oxide and magnesium oxide. The preparation method comprises the following steps: plastifying chloroprene rubber, pressurizing and banburying with the anti-aging agent and the plasticizer, adding carbon black, the processing aid and magnesium oxide, carrying out internal mixing, adding zinc oxide and the accelerant, carrying out internal mixing, discharging the rubber material when the temperature reaches 100-150 DEG C, carrying out re-mixing on an open mill for 3-6 minutes, pressing into a rubber sheet with an appropriate size by using a tablet press, standing for later use, putting the rubber sheet obtained in the step A into a special mold forthe windshield wiper rubber strip of a compression molding machine, molding for 3-10 minutes at the molding temperature of 150-180 DEG C to obtain a semi-finished product of the chloroprene rubber windshield wiper rubber strip, and performing post-treatment, cleaning, cutting, plasma treatment, spraying and other processes on the semi-finished windshield wiper rubber strip obtained in the step B to obtain the finished chloroprene rubber windshield wiper rubber strip.

Owner:JIANGSU YUNRUI AUTOMOBILE ELECTRIC SYST CO LTD

Epoxy resin composition for transformer and preparation method thereof

The invention relates to the field of polymer chemical engineering, and particularly provides an epoxy resin composition for a transformer as well as a preparation method and application of the epoxyresin composition. The invention, in the first aspect, provides an epoxy resin composition for a transformer, which is prepared from the following raw materials in parts by weight: 80-100 parts of epoxy resin, 50-60 parts of a curing agent, 0.05-0.5 part of an accelerant, 30-70 parts of inorganic filler and 3-5 parts of a toughening agent.

Owner:SHANGHAI XIONGRUN RESIN

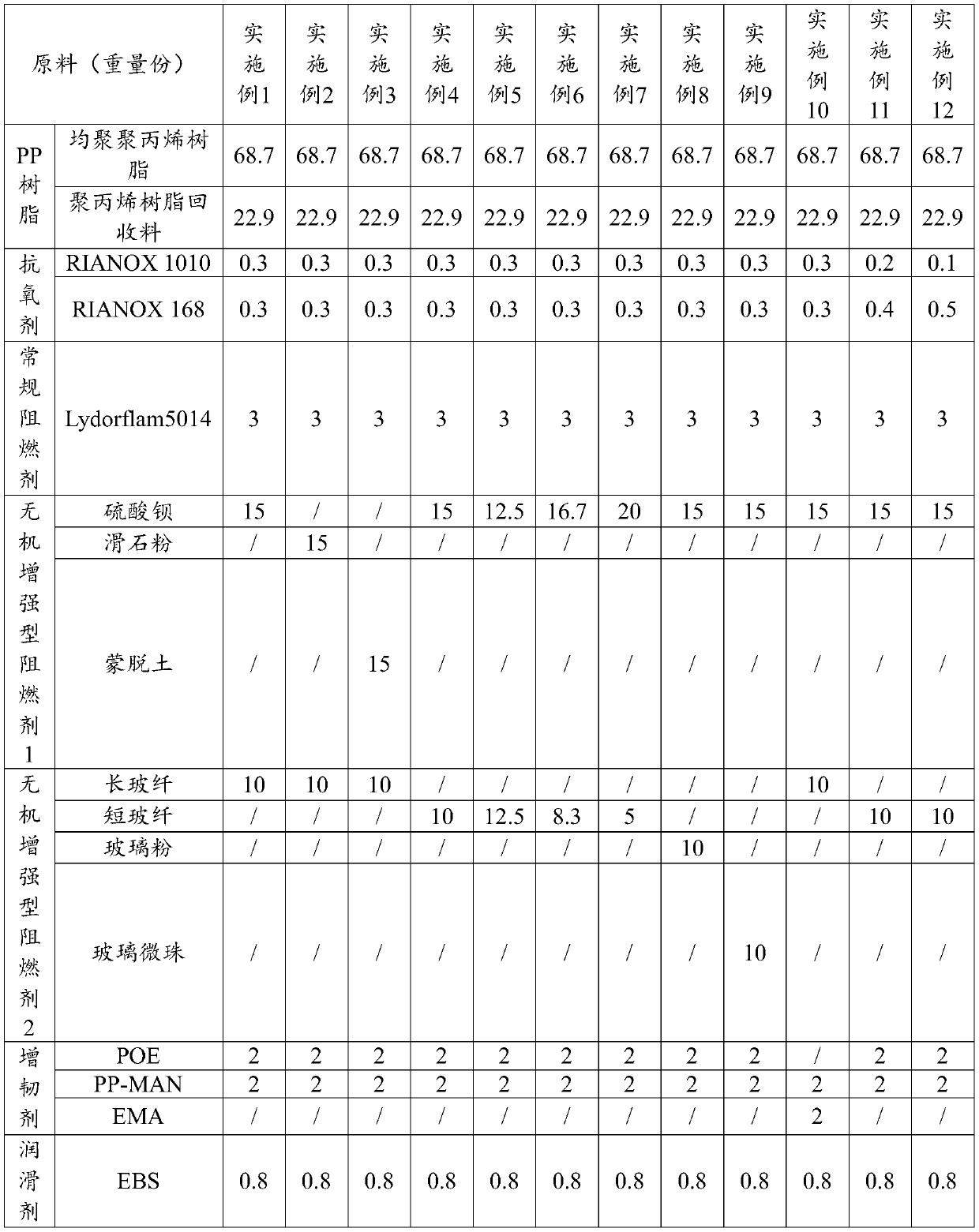

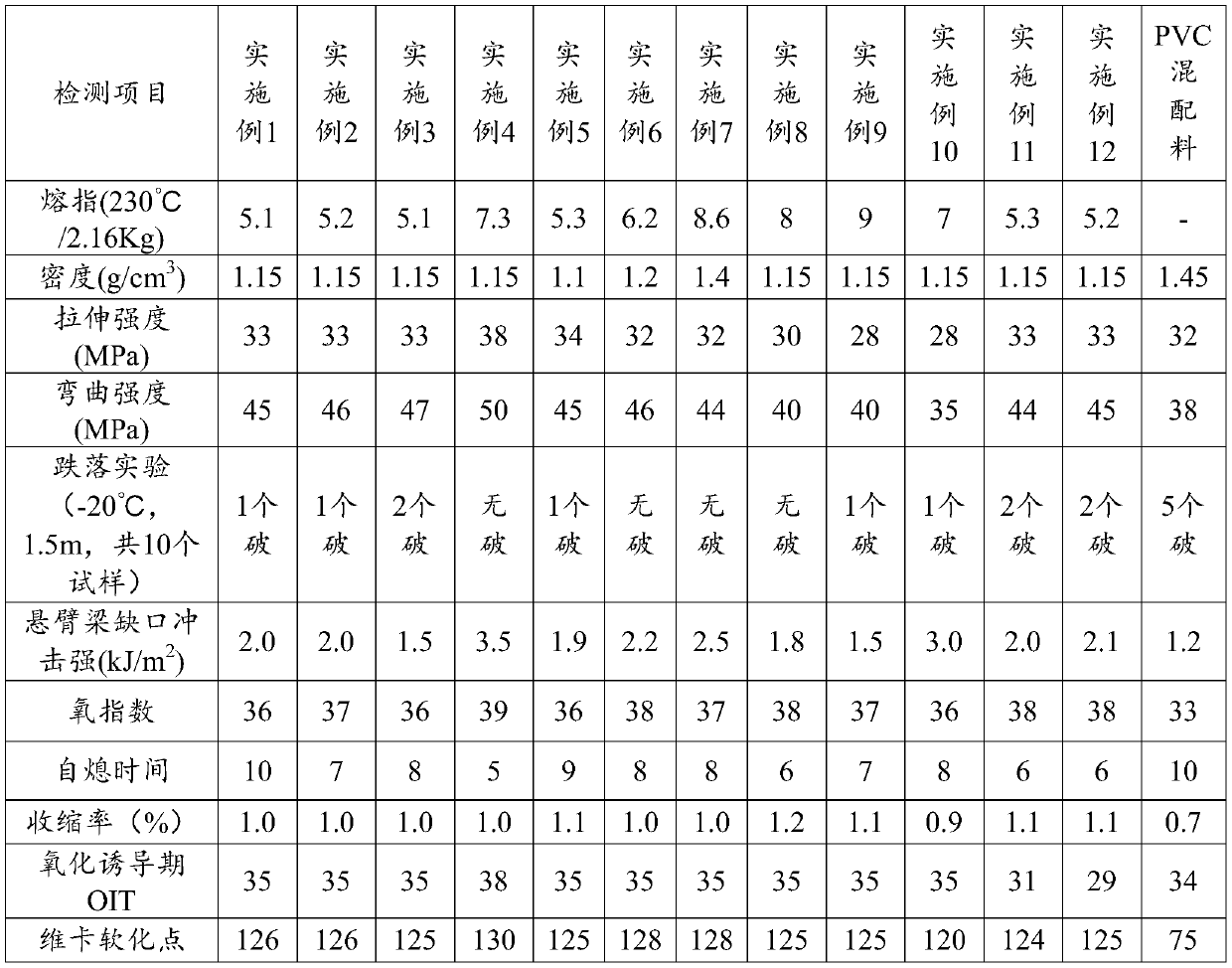

Polypropylene flame-retardant material capable of being used for producing concealed bottom box and preparation method thereof

The invention discloses a polypropylene flame-retardant material capable of being used for producing a concealed bottom box and a preparation method of the polypropylene flame-retardant material. Thepolypropylene flame-retardant material comprises the following components in parts by weight: 60-100 parts of polypropylene resin, 2-5 parts of a conventional flame retardant, 20-40 parts of an inorganic enhanced flame retardant, 2-5 parts of a toughening agent, 0.2-0.6 part of an antioxidant and 0.5-1.0 part of a lubricant. The polypropylene flame-retardant material disclosed by the invention iscompletely free of corrosion to a mold, small in damage to a screw rod of an injection molding machine, wide in processing temperature range, stable in product color and lighter in product piece weight, is more suitable for a low-temperature environment after toughening modification, and has a higher vicat softening point and lower cost compared with PVC. The material can be applied to the field of electrical products such as extension sockets, power boxes and switch backseats, and can completely meet various standard requirements in the field of electrical application.

Owner:RIFENG ENTERPRISE GRP CO LTD +2

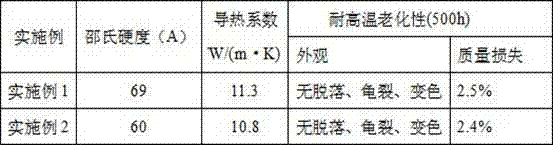

Heat conduction material used for combustion furnace liner

ActiveCN104726076AExcellent high temperature aging resistanceImprove thermal conductivityHeat-exchange elementsCombustionAnti ageing

The invention discloses a heat conduction material used for a combustion furnace. The heat conduction material comprises the following components in parts by weight: 5-10 parts of an anti-aging agent, 10-20 parts of a compatilizer, 10-15 parts of an antioxidant, 35-55 parts of filler with high heat conductivity, 15-25 parts of a heat conduction aid, 25-40 parts of a curing agent and 20-30 parts of a curing agent accelerator. The heat conduction material has the technical effects that the heat conduction material has high heat conductivity and good elasticity and is waterproof and dampproof; experimental results show that the heat conductivity of the heat conduction material can be more than 10.8W / (m.K); the heat conduction material has excellent high temperature aging resistance and can resist a high temperature of 500 DEG C for a long time; experimental results show that a heat conduction coating prepared by adopting the heat conduction material can be used in an environment at 500 DEG C.

Owner:HAIMEN CITY RUITAI TEXTILE TECH CO LTD

A kind of high thermal conductivity and high temperature resistant polysiloxane ceramic composite material and its preparation method and application

ActiveCN103951983BImprove thermal conductivityIncrease elasticityHeat-exchange elementsCeramic compositePtru catalyst

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

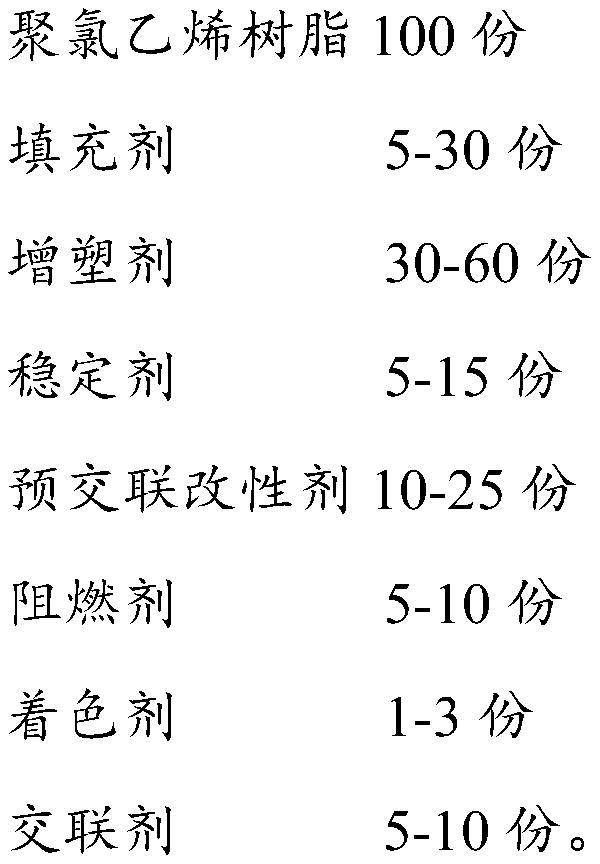

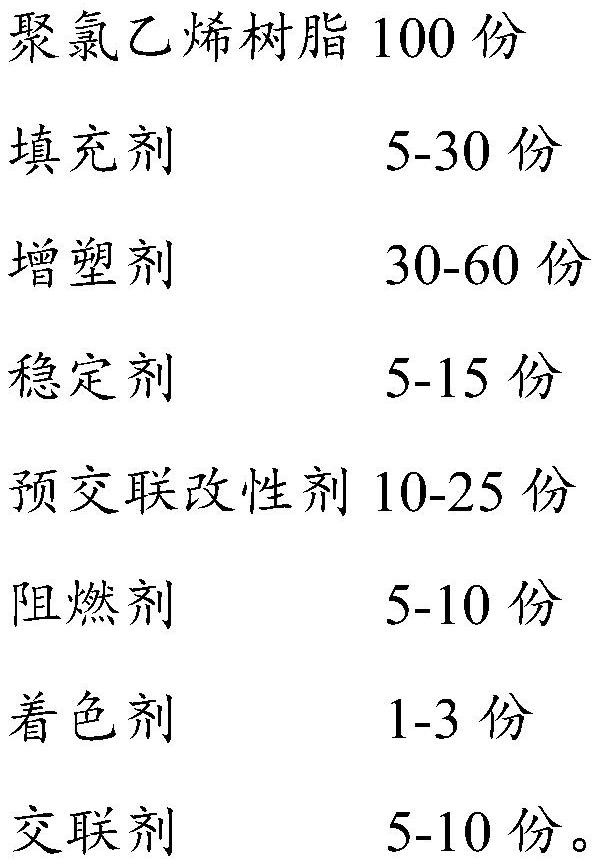

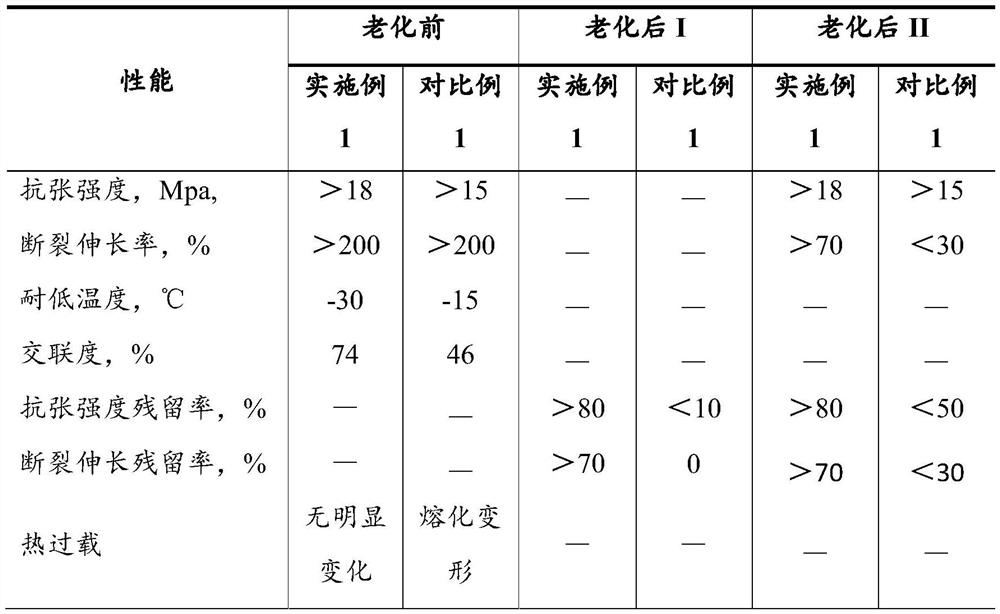

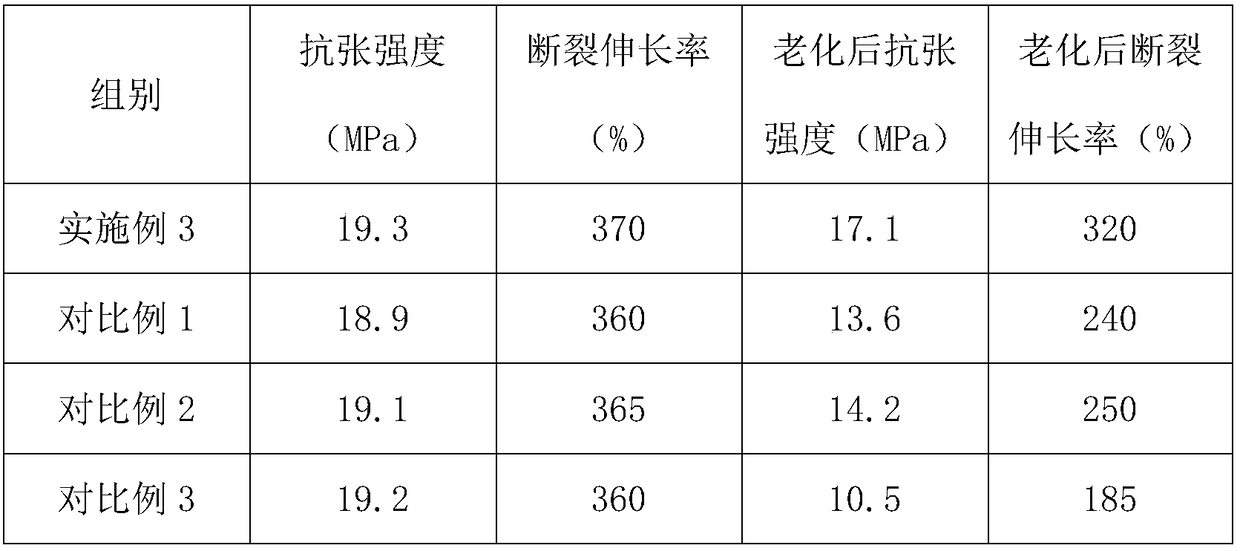

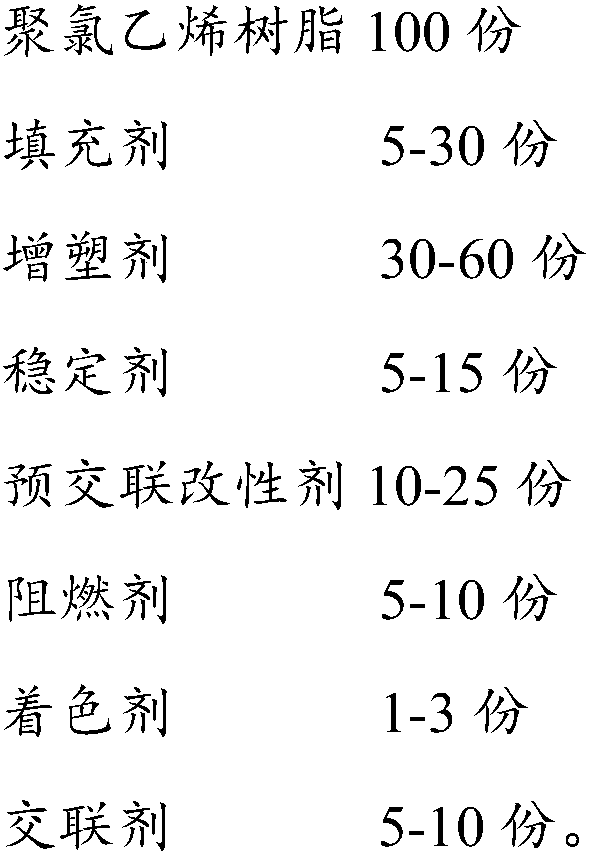

Polyvinyl chloride cable composite material, manufacturing method thereof, and cable

ActiveCN109422977BImprove high temperature resistanceHigh temperature aging resistancePlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention discloses a polyvinyl chloride cable composite material, a preparation method thereof and a cable. The polyvinyl chloride cable composite material of the present invention comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin, 5-30 parts of filler, 30-60 parts of plasticizer, 5-15 parts of stabilizer, pre-crosslinked modification 10-25 parts of stabilizer, 5-10 parts of flame retardant, 1-3 parts of colorant, 5-10 parts of crosslinking agent. The inventive cable comprises the inventive polyvinyl chloride cable material. The polyvinyl chloride cable composite material in the embodiment of the present invention has excellent high temperature resistance, low temperature resistance, oil resistance, environmental protection and non-toxicity. The polyvinyl chloride cable composite material produced by the preparation method has stable performance and reduces cost.

Owner:深圳市帝源新材料科技股份有限公司

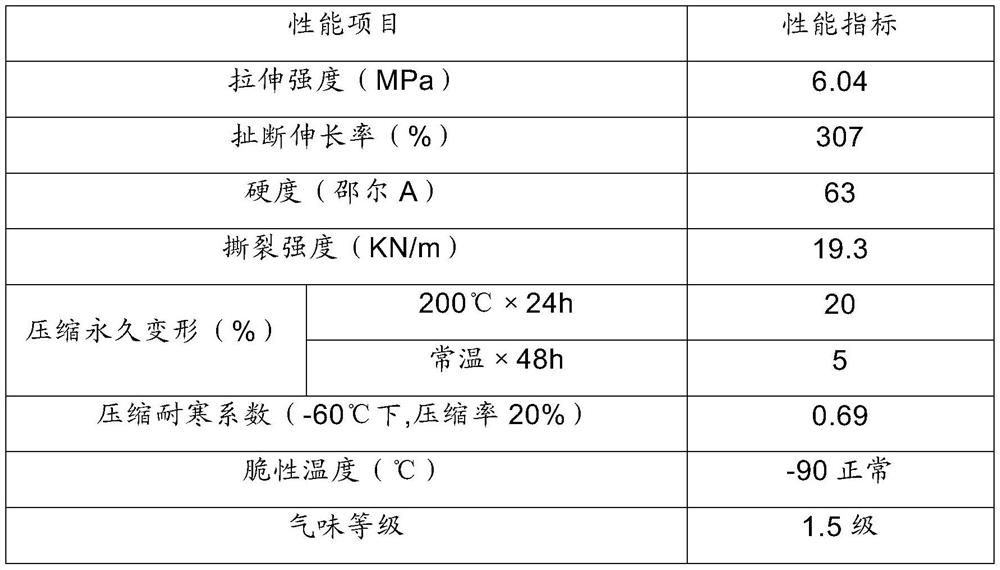

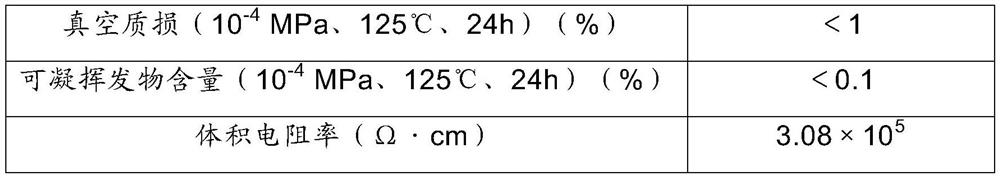

A space-grade antistatic sealing material and its preparation method and application

The invention provides an antistatic sealing material and its preparation method and application. The antistatic sealing material includes 100 parts by mass of silicone rubber, 40-60 parts by mass of reinforcing white carbon black, 8-15 parts by mass of superconducting carbon black, 3-5 parts by mass of graphene, 4-8 parts by mass of heat-resistant additive, 5-10 parts by mass of anti-radiation agent, and 0.5-1.5 parts by mass of peroxide curing agent. The sealing material provided by the invention is non-toxic and pollution-free, has good electrical conductivity, high and low temperature resistance, small compression permanent deformation and excellent comprehensive performance, and is suitable for the sealing of space vehicles.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

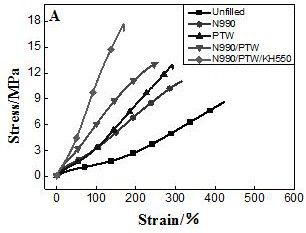

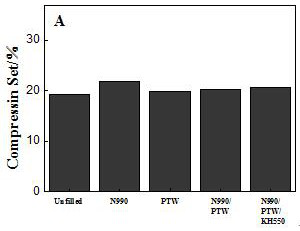

A kind of high-strength low-pressure variable fluorine rubber material and its preparation method

The invention provides a high-strength ow-pressure-change fluoro-rubber material and a preparation method thereof, and belongs to the technical field of high-performance rubber materials. The technical scheme is that the high-strength ow-pressure-change fluoro-rubber material comprises the following components in parts by mass: 100 parts of fluoro-rubber, 2-5 parts of active MgO, 3-7 parts of Ca(OH)2, 0.5-1.5 parts of palm wax, 0.4-0.7 part of an accelerant, 1.0-2.0 parts of a vulcanizing agent, 15-25 parts of carbon black, 5-9 parts of potassium titanate whisker (PTW) and 0.5-1.2 parts of a coupling agent. A preparation method is also disclosed. The fluoro-rubber material provided by the invention has the beneficial effects that the fluoro-rubber material prepared by the method provided by the invention has high strength, high modulus and low compression permanent deformation, and has excellent high temperature resistance and aging resistance.

Owner:QINGDAO UNIV OF SCI & TECH

Ratproof cable rubber sheath material as well as preparation method and application thereof

InactiveCN102311565BHigh strengthImprove mechanical propertiesInsulated cablesInsulated conductorsVulcanizationWeather resistance

The invention belongs to the manufacturing field of cables, particularly relates to a ratproof cable rubber sheath material which is mainly prepared from the following raw materials in part by weight: 100 parts of polychloroprene, 5 parts of zinc oxide, 1.5-3 parts of vulcanization accelerator, 0.75-1.5 parts of scorch retarder, 3.5-5 parts of antiager, 4 parts of magnesium oxide, 30-60 parts ofcalcium carbonate, 30-50 parts of reinforcing filler, 1.5-2.5 parts of silane coupling agent, 5-10 parts of operating agent and 2.5-7.5 parts of synthetic capsaicin. The ratproof cable rubber sheath material provided by the invention has the characteristics of better flexibility, oil resistance, weather resistance, inflaming retarding and the like, and not only meets the requirements of field andusers on rubber cable rat bite prevention, but also brings convenience for the users.

Owner:浙江万马股份有限公司

A high temperature resistant silicone adhesive

ActiveCN104974711BImprove high temperature resistanceEasy to operateNon-macromolecular adhesive additivesCross-linkUltimate tensile strength

Owner:武汉双键新材料股份有限公司 +1

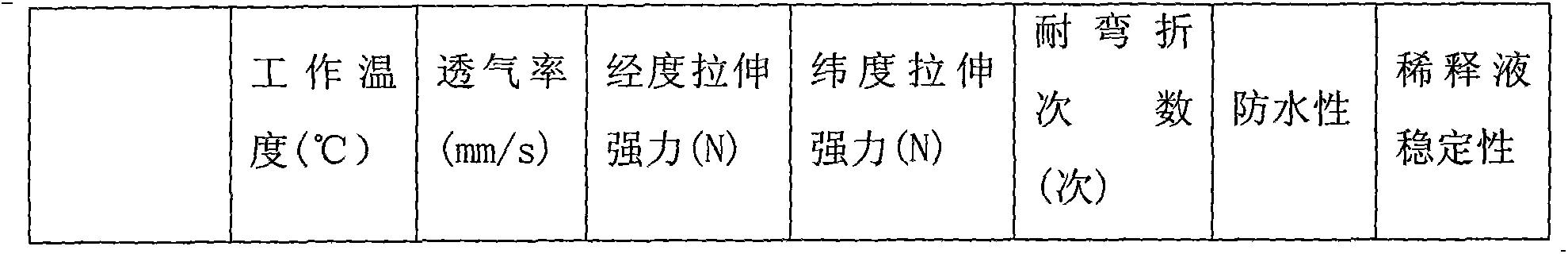

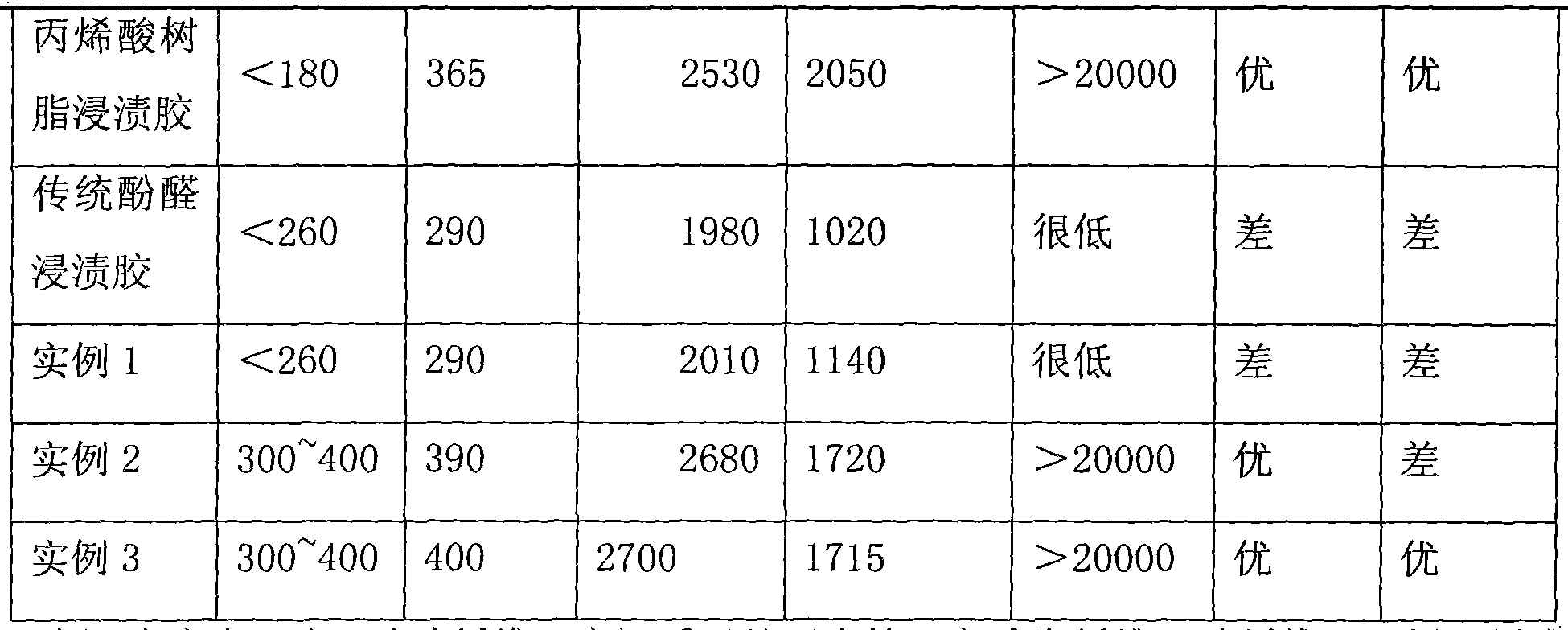

Composite dipping glue used for preparing high temperature filter material and usage method

ActiveCN103160230BGood water solubilityThe dilution factor can be adjusted widelyFibre treatmentAldehyde/ketone condensation polymer adhesivesCarbon fibersPolypropylene

The invention relates to a composite dipping glue used for preparing a high temperature filter material, which comprises the following components: phenolic resin, a catalyst, a flexibilizer, a cosolvent, an inorganic bonding agent, a coupling agent, a waterproof oil-proofing agent, an anti-grinding agent, a chelating agent, a carbonization agent, a flame retardant agent and a stabilizing agent. According to the invention, a normal temperature mixing stirring method is employed to prepare an aqueous dipping glue, the water-soluble performance of the prepared dipping glue is excellent, the dilution ratio enables wide adjustable degree, the adhesiveness is good, the impregnation is easy, no unfriendly component on environment such as heavy metal ions can be contained, the usage is convenient, the production process control is simple, the pollutant discharge capacity is low, and the cost is low. Compared with other resin-based dipping glue, the modification effect of the composite dipping glue on a filtering base material surface is obvious, The filter material prepared by the dipping glue has excellent high temperature resistance and aging resistance performances and good acid and alkali resistance and corrosivity resistance performances, the conservation rate of toughness under high temperature is high, and the waterproof and oil-proof performances are prominent. The dipping glue can treat various organic and inorganic fiber such as glass fiber, rock wool, basalt fiber, carbon fiber, stainless steel fiber, aramid fiber, polyphenylene sulfide (PPS), terylene and polypropylene.

Owner:BEIJING RUNHIGH SCI & TECH

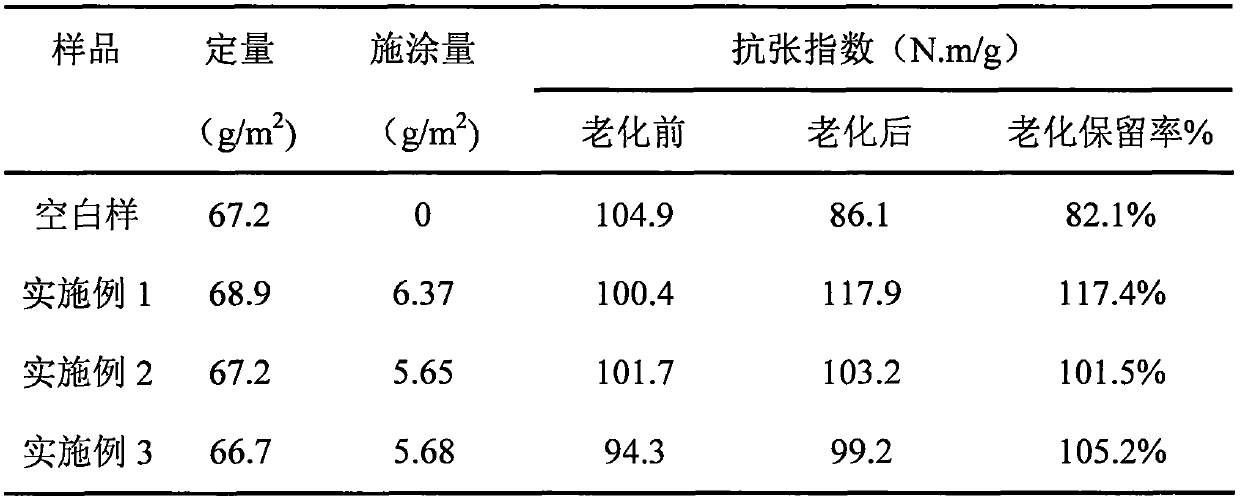

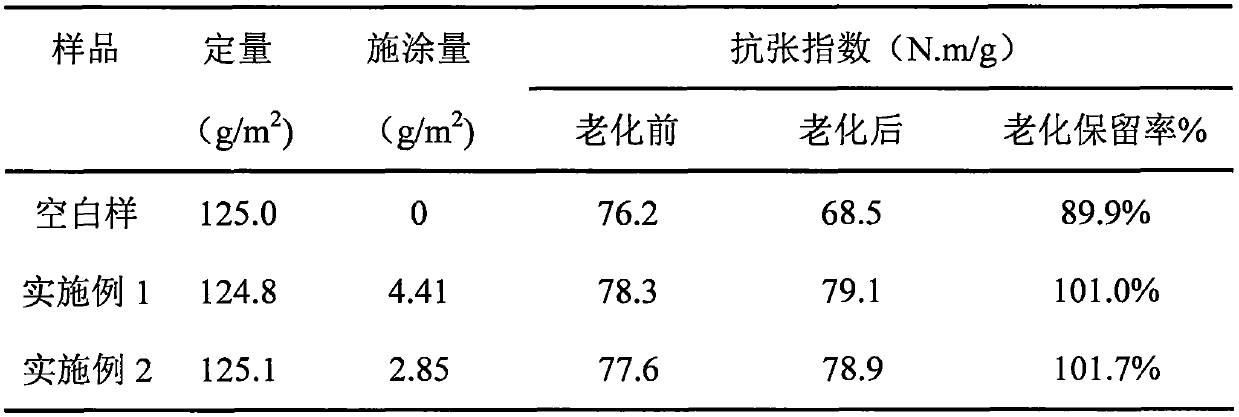

Heat-resistant additive for transformer insulating paper, preparation method and application thereof

ActiveCN106812020BExcellent high temperature aging resistanceImprove high temperature aging resistanceCoatings with pigmentsPaper/cardboardChemical LinkageFiber

The invention discloses a preparation and application method of an assistant for improving high-temperature aging resistance of transformer insulating paper and belongs to the field of the transformer insulating paper. The method comprises the steps of compounding a polyvinyl pyrrolidone macromolecular compound with a high-temperature self-crosslinking property, an initiator and a nitrogen containing compound so as to prepare the heat-resistant assistant, and applying the heat-resistant assistant to the surface of the insulating paper by a coating, spray-coating or dipping method. Polyvinyl pyrrolidone is subjected to a self-crosslinking reaction in the presence of the initiator at a high temperature so as to form a three-dimensional network structure, and fibers of the paper are interwoven in a chemical bond forming manner, so that the bonding action among the fibers is enhanced, and the improvement on the aging resistance of the paper is facilitated. According to the insulating paper prepared by adding the heat-resistant assistant disclosed by the invention, the high-temperature aging resistance is excellent and is improved by 15% to 30% under the same conditions, and the insulating performance of a transformer system is not affected.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Polypropylene cable material with excellent high temperature ageing resistant performance

InactiveCN108707285AImprove mechanical propertiesImprove securityPlastic/resin/waxes insulatorsPolymer scienceAntioxidant

The invention discloses a polypropylene cable material with excellent high temperature ageing resistant performance. The polypropylene cable material is prepared from the following materials in partsby weight: 120 to 130 parts of polypropylene, 30 to 35 parts of a styrene-isoprene-styrene block copolymer, 10 to 15 parts of maleic anhydride grafted polypropylene, 1 to 2 parts of antioxidant, 13 to17 parts of magnesium hydroxide, 2 to 5 parts of polyethylene wax, 1 to 2 parts of calcium stearate, 4 to 8 parts of talcum powder, 8 to 12 parts of calcined pottery clay, 4 to 8 parts of calcium-zinc stabilizing agent, 3 to 6 parts of red lac and 2 to 3 parts of abietic acid. The invention discloses a preparation method of the polypropylene cable material with the excellent high temperature ageing resistant performance; the polypropylene cable material prepared by the invention has good mechanical properties and can meet market requirements; the polypropylene cable material has excellent high temperature ageing resistant performance and the safety of the cable material in a utilization process can be improved; the defect that the polypropylene cable material is easy to age is made up, sothat the polypropylene cable material prepared by the invention is good for expanding an application field of the polypropylene cable material and the polypropylene cable material has a wide market prospect.

Owner:武汉中智德远科技开发有限公司

Polyvinyl chloride cable composite material, preparation method thereof and cable

ActiveCN109422977AImprove high temperature resistanceHigh temperature aging resistancePlastic/resin/waxes insulatorsCross-linkPlasticizer

The invention discloses a polyvinyl chloride cable composite material, a preparation method thereof and a cable. The polyvinyl chloride cable composite material comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin, 5-30 parts of filler, 30-60 parts of a plasticizer, 5-15 parts of a stabilizer, 10-25 parts of a pre-crosslinking modifier, 5-10 parts of a flameretardant, 1-3 parts of a coloring agent and 5-10 parts of a cross-linking agent. The cable provided by the invention comprises the polyvinyl chloride cable material provided by the invention. The polyvinyl chloride cable composite material disclosed by the embodiment of the invention has excellent high-temperature resistance, low-temperature resistance and oil resistance, is environmentally friendly, and is free of toxicity. The polyvinyl chloride cable composite material prepared by the preparation method is stable in performance, and cost is reduced.

Owner:深圳市帝源新材料科技股份有限公司

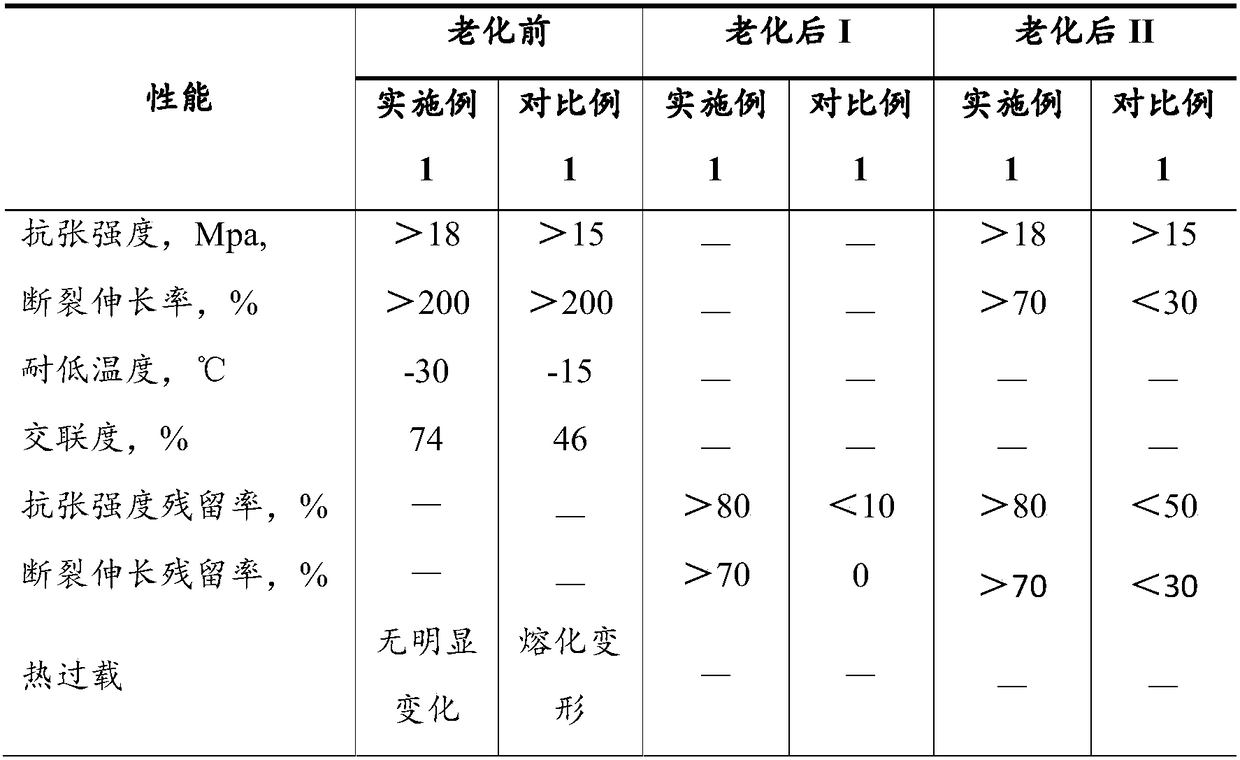

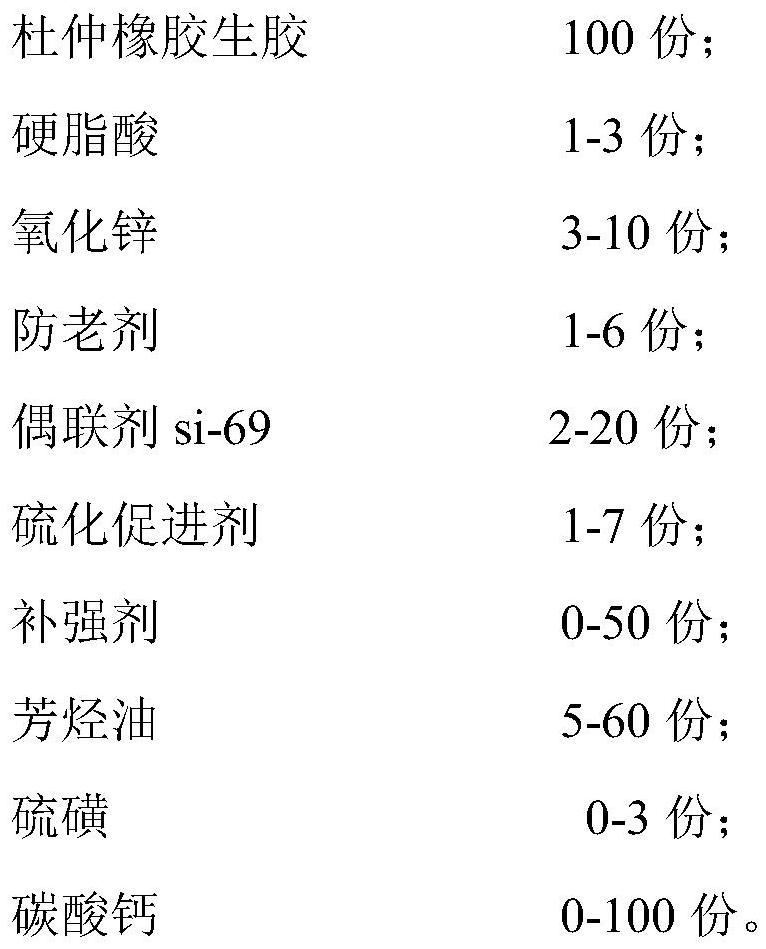

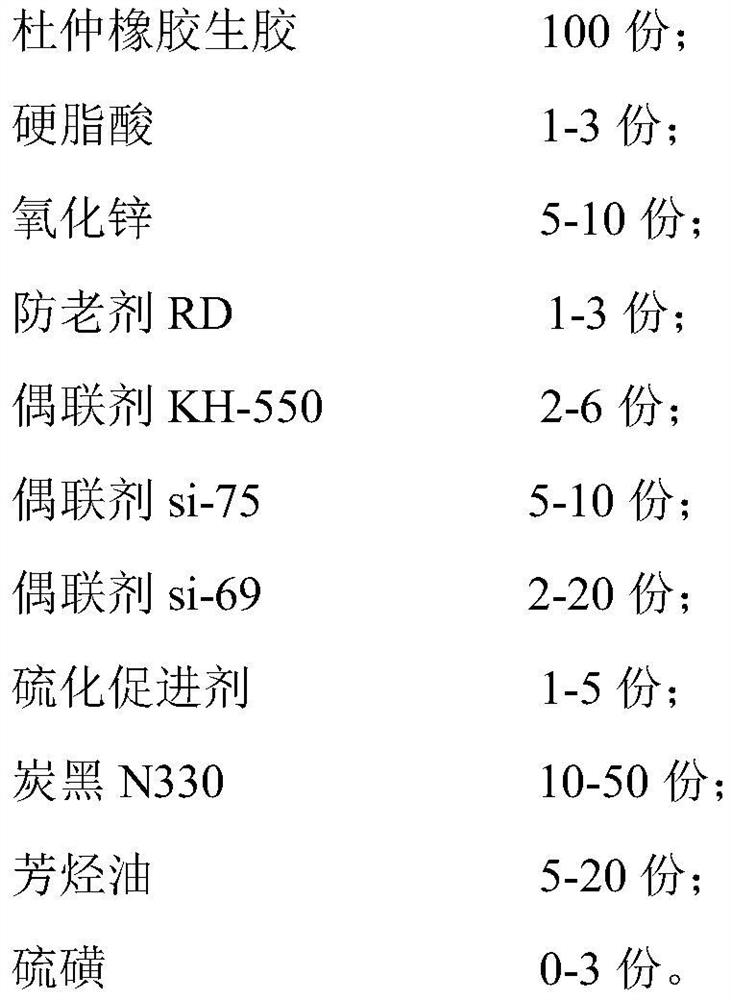

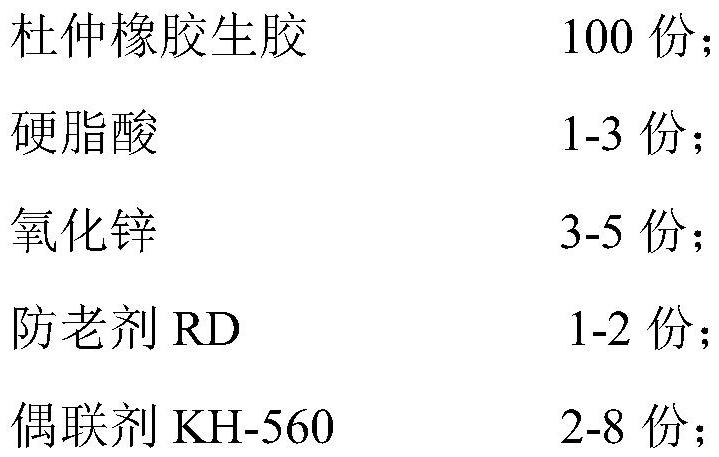

High-temperature-aging-resistant eucommia ulmoides rubber, eucommia ulmoides rubber vulcanized rubber and preparation method of eucommia ulmoides rubber vulcanized rubber

ActiveCN112250914AGood physical and mechanical propertiesExcellent high temperature aging resistanceRolling resistance optimizationPolymer scienceStearic acid

The invention discloses high-temperature-aging-resistant eucommia ulmoides rubber, eucommia ulmoides rubber vulcanized rubber and a preparation method of the eucommia ulmoides rubber vulcanized rubber. The eucommia ulmoides rubber comprises the following components in parts by weight: 100 parts of eucommia ulmoides rubber raw rubber; 1-3 parts of stearic acid; 3-10 parts of zinc oxide; 1-6 parts of an anti-aging agent; 2-20 parts of a coupling agent Si-69; 1-7 parts of a vulcanization accelerator; 0-50 parts of a reinforcing agent; 5-60 parts of aromatic hydrocarbon oil; 0-3 parts of sulfur; and 0-100 parts of calcium carbonate. According to the invention, the eucommia ulmoides rubber vulcanized rubber obtained after vulcanization of the eucommia ulmoides rubber not only has good physicaland mechanical properties, but also has good high-temperature aging resistance, and solves the problems that vulcanized rubber obtained by a traditional sulfur vulcanization system is poor in aging resistance, and the vulcanized rubber obtained by a sulfur donor or an organic peroxide vulcanization system is poor in mechanical property.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

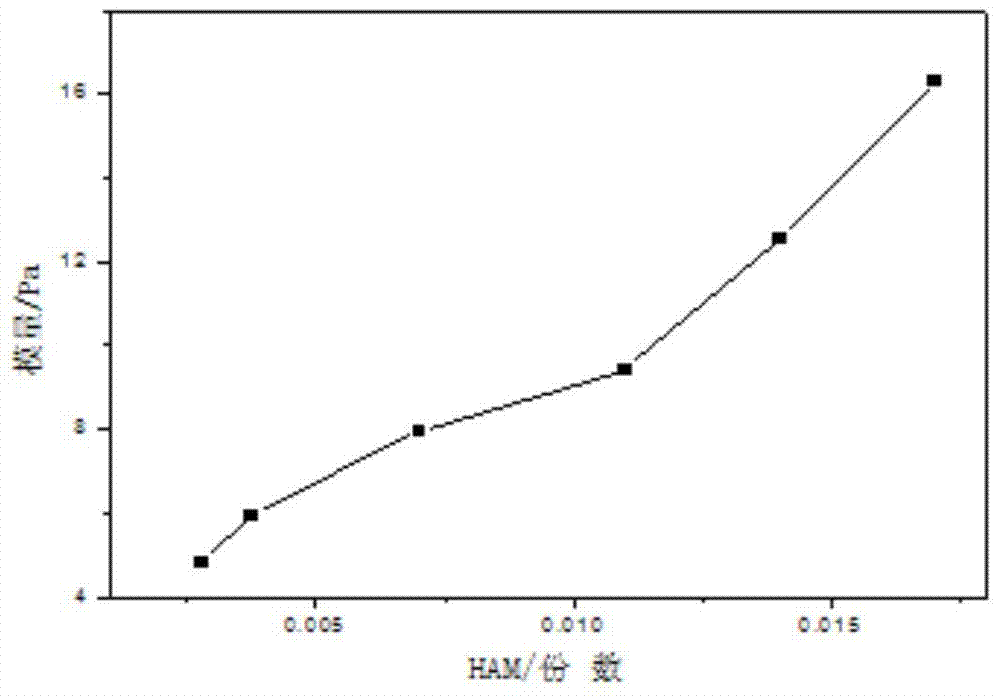

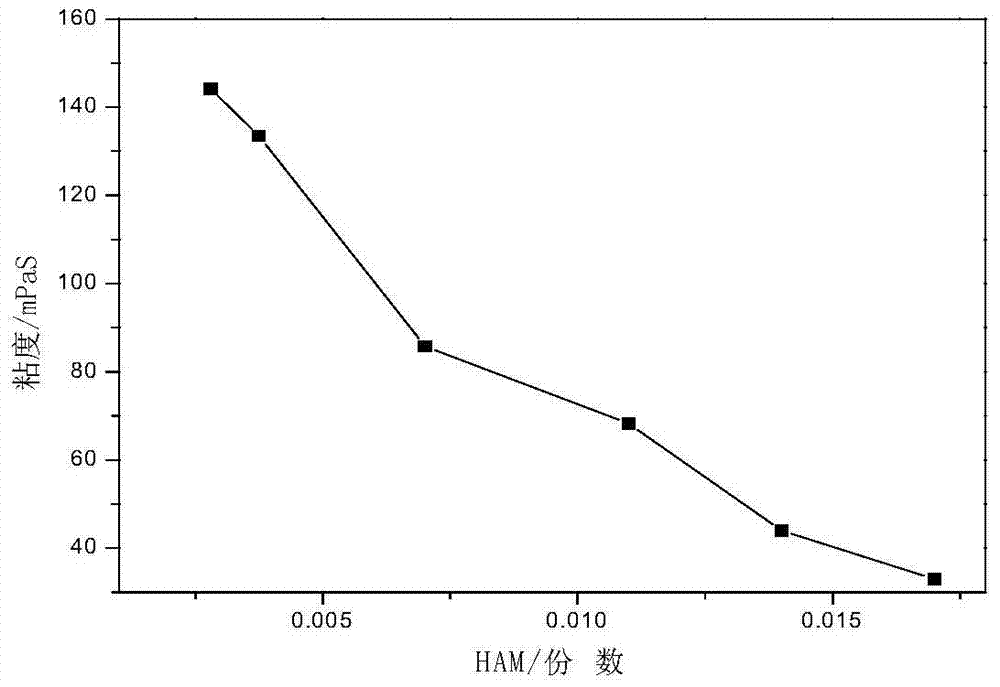

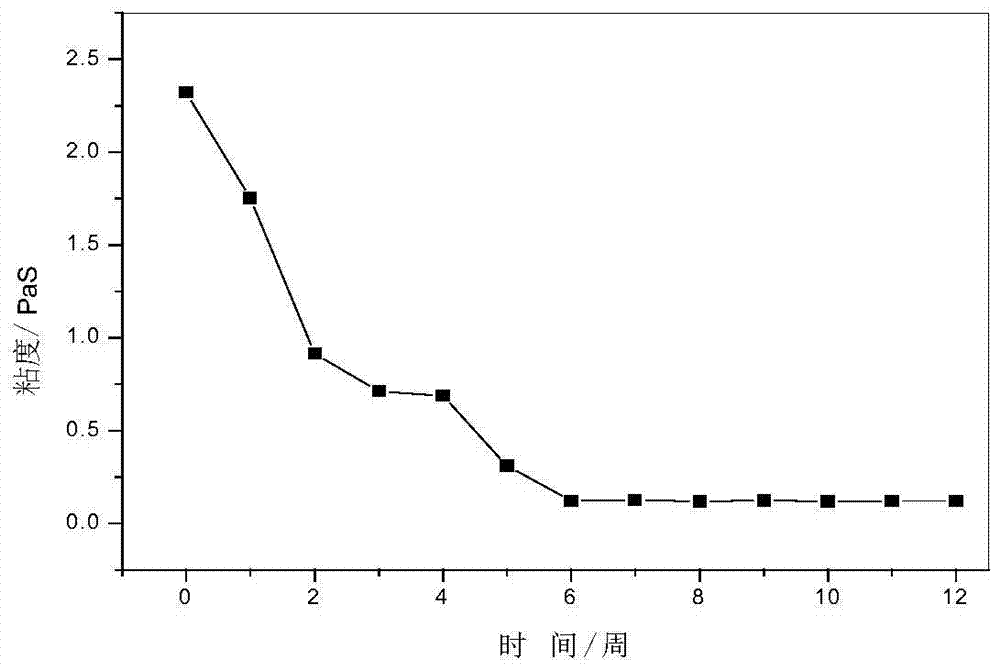

A double network partially crosslinked partially branched polymer oil displacement agent and its preparation method

ActiveCN105085798BSuspension stabilityHigh viscosityDrilling compositionCross-linkPotassium persulfate

The invention discloses a double network partially cross-linked partially branched polymer oil displacement agent and a preparation method thereof. The raw material components of the polymer oil displacement agent mainly include acrylamide, potassium persulfate, sodium bisulfite, methylol Acrylamide and N, N-dimethylaminoethyl methacrylate; its preparation method: each component of the raw material is dissolved in deionized water not less than 1.0 times the mass of the formula, and the solution of each component is prepared ; Add acrylamide solution, methylolacrylamide solution, and N,N-dimethylaminoethyl methacrylate solution into the reactor, while stirring, pass nitrogen gas at 0-30°C to remove the oxygen in the discharge container, add Potassium persulfate solution and sodium bisulfite solution, after the reaction system begins to polymerize, the viscosity increases significantly, stop feeding nitrogen and stirring, and polymerize until the temperature is constant, that is, the colloidal oil displacing agent is prepared. The invention has good elasticity and shearing resistance, and excellent aging resistance and salt resistance under high-temperature and high-salt conditions.

Owner:SICHUAN UNIV +1

A long-life double-layer co-extruded insulation radiation cross-linked halogen-free low-smoke flame-retardant power cable

ActiveCN110534249BPromote environmental protectionImprove high temperature resistanceInsulated cablesPower cablesElectrical conductorAluminium hydroxide

The invention discloses a long-life double-layer co-extruded insulating radiation cross-linked halogen-free low-smoke flame-retardant power cable, which comprises a conductor, a refractory layer wrapped outside the conductor, a double-layer co-extruded insulating layer wrapped outside the refractory layer and The outer sheath wrapped on the outside of the double-layer co-extruded insulation layer; the outer sheath is prepared from EPDM composite materials; the raw materials of the EPDM composite materials include: EPDM rubber, Silicone rubber, silica, bentonite, talc, zinc oxide, stearic acid, vulcanizing agent, ammonium polyphosphate, aluminum hydroxide, microencapsulated red phosphorus, melamine pyrophosphate, pentaerythritol, accelerator, anti-aging agent. The long-life double-layer co-extruded insulation irradiation cross-linked halogen-free low-smoke flame-retardant power cable proposed by the invention has good flame retardancy and smoke suppression, excellent heat resistance and aging resistance, and long service life.

Owner:ANHUI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com