Heat conduction material used for combustion furnace liner

A technology of heat-conducting materials and combustion furnaces, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of increasing production costs and achieve excellent high-temperature aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

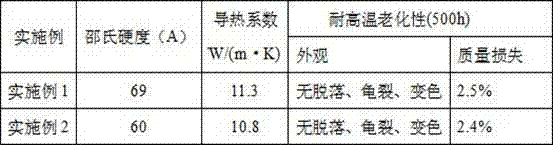

Embodiment 1

[0032] A thermally conductive material for a combustion furnace liner, comprising an anti-aging agent, a compatibilizer, an antioxidant, a high thermally conductive filler, a thermally conductive auxiliary agent, a curing agent and a curing agent accelerator, wherein the parts by weight of each component are:

[0033] Anti-aging agent: 5 parts,

[0034] Compatibilizer: 10 parts,

[0035] Antioxidant: 10 parts,

[0036] High thermal conductivity filler: 35 parts,

[0037] Thermal conductivity additive: 15 parts,

[0038] Curing agent: 25 parts,

[0039] Curing agent accelerator: 20 parts.

[0040] The anti-aging agent is anti-aging agent 2246.

[0041] The compatibilizer is epoxy resin.

[0042] The antioxidant is antioxidant 264.

[0043] The high thermal conductivity filler is boron nitride powder.

[0044] The thermal conductivity additive is graphene oxide.

[0045] The curing agent is hexahydrophthalic anhydride.

[0046] The curing agent accelerator is a modifie...

Embodiment 2

[0048] A thermally conductive material for a combustion furnace liner, comprising an anti-aging agent, a compatibilizer, an antioxidant, a high thermally conductive filler, a thermally conductive auxiliary agent, a curing agent and a curing agent accelerator, wherein the parts by weight of each component are:

[0049] Anti-aging agent: 10 parts,

[0050] Compatilizer: 20 parts,

[0051] Antioxidant: 15 parts,

[0052] High thermal conductivity filler: 55 parts,

[0053] Heat conduction aid: 25 parts,

[0054] Curing agent: 40 parts,

[0055] Curing agent accelerator: 30 parts.

[0056] The anti-aging agent is anti-aging agent 2246.

[0057] The compatibilizer is modified polyacrylate.

[0058] The antioxidant is antioxidant 264.

[0059] The high thermal conductivity filler is aluminum nitride powder.

[0060] The thermal conductivity additive is graphene oxide.

[0061] The curing agent is hexahydrophthalic anhydride.

[0062] The curing agent accelerator is a modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com