High-temperature-aging-resistant eucommia ulmoides rubber, eucommia ulmoides rubber vulcanized rubber and preparation method of eucommia ulmoides rubber vulcanized rubber

A technology of eucommia rubber and high temperature resistance, which is applied in the field of eucommia rubber, eucommia rubber vulcanizate and its preparation. It can solve the problems of vulcanized eucommia rubber, such as poor high temperature aging resistance and poor tear strength, so as to improve vulcanization efficiency and good tensile strength. Strength, the effect of increasing the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

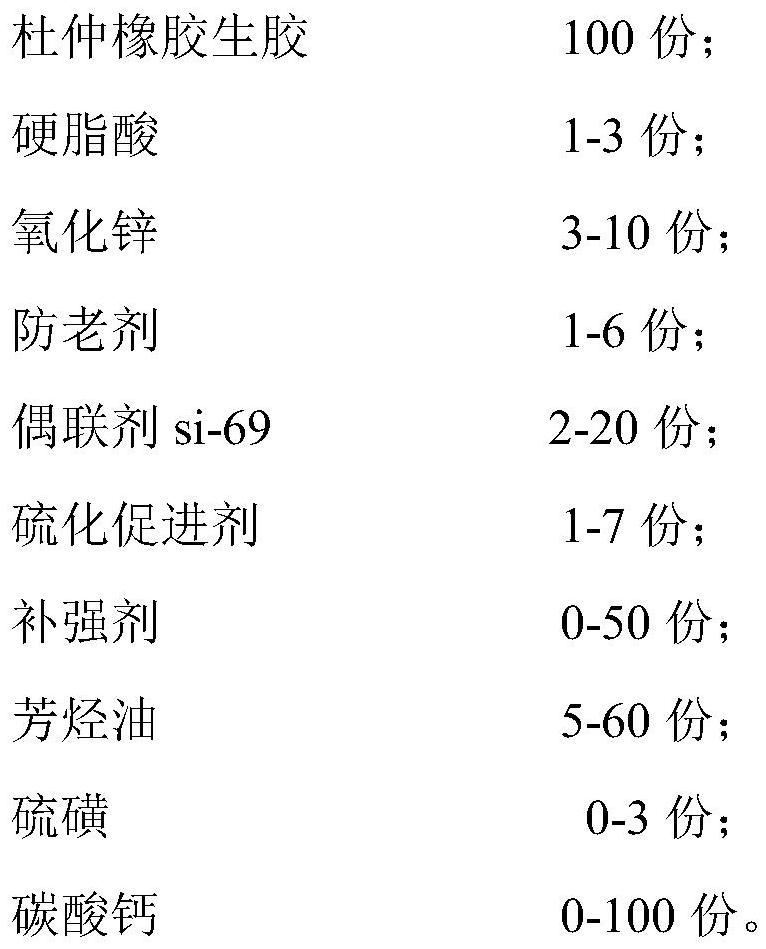

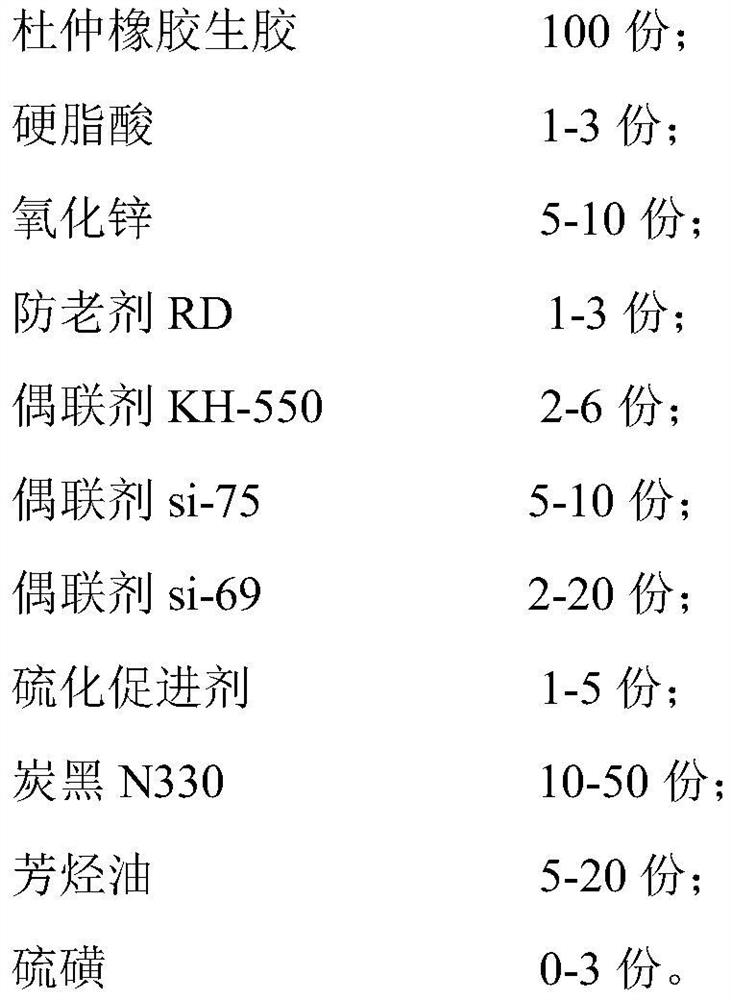

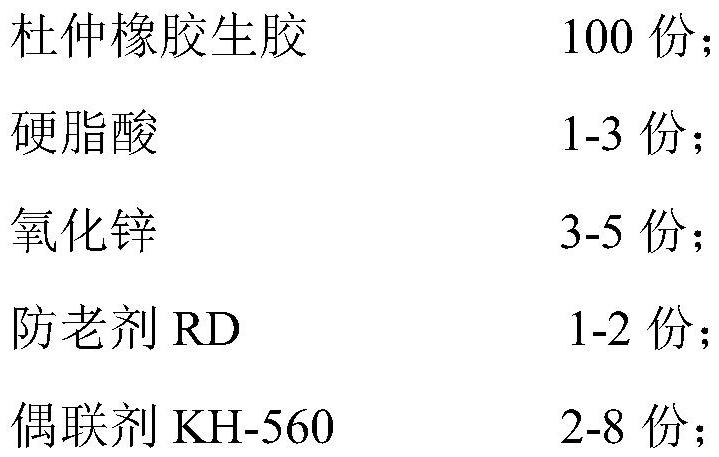

Method used

Image

Examples

Embodiment 1

[0033]Put 100g of eucommia rubber raw rubber on a double-roll mill with a roll temperature of 60-80℃ and a roll distance of 0.5mm. After the rubber is wrapped, add 5g of zinc oxide, 2g of stearic acid and coupling agent KH- 5502g, coupling agent CG-si759g, coupling agent si694g, antioxidant RD 2g, accelerator DM 1g, accelerator OTOS 2g, aromatic oil 10g, N330 carbon black 40g (reinforcing agent); after adding, Botong 5 Next film.

[0034]After being left for 24 hours, it was vulcanized on a plate vulcanizer at 170° C. and a pressure of 11 MPa to obtain eucommia rubber vulcanizate. Then, the tensile strength, elongation, tear strength of the obtained eucommia rubber vulcanizate and the retention of thermal aging tensile strength, elongation and tear strength of (70℃, 100℃; 120h) were tested. The performance characterization results of the eucommia rubber vulcanizate are shown in Table 1.

Embodiment 2

[0042]Put 100g of eucommia rubber raw rubber on a two-roll mill with a roll temperature of 60-80°C and a roll pitch of 0.5mm. After the rubber is wrapped, add 3g of zinc oxide, 1g of stearic acid, and coupling agent KH- 5603g, coupling agent KH-5909g, coupling agent si696g, antioxidant RD 2g, accelerator DM 2g, accelerator NOBS 1g, aromatic oil 30g, precipitation method white carbon black 40g (reinforcing agent); after adding, thin Pass the film 5 times.

[0043]After being left for 24 hours, it was vulcanized on a plate vulcanizer at 170° C. and a pressure of 11 MPa to obtain eucommia rubber vulcanizate. Then, the tensile strength, elongation, tear strength of the obtained eucommia rubber vulcanizate and the retention of thermal aging tensile strength, elongation and tear strength of (70℃, 100℃; 120h) were tested. The performance characterization results of the eucommia rubber vulcanizate are shown in Table 2.

Embodiment 3

[0051]Put 100g of eucommia rubber raw rubber on a two-roll mill with a roll temperature of 60-80°C and a roll pitch of 0.5mm. After the rubber is wrapped, add 9g of zinc oxide, 3g of stearic acid, and coupling agent KH- 5903g, coupling agent CG-si755g, coupling agent si698g, antioxidant RD 2g, antioxidant 4010NA 1.5g, accelerator DM 1.5g, accelerator TMTD 1g, aromatic oil 30g, light calcium carbonate 40g; after adding, Thin the film 5 times.

[0052]After being left for 24 hours, it was vulcanized on a plate vulcanizer at 170° C. and a pressure of 11 MPa to obtain eucommia rubber vulcanizate. Then, the tensile strength, elongation, tear strength of the obtained eucommia rubber vulcanizate and the retention of thermal aging tensile strength, elongation and tear strength of (70℃, 100℃; 120h) were tested. The performance characterization results of the eucommia rubber vulcanizate are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com