Polyvinyl chloride cable composite material, preparation method thereof and cable

A polyvinyl chloride cable and composite material technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of limited use, unsatisfactory high temperature resistance, poor high temperature resistance, etc., and achieve low temperature resistance Oil resistance, stable performance, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] On the other hand, the embodiment of the present invention provides a preparation method of the polyvinyl chloride cable composite material in the above embodiment. In one embodiment, the preparation method of the polyvinyl chloride cable composite material includes the following steps:

[0032] Step S01: Weigh the raw materials of each component according to the components contained in the polyvinyl chloride cable composite material and the content of each component in the above-mentioned invention embodiment;

[0033] Step S02: Mixing the weighed polyvinyl chloride resin, filler, stabilizer, crosslinking agent, flame retardant and pre-crosslinking modifier to obtain a first mixed material;

[0034] Step S03: adding the weighed plasticizer into the first mixed material, heating and performing mixing treatment to obtain a second mixed material;

[0035] Step S04: Melt extruding the second mixed material.

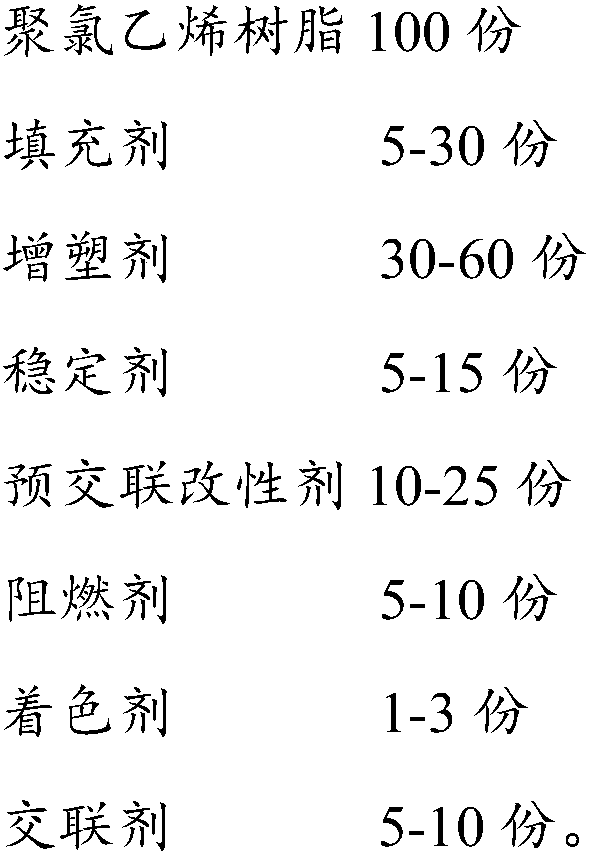

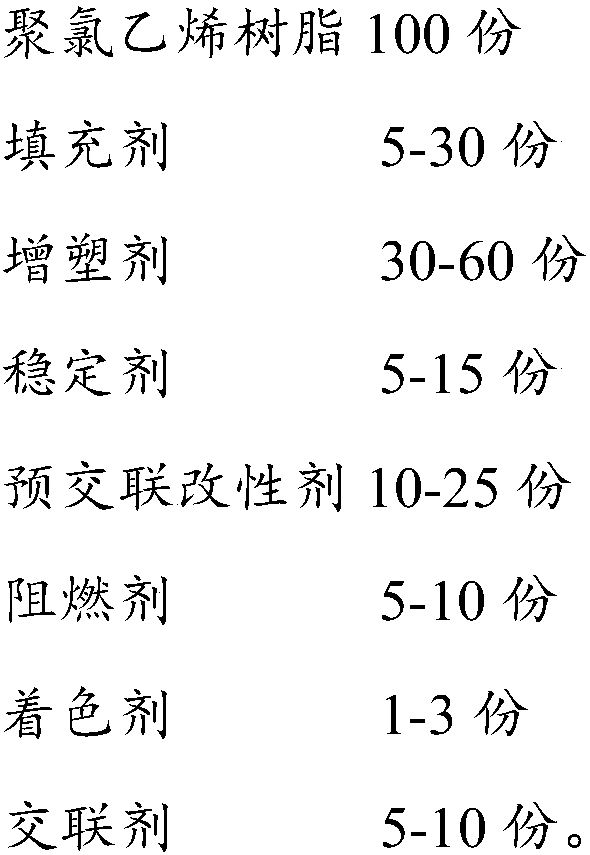

[0036] Wherein, the content of each component weighed in the abo...

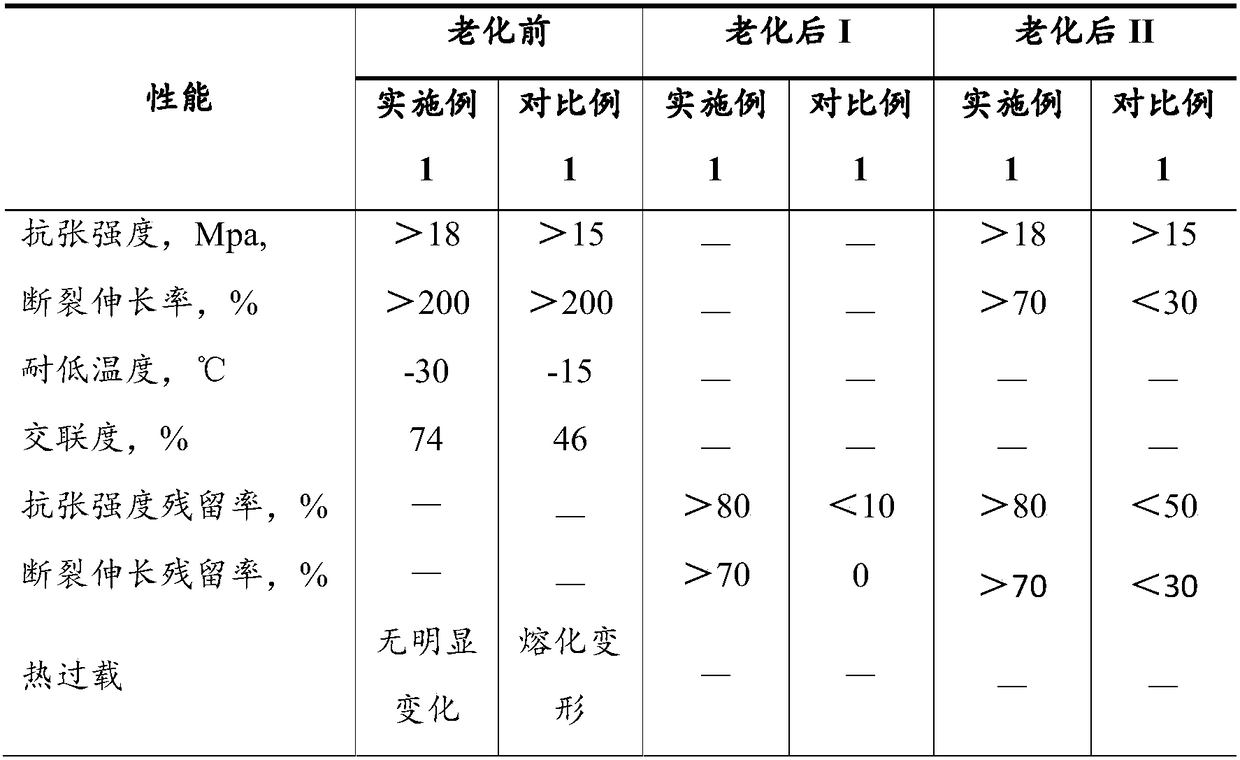

Embodiment 1

[0050] This embodiment provides a polyvinyl chloride cable composite material and a preparation method thereof. Wherein, the polyvinyl chloride cable composite material includes the following components in parts by weight:

[0051] Polyvinyl chloride resin (polymerization degree 2500): 100 parts,

[0052] Filler I (heavy calcium carbonate 2800): 8 parts,

[0053] Filler II (nano calcium carbonate CCR): 8 parts

[0054] High temperature plasticizer (W-797-ZH): 45 parts,

[0055] Environmental stabilizer (RUP-110C): 6 parts,

[0056] Pre-crosslinking modifier (P95): 15 parts,

[0057] Environmentally friendly flame retardant (antimony trioxide): 6 parts

[0058] Colorant: 2 parts

[0059] Cross-linking agent (TMPTMA): 7

[0060] The preparation method of the polyvinyl chloride cable composite material is as follows:

[0061] S11. Take the corresponding weight fractions of the components contained in the polyvinyl chloride according to the present embodiment;

[0062] S1...

Embodiment 2

[0066] This embodiment provides a polyvinyl chloride cable composite material and a preparation method thereof. Wherein, the polyvinyl chloride cable composite material includes the following components in parts by weight:

[0067] Polyvinyl chloride resin (polymerization degree 2500): 100 parts,

[0068] Filler I (heavy calcium carbonate 2800): 15 parts,

[0069] Filler II (nanometer calcium carbonate CCR): 15 parts

[0070] High temperature plasticizer (UN-380): 60 parts,

[0071] Environmental stabilizer (RUP-110C): 15 parts,

[0072] Pre-crosslinking modifier (P95): 15 parts,

[0073] Environmentally friendly flame retardant (antimony trioxide): 10 parts

[0074] Colorant: 3 parts

[0075] Cross-linking agent (TMPTMA): 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com