A kind of high-strength low-pressure variable fluorine rubber material and its preparation method

A technology of fluororubber and low-pressure variable, which is applied in the field of high-strength low-pressure variable fluororubber materials and its preparation, and can solve problems such as low strength, restricted application, and large compression permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

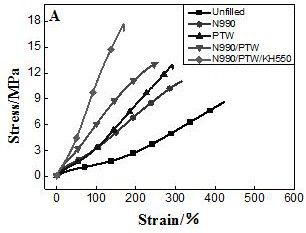

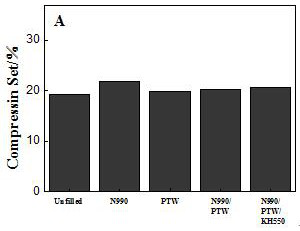

[0018] The embodiment of the present invention provides a high-strength low-pressure variable fluorine rubber material, including the following components in mass fractions: 100 parts of FKM26, 2 parts of active MgO, 3 parts of Ca(OH) 2 , 0.5 parts of palm wax, 0.4 parts of accelerator BPP, 1.0 parts of vulcanizing agent bisphenol AF, 15 parts of carbon black N990, 5 parts of potassium titanate whisker (PTW), 0.5 parts of coupling agent KH550.

Embodiment 2

[0020] The embodiment of the present invention provides a high-strength low-pressure variable fluorine rubber material, including the following components in mass fractions: 100 parts of FKM26, 5 parts of active MgO, 7 parts of Ca(OH) 2 , 1.5 parts of palm wax, 0.7 parts of accelerator BPP, 2.0 parts of vulcanizing agent bisphenol AF, 25 parts of carbon black N990, 9 parts of potassium titanate whisker (PTW), 1.2 parts of coupling agent KH550.

Embodiment 3

[0022] The embodiment of the present invention provides a high-strength low-pressure variable fluorine rubber material, including the following components in mass fractions: 100 parts of FKM26, 4 parts of active MgO, 5 parts of Ca(OH) 2 , 1 part of palm wax, 0.6 parts of accelerator BPP, 1.7 parts of vulcanizing agent bisphenol AF, 20 parts of carbon black N990, 7 parts of potassium titanate whisker (PTW), 0.9 parts of coupling agent KH550.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com