A space-grade antistatic sealing material and its preparation method and application

A sealing material and antistatic technology, applied in the field of antistatic sealing material and its preparation, can solve the problems of compression permanent deformation, deterioration of heat resistance comprehensive performance, etc., and achieve good mechanical properties, excellent high temperature aging resistance, and space resistance. Excellent effect of irradiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] An embodiment of the present invention provides a method for preparing a space-grade antistatic sealing material, comprising the following steps:

[0042] (1) Take raw materials according to the following ratio:

[0043] 100 parts by mass of silicone rubber, 40 to 60 parts by mass of reinforcing silica, 8 to 15 parts by mass of superconducting carbon black, 3 to 5 parts by mass of graphene, 4 to 8 parts by mass of heat-resistant auxiliary agent, 5 to 5 parts by mass of radiation protection agent 10 parts by mass, 0.5-1.5 parts by mass of peroxide curing agent;

[0044] The raw materials used in this embodiment are all provided by the above-mentioned embodiments, and the specific descriptions and effects refer to the above-mentioned embodiments, which will not be repeated here.

[0045] (2) The weighed raw materials other than the peroxide curing agent are mixed and thinned, and then the weighed peroxide curing agent is added and kneaded to obtain a space-grade antistat...

Embodiment 1

[0050] This embodiment provides an antistatic sealing material, the preparation method comprising:

[0051] (1) Take raw materials according to the formula in Table 1, wherein: phenyl silicone rubber is the silicone rubber of the SD-1 model purchased from Shandong University, and fumed silica is the fumed silica of the A380 model purchased from Shenyang Chemical Industry ;

[0052] (2) Mix the weighed components except dicumyl peroxide in the internal mixer evenly, after passing through the mixer for 2 times, heat to 45°C, add the weighed dicumyl peroxide , smelting for 3 minutes, and cutting to obtain an antistatic sealing material.

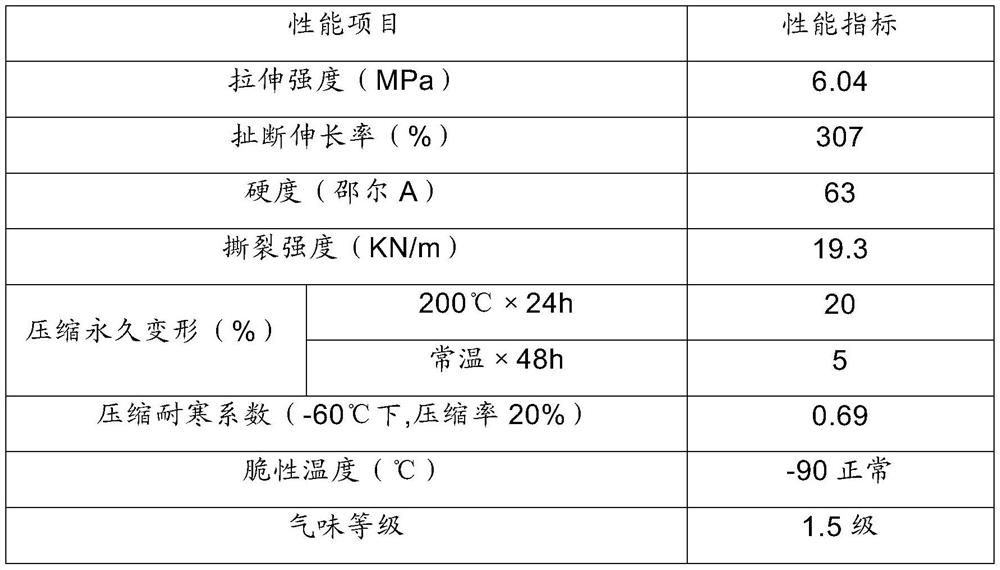

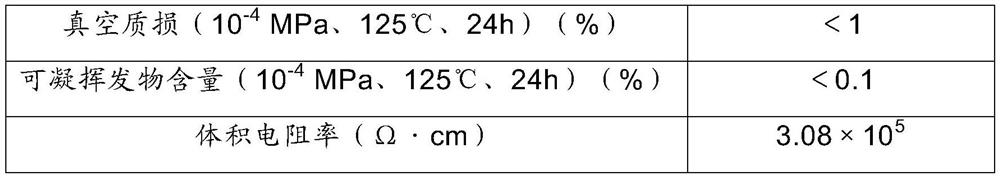

[0053] After parking for 24 hours, perform a performance test on the obtained antistatic sealing material, and the test results are shown in Table 2.

[0054] Table 1 Example 1 formula table

[0055] raw material name Mass parts / parts Phenyl silicone rubber (6% phenyl mass content) 100 Fumed silica 60 Superconducti...

Embodiment 2

[0061] This embodiment provides an antistatic sealing material, the preparation method comprising:

[0062] (1) Take raw materials according to the formula in Table 3, wherein: phenyl silicone rubber is the silicone rubber of the SD-1 model purchased from Shandong University, and fumed silica is the fumed silica of the A380 model purchased from Shenyang Chemical Industry ;

[0063] (2) Mix the weighed components except dicumyl peroxide evenly in the internal mixer. After passing through the mixer for 2 times, heat to 55°C and add the weighed dicumyl peroxide , smelting for 5 minutes, and cutting to obtain an antistatic sealing material.

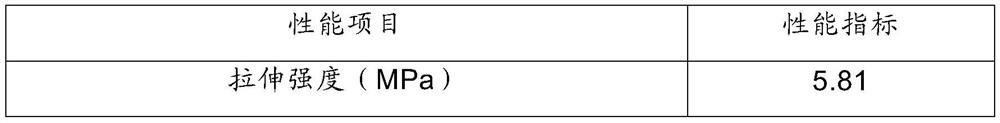

[0064]After parking for 24 hours, the performance test of the obtained antistatic sealing material was carried out, and the test results are shown in Table 2.

[0065] Table 3 Example 2 formula table

[0066] raw material name Mass parts / parts Phenyl silicone rubber (9%) 100 Fumed silica 45 Superconducting carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com