Polyvinyl chloride cable composite material, manufacturing method thereof, and cable

A technology of polyvinyl chloride cables and composite materials, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of limited use, unsatisfactory high temperature resistance, poor high temperature resistance, etc. The effect of oil resistance, stable performance and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] On the other hand, the embodiment of the present invention provides a preparation method of the polyvinyl chloride cable composite material in the above embodiment. In one embodiment, the preparation method of the polyvinyl chloride cable composite material includes the following steps:

[0032] Step S01: Weigh the raw materials of each component according to the components contained in the polyvinyl chloride cable composite material and the content of each component in the above-mentioned invention embodiment;

[0033] Step S02: Mixing the weighed polyvinyl chloride resin, filler, stabilizer, crosslinking agent, flame retardant and pre-crosslinking modifier to obtain a first mixed material;

[0034] Step S03: adding the weighed plasticizer into the first mixed material, heating and performing mixing treatment to obtain a second mixed material;

[0035] Step S04: Melt extruding the second mixed material.

[0036] Wherein, the content of each component weighed in the abo...

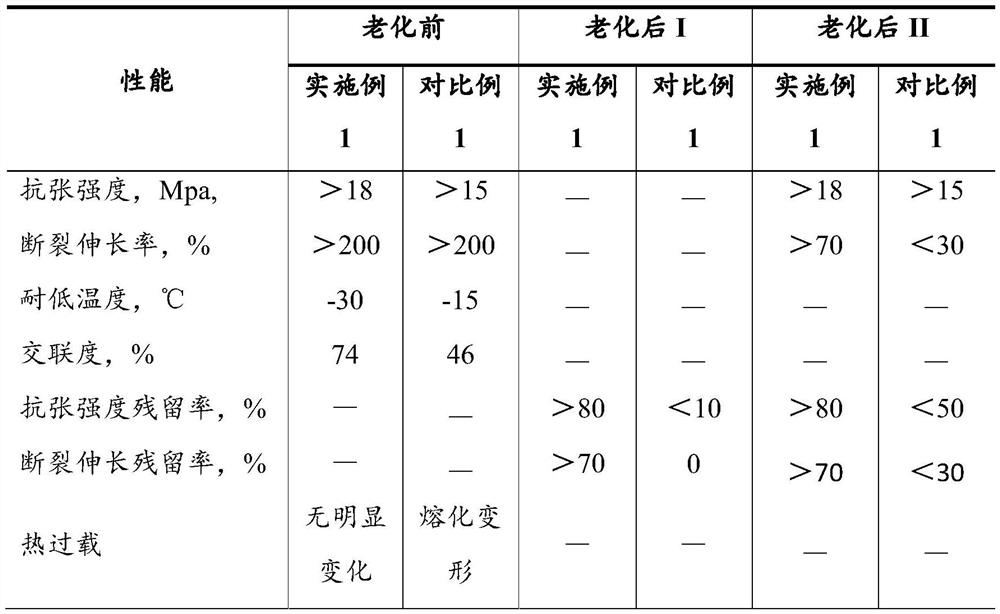

Embodiment 1

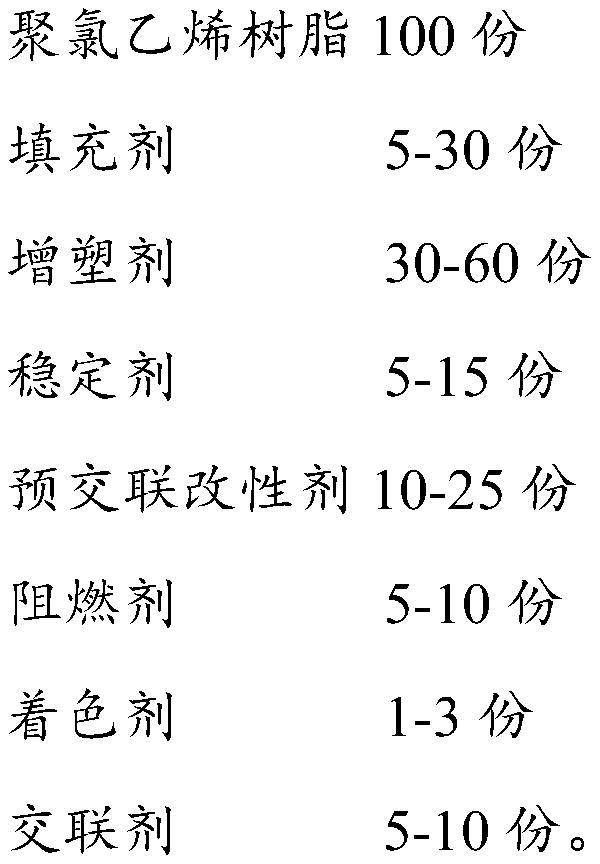

[0050] This embodiment provides a polyvinyl chloride cable composite material and a preparation method thereof. Wherein, the polyvinyl chloride cable composite material includes the following components in parts by weight:

[0051] Polyvinyl chloride resin (polymerization degree 2500): 100 parts,

[0052] Filler I (heavy calcium carbonate 2800): 8 parts,

[0053] Filler II (nano calcium carbonate CCR): 8 parts

[0054] High temperature plasticizer (W-797-ZH): 45 parts,

[0055] Environmental stabilizer (RUP-110C): 6 parts,

[0056] Pre-crosslinking modifier (P95): 15 parts,

[0057] Environmentally friendly flame retardant (antimony trioxide): 6 parts

[0058] Colorant: 2 parts

[0059] Cross-linking agent (TMPTMA): 7

[0060] The preparation method of the polyvinyl chloride cable composite material is as follows:

[0061] S11. Take the corresponding weight fractions of the components contained in the polyvinyl chloride according to the present embodiment;

[0062] S1...

Embodiment 2

[0066] This embodiment provides a polyvinyl chloride cable composite material and a preparation method thereof. Wherein, the polyvinyl chloride cable composite material includes the following components in parts by weight:

[0067] Polyvinyl chloride resin (polymerization degree 2500): 100 parts,

[0068] Filler I (heavy calcium carbonate 2800): 15 parts,

[0069] Filler II (nanometer calcium carbonate CCR): 15 parts

[0070] High temperature plasticizer (UN-380): 60 parts,

[0071] Environmental stabilizer (RUP-110C): 15 parts,

[0072] Pre-crosslinking modifier (P95): 15 parts,

[0073] Environmentally friendly flame retardant (antimony trioxide): 10 parts

[0074] Colorant: 3 parts

[0075] Cross-linking agent (TMPTMA): 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com