High temperature-resistant and gas channeling-resistant cement system and preparation method thereof

A technology of anti-gas channeling and high temperature resistance, which is applied in the field of petroleum drilling engineering, can solve the problems of difficult gas channeling prevention of cement slurry, high formation pressure, high temperature stability of cement slurry, etc., and achieve excellent high temperature aging resistance, Good strength stability at high temperature, uniform and dense microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] According to another aspect of the present invention, the present invention provides a method for preparing a high temperature resistant and anti-gas channeling cement system, comprising the following steps:

[0059] (1) Mix G-grade oil well cement, silica fume, and inorganic toughening fiber evenly according to the proportion;

[0060] (2) Mix fluid loss reducer, dispersant, latex anti-channeling agent, latex stabilizer, nano liquid silicon, high temperature retarder, defoamer and water according to the proportion;

[0061] (3) Slowly pour the mixture of step (1) into the mixture of step (2), and stir rapidly with a high-speed mixer at a speed of 4000 rpm.

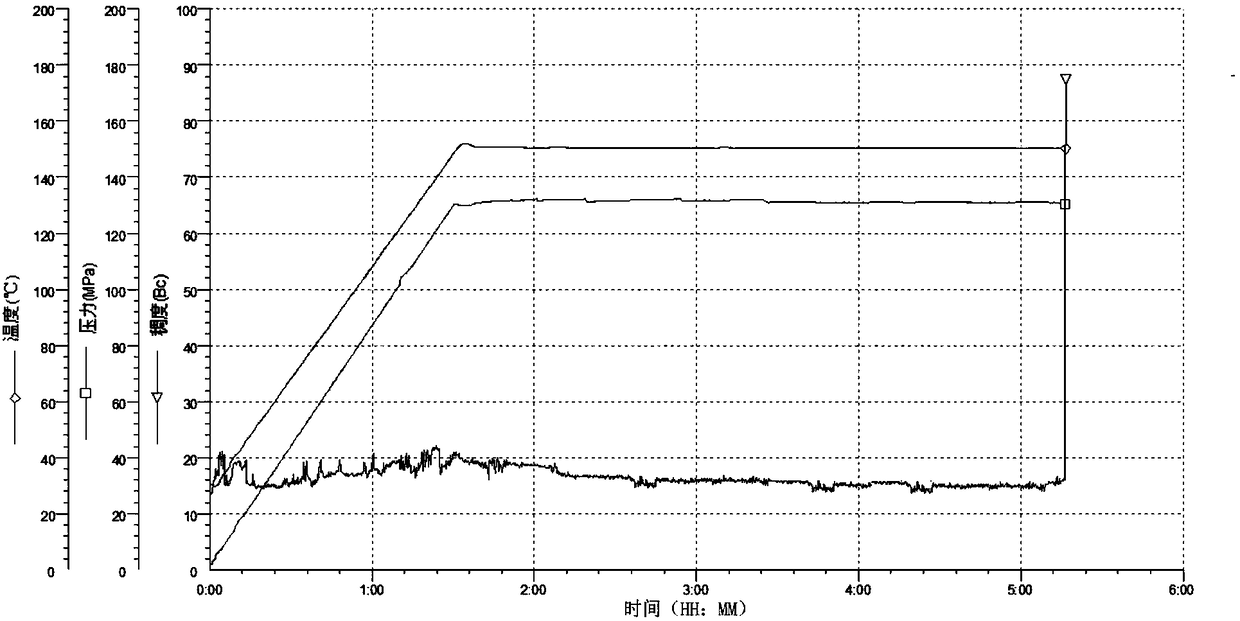

Embodiment 1

[0066] (1) Mix cement, silica fume, and inorganic toughening fiber evenly according to the ratio; (2) Mix fluid loss reducer, dispersant, latex anti-channeling agent, latex stabilizer, nano liquid silicon, high temperature retarder, (3) Slowly pour the mixture of step (1) into the mixture of step (2), and stir rapidly with a high-speed mixer at a speed of 4000 rpm.

[0067] Among them, the composition of the mass parts of the cement slurry is as follows: 100 parts of cement, 60 parts of composite silica fume, 1 part of inorganic toughening fiber, 2 parts of fluid loss reducer, 0.5 part of dispersant, 10 parts of latex anti-channeling agent, 1 part of latex stabilizer 10 parts of nano liquid silicon, 2.8 parts of high temperature retarder, 1.2 parts of defoamer, 65 parts of water.

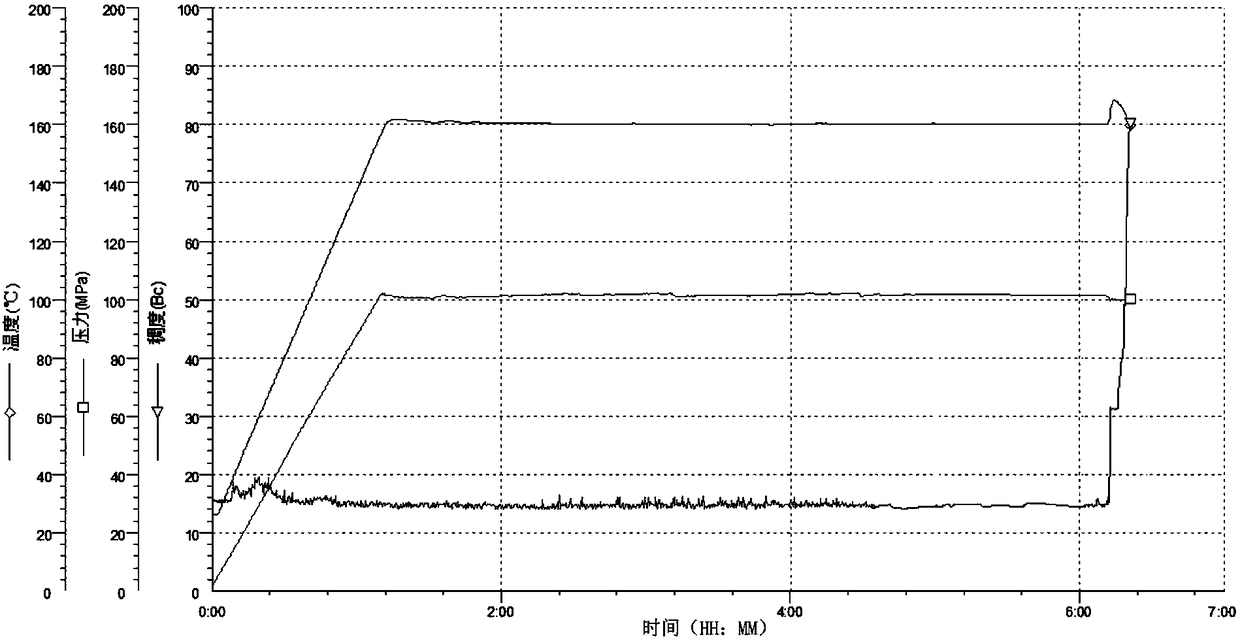

Embodiment 2

[0069] Prepare the cement slurry of the high temperature resistant and anti-gas channeling cement system according to the same method as in Example 1, wherein the mass parts of each component in the cement slurry are composed as follows: 100 parts of cement, 60 parts of composite silica fume, 40 parts of iron ore powder, inorganic additives 1.5 parts of tough fiber, 1.8 parts of fluid loss reducer, 0.7 parts of dispersant, 10 parts of latex anti-channeling agent, 1.2 parts of latex stabilizer, 6 parts of nano liquid silicon, 2.5 parts of high temperature retarder, 1.2 parts of defoaming agent, water 70 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com