Patents

Literature

51results about How to "Uniform and dense microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum oxide reinforced copper base composite material and preparation method thereof

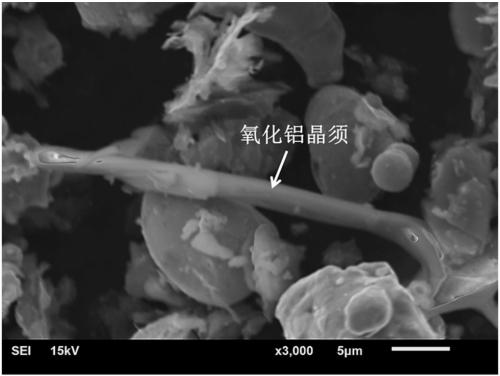

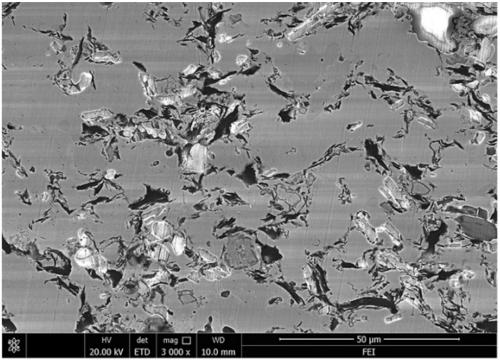

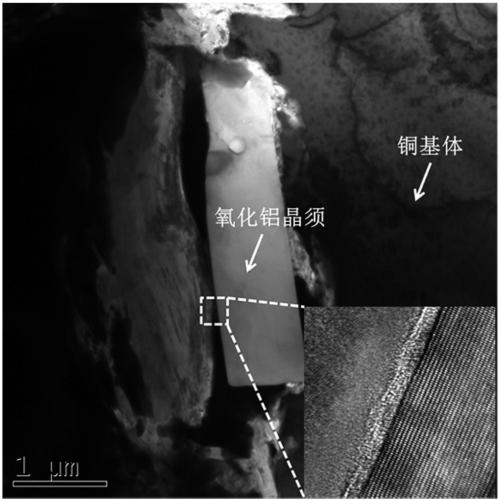

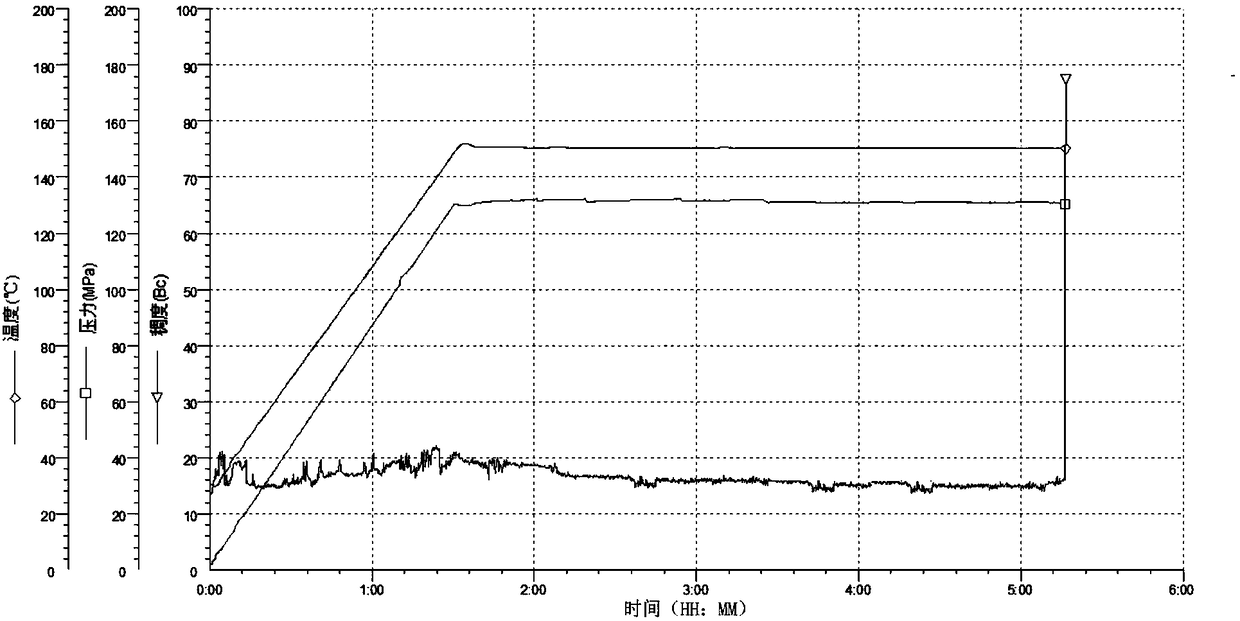

The invention discloses an aluminum oxide reinforced copper base composite material. The aluminum oxide reinforced copper base composite material is characterized by comprising the following components in percentage by weight: 1-6% of modified ceramic aluminum oxide, 2-10% of graphite, 0.5-5% of Ti3SiC2, 2-8% of nickel, 2-8% of iron, 2-10% of tin, 1-5% of bismuth, 0.1-1% of zirconium oxide, 0.1-0.5% of lanthanum, and the balance of copper; and the modified ceramic aluminum oxide is surface-modified Al2O3 particles and surface-modified Al2O3 whiskers. The surfaces of the Al2O3 particles and theAl2O3 whiskers for the copper base composite material are modified by lauryl sodium sulfate water solution; through surface modification, the impurity content of the ceramic aluminum oxide is obviously reduced; multiple metal elements are matched for assisting and cooperating with a welding structure, so that the dispersibility is excellent, the ceramic aluminum oxide and a copper basal body arefirmly bonded, and the acceleration effect is prominently improved; and when the effect of external force is suffered, through excellent combined interfaces, the load transfer effect can be effectively achieved, the stress concentration is reduced, and defects are reduced.

Owner:SOUTHWEST JIAOTONG UNIV

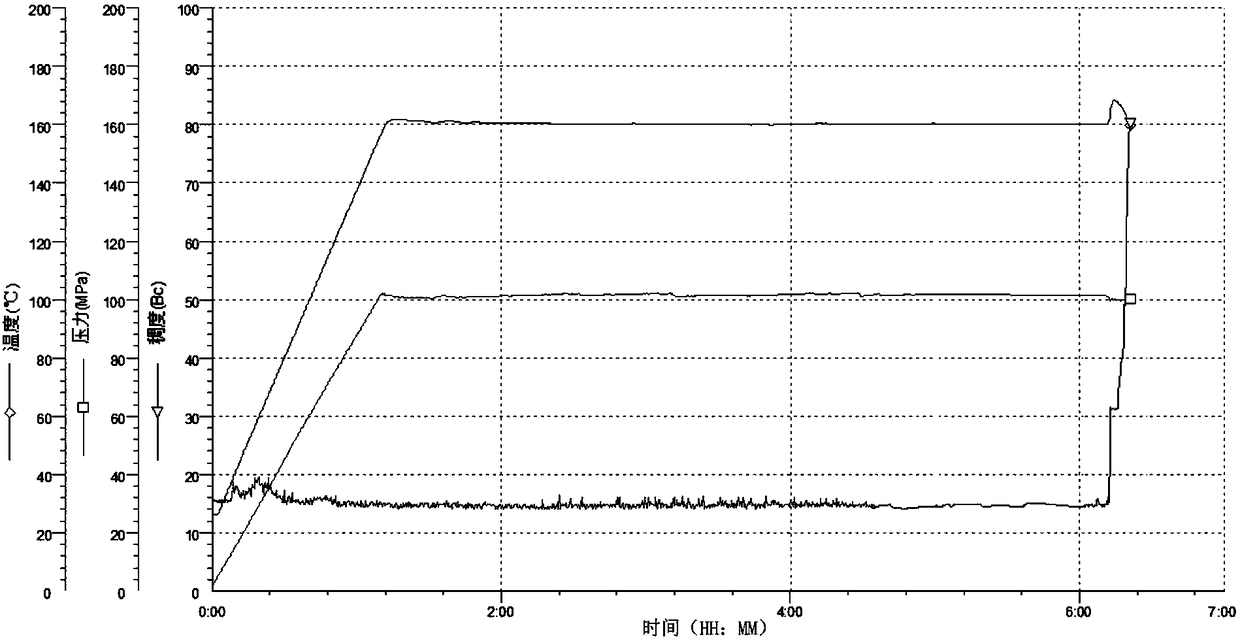

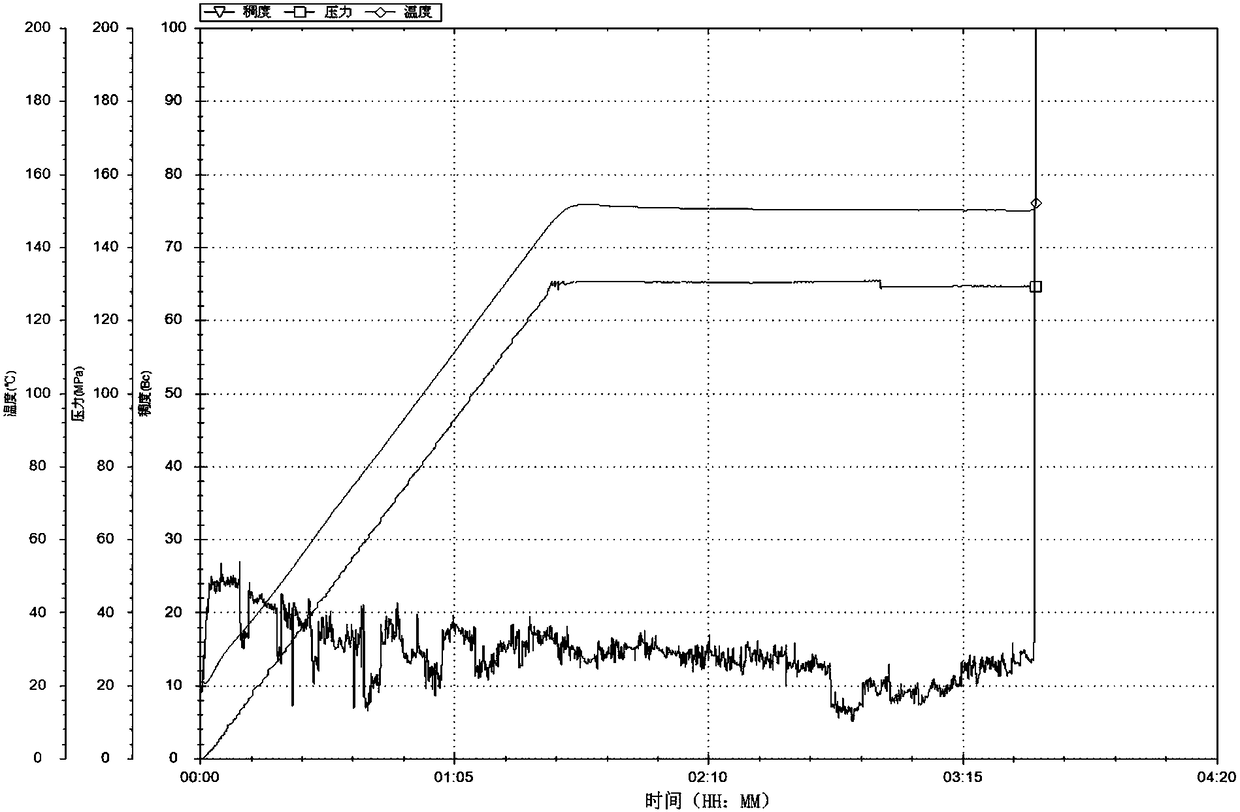

High temperature-resistant and gas channeling-resistant cement system and preparation method thereof

The invention relates to the field of petroleum drilling engineering, and especially relates to a high temperature-resistant and gas channeling-resistant cement system and a preparation method thereof. The high temperature-resistant and gas channeling-resistant cement system comprises, by weight, 100 parts of cement, 60 parts of composite silicon powder, 1-1.5 parts of inorganically toughened fibers, 1.5-3 parts of a fluid loss agent, 0.3-0.7 part of a dispersant, 6-10 parts of a latex gas channeling inhibitor, 1-1.2 parts of a latex stabilizer, 6-10 parts of nano-liquid silicon, 2.5-8 parts of a high temperature retarder, 1-1.5 parts of an antifoaming agent and 65-90 parts of water. The preparation method of the high temperature-resistant and gas channeling-resistant cement system comprises the following steps: (1) uniformly mixing the cement, the silicon powder and the inorganically toughened fibers in proportion; (2) uniformly mixing the fluid loss agent, the dispersant, the latex gas channeling inhibitor, the latex stabilizer, the nano-liquid silicon, the high temperature retarder, the antifoaming agent and the water in proportion; and (3) slowly adding the mixture obtained instep (1) into a mixture obtained in step (2), and performing rapid stirring by a stirrer.

Owner:CHINA PETROLEUM & CHEM CORP

Technique for preparing tungsten copper heat-sink and electric packaging material

The invention provides a novel process for preparing tungsten-copper heat sink and electronic package materials, in order to overcome the problems that the prior tungsten-copper heat sink and electronic package materials are not excellent enough in quality, high in preparation cost and low in production efficiency. The process comprises the steps of preparing powder, adding inducers, mixing materials, molding for automatic forming, performing isostatic pressing and covering, presintering and infiltrating liquid copper. The process which is adopted to prepare the tungsten-copper heat sink and electronic package materials has the advantages of low cost and high production efficiency; in addition, the prepared tungsten-copper heat sink and electronic package materials are compact in structure and show excellent properties in all aspects.

Owner:安泰天龙钨钼科技有限公司

Method for preparing bamboo charcoal with controllable aperture

InactiveCN104607145AUniform and dense microstructureRipe evenlyOther chemical processesAlkali metal oxides/hydroxidesNitrogenRoom temperature

The invention relates to a method for preparing bamboo charcoal with a controllable aperture. The method comprises the following steps: cutting bamboo, selecting a middle section of cut bamboo which is more than 1m above the ground for drying treatment, controlling the water content of the bamboo to be less than 20%, placing the bamboo in a high-temperature furnace, feeding high-purity nitrogen or argon into the high-temperature furnace at a flowing rate of more than 5L / min to carry out deoxidization, then, raising the temperature of the high-temperature furnace to 400-1,500 DEG C at a speed of 3-40 DEG C / min, charring at the constant temperature for 1 to 8h, naturally cooling the high-temperature furnace to the room temperature after the thermal decomposition and the charring are finished, taking the product out and grinding, controlling the fineness of the product to be more than 20 meshes, and modifying the pore structure to obtain the bamboo charcoal with the controllable aperture. Compared with the prior art, the method is simple in preparation process, can effectively reduce the production cost by pressure maintaining and charring and effectively improve the adsorption capability of the bamboo charcoal by adopting the pore structure modification; moreover, the prepared bamboo charcoal can be suitable for application scenarios of different adsorbates, and is wide in application range.

Owner:TONGJI UNIV

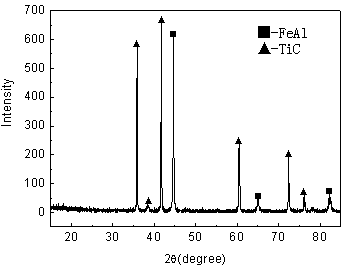

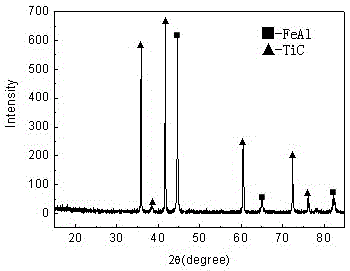

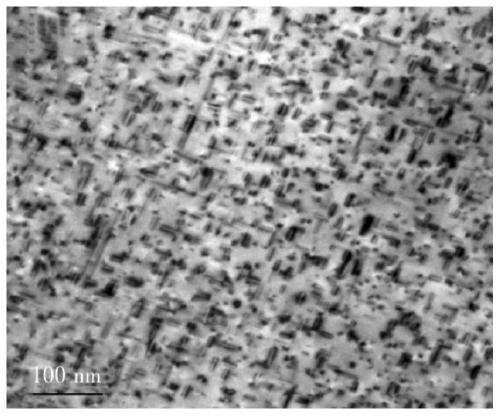

Preparation method for sintering FeAl/TiC composite material under normal pressure

The invention relates to a preparation method for sintering a FeAl / TiC composite material under normal pressure, which comprises the following steps: 1) employing a mechanical alloying technology to prepare FeAl intermetallic compound powder; 2)poforming a high temperature hot treatment process on the FeAl intermetallic compound powder; wherein the ball-milling time of the mechanical alloying technology is 60 hours, the heat treatment temperature is 800 DEG C, and the insulation time is 1 hour; 3)mixing the prepared FeAl intermetallic compound powder and TiC powder to prepare the FeAl / TiC composite powder, and preparing a bar-shaped sample through compression moulding, and 4)performing a sintering process under normal pressure, wherein the sintering temperature is 1600 DEG C, insulating for 2 hours, and preparing the FeAl / TiC composite material bulk under normal pressure by the sintering process. According to the invention, the melting point of the FeAl intermetallic compound is 1250-1400 DEG C, when the sintering temperature is 1600 DEG C, the FeAl intermetallic compound is molten to be a liquid phase, the molten FeAl intermetallic compound and TiC particles are sintered together to form a compact sintering bulk. The preparation method has the advantages of low preparation cost, simple technology and suitability for large-scale industrial production.

Owner:XI'AN PETROLEUM UNIVERSITY

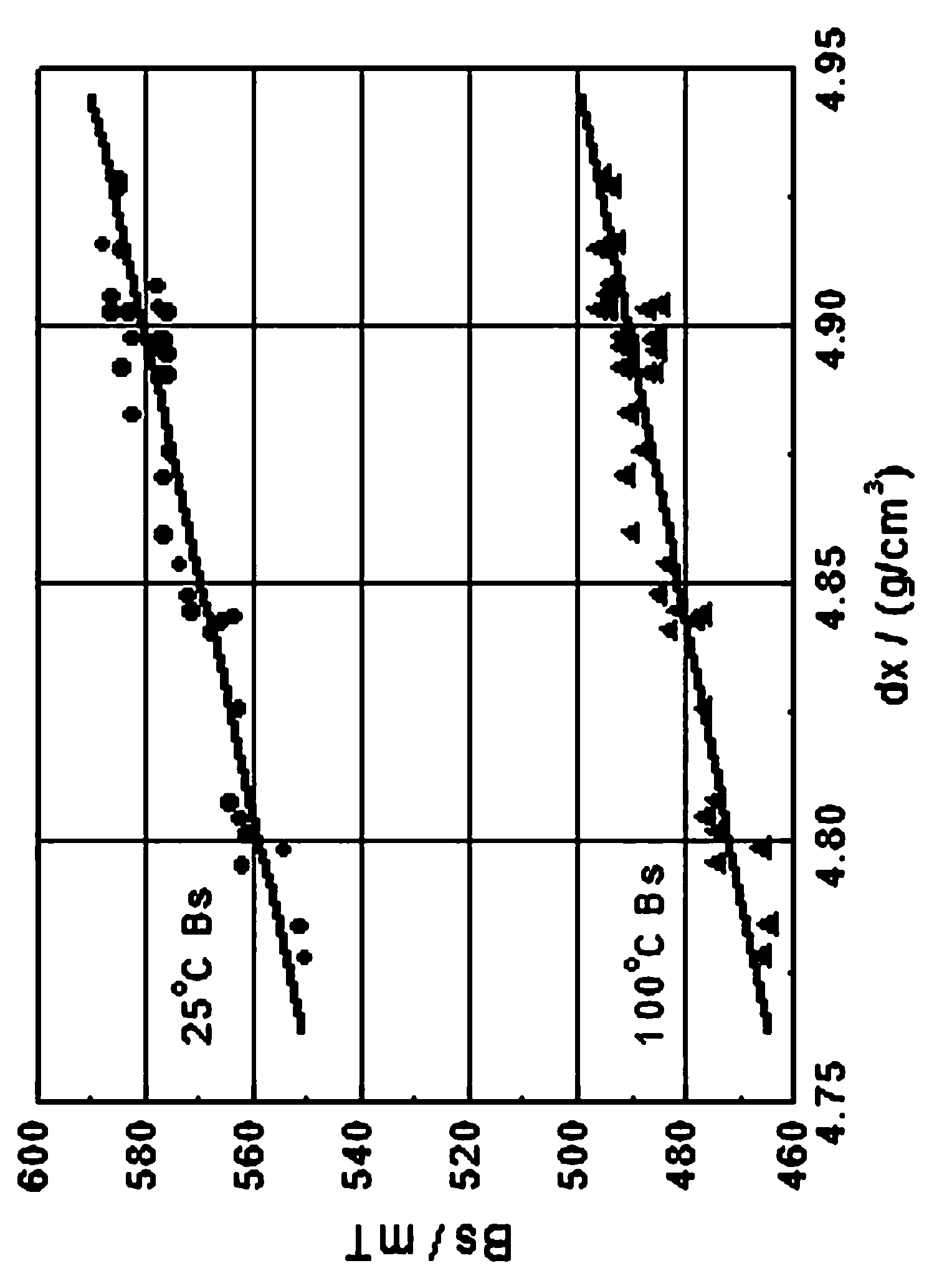

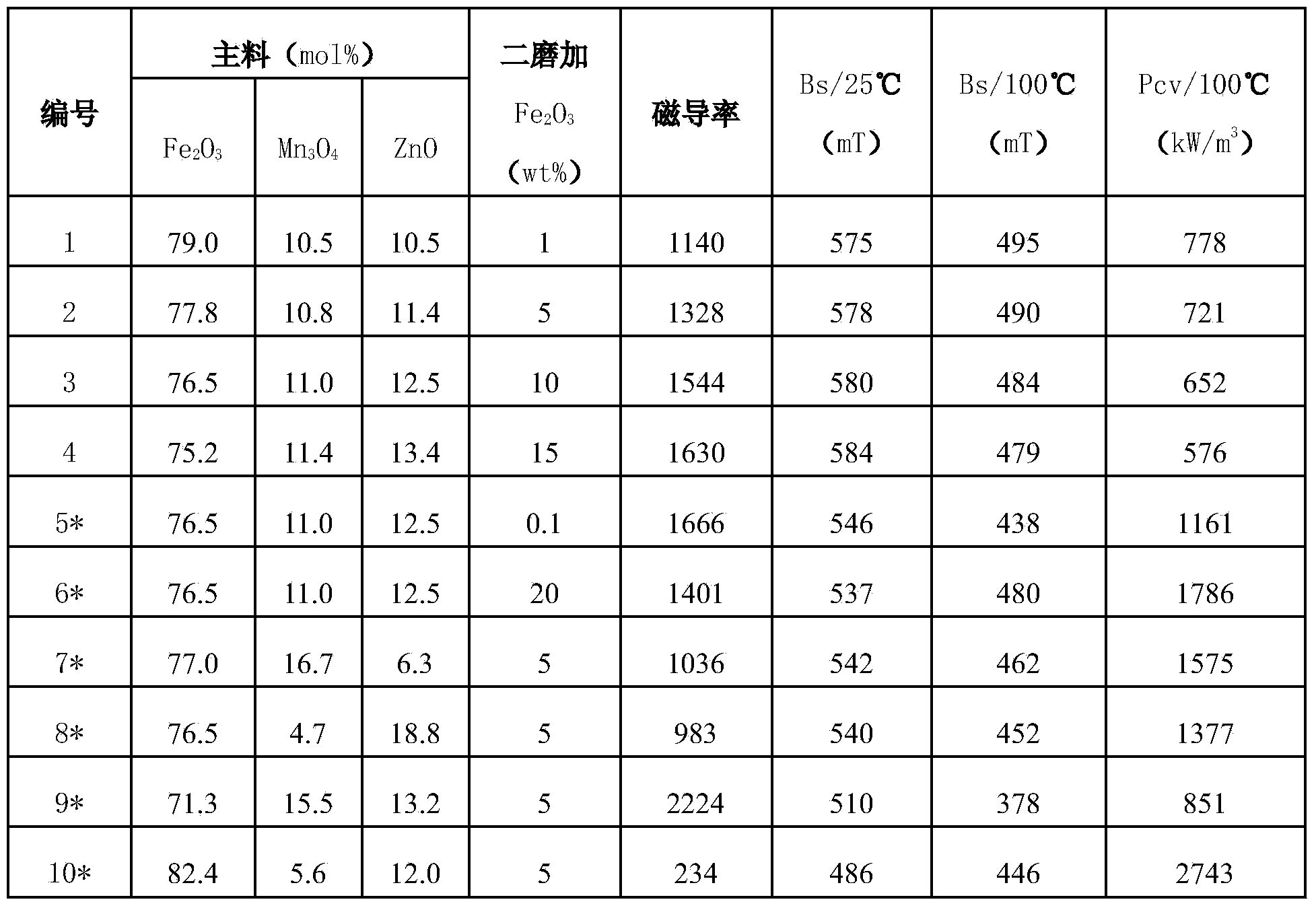

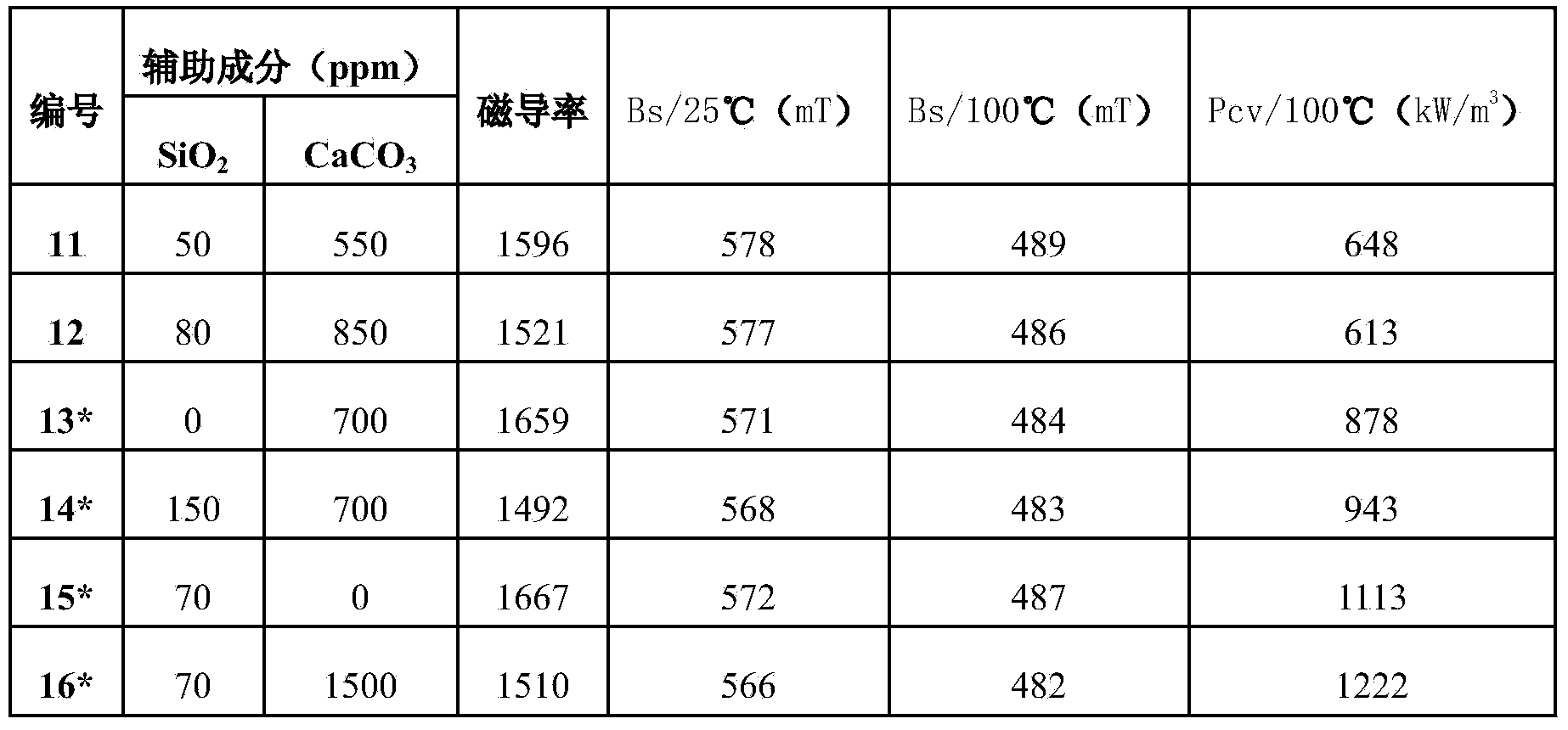

Ultrahigh-Bs (saturation magnetic flux density) low-loss MnZn powder ferrite material and making method thereof

ActiveCN103664155AAccurate ingredientsZnO compact, increase the Zn vapor pressure in the kiln cavityMetallurgyRaw material

The invention provides an ultrahigh-Bs (saturation magnetic flux density) low-loss MnZn powder ferrite material and a making method thereof, the material has an ultrahigh Bs and low power loss, and the material is prepared from as raw materials comprising 75wt%-79wt% of Fe2O3, 10wt% -14wt% of Mn3O4 and 10wt%-14wt% of ZnO by blending, first grinding, presintering, second grinding, pelletizing, molding, sintering and other processes. The innovation of the material is to eliminate the technical prejudice, and by adding of the quantitative component Fe2O3 in the second grinding, the power loss is significantly reduced, and at the same time, the ultrahigh Bs and the low loss are realized.

Owner:江门安磁电子有限公司

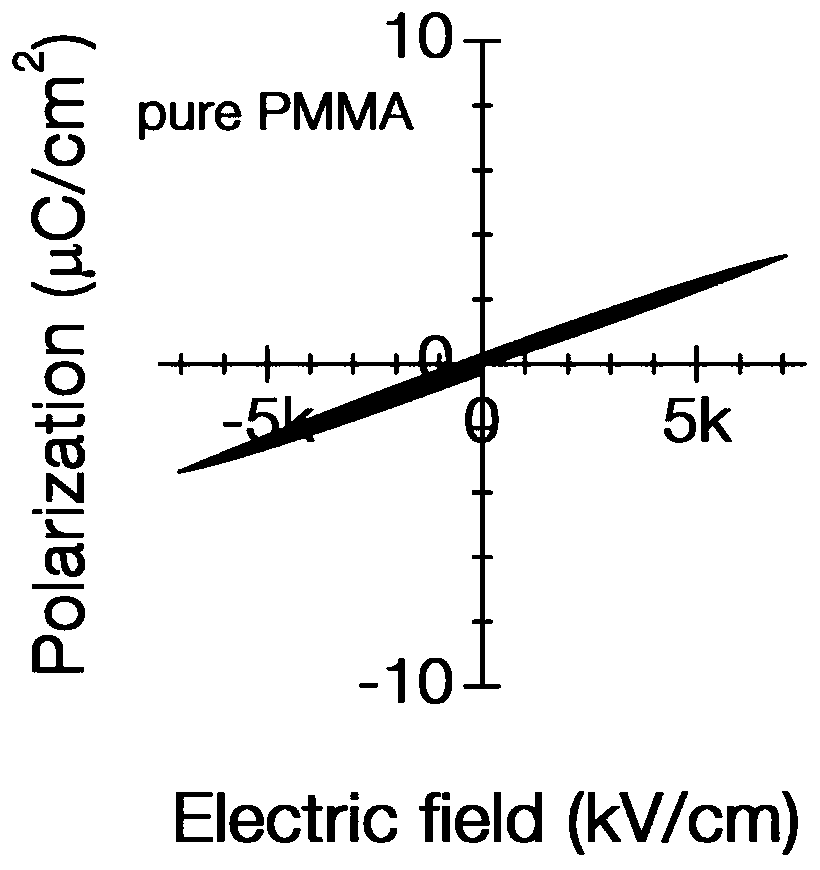

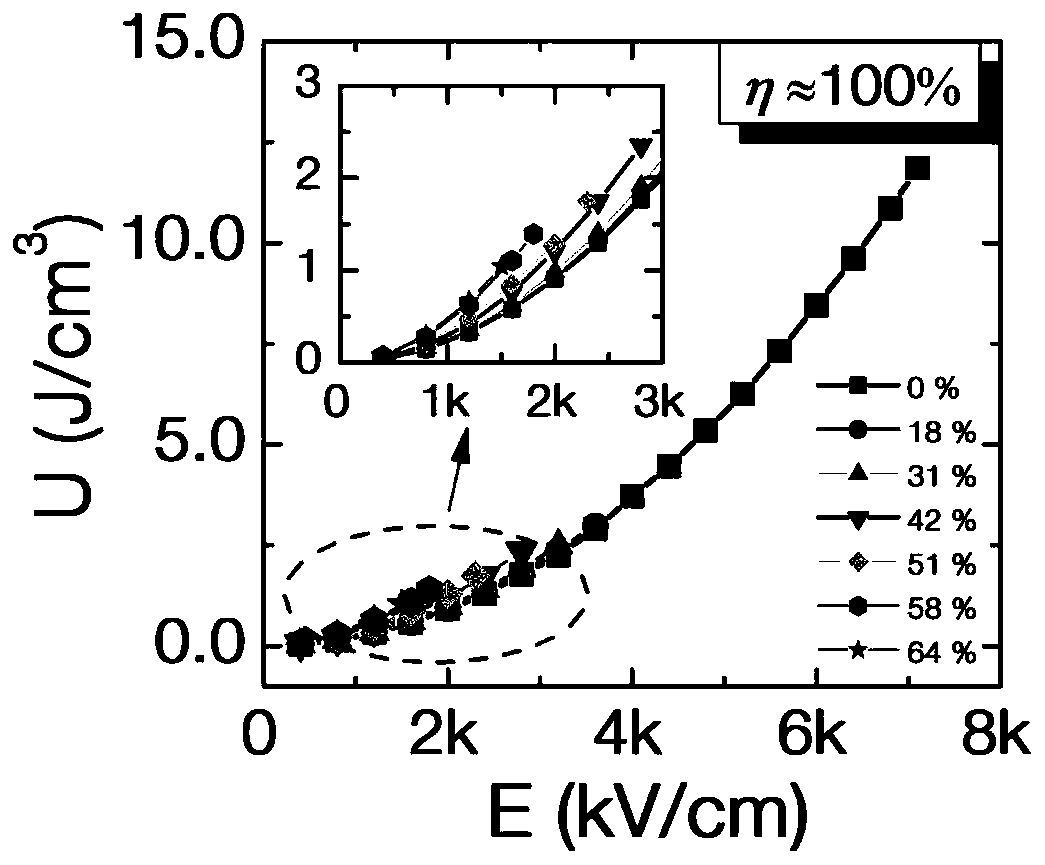

Polymer-ceramic composite dielectric energy storage material and preparation method thereof

InactiveCN110643129AHigh energy storage densityImprove charge and discharge efficiencyApparatus for manufacturing conducting/semi-conducting layersThin membranePolypropylene

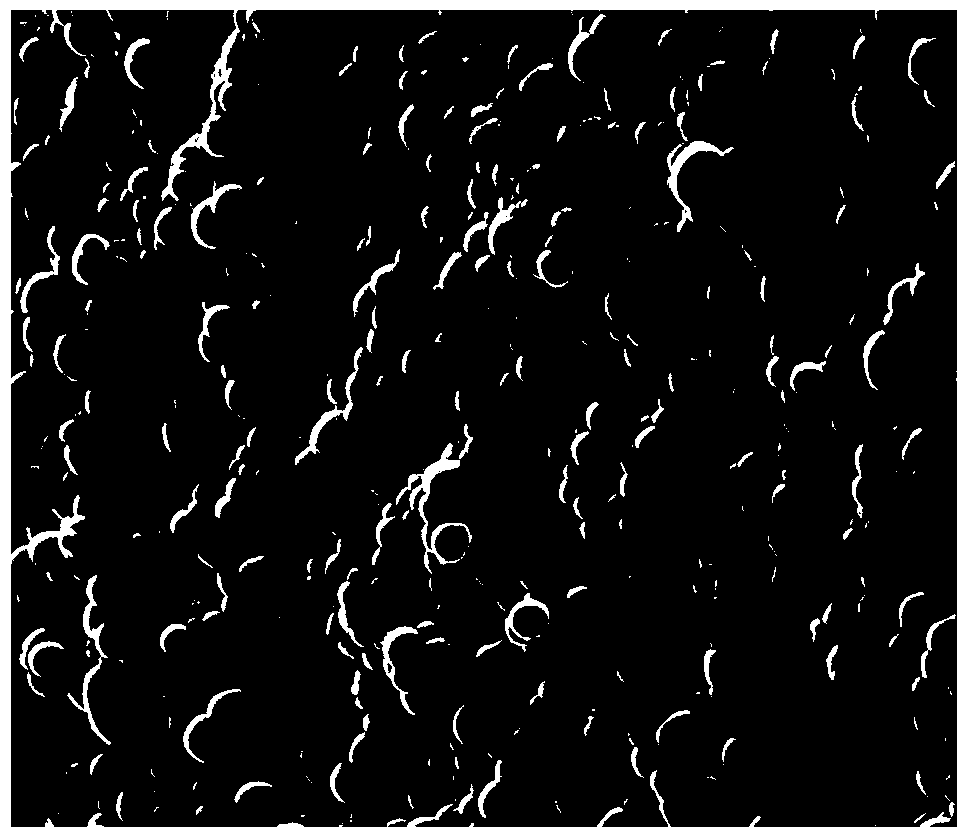

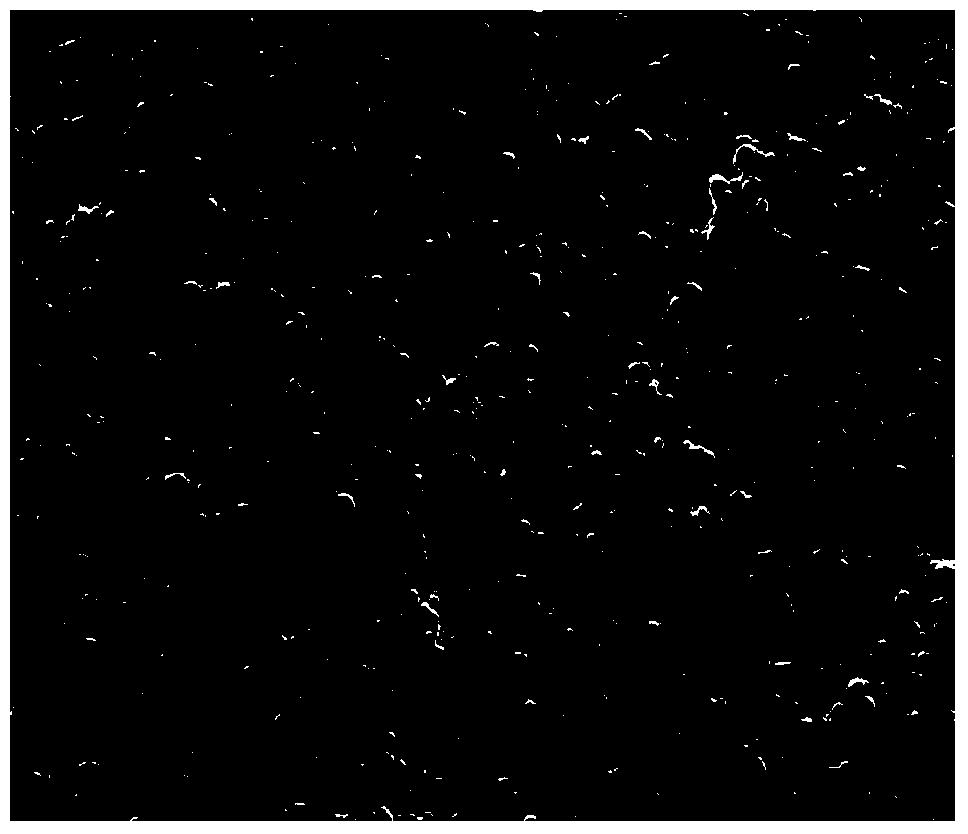

A polymer-ceramic composite dielectric energy storage material comprises polymethyl methacrylate (PMMA) as a matrix and barium strontium titanate (BST) nanoparticles as a filler. A preparation methodof the material comprises the following steps: 1) weighing materials; 2) preparing a PMMA solution; 3) preparing a PMMA-BST mixed solution; 4) preparing a PMMA-BST composite material film; 5) performing heat treatment; and 6) preparing an electrode. A film sample has a uniform and compact microstructure, good transparency and good flexibility, has a far higher energy storage density than biaxiallyoriented polypropylene, has a far higher charging and discharging efficiency than of a composite dielectric material system taking a ferroelectric polymer as a matrix, and meets the practical application requirements of high energy storage density and high charging and discharging efficiency.

Owner:XIAN UNIV OF TECH

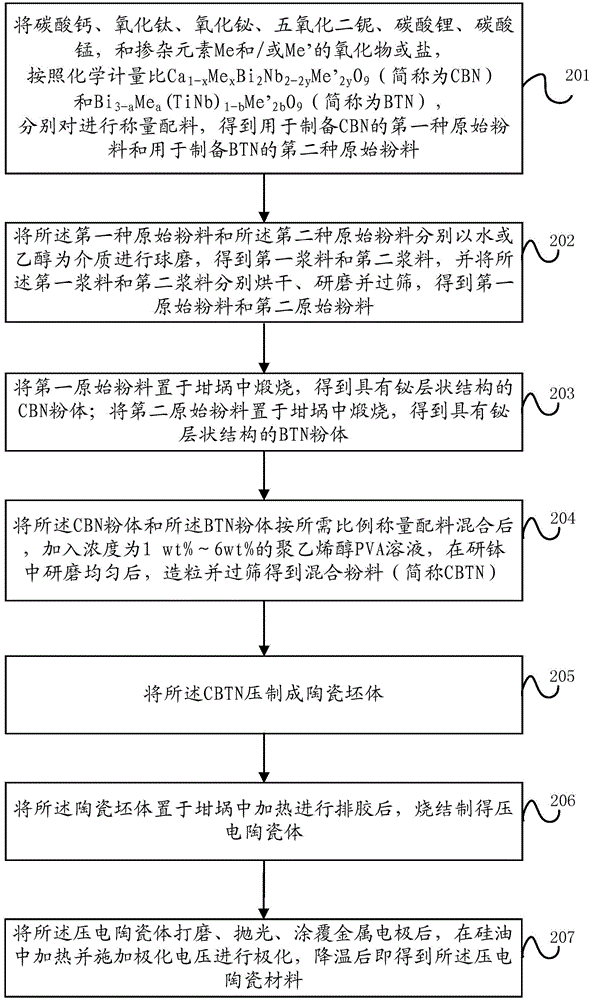

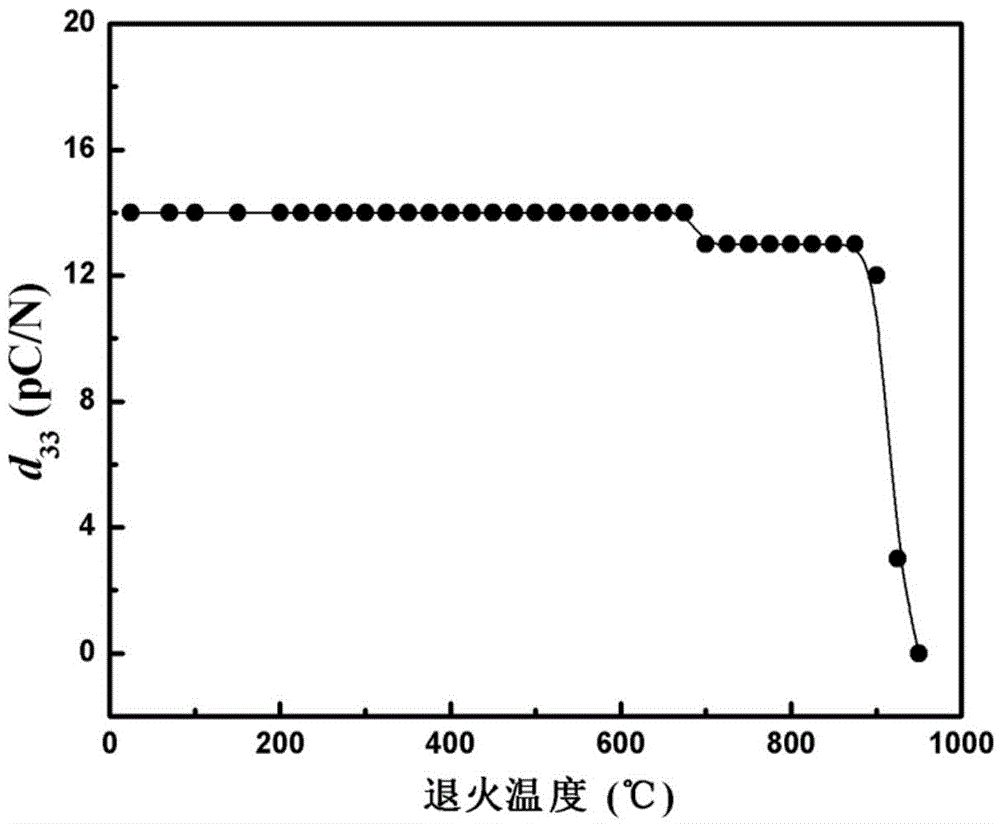

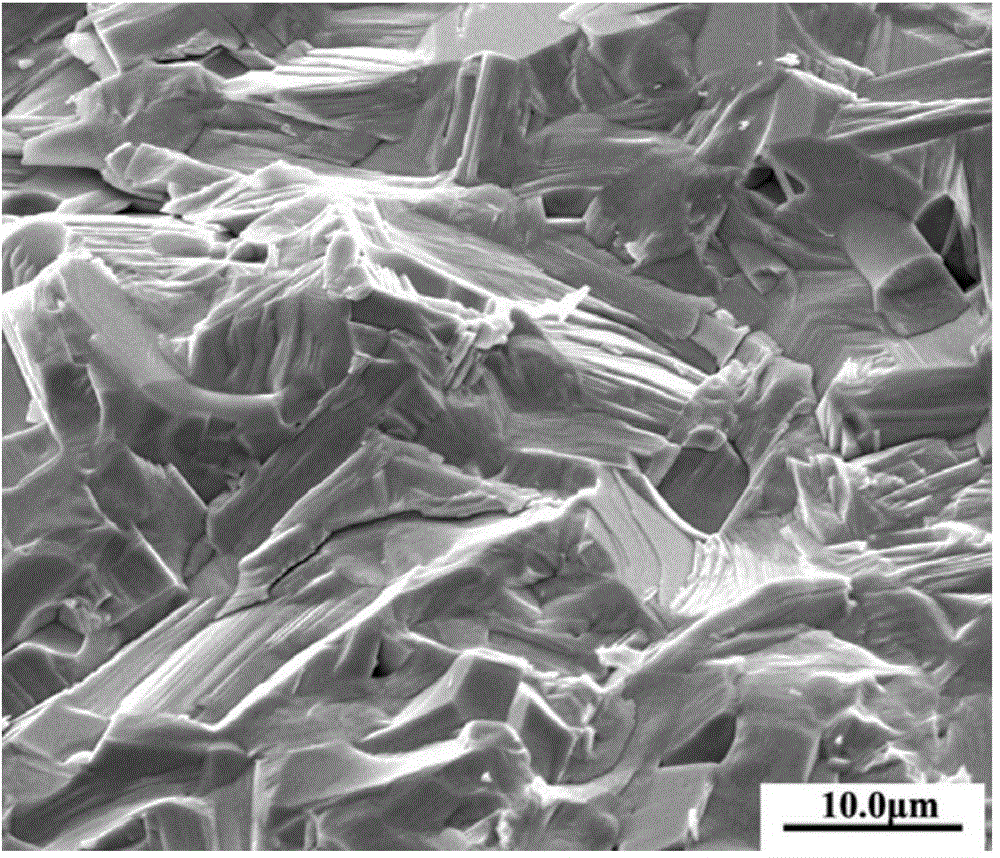

Piezoelectric ceramic material in bismuth laminar composite structure and preparation method of piezoelectric ceramic material

The invention discloses a piezoelectric ceramic material in a bismuth laminar composite structure and a preparation method of the piezoelectric ceramic material. The chemical formula of the material is [Ca(1-x)MexBi2Nb(2-2y)Me'2yO9]1-z-[Bi3-aMea(TiNb)1-bMe'2bO9]z, wherein Me and Me' are respectively doping elements suitable for different lattice positions; M is one or more of Li, Mn and Ce; Me' is one or more of Ta and W; x, y, z, a and b are respectively molar fractions: x is greater than or equal to 0 but less than or equal to 0.05, y is greater than or equal to 0 but less than or equal to 0.05, b is greater than or equal to 0 but less than or equal to 0.05 and z is greater than or equal to 0.2 but less than or equal to 0.8. The piezoelectric ceramic material has high Curie temperature, excellent piezoelectric property and adjustable comprehensive electric property and can be used for various high-temperature piezoelectric apparatuses.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Making method of fresh and wet rice noodles with relatively long shelf life

InactiveCN111887378AExtended shelf lifeImprove food qualityFood thermal treatmentFood preservationHorticultureTrehalose

Disclosed is a making method of fresh and wet rice noodles with a relatively long shelf life. The method comprises the following steps: selecting rice locally planted and produced in Yunnan province,soaking the rice in clean water for 3-6 hours, and then filtering out water; adding trehalose accounting for 5.5-6.5% of the mass of the rice and table salt accounting for 3.5-4.5% of the mass of therice into the soaked rice, performing uniform stirring, and performing grinding to form thick rice milk; injecting the rice milk into a rice noodle processing machine, extruding the rice milk into long strips, and curing the long strips to prepare fresh wet rice noodles; soaking the fresh wet rice noodles in a fresh-keeping solution, prepared by mixing epsilon-polylysine hydrochloride and lactic acid, for 1-3 minutes, and then filtering out moisture; and performing vacuum packaging on the fresh wet rice noodles, and performing heating sterilization. According to the method, the eating qualityof the fresh wet rice noodles is improved, the shelf life of the fresh wet rice noodles is effectively prolonged, and the problems that the shelf life of the fresh wet rice noodles produced by a traditional method is short, the quality of the rice noodles is unstable in a traditional rice noodle production and improvement process, the usage amount and variety of a quality improver are difficult tocontrol, and food potential safety hazards exist are solved.

Owner:杜琼媛

High-precision honing strip

ActiveCN101817169AUniform and dense microstructureImprove mechanical strengthAbrasion apparatusHoning toolsRare-earth elementZinc

The invention relates to a high-precision honing strip, comprising the following components by weight percentage: 50-70% of copper, 5-10% of nickel, 5-10% of zinc, 1-5% of cobalt, 5-10% of silver, 5-10% of manganese, 1-5% of lead, 0.1-5% of rare-earth element and 5-10% of CBN grinding material, wherein the purities of copper, nickel, zinc, cobalt, silver and manganese are 95% above and the purity of the CBN grinding material is 75% above. The zinc can be replaced by tin and the CBN grinding material is micro powders with the granularity smaller than 300 meshes. After being honed by the honing strip, the surface roughness, roundness and cylindricity can meet the machining requirements. The exposure effect, the machining efficiency and the service life of the honing strip can achieve the desired effect.

Owner:SUZHOU XINNENG PRECISE MACHINERY

Nickel and silicon intermetallic compound based composite coat making method

InactiveCN103726045AHigh bonding strengthIncrease added valueHeat inorganic powder coatingCeramic compositeWear resistant

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

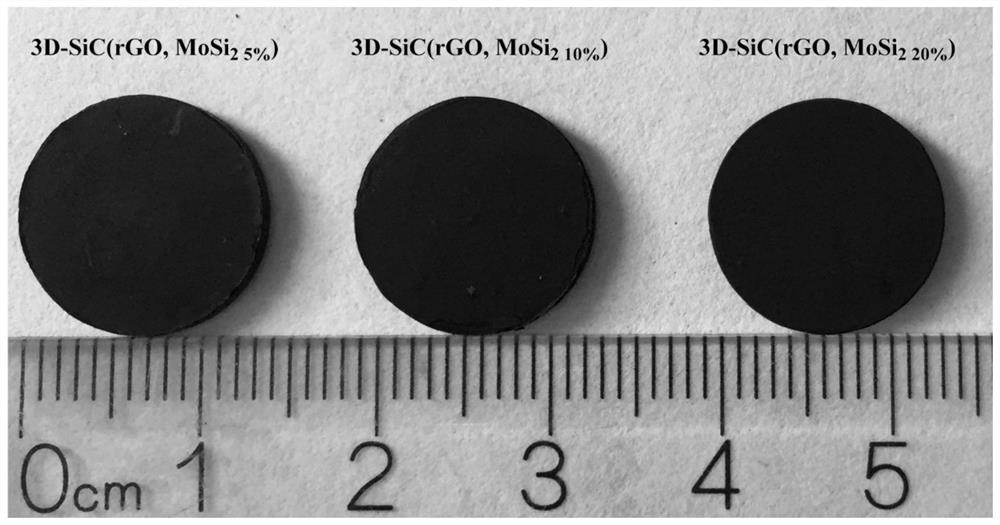

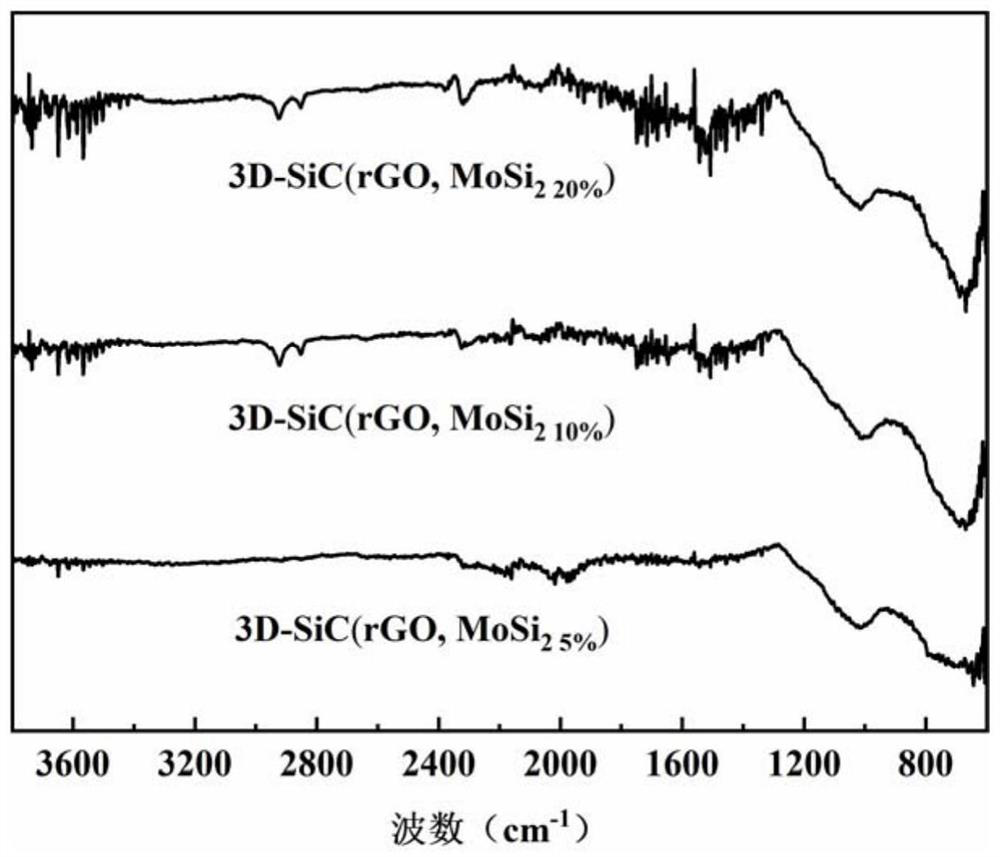

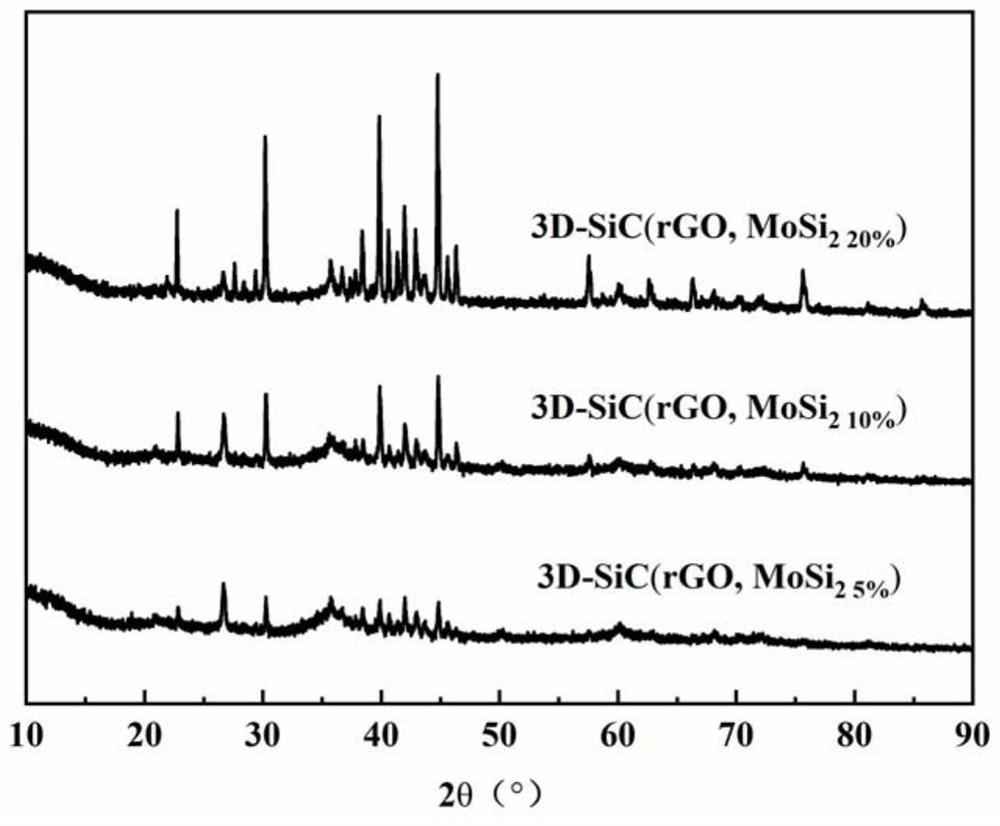

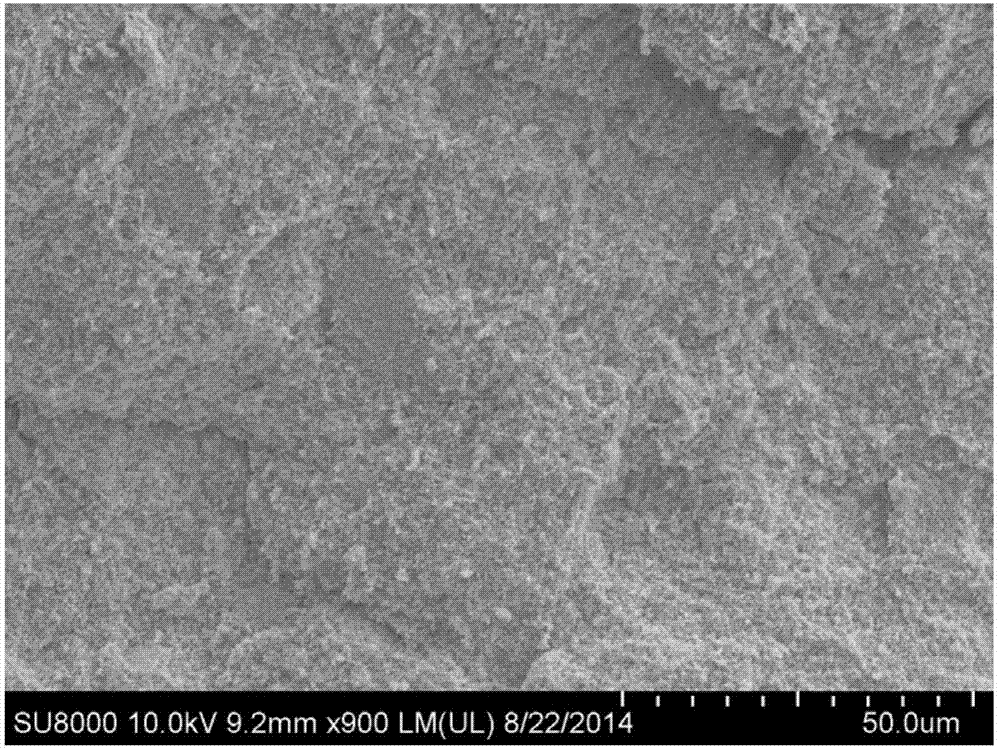

Molybdenum disilicide/silicon carbide three-dimensional polymer precursor ceramic and preparation method thereof

The invention discloses molybdenum disilicide / silicon carbide three-dimensional polymer precursor ceramic and a preparation method thereof, belonging to preparation of ceramic materials. The preparation method comprises the following steps: putting precursor PVG powder into a graphite paper boat and carrying out high-temperature cracking under the protection of an inert atmosphere; mixing MoSi2, cracked SiC(rGO)p ceramic particles and the precursor PVG powder to form a MoSi2 / SiC(rGO)p / PVG mixture, carrying out ball milling and uniform mixing in an alcohol medium, and then drying the MoSi2 / SiC(rGO)p / PVG mixture in an oven; and loading the mixture into a mold for compression molding, conducing demolding to obtain a biscuit, putting the biscuit into an inert atmosphere tube furnace for high-temperature sintering, and conducting cooling along with the furnace to obtain black molybdenum disilicide / silicon carbide three-dimensional polymer precursor ceramic, namely 3D-SiC(rGO, MoSi2x) nanometer composite block ceramic for short, wherein x is the mass fraction of silicon carbide in the whole biscuit. The obtained ceramic is high in heat conductivity and electric conductivity and good in formability and component uniformity; and the preparation method is simple and economical in process.

Owner:中科德胜(常州)电子科技有限公司

Preparation method of high-density ITO target molded by slip casting

InactiveCN107226680ALow viscosityGood stabilityVacuum evaporation coatingSputtering coatingGypsumAmmonium hydroxide

The invention discloses a preparation method of a high-density ITO target molded by slip casting. The preparation method comprises adding a dispersant into water, stirring evenly the solution, adjusting the pH to 8 to 11 through ammonium hydroxide so that a premixed solution is obtained, adding ITO powder into the premixed solution, carrying out wet grinding by a ball mill, carrying out vacuum degassing on the slurry, injecting the degassed slurry into a gypsum mold, carrying out slurry suction molding, carrying out demolding, airing a green body for 72h or more to obtain an ITO biscuit and sintering the ITO biscuit to obtain the ITO target. Through the process route of pouring and molding and non-pressure ITO target sintering in the oxygen atmosphere, the high-density high-quality ITO target is produced in a low cost.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

Nanometer crystal blue ceramic corundum abrasive and preparation method thereof

ActiveCN106083001ABroaden your optionsChange color characteristicsOther chemical processesCompressive strengthGrinding wheel

The invention discloses a nanometer crystal blue ceramic corundum abrasive and a preparation method thereof. A sol-gel method is adopted for preparing an aluminiferous precursor, an additive is introduced, and granulation, sieving, calcination and other technologies are adopted for obtaining the ceramic corundum abrasive. Al2(SO4)3.18H2O or Al(NO3)3.9H2O is adopted as a raw material, an additional additive accounts for 0.15-0.8% of the raw material by mass, the additive is prepared from 5-25% of Co(NO3)2.6H2O, 5-20% of (NH4)3AlF6, 0-65% of C16H36O4Ti, 0-40% of Si(OC2H5)4, 0-50% of Mg(NO3)2.6H2O and 0-20% of Ca(NO3)2.4H2O. According to the nanometer crystal blue ceramic corundum abrasive, the color development characteristic of the corundum abrasive is changed, the production temperature is lowered by 400-800 DEG C compared with an electric smelting method, the microscopic structure inside the corundum abrasive is optimized, the compressive strength of a single particle can reach 58.6 N, the impact toughness is improved by 15-25% compared with an existing ceramic corundum abrasive, the grinding efficiency of an obtained ceramic corundum grinding wheel is improved by 55% or above compared with a common corundum wheel, and the service life is correspondingly prolonged.

Owner:TIANJIN UNIV

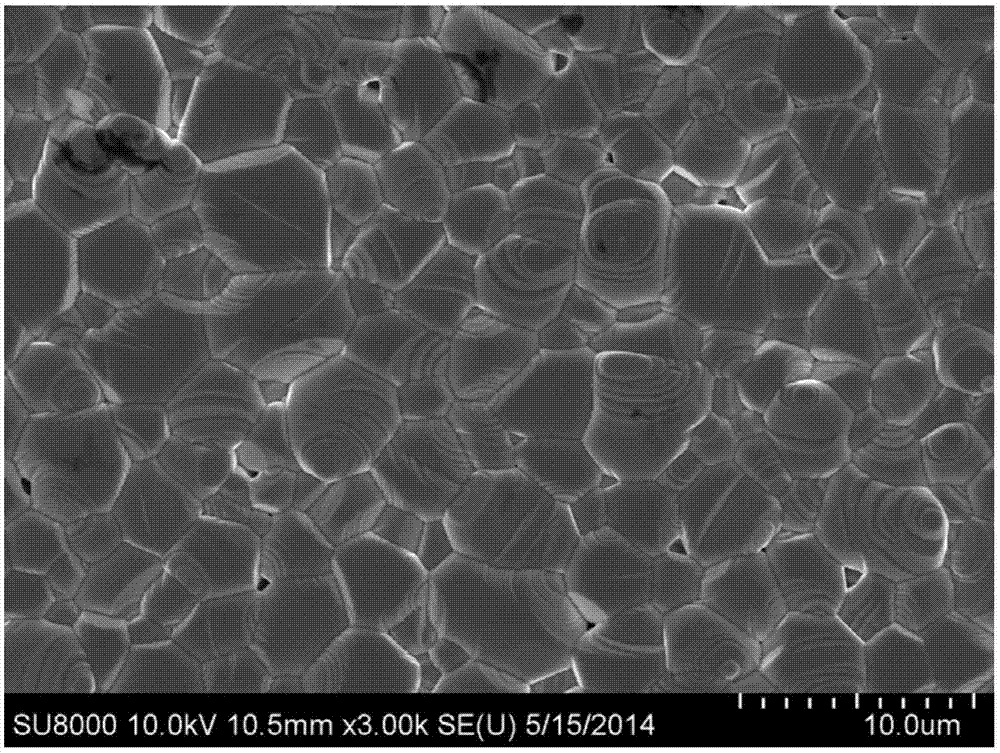

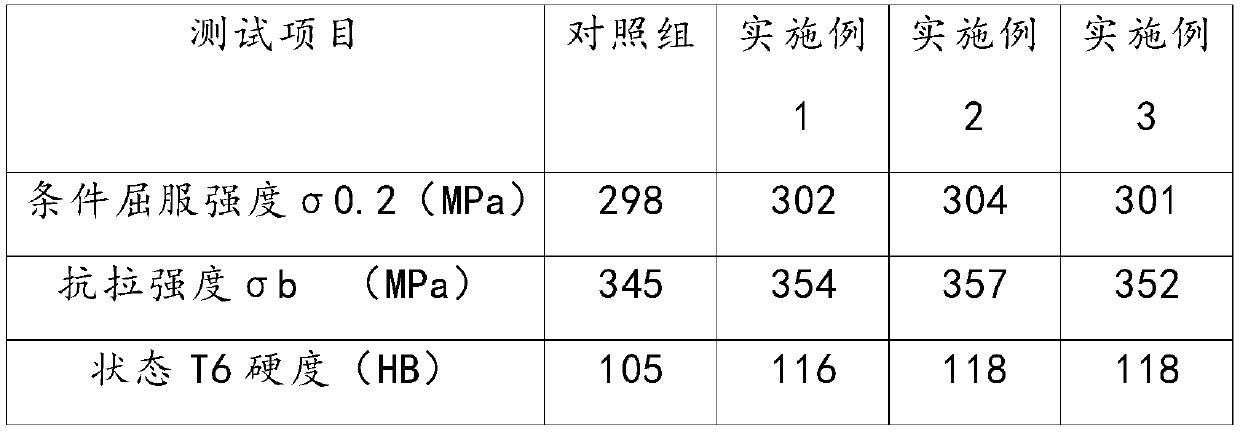

Aluminum alloy for new energy automobile battery case and production process thereof

The invention relates to the metallurgy field, in particular to an aluminum alloy for a new energy automobile battery case and a production process thereof. By weight percent, the aluminum alloy product consists of elements of 3.4-5.1 of Zn, 2.3-2.7 of Mg, 1.7-1.9 of Cu, 0.3-0.8 of Fe, 0.1-0.4 of Mn, 0.1-0.3 of Si, 0.15-0.26 of Cr, 0.12-0.15 of Ti, the balance Al and inevitable impurities. The preparation process includes multiple procedures of refining, filtering, casting, calendaring, homogenization treatment, artificial aging, hot static pressure treatment and the like. The aluminum alloy sheet produced by using the production process is characterized by being high in tensile strength and yield strength, large in hardness and excellent in fatigue resistance, and is suitable for manufacture of the new energy automobile battery case.

Owner:山东创新精密科技有限公司

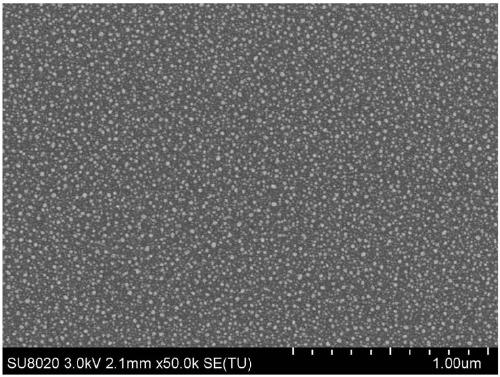

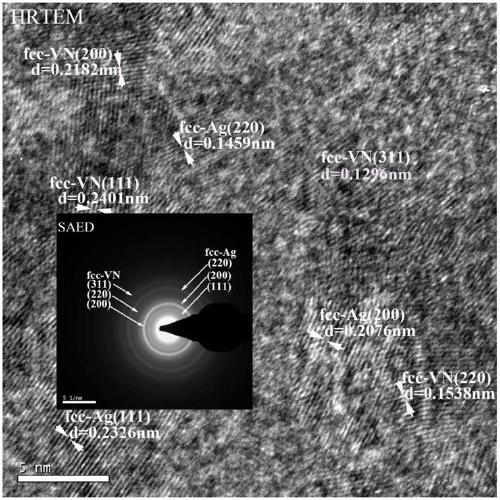

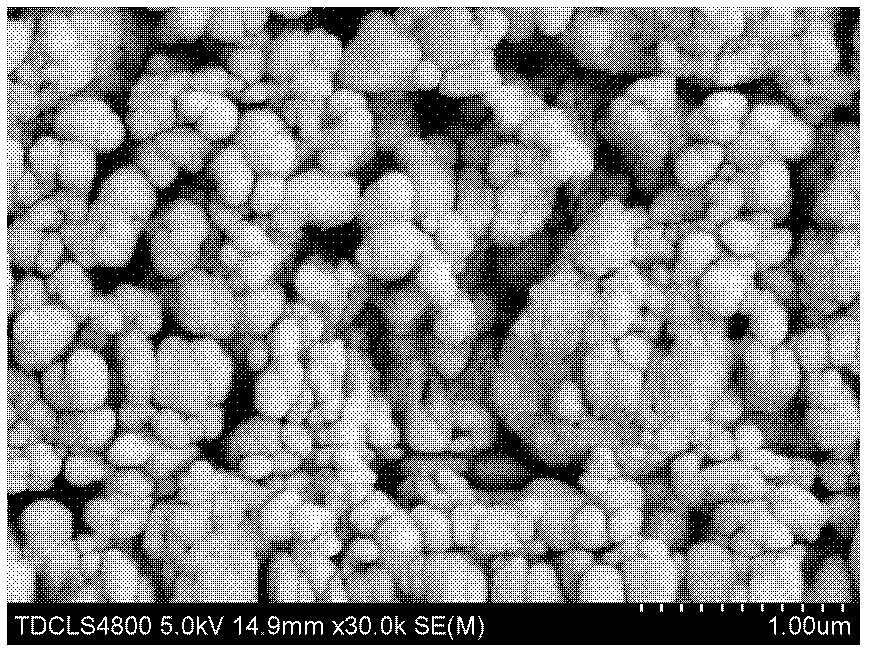

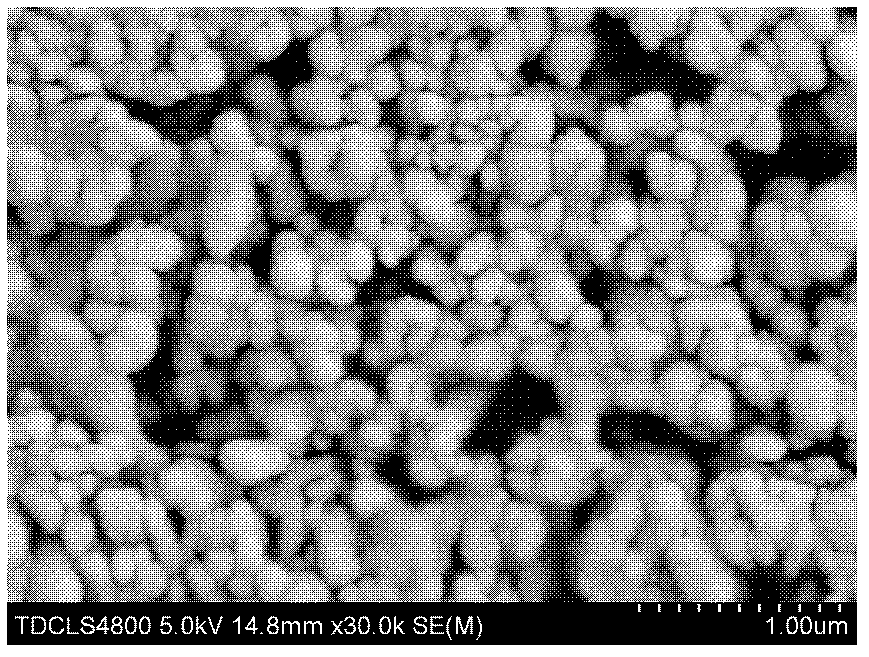

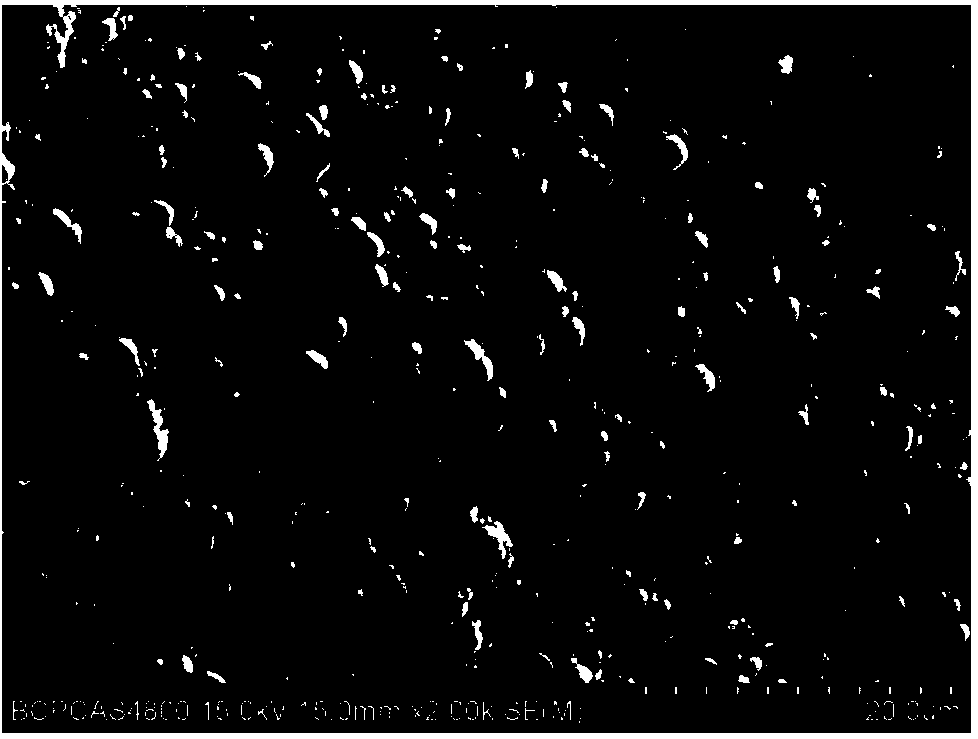

Preparation method for VN/Ag wide-temperature-area lubricating composite films

InactiveCN109628892AUniform and dense microstructureEffective anti-friction lubricationVacuum evaporation coatingSputtering coatingFriction reductionComposite film

The invention discloses a preparation method for VN / Ag wide-temperature-area lubricating composite films; and aiming at a single-beam pulse laser deposition system, VN / Ag composite films meeting a chemical metering ratio are prepared by one step through a target assembly process. The prepared composite films have uniform and compact microscopic structures; Ag particles with sizes of 10-20 nm are uniformly embedded in VN basal bodies; Ag is used as low / medium-temperature lubricating phases, and high-temperature friction chemical reaction products of vanadium oxide and silver vanadate are used as medium / high-temperature lubricating phase to realize continuous lubrication within a range from room temperature to 900 DEG C; and the friction coefficient in the range from room temperature to 900DEG C is maintained within 0.08-0.3, so that the effective anti-friction lubricating effect is achieved. The preparation method prepares the composite films with continuous and reliable lubricity; andthe preparation process is simple, and can be widely applied to wear resistance and friction reduction of mechanical parts under a wide temperature area.

Owner:LANZHOU CITY UNIV

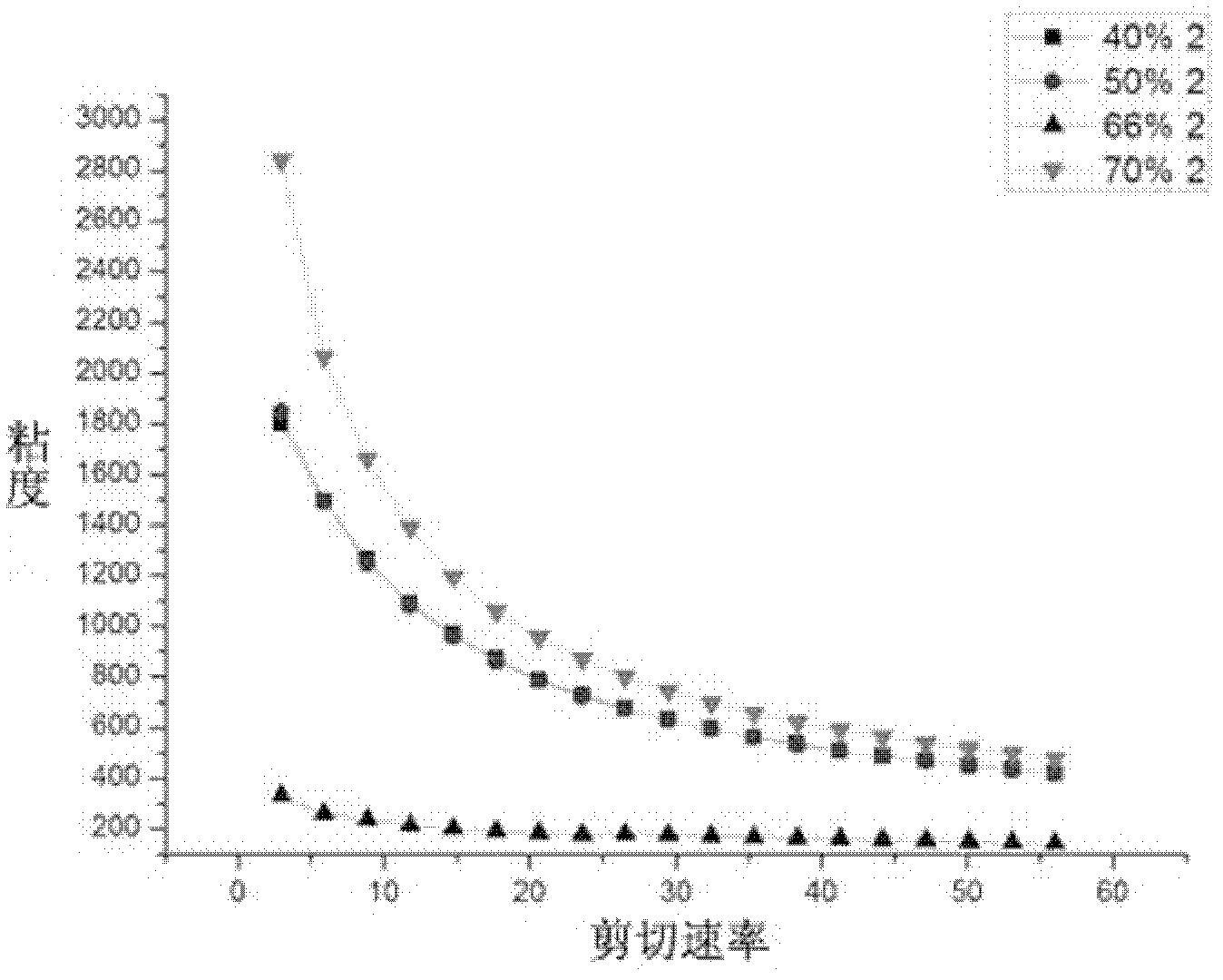

Method for preparing BST-MgO (barium strontium titanate-magnesium oxide) based ceramic tape-casting slurry and blanks

InactiveCN102408232AImproved rheological propertiesLow viscosityBarium strontium titanatePolyethylene glycol

The invention relates to a method for preparing BST-MgO (barium strontium titanate-magnesium oxide) based ceramic tape-casting slurry and blanks, which is characterized in that through the selection of organic additives and the pretreatment of powder and the like, the reaction between B2O3 and PVB in a formula is restrained, then, a tape-casting slurry system which is moderate in viscosity and good in liquidity is obtained, and finally, a BST-MgO tape-casting blank which is good in structure and performance is prepared. The method provided by the invention is implemented according to the following technical scheme: through taking ethanol-xylene as a solvent, polyvinyl butyral (PVB) as an adhesion agent, polyethylene glycol (PEG) as a dispersant and dibutyl phthalate (DBP) as a plasticizer, BST-MgO based tape-casting slurry taking B2O3-Li2CO3 as a sintering assistant is prepared, and finally, a high-quality tape-casting blank is formed for laying an application foundation for LTCC (low temperature co-fired ceramic) devices. The slurry prepared by using the method disclosed by the invention is good in rheological properties and low in viscosity; and the blank prepared by using the method disclosed by the invention is uniform and compact in microstructure, and the strength of the blank is suitable for machining needs.

Owner:TIANJIN UNIV

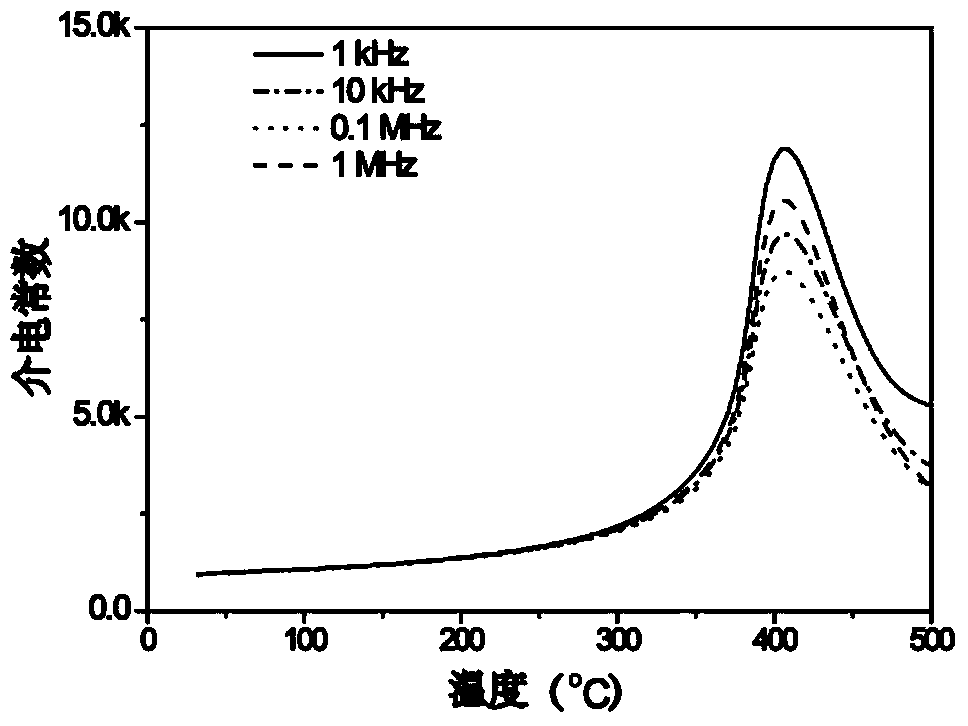

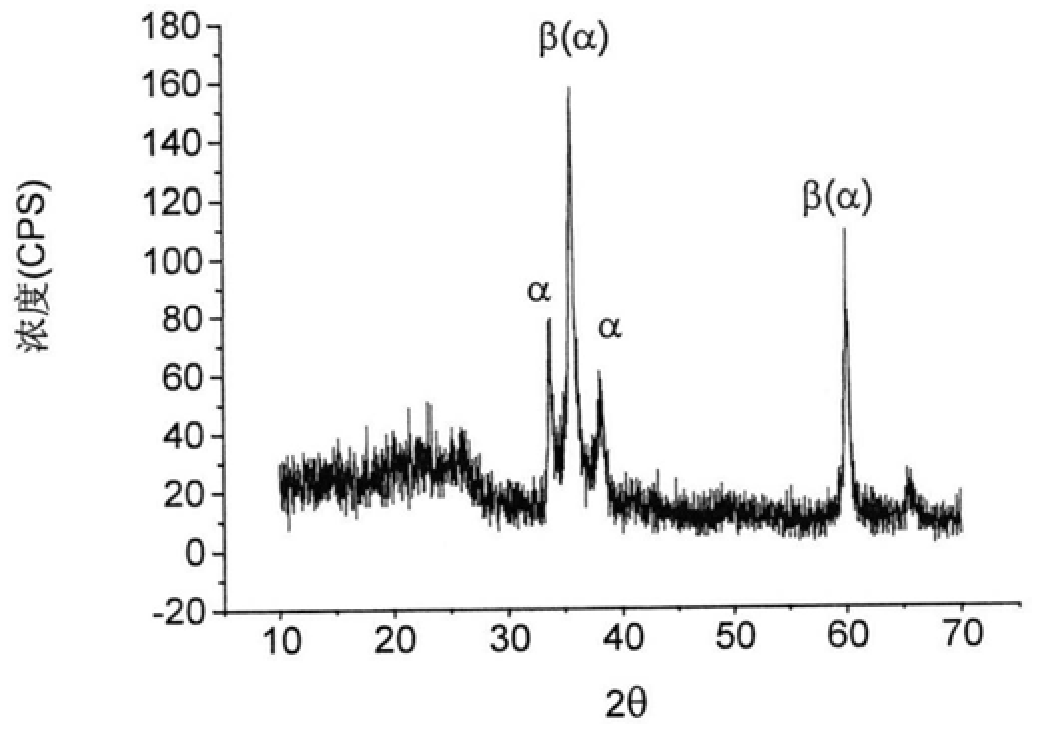

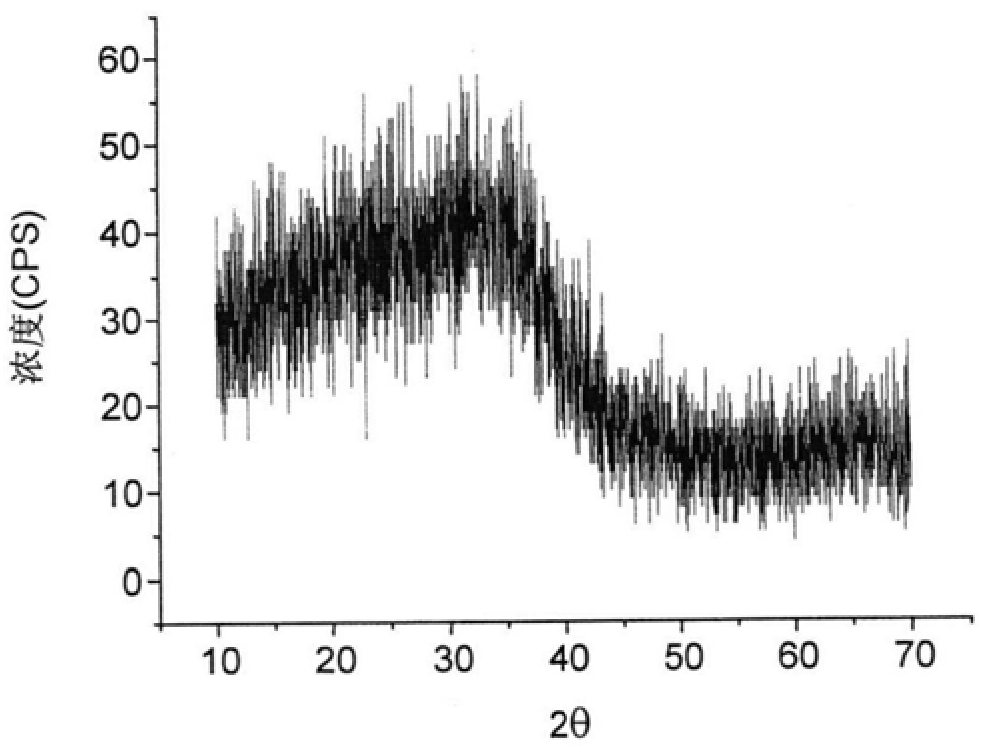

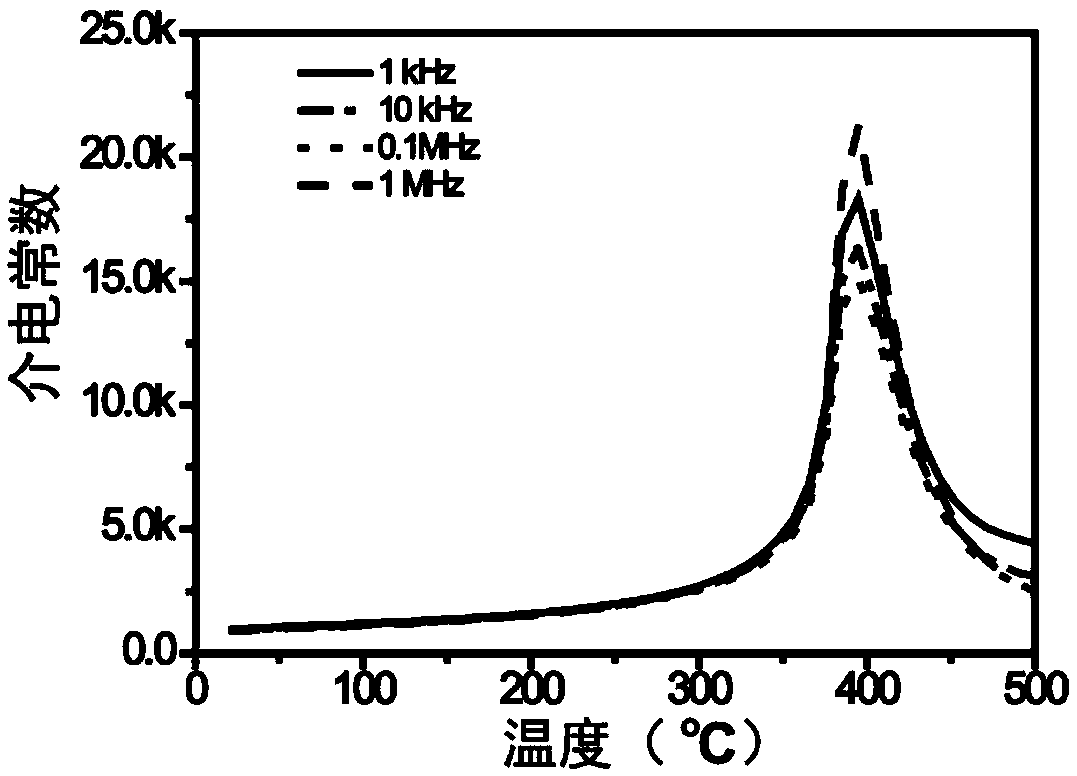

Chemical preparation method of doped composite high-Curie-temperature piezoelectric ceramic

The invention relates to a chemical preparation method of doped composite high-Curie-temperature piezoelectric ceramic. The general formula of the ceramic material is (1-x)(0.1BiYbO3-0.9PbTiO3)-xPbZrO[3-y]Me, wherein x=0.3-0.6, y=0.0005-0.05, and Me is Cr or Mn. The method comprises the following steps: by using salts of bismuth, ytterbium, lead, zirconium, manganese, chromium and titanium as initial raw materials, preparing a uniform solution by using the appropriate dispersion medium and chelator and controlling temperature, concentration and other technical parameters; drying, calcining, carrying out ball milling and drying to prepare nano powder; and granulating, pelleting, sintering, coating silver, and polarizing to obtain the required piezoelectric ceramic. The preparation method has the advantages of stable technique, favorable repetitiveness, low cost, low sintering temperature and the like. The ceramic material prepared by the method is compact and uniform, has the advantages of higher Curie temperature (390-410 DEG C), higher piezoelectric constant (250-370 pC / N), variable mechanical quality factor (50-500) within a wide range, and lower dielectric loss (0.005-0.03), and can satisfy different piezoelectric device demands. The piezoelectric ceramic has favorable application prospects.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

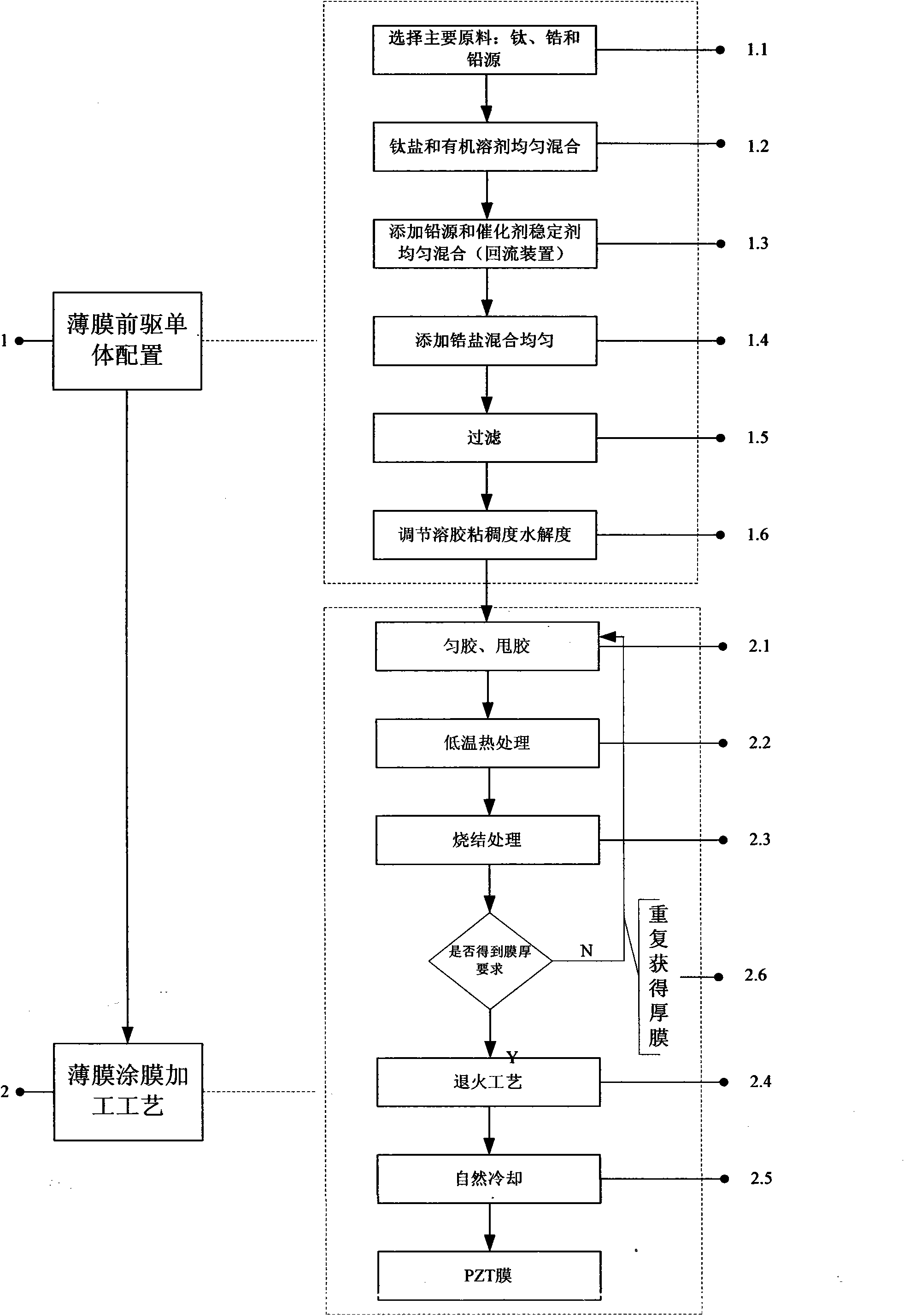

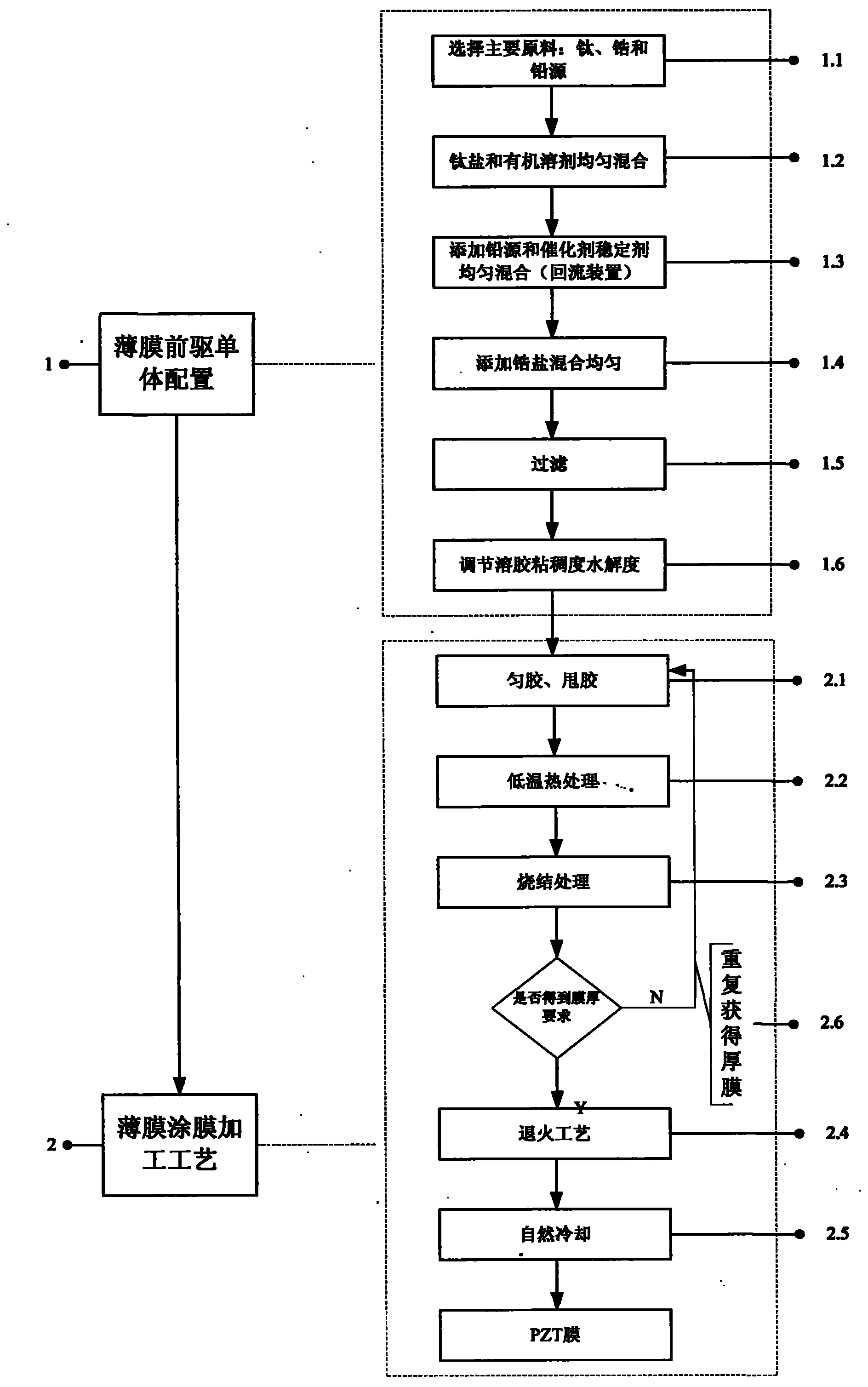

Technology for processing audio directional loudspeaker film

The invention provides technology for processing an audio directional loudspeaker film, namely technology for processing a PZT piezoelectric film. The processing technology comprises preparation of a PZT solution precursor monomer and coating of the PZT film, and mainly comprises the following steps of: selecting titanium salt, zircon salt, lead acetate raw materials and an organic solvent; mixing a certain amount of titanium salt and a certain amount of organic solvent, and heating and uniformly stirring to form solution A; adding a certain amount of lead acetate, catalyst and stabilizing agent into the solution A, and heating and uniformly stirring under the action of a condensation and reflux device to form solution B; adding a certain amount of zircon salt into the solution B, and heating and uniformly stirring to form solution C; filtering the solution C to obtain PZT sol; adding an additive into the sol to adjust viscosity and hydrolyzing degree; dripping the PZT sol onto an SI substrate or an Si\SiO2\Si3N4\Pt\Ti structure substrate, and performing sol smoothening and sol throwing to obtain a substrate A; performing low temperature heat treatment on the substrate A to obtain a substrate B; sintering and annealing the substrate B to obtain substrates C and D; and naturally cooling the substrate D to room temperature to obtain a single-layer PZT film. The processing technology is mature in technique, the process equipment is simple, the cost is low, vacuum is not needed, an even film can be prepared on a large-area substrate; meanwhile, the temperature of the heat treatment is low, so the stoichiometric ratio of the film is easily controlled; and the technology can be compatible with the micro electronic technique, and can meet the requirement of an audio directional loudspeaker on an inorganic piezoelectric film with a crystalline structure to some extent.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

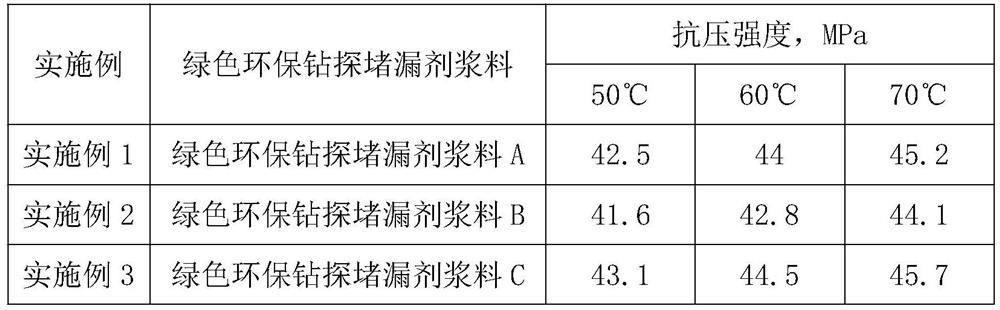

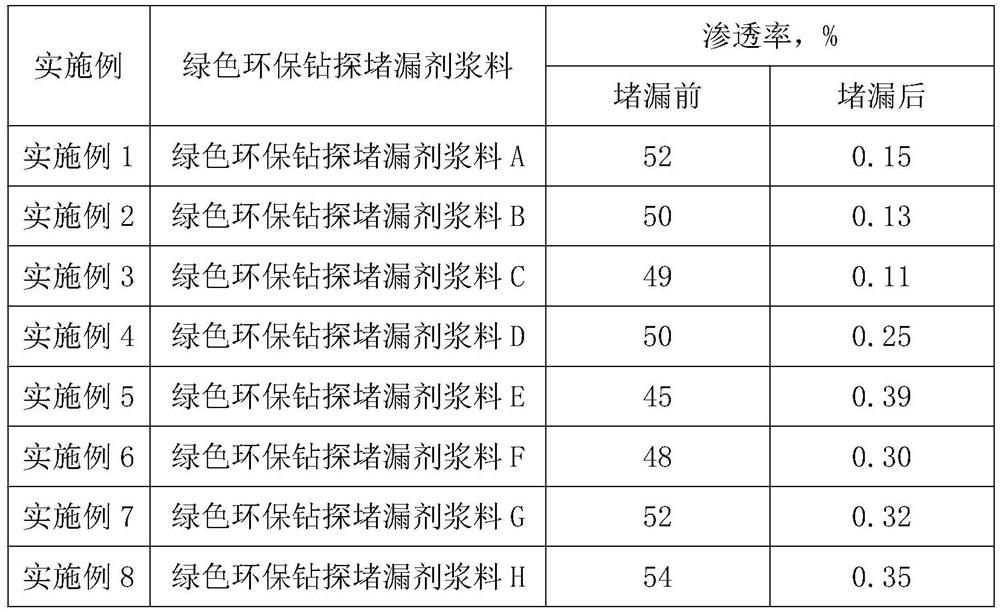

Green and environment-friendly drilling plugging agent and using method thereof

InactiveCN112694871AHigh chemical activityFine and uniform particlesDrilling compositionFiberNano silicon

The invention relates to the technical field of petroleum and natural gas, in particular to a green and environment-friendly drilling plugging agent and a using method thereof. The green and environment-friendly drilling plugging agent is prepared from cement, nano silicon oxide, nano calcium carbonate, hollow microspheres, elastic sponge particles, flexible graphite, asbestos fibers, a retarder, a fluid loss agent and sodium hydroxide; according to the inorganic gel plugging agent taking the inorganic gel material cement as the main raw material provided by the invention, a three-dimensional network structure taking a nano material as a core is generated, and meanwhile, a bridging effect is generated through the elastic sponge particles and the asbestos fibers, so that the technical problem of poor plugging effect of a cement-based material plugging agent in the prior art is solved; the plugging agent is an environment-friendly plugging agent material.

Owner:中煤地一七三勘探队涿州有限责任公司

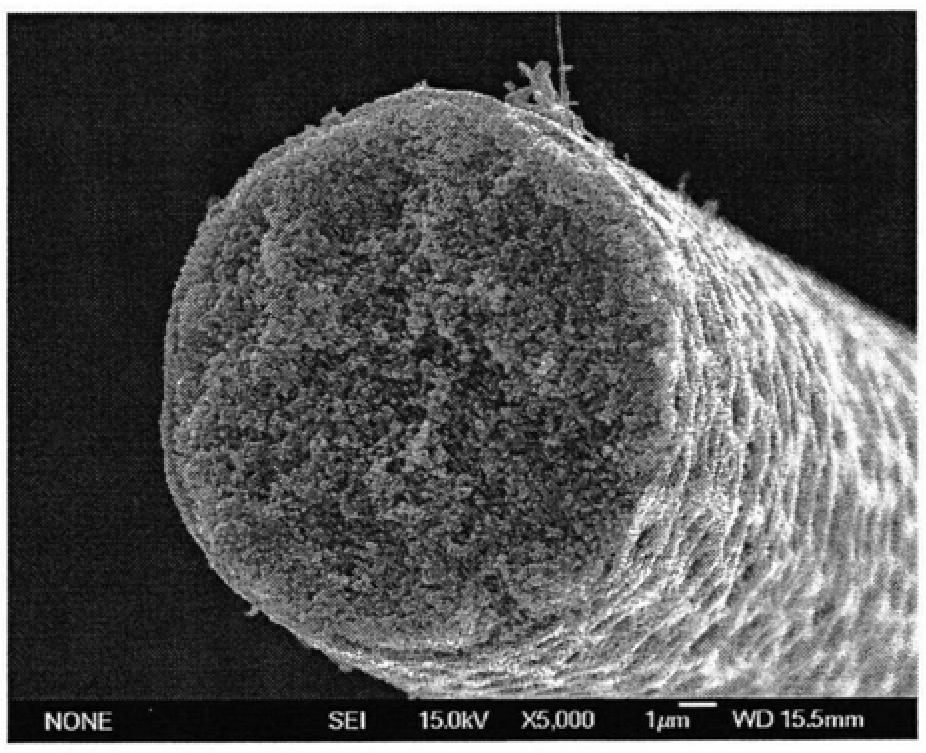

A treatment method for improving the service temperature and performance of silicon carbide fiber

ActiveCN106342085BWell crystallizedUniform and dense microstructureInorganic material artificial filamentsAfter treatmentPyrolysis

The invention relates to a treatment method for improving the use temperature and performance of SiC fibers, which is characterized in that two treatment methods are used, one of which is to immerse commercially available SiC fibers in a 15-35vol% organic polymer solution and dry After winding on the graphite tube, heat treatment in a high-temperature furnace at 30-200Mpa, 1600-2000°C in an argon atmosphere, so that the carbon formed by the pyrolysis of the organic polymer and the SiO decomposed by the SiC fiber under high temperature and low pressure are in situ Reaction to generate SiC; another method is to directly wind SiC on the graphite cylinder, and use the same heat treatment conditions as described in the first method to make free carbon in the fiber react with SiO in situ to generate SiC. The characteristics of the present invention avoid SiC fiber Degradation at high temperature leads to performance attenuation, and the oxygen content of the SiC fiber drops from 21wt% to 5wt% after being treated by the method provided by the invention.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Chemical preparation method of piezoelectric ceramic with high Curie temperature of composite system

The invention provides a preparation method of piezoelectric ceramic with high Curie temperature of a composite system. The method comprises the following steps: burdening salts of bismuth, ytterbium, lead, zirconium and titanium as initial raw materials according to the chemical composition of (1-x)(0.1BiYbO3-0.9PbTiO3)-xPbZrO3 (x=0.3-0.6), and then preparing a stable solution by selecting a proper dispersing medium combined with chelation of a stabilizer; forming uniform sol from metal salts by controlling the process conditions such as temperature, concentration and feeding order; concentrating, drying and fully burning to prepare nanoscale piezoelectric ceramic fine powder, so as to pellet, press, discharge and sinter the required piezoelectric ceramic. The preparation method of the high-temperature piezoelectric ceramic of the composite system provided by the invention has the advantages of low preparation temperature, low cost, good repeatability, and uniform and stable sample performance, and has a wide application prospect, and the comprehensive electrical properties can be greatly improved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

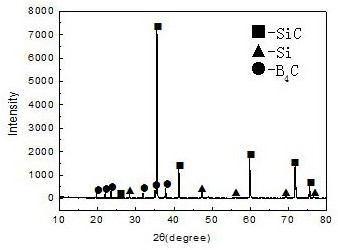

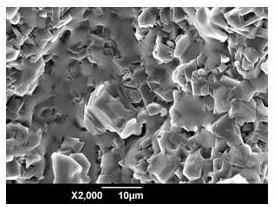

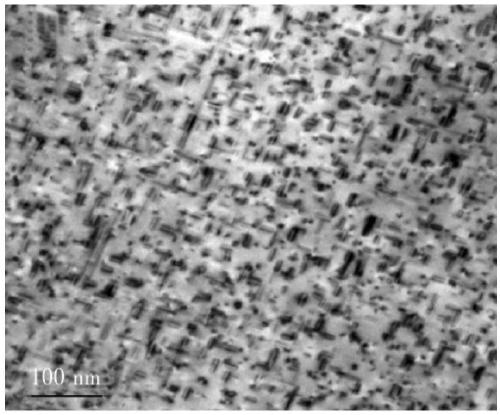

B4C-SiC-Si composite material generated by siliconizing reaction of B4C/graphite preform, and preparation method of B4C-SiC-Si composite material

A B4C-SiC-Si composite material generated by a siliconizing reaction of aB4C / graphite preform comprises the following components: boron carbide ceramic powder; graphite powder; a phenolic resin binder; and silicon powder. A preparation method of the composite material comprises the following steps: step 1, mixing the boron carbide ceramic powder and the graphite powder into a mixed material; step 2, loading the mixed material into a ball milling tank, adding absolute ethyl alcohol and agate grinding balls, carrying out ball milling to obtain slurry, and drying to obtain a B4C / graphite composite powder; step 3, adding the phenolic resin binder, absolute ethyl alcohol and the agate grinding balls into the B4C / graphite composite powder, performing wet ball milling and mixing in a ball milling tank to prepare slurry, and drying to prepare B4C / graphite mixed powder; step 4, loading the B4C / graphite mixed powder obtained in the step 3 into a steel mold, and drying the B4C / graphite mixed powder to obtain a strip-shaped sample prefabricated blank; and step 5, putting the strip-shaped sample prefabricated blank into a graphite crucible, covering the surface of the strip-shaped sample prefabricated blank with coarse silicon powder, and performing high-temperature siliconizing to obtain the B4C-SiC-Si composite material. The composite material has the characteristics of high hardness, wear resistance, high-temperature oxidation resistance, simple preparation process and low cost.

Owner:XI'AN PETROLEUM UNIVERSITY

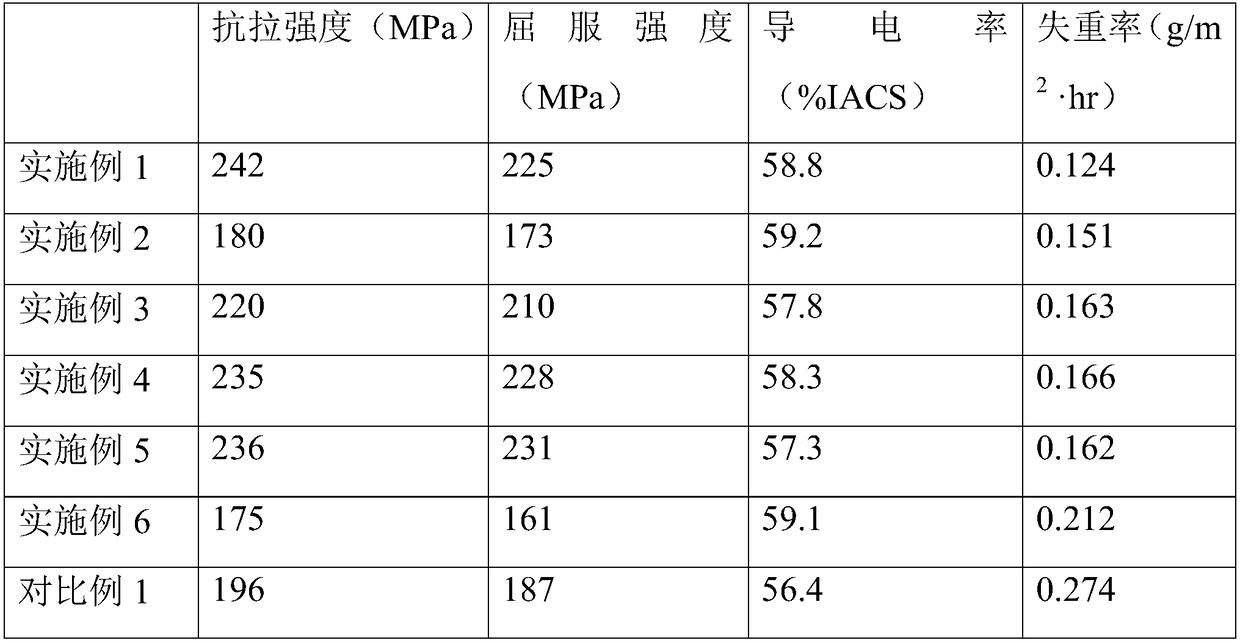

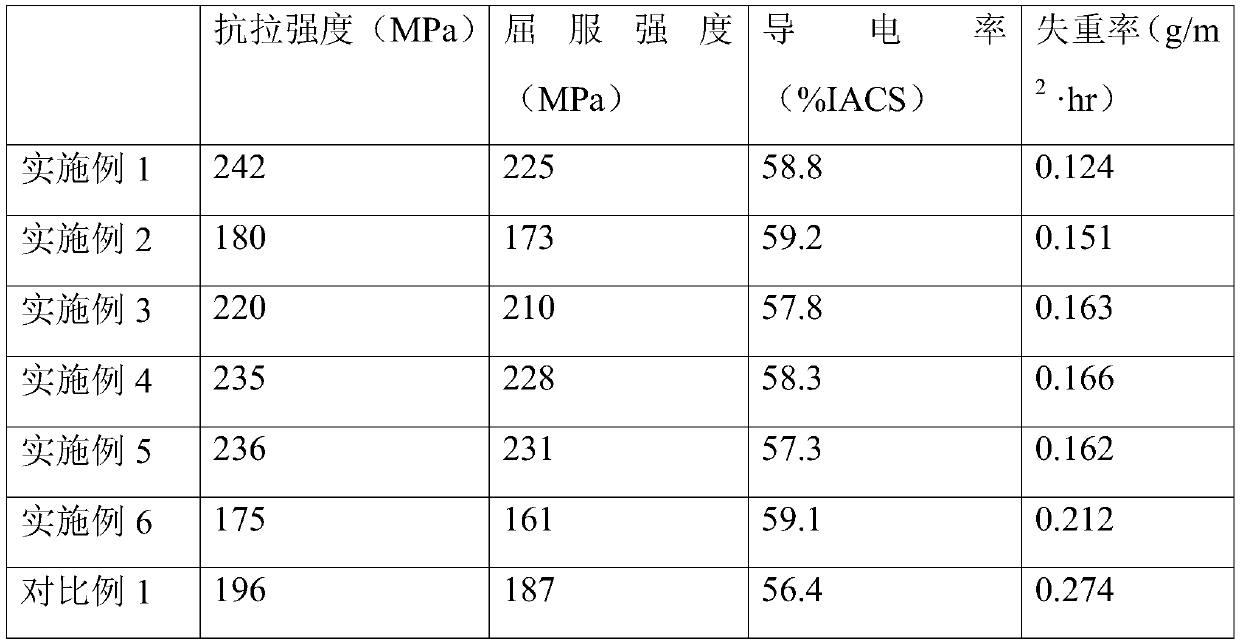

High-conductivity corrosion-resistant aluminum alloy and preparation method thereof

ActiveCN109161738AHigh conductivity and corrosion resistanceEnhanced interfacial strain energyHigh conductivityImpurity

The invention relates to the technical field of aluminum alloys, and particularly relates to a high-conductivity corrosion-resistant aluminum alloy and a preparation method thereof. The aluminum alloycomprises the following elements by weight percentage: 0.3-0.6% of Si, 0.6-0.9% of Mg, 0.01-0.04% of B, 0.01-0.02% of Ti, 0.005-0.01% of Sr, 0.001-0.005% of Pr, 0.02-0.1% of Er, 0.2-0.4% of Fe, 0.01-0.02% of Mn, 0.01-0.02% of Cr, 0.005-0.015% of Zr, 0.02-0.05% of Cu, 0.03-0.07% of Zn and the balance of aluminum and unavoidable impurities. The aluminum alloy is relatively high in tensile strength(240 MPa or more than 240 MPa), yield strength, electric conductivity (58% or more than 58%) and corrosion resistance.

Owner:东莞市东兴铝业有限公司

A kind of atmospheric pressure sintering preparation method of feal/tic composite material

The invention relates to a preparation method for sintering a FeAl / TiC composite material under normal pressure, which comprises the following steps: 1) employing a mechanical alloying technology to prepare FeAl intermetallic compound powder; 2)poforming a high temperature hot treatment process on the FeAl intermetallic compound powder; wherein the ball-milling time of the mechanical alloying technology is 60 hours, the heat treatment temperature is 800 DEG C, and the insulation time is 1 hour; 3)mixing the prepared FeAl intermetallic compound powder and TiC powder to prepare the FeAl / TiC composite powder, and preparing a bar-shaped sample through compression moulding, and 4)performing a sintering process under normal pressure, wherein the sintering temperature is 1600 DEG C, insulating for 2 hours, and preparing the FeAl / TiC composite material bulk under normal pressure by the sintering process. According to the invention, the melting point of the FeAl intermetallic compound is 1250-1400 DEG C, when the sintering temperature is 1600 DEG C, the FeAl intermetallic compound is molten to be a liquid phase, the molten FeAl intermetallic compound and TiC particles are sintered together to form a compact sintering bulk. The preparation method has the advantages of low preparation cost, simple technology and suitability for large-scale industrial production.

Owner:XI'AN PETROLEUM UNIVERSITY

Preparation method of lead-tin-based solder alloy and prepared solder alloy

ActiveCN111996413AUniform and dense microstructureExcellent overall performanceWelding/cutting media/materialsSoldering mediaGraphiteRaw material

The invention discloses a preparation method of a lead-tin-based solder alloy. The preparation method comprises the following steps that (1), powder preparing is carried out, specifically, the following raw material of, in percentage by weight, 45-60% of Sn powder, 25-35% of Pb powder, 10-25% of In powder, 1.5-5% of Bi powder, 0.02-0.08% of Tb powder, 0.1-0.7% of Zr powder, 0.7% of Fe powder and the balance of Se powder are mixed; and (2), sintering is carried out, specifically, the mixed powder is put into a graphite mold, pre-pressing is carried out, the pre-pressed mold is put into a sparkplasma sintering furnace, vacuumizing is carried out, the sintering pressure is 50 Mpa, the heating rate is 45 DEG C / min, the temperature is raised to 520 DEG C, then heat preservation is carried outfor 5 min, and after furnace cooling, lead-tin-based solder alloy is prepared. The invention further provides the solder alloy prepared by the preparation method. The lead-tin-based solder alloy has the beneficial effects that the microstructure of the lead-tin-based solder alloy is uniform and compact, the wettability of the solder alloy is improved, and the lead-tin-based solder alloy has a lowmelting point.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

A kind of aluminum alloy with high conductivity and corrosion resistance and preparation method thereof

ActiveCN109161738BHigh conductivity and corrosion resistanceEnhanced interfacial strain energyUltimate tensile strengthHigh conductivity

Owner:东莞市东兴铝业有限公司

A kind of high vanadium high chromium type vanadium titanium magnetite pellets

ActiveCN107267748BGuaranteed outputQuality assuranceBlast furnace detailsMagnetiteBlast furnace smelting

A high-vanadium and high-chromium vanadium-titanium magnetite pellet belongs to the field of blast furnace smelting technology in the comprehensive utilization method of high-vanadium and high-chromium vanadium-titanium magnetite. The chemical composition and mass percentage of the high-vanadium and high-chromium vanadium-titanium magnetite pellets are: V2O5: 0.45-0.62%, TiO2: 2.29-3.20%, Cr2O3: 0.22-0.48%, TFe: 61.88-64.22 %, CaO: 0.11~0.63%, SiO2: 3.18~4.77%, MgO: 0.32~0.89%, Al2O3: 1.62~4.0%, the balance is unavoidable impurities; among them, in TFe, Fe2O3 accounts for pellet mass percentage: 87.51~91.41%, FeO accounts for 0.3~0.8% of the pellet mass. The ratio of raw materials used to prepare pellets, the bentonite ratio is reduced by more than 1%, and the pellet grade is improved; the quality of green pellets is effectively improved, and the output and quality of pellets are guaranteed.

Owner:NORTHEASTERN UNIV LIAONING

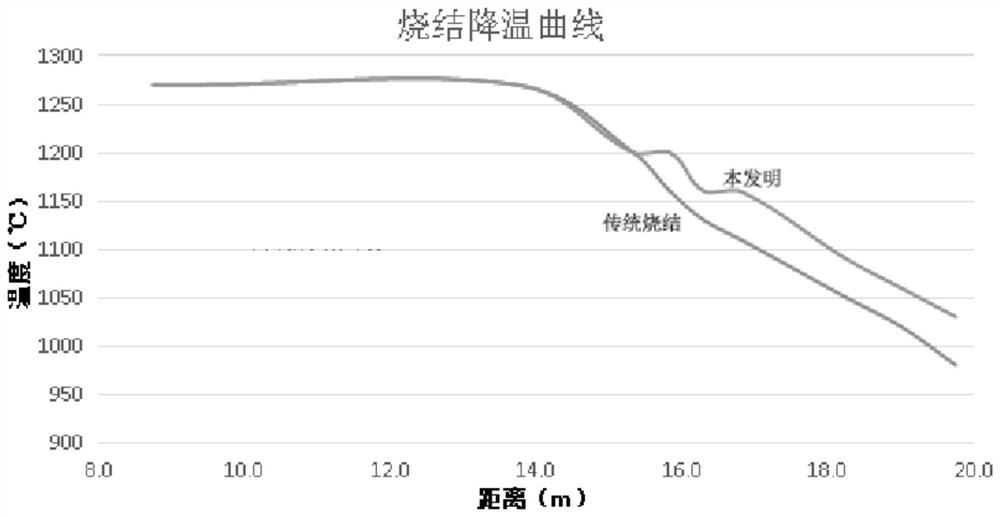

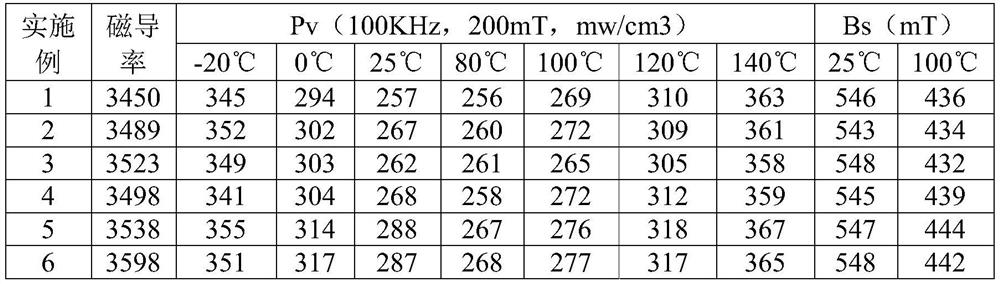

A kind of soft magnetic material and its preparation method and application in automotive electronic system

ActiveCN110436911BUniform and refined grain distributionControl grain boundary porosityInorganic material magnetismInductances/transformers/magnets manufactureElectronic systemsPhysical chemistry

The invention discloses a soft magnetic material, a preparation method thereof and an application in an automobile electronic system. Soft magnetic materials include main components and subcomponents, where the main component includes Fe 2 o 3 , MnO, ZnO, the mass percent of the secondary components is: CaCO 3 , V 2 o 5 , Nb 2 o 5 , SnO 2 ,Co 2 o 3 ,TiO 2 , ZrO 2 , NiO. The present invention obtains a material with low loss and high saturation magnetic flux at -20-140°C by setting specific components and their content ratios, the loss index has better wide temperature characteristics, and has high saturation magnetic flux Density, soft magnetic materials in the preparation process through the optimization of the powder ratio and the special segmental cooling sintering process, the performance of ultra-wide temperature, low power consumption and high saturation magnetic flux density is achieved. The product has wide temperature adaptability and can cope with the global The environment with large temperature difference is widely used in the field of automotive electronic systems to ensure stability.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

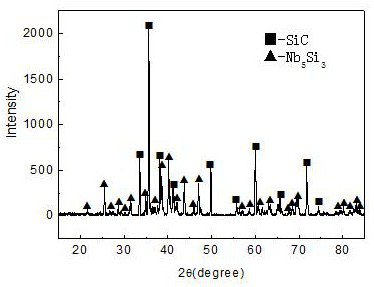

Nb5Si3/SiC composite material and hot pressed sintering preparation method thereof

An Nb5Si3 / SiC composite material comprises the following components that in the Nb5Si3 / SiC composite material, an Nb5Si3 intermetallic compound is used as a reinforcing and toughening phase, and SiC is used as a matrix, wherein the mass fraction of the Nb5Si3 intermetallic compound in the Nb5Si3 / SiC composite material is 10wt%-60wt%. A hot pressed sintering preparation method of the Nb5Si3 / SiC composite material comprises the steps that firstly, Nb-Si intermetallic compound powder is prepared through a mechanical alloying technology, wherein the molar ratio of Nb to Si is 63:37; Nb5Si3 intermetallic compound powder is prepared through a high-temperature heat treatment technology, wherein the ball-milling time of the mechanical alloying process is 60 hours, the heat treatment temperature is 800-1200 DEG C, and the heat preservation time is 1 hour, so that the Nb5Si3 intermetallic compound powder is prepared; the prepared Nb5Si3 intermetallic compound powder and SiC powder are mixed to prepare Nb5Si3 / SiC composite powder, the Nb5Si3 / SiC composite powder is subjected to a hot pressed sintering process, the hot pressed sintering temperature is 1600 DEG C, the pressure is 35 MPa, and the heat preservation time is 2 h; and an Nb5Si3 / SiC composite material block is prepared through the hot pressed sintering process, the Nb5Si3 / SiC composite material block prepared by the hot pressed sintering process has the advantages of high preparation efficiency and simple preparation process, the Nb5Si3 / SiC composite material product can be rapidly sintered and manufactured, and the Nb5Si3 / SiC composite material prepared by the hot pressed sintering process has high density and high mechanical properties.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com