Method for preparing BST-MgO (barium strontium titanate-magnesium oxide) based ceramic tape-casting slurry and blanks

A magnesia-based ceramics, casting slurry technology, applied in the field of electronic materials, can solve the problems affecting the electrical properties of the sintered body, the uneven microstructure of the green sheet, and the increase of the viscosity of the slurry, so as to achieve uniform and dense microstructure and suitable strength. , the effect of suppressing the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Casting powder pretreatment:

[0023] (1) Use an electronic balance to weigh 30gBST, 30gMgO, 0.45gB 2 o 3 and 2.25gLi 2 CO 3 .

[0024] (2) Put the weighed powder into a ball mill jar, add 110 ml of ethanol and 150 zirconia grinding balls, and use a planetary ball mill for 4 hours.

[0025] (3) Put the ball-milled slurry into a tray, put it into an oven, and dry it at 80°C.

[0026] (4) Grinding the dried powder and passing through a 100-mesh sieve.

[0027] (5) The powder is put into an electric furnace, and calcined at a temperature of 700° C., with a heating rate of 3° C. / minute, and kept for 2 hours.

[0028] 2. Preparation of cast slurry

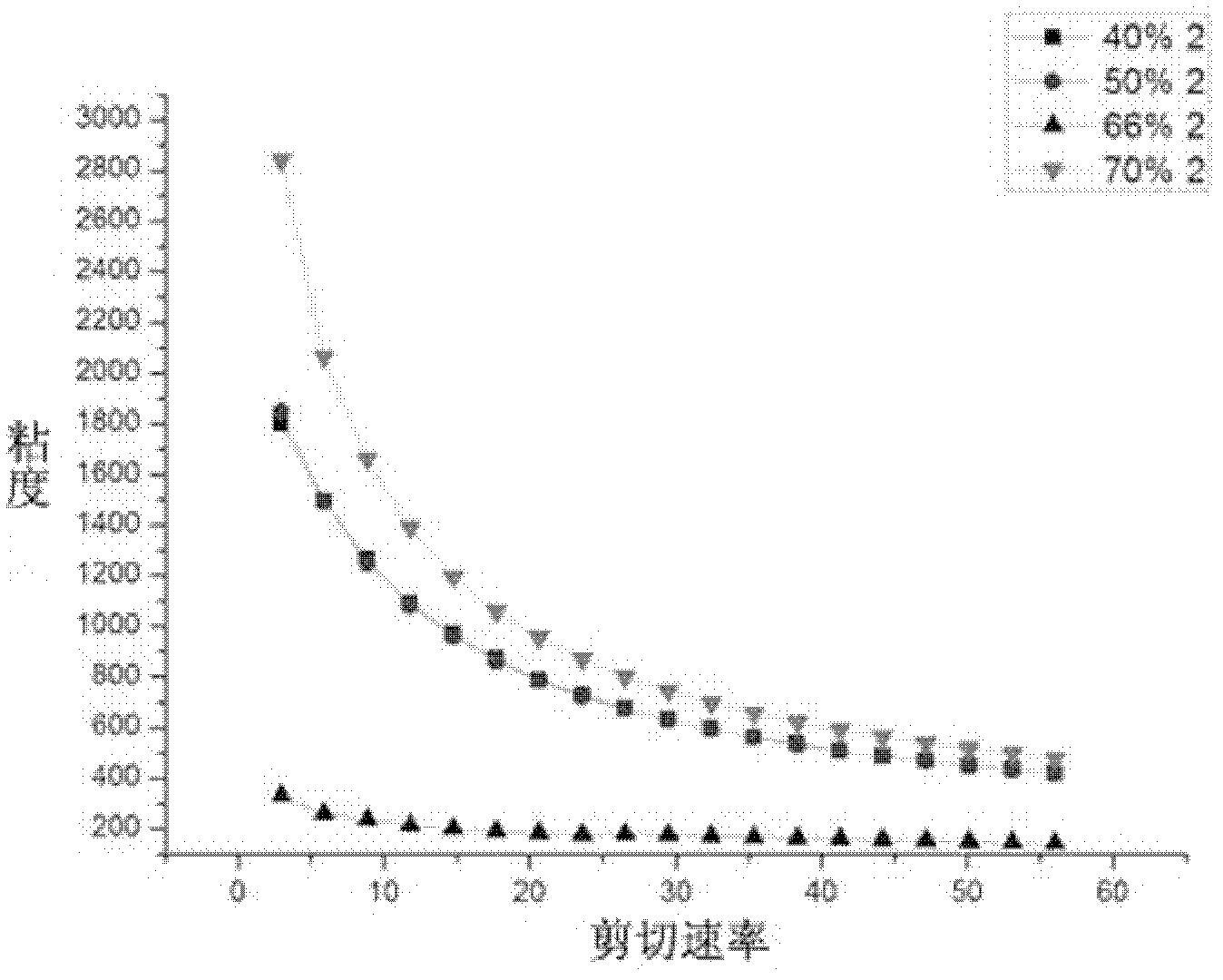

[0029] (1) Use an electronic balance to weigh 11.19g ethanol and 27.975g xylene solution and mix them evenly, then add 0.525gPVB to the mixed solution, ultrasonic treatment for 20 minutes, after the PVB dissolves, add 30g casting powder, and use planetary Ball milling for 4 hours. A primary casting slurry with a visco...

Embodiment 2

[0036] 1. Casting powder pretreatment:

[0037] The preparation process steps are the same as in Example 1, except that the powder ball milling time in (2) is 5 hours, the calcination temperature in (5) is 750° C., and the holding time is 1.5 hours.

[0038] 2. Preparation of cast slurry

[0039] (1) Weigh 11.04g of ethanol and 16.56g of butanone solution with electronic balance and mix them evenly, then add 0.3g of PVB to the mixed solution, ultrasonic treatment for 20 minutes, after the PVB is dissolved, add 30g of casting powder, and use planetary Ball milling for 4 hours. A primary casting slurry with a viscosity of 20 mPa·s was obtained.

[0040](2) Add 1.2gPVB binder, 0.45gPEG and 0.45gDBP to the primary casting slurry, and use a rolling ball mill for ball milling for 24 hours, and finally age the slurry for 50 hours to obtain a flow that exhibits shear thinning fluid characteristics Extension slurry.

[0041] 3. Preparation of cast blanks

[0042] (1) Pour the aged...

Embodiment 3

[0046] 1. Casting powder pretreatment:

[0047] The preparation process steps are the same as in Example 1, except that the powder ball milling time in (2) is 6 hours, the calcination temperature in (5) is 800° C., and the holding time is 1 hour.

[0048] 2. Preparation of cast slurry

[0049] (1) Use electronic balance to weigh 11.34g ethanol and 17.01g butanone solution and mix them evenly, then add 0.6gPVB to the mixed solution, ultrasonic treatment for 20 minutes, after PVB dissolves, add 30g casting powder, and use planetary Ball milling for 4 hours. A primary casting slurry with a viscosity of 20 mPa·s was obtained.

[0050] (2) Add 0.6gPVB binder, 0.225gPEG and 0.225gDBP to the primary casting slurry, and use a rolling ball mill for ball milling for 24 hours, and finally age the slurry for 16 hours to obtain a flow that exhibits shear thinning fluid characteristics Extension slurry.

[0051] 3. Preparation of cast blanks

[0052] (1) Pour the aged final tape castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com