Crystalline silicon solar cell front silver paste and preparation method thereof

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of loose sintered film structure, poor storage and transportation stability, and poor continuous printing stability of nano-silver powder, and achieves high electrode adhesion strength and large grid line morphology. , the effect of uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of glass powder

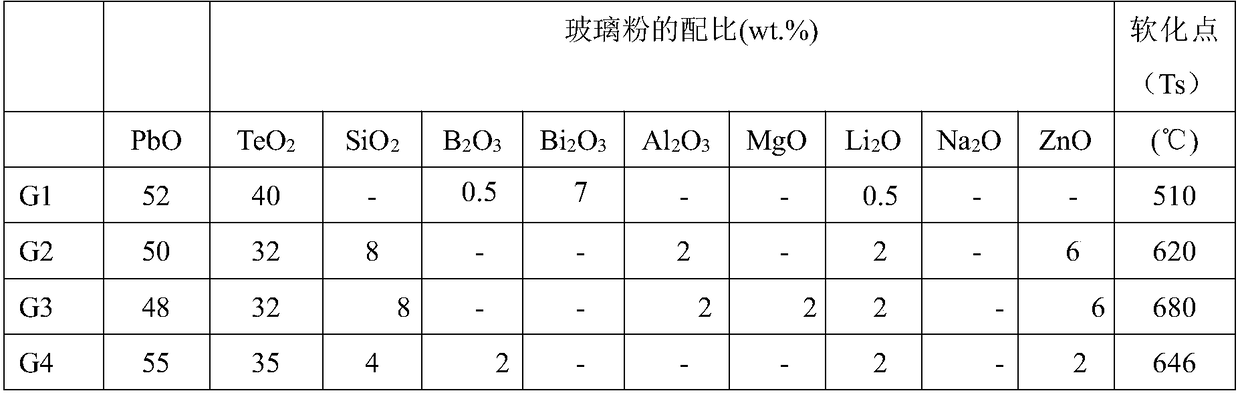

[0031] Use the following glass powder components to prepare glass powder, and use DSC to measure the softening point. The proportion and softening point of glass powder are shown in Table 1.

[0032] Table 1 Proportion and softening point of glass frit

[0033]

[0034] (1) Preparation of glass powder

[0035] The glass powder G1 consists of the following components and mass percentages: 52% of PbO, 40% of TeO 2 , 0.5% B 2 o 3 , 7% Bi 2 o 3 , 0.5% Li 2 O.

[0036] The preparation method is as follows: mix the components of the glass powder evenly, then put them into a crucible, and then heat the crucible in an electric furnace for melting at 1200°C and keep it warm for 30 minutes; immediately pour the melted glass into water for quenching , drying the water-quenched glass frit; sieving the dried glass frit by planetary ball milling to obtain a glass powder with a particle size D50 of 0.2-2 μm, to obtain a glass powder G1.

[003...

Embodiment 1

[0047] A front silver paste of a crystalline silicon solar cell, its composition and weight percentage are: 88% silver powder, 3% composite glass powder, 8.95% organic carrier, 0.05% rhodium 2-ethylhexanoate; composite glass The powder is mixed with 2.5% glass powder G1 and 0.5% glass powder G2.

[0048] Organic vehicle preparation: take by weighing ethyl cellulose 200 and 2.5% ethyl cellulose 300, 35% terpineol, 25% butyl carbitol, 25% butylated Carbitol acetate, 4% methyl silicone oil, 0.5% polyvinyl chloride, 0.5% polyacrylamide, heated and stirred at 100°C to obtain an organic vehicle;

[0049] Taking by weighing 30% of the total mass of the silver powder D50 is 1.0 μm, the D50 of 32% of the total mass of the silver powder is 1.5 μm, and the D50 of 38% of the total mass of the silver powder is 2.2 μm spherical or nearly spherical silver powder, 8.95% organic carrier, 3 % compound glass powder, 0.05% rhodium 2-ethylhexanoate, stir evenly, roll through a three-roller machin...

Embodiment 2

[0051] A front silver paste for a crystalline silicon solar cell, the composition and weight percentage of which are: 90% silver powder, 1.5% composite glass powder, 7.5% organic vehicle, 0.5% silicon dioxide, 0.5% carbon black; The composite glass powder is mixed with 0.5% glass powder G1 and 1.0% glass powder G2.

[0052] Preparation of organic vehicle: Weigh 7.5% ethyl cellulose 200, 2.5% ethyl cellulose 300, 10% acrylic resin NeoCryl B-723, 35% dibutyl phthalate, which occupy 7.5% of the total mass of organic vehicle raw materials , 30% tributyl citrate, 14% DBE, 0.5% F3100, 0.5% polyacrylamide, heated and stirred at 50°C to obtain an organic vehicle;

[0053] D50 accounting for 75% of the total mass of the silver powder is 1.5 μm, D50 accounting for 25% of the total mass of the silver powder is 1.0 μm spherical or nearly spherical silver powder, 7.5% organic carrier, 1.5% composite glass powder, 0.5% silicon dioxide, 0.5 The % carbon black is stirred evenly, rolled by a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com