Printing technology of knotless screen

A kind of technology without mesh and screen, applied in screen printing machine, printing, printing machine and other directions, can solve the problems of cumbersome production process, slow output and other problems, to improve efficiency, optimize the aspect ratio, and avoid the obstruction of mesh The effect of ink permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

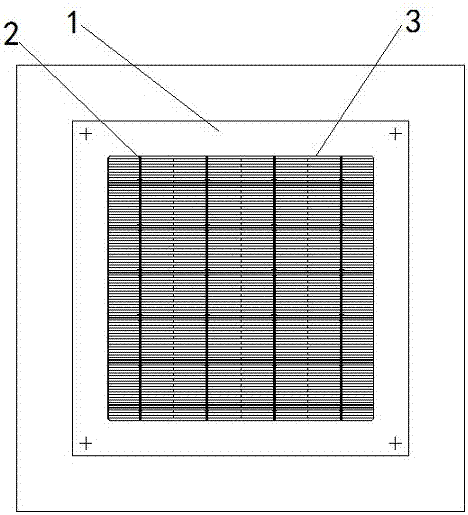

[0019] figure 1 It is a schematic diagram of the mechanism of the knotless screen plate according to the embodiment of the present invention.

[0020] The invention describes a printing process of a knotless screen plate. The knotless screen plate includes a screen frame 1, and several warp threads 2 and weft threads 3 are fixed in the screen frame 1. The warp threads arranged in parallel 2 and then vertically interweave with the parallel weft 3, the warp 2 and weft 3 intersect to form a square and / or rectangular shape, the contact between the warp 2 and the weft 3 is bonded and fixed, the warp 2 and the weft 3 The two ends are fixed on the screen frame 1, and a printing pattern is arranged in the middle of the screen frame 1. The printing is carried out with fine line printing silver paste, wherein the width of the warp 2 and weft 3 is 30 microns.

[0021] The warp 2 and weft 3 are metal wires, and the warp 2 and weft 3 are hot-pressed and positioned with a hot-melt adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com