Solar cell front conductive silver paste and preparation method thereof

A technology of solar cells and conductive silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of low mass production and yield, and achieve excellent control ability, Excellent fine-line ink penetration, optimized compatibility and lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

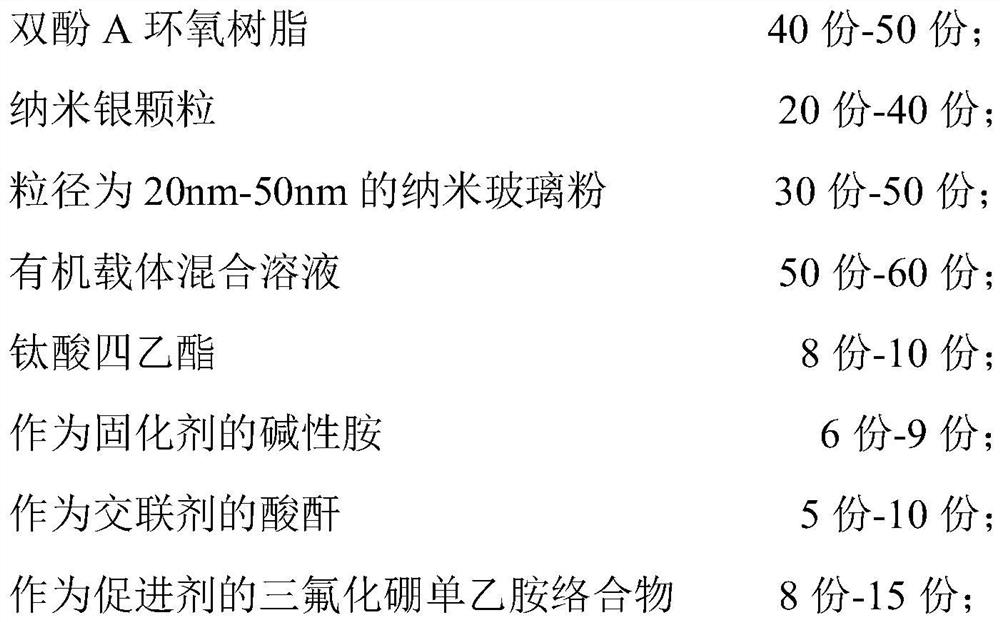

[0040] The present embodiment provides a kind of solar cell positive conductive silver paste, the preparation material of described conductive silver paste, by weight, comprises the following components:

[0041]

[0042]

[0043] The organic carrier mixed solution includes dodecylbenzenesulfonic acid doped polyfuran / epoxy soybean oil with a mass fraction concentration of 15%, and butyl soluble anhydride acetate with a mass fraction concentration of 85%.

[0044] Wherein, the preparation method of dodecylbenzenesulfonic acid doped polyfuran / epoxy soybean oil comprises the following steps:

[0045] M1: Mix 4 parts of aniline and 15 parts of dodecylbenzenesulfonic acid in 300 parts of distilled water, and stir at 200 rpm for 60 minutes at 0°C to form a mixed solution;

[0046] M2: Slowly add 12 parts of ammonium persulfate and 12 parts of polyfuran to the mixed solution obtained in the M1 step, so that the molar ratio of ammonium persulfate, dodecylbenzenesulfonic acid and...

Embodiment 2

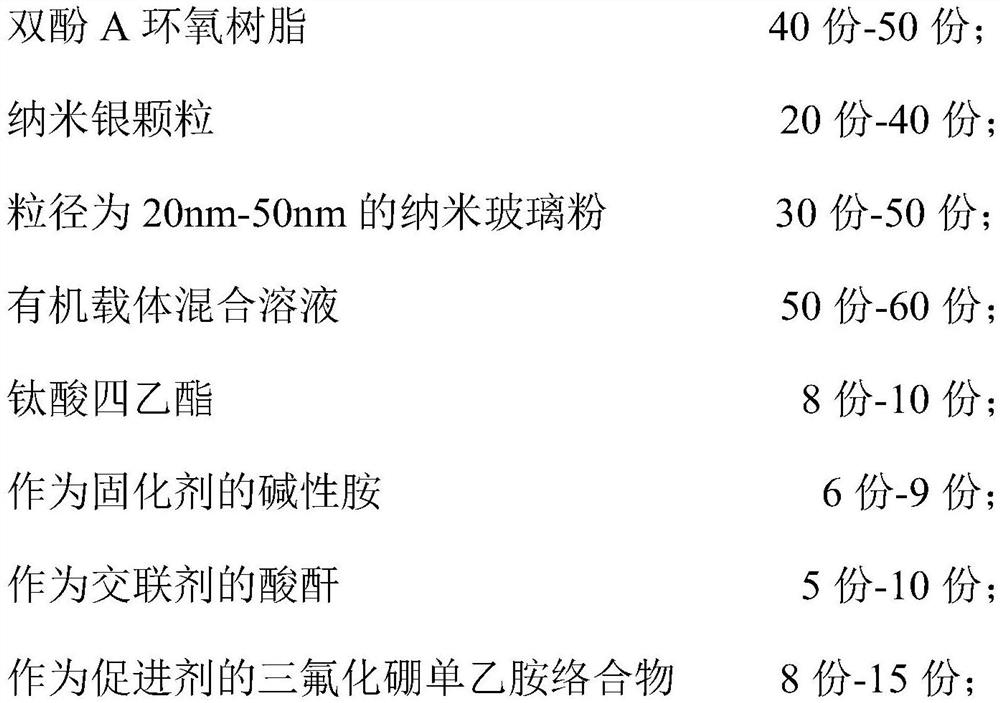

[0061] The present embodiment provides a kind of solar cell positive conductive silver paste, the preparation material of described conductive silver paste, by weight, comprises the following components:

[0062]

[0063] The organic carrier mixed solution includes camphorsulfonic acid doped polyacetylene / epoxy soybean oil with a mass fraction concentration of 20%, and diethylene glycol ethyl ether acetate with a mass fraction concentration of 80%.

[0064] Wherein, the preparation method of camphorsulfonic acid doped polyacetylene / epoxy soybean oil comprises the following steps:

[0065] M1: Mix 5 parts of aniline and 12 parts of camphorsulfonic acid in 250 parts of distilled water, and stir at 2°C for 50 minutes at 220 rpm to form a mixed solution;

[0066] M2: Slowly add 10 parts of ammonium persulfate and 15 parts of polyacetylene to the mixed solution obtained in the M1 step, so that the molar ratio of ammonium persulfate, camphorsulfonic acid and polyacetylene is 0.75...

Embodiment 3

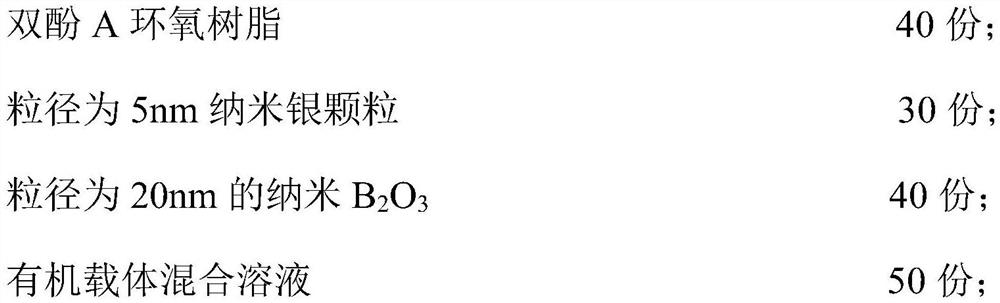

[0081] The front conductive silver paste of a solar cell provided in this embodiment, the preparation material of the conductive silver paste, in parts by weight, includes the following components:

[0082]

[0083] The organic carrier mixed solution includes p-toluenesulfonic acid doped poly-p-phenylene / epoxy soybean oil with a mass fraction concentration of 18%, and diethylene glycol butyl ether acetate with a mass fraction concentration of 82%.

[0084] Wherein, the preparation method of described p-toluenesulfonic acid doped poly-p-phenylene / epoxy soybean oil comprises the following steps:

[0085] M1: Mix 7 parts of aniline and 10 parts of p-toluenesulfonic acid in 200 parts of distilled water, and stir at 250 rpm for 45 minutes at 4°C to form a mixed solution;

[0086]M2: Slowly add 15 parts of ammonium persulfate and 10 parts of poly-p-phenylene to the mixed solution obtained in the M1 step, so that the molar ratio of ammonium persulfate, p-toluenesulfonic acid and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com