Patents

Literature

89results about How to "Improve welding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superplastic forming/diffusion bonding forming method for heat-resistant titanium alloy envelope

ActiveCN106271439AHigh strengthIncrease stiffnessWelding apparatusTitanium alloyUltimate tensile strength

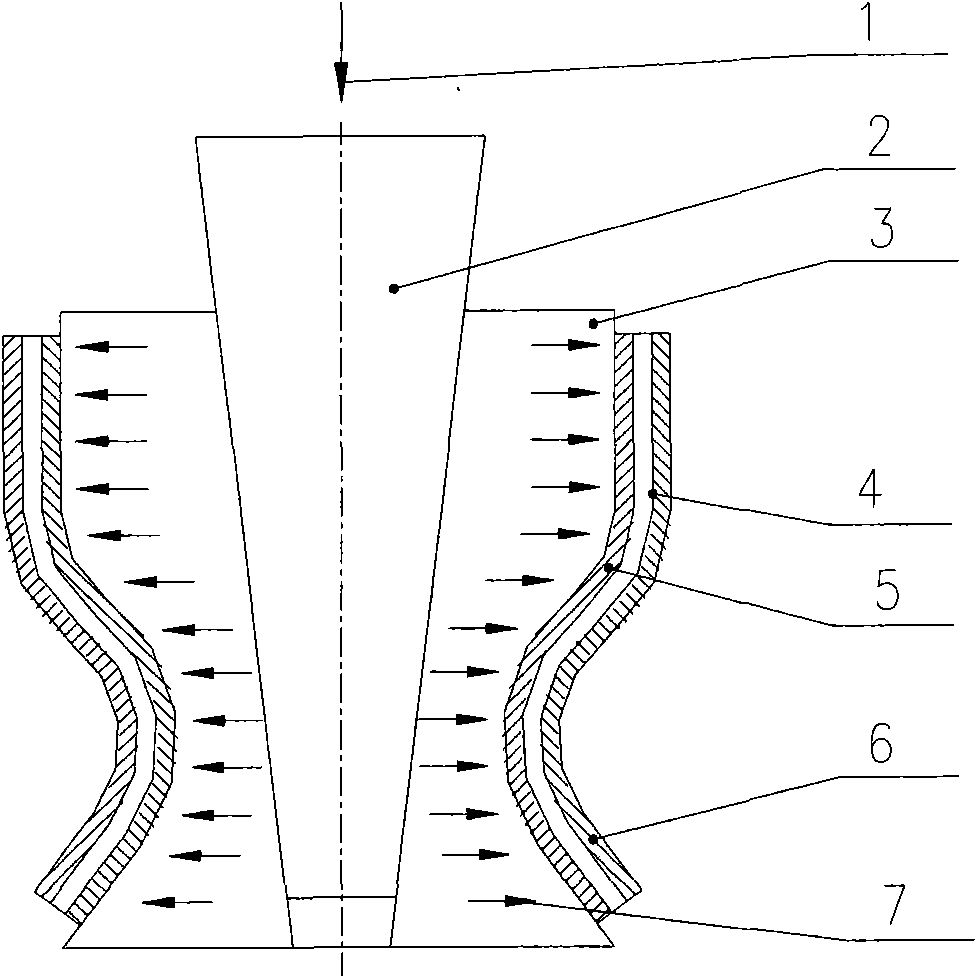

The invention belongs to the technical field of metal plastic processing, and aims at providing a superplastic forming / diffusion bonding forming method for a heat-resistant titanium alloy envelope with high material utilization ratio, high dimension control precision and high product performance. As a mould is adopted to control the appearance and dimension of a workpiece, the forming of a titanium alloy workpiece provided with a complex profile is completed, the production process of the heat-resistant envelope workpiece is shortened, and production cost is lowered; as the process of diffusion bonding followed by superplastic forming is adopted, the diffusion bonding is realized at the contact part of an inner envelope and an outer envelope, and the superplastic forming is realized at a separated part, the once-formed heat-resistant envelope with the complex profile and a hollow structure has the advantages of greatly improved structural integrity of a component, enhanced specific strength and specific stiffness of the component and increased welding rate of the diffusion bonding; the processed workpiece has the advantages of high dimension accuracy, high integral performance, light weight and the like; and the method disclosed by the invention has the advantages of shortened processing period, high material utilization ratio and lowered production cost.

Owner:北京普惠三航科技有限公司

Preparing method for porous metal matrix compound brazing filler metal alloy soldering head

ActiveCN104191057ASuitable for brazingHigh strengthSoldering apparatusThermal dilatationUltrasonic vibration

The invention discloses a preparing method for a porous metal matrix compound brazing filler metal alloy soldering head. The method adopts porous metal matrix compound brazing filler metal alloy filled up with brazing filler metal alloy, a compound brazing filler metal layer is prefabricated between hard base metal, then the brazing filler metal alloy filled into the porous metal layer is heated to melt, and a tool head of an ultrasonic vibrating device acts on the surface of the base metal and exerts certain-pressure certain-time ultrasonic vibration on the surface of the base metal to finish a brazing process. When the method is used for preparing the brazing soldering head, the porous metal with high melting point can have a supporting function to a soldering seam layer in a brazing soldering process, the liquid-phase brazing filler metal alloy is prevented from being extruded out excessively in the ultrasonic vibration action. Thus, the preparation of the brazing soldering head with a large fuse face is achieved. In addition, the porous metal layer in the brazing seam layer can reduce the thermal expansion coefficients of the brazing seam layer, and the strength of the brazing seam layer and the strength of the connection interface between the brazing seam layer and the base metal are improved.

Owner:CHINA NAT ELECTRIC APP RES INST +1

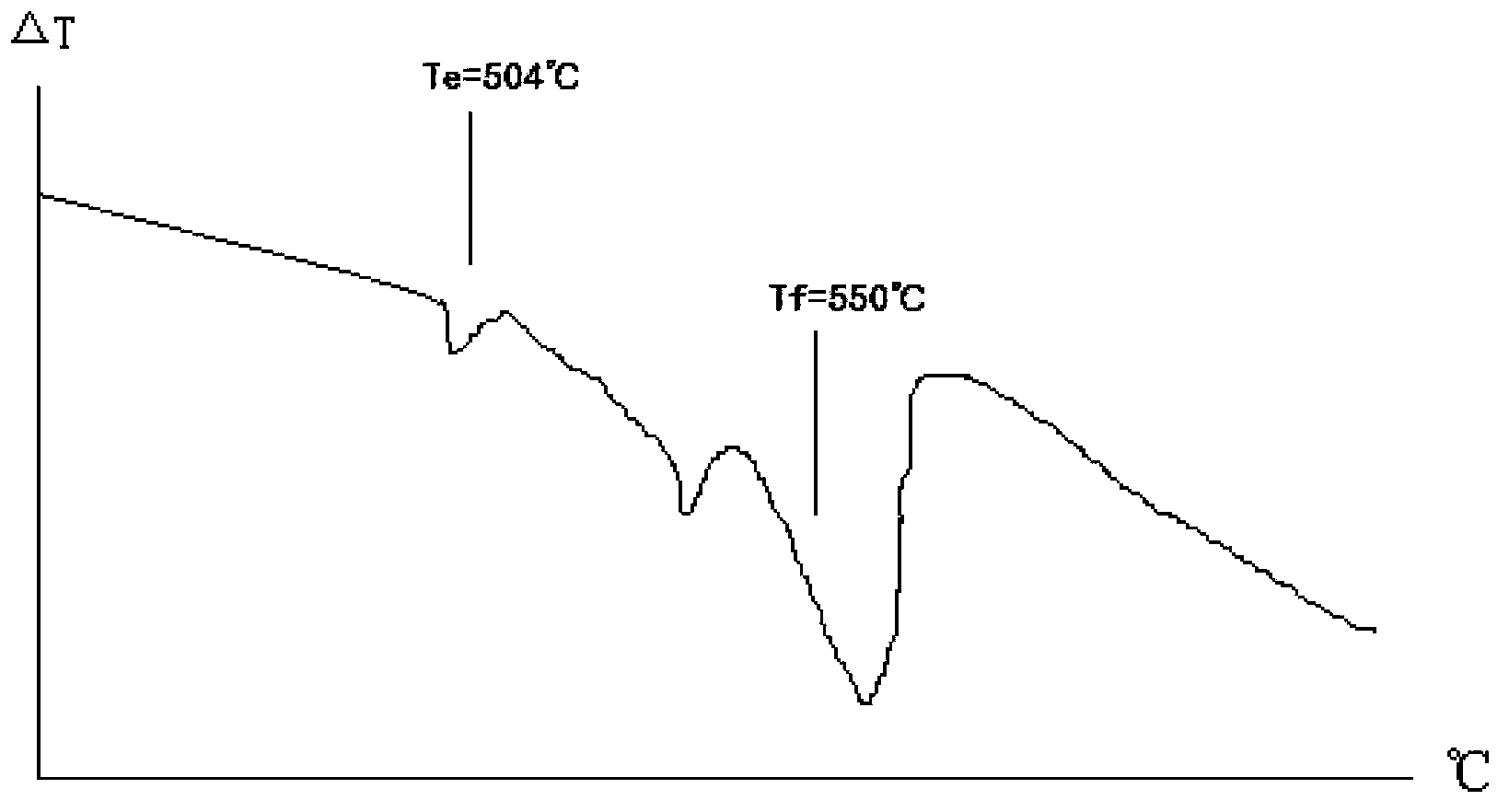

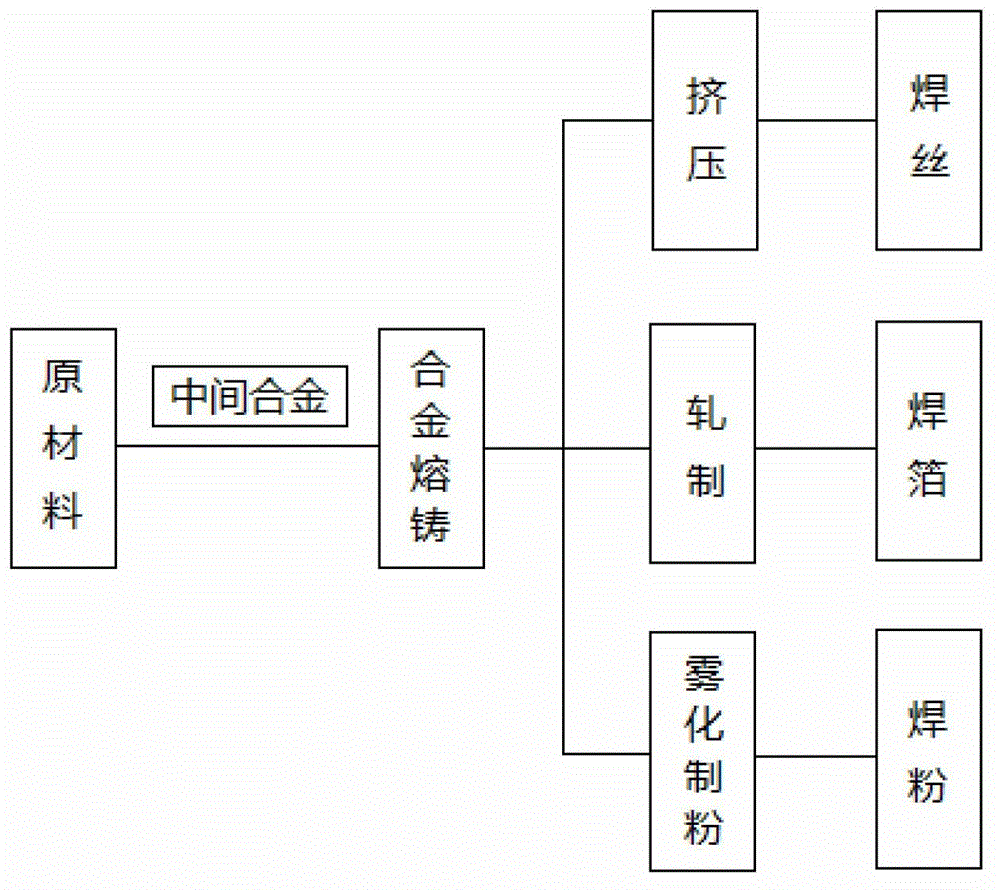

Al-Si-Cu-Mg aluminum-base alloy foil solder and preparation method thereof

ActiveCN103567655AGood brazing processImprove wettabilityWelding/cutting media/materialsSoldering mediaSolderingUltimate tensile strength

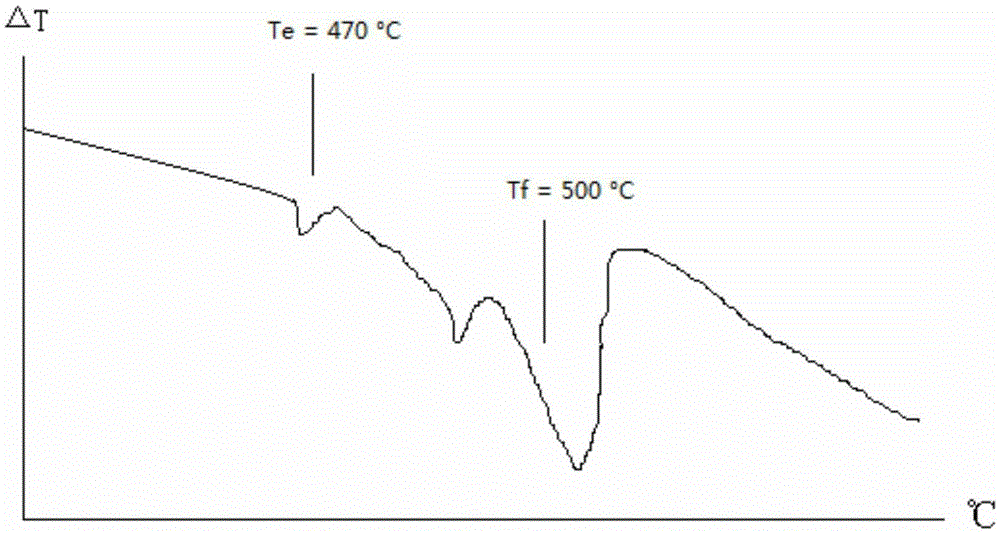

Al-Si-Cu-Mg aluminum-base alloy foil solder and a preparation method thereof are mainly applied to vacuum soldering of aluminum alloy. The solder is made with 10.5-13.5wt% of Si, 3.5-5.5wt% of Cu, 1.0-2.2wt% of Mg, and the balance of Al. The solder is low in melting temperature, good in soldering efficiency, good in wetting property, higher than 85% in welding area ratio, not smaller than 100MPa in weld tensile strength alpha b, not smaller than 50MPa in shear strength tau, and applicable to medium-temperature or graded vacuum soldering of various aluminum alloys such as 3A21, 2A50, 6063 and 6061. The preparation method includes: preparation of materials, preparation of intermediate alloy, alloy casting, heat treatment, hot extrusion, rolling and the like. The preparation method is simple and is convenient for batch production. The foil solder 0.10mm in thickness and 320mm in width prepared by the method is better applicable to vacuum soldering of large-sized aluminum alloy components.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

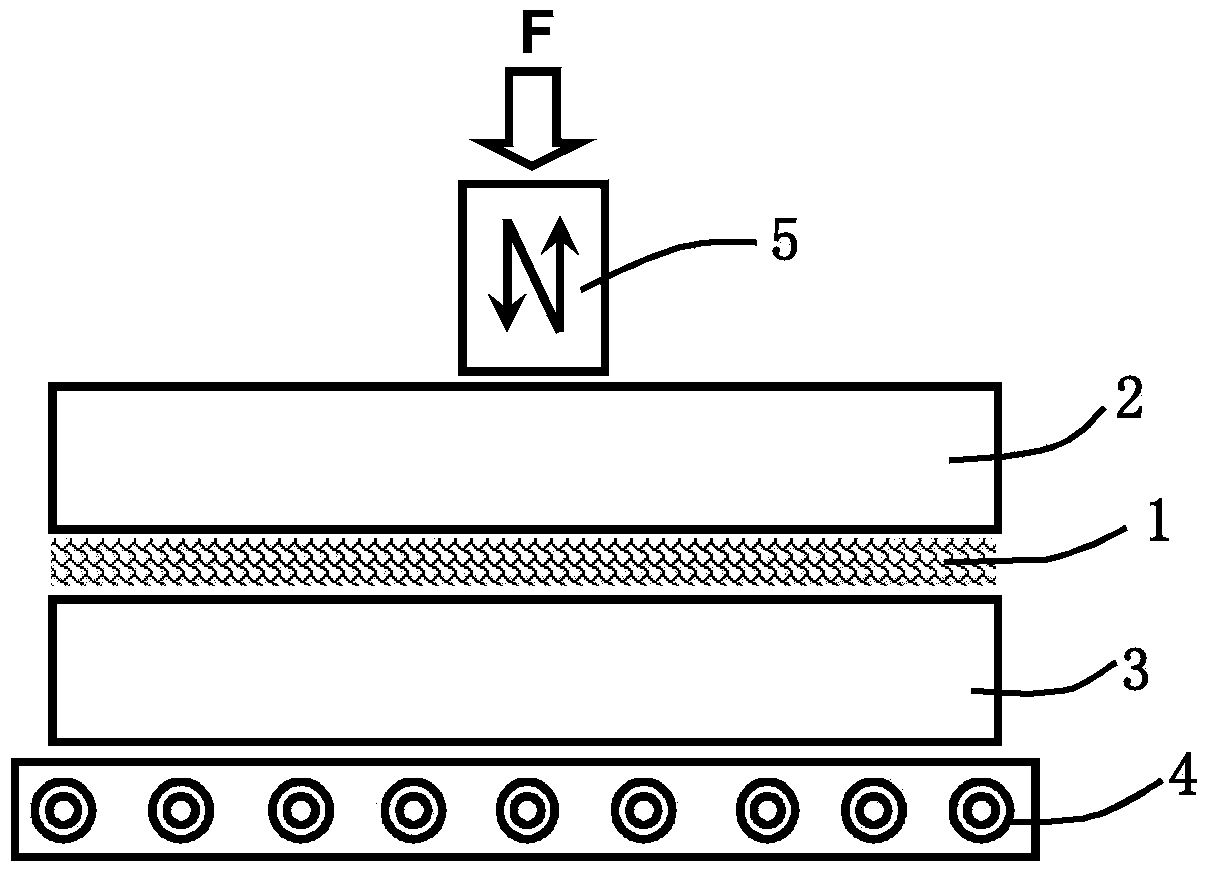

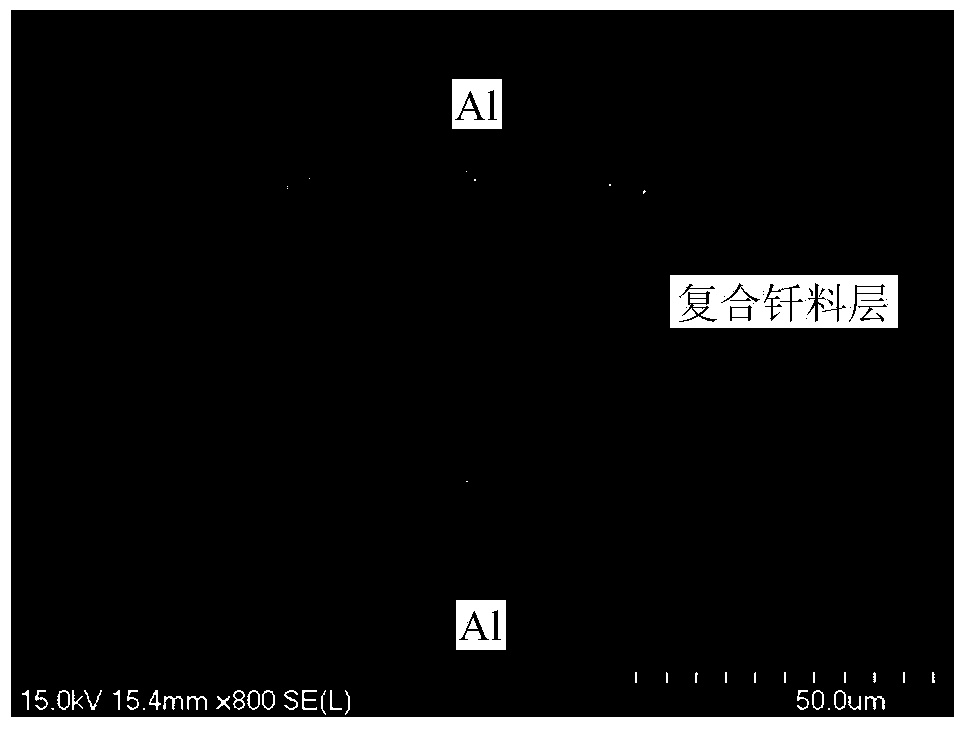

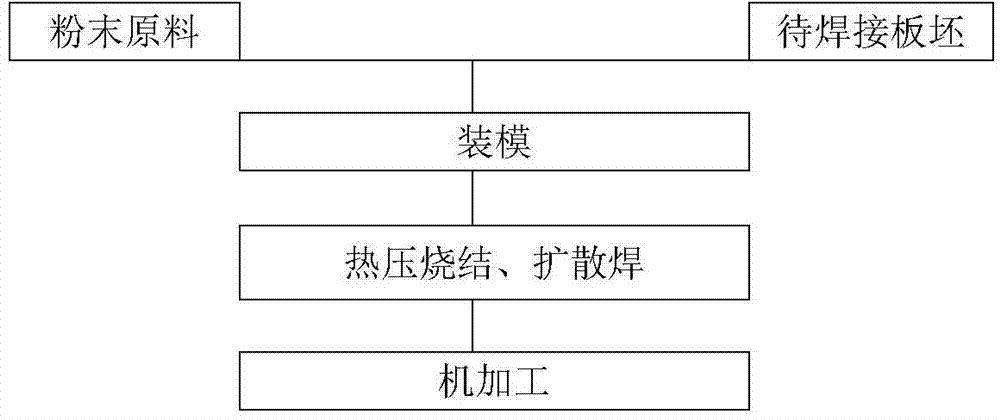

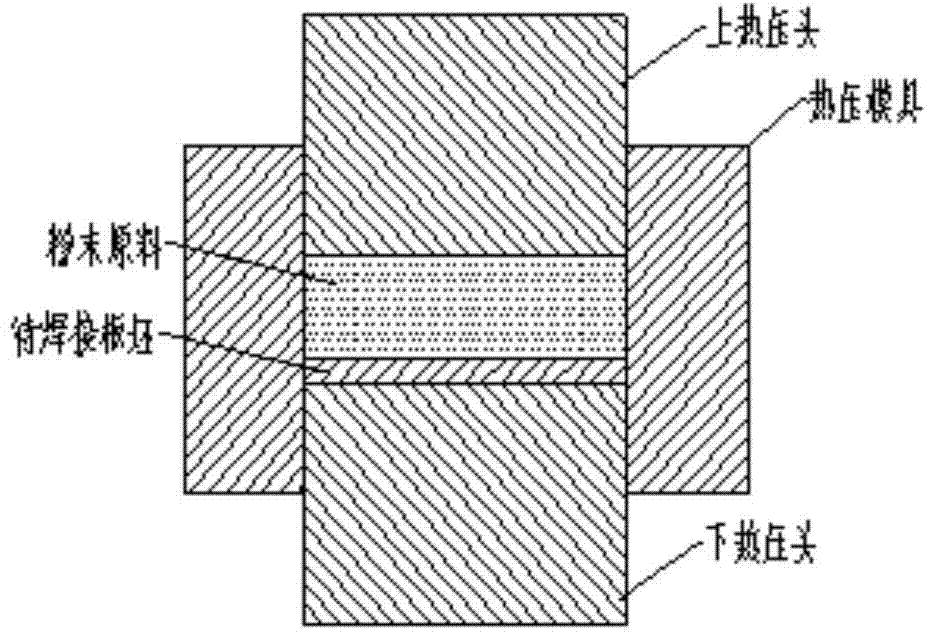

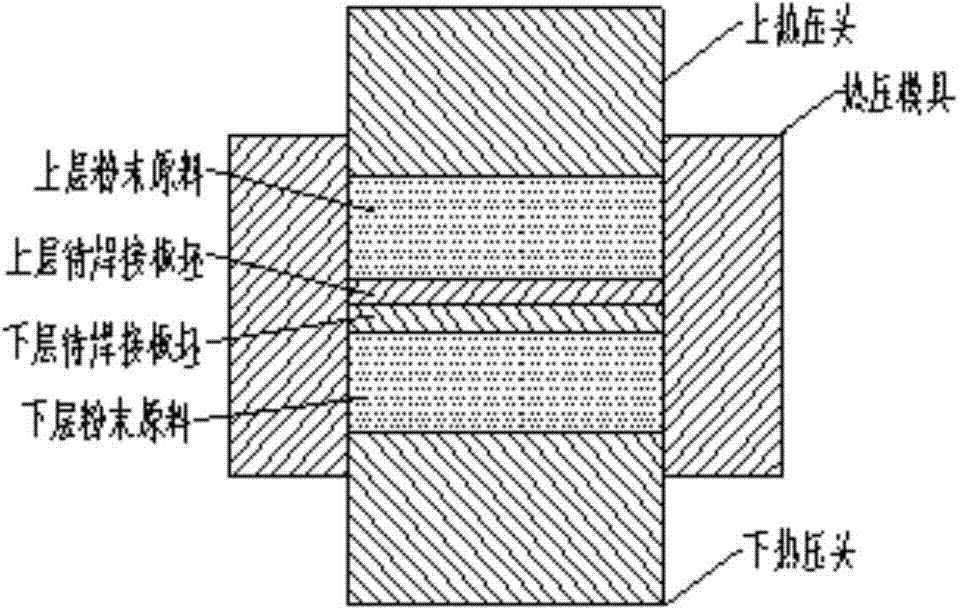

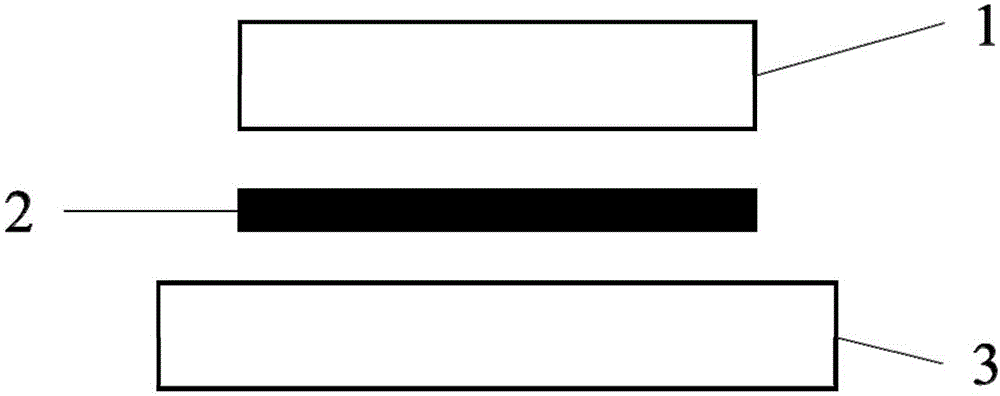

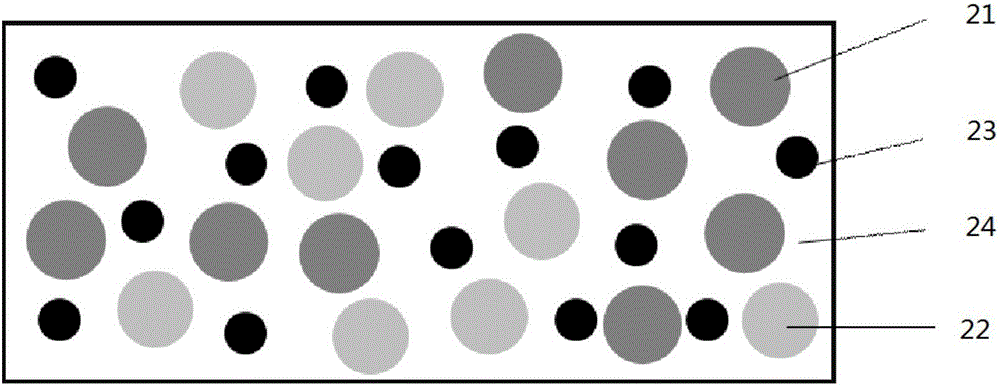

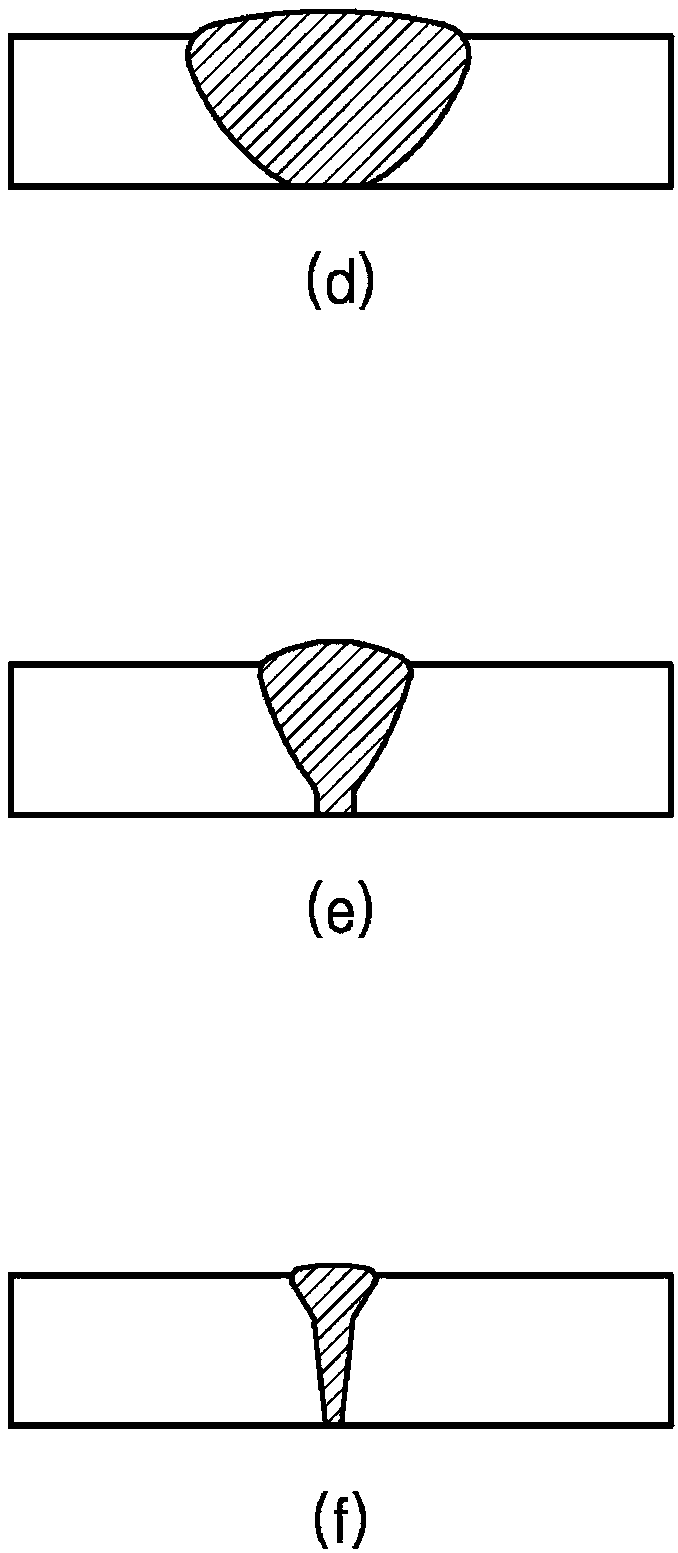

Diffusion welding method for W-Ti alloy target assembly

InactiveCN104708192AAdvantages of Diffusion Welding MethodImprove welding rateVacuum evaporation coatingSputtering coatingAlloyFilm-coated tablet

A method for diffusion welding a W-Ti alloy target material assembly for film coating, the method comprising: placing powdered raw material of W-Ti alloy target material and corresponding plate blank material to be welded and composited into a hot press mold and then into a hot press sintering furnace; synchronously conducting hot press sintering molding on the target blank and conducting diffusion welding on the target blank and plate blank to obtain a welded composite W-Ti alloy target material assembly; or utilizing the plate blank as a back plate or a transition layer to obtain the W-Ti alloy target material assembly or a composite three-layer structure of W-Ti alloy target material / transition layer / back plate. The method realizes synchronization between target blank hot press sintering molding and hot press diffusion welding of target blank and plate blank, with a welding tensile strength of greater than 50 MPa.

Owner:GRIKIN ADVANCED MATERIALS

Interconnection brazing material and interconnection forming method thereof

ActiveCN106271177ASolve the problem of long time consumption of phase methodLow Young's modulusWelding/cutting media/materialsMetal working apparatusAmount of substanceThird phase

The invention provides an interconnection brazing material and an interconnection forming method thereof. The heating technological temperature of a product applied by the interconnection brazing material is T, the interconnection brazing material contains a component A with the melting point larger than T, a component B with the melting point smaller than T and a third-phase component C with the melting point larger than T; the third-phase component C accounts 0-30% the total mass of the component A, the component B and the third-phase component C. A compound AxBy is formed through a reaction between the component A and the component B at the heating technological temperature; the ratio of amounts of substances of the component A to the component B is larger than x / y, the third-phase component C does not react with the component A or the component B, the hardness of the third-phase component C is smaller than those of the component A, the component B and the compound AxBy. According to the technical scheme, a high-melting-point welding joint is obtained, and the Young modulus and the thermal expansion coefficient of a joint can be adjusted by adjusting the proportion of the components inside the brazing material.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

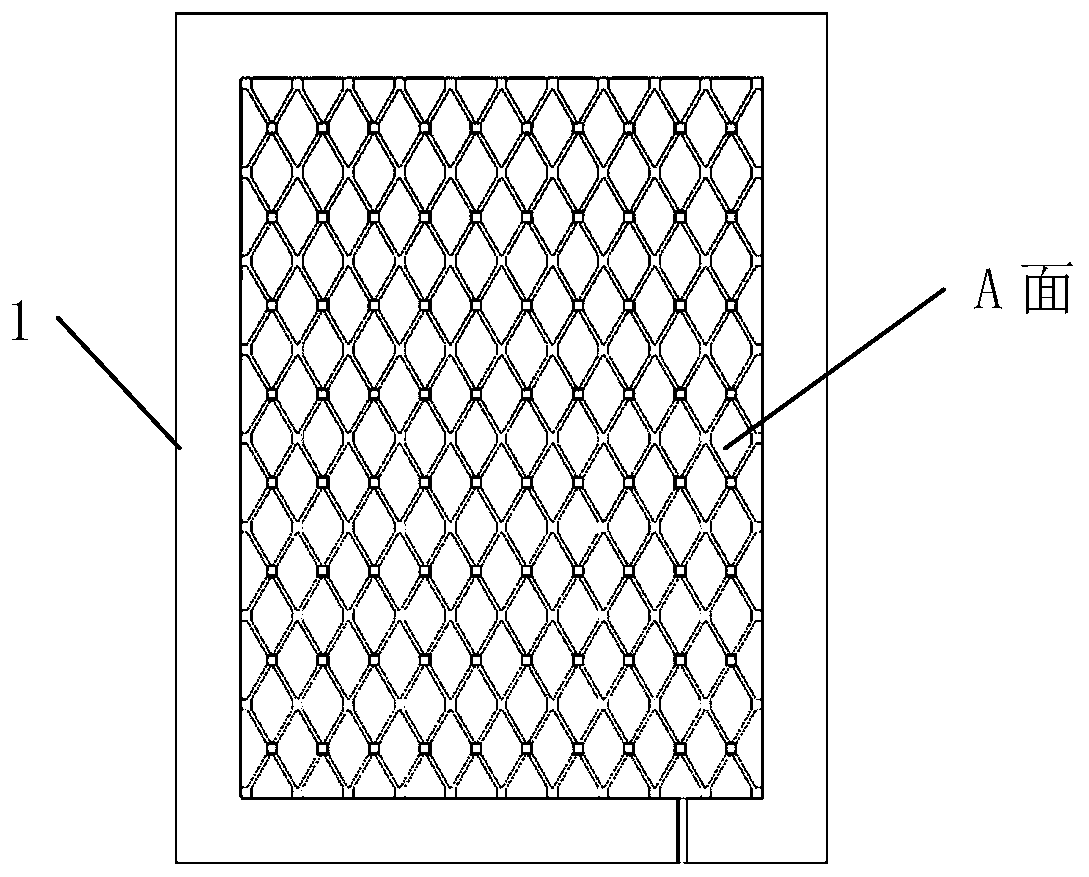

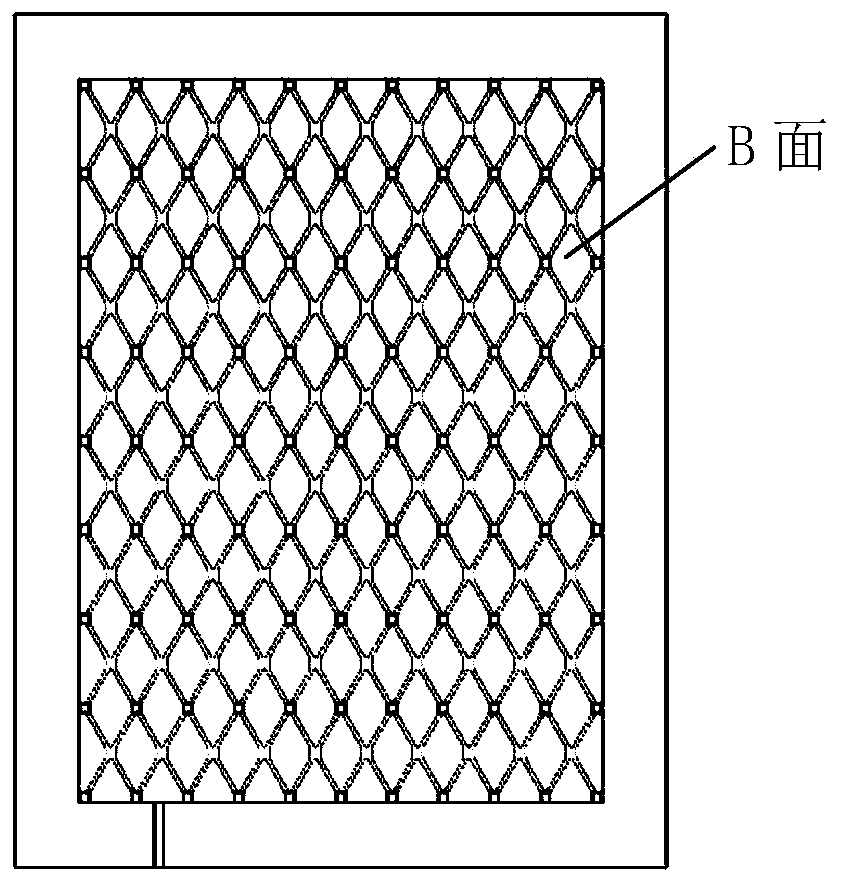

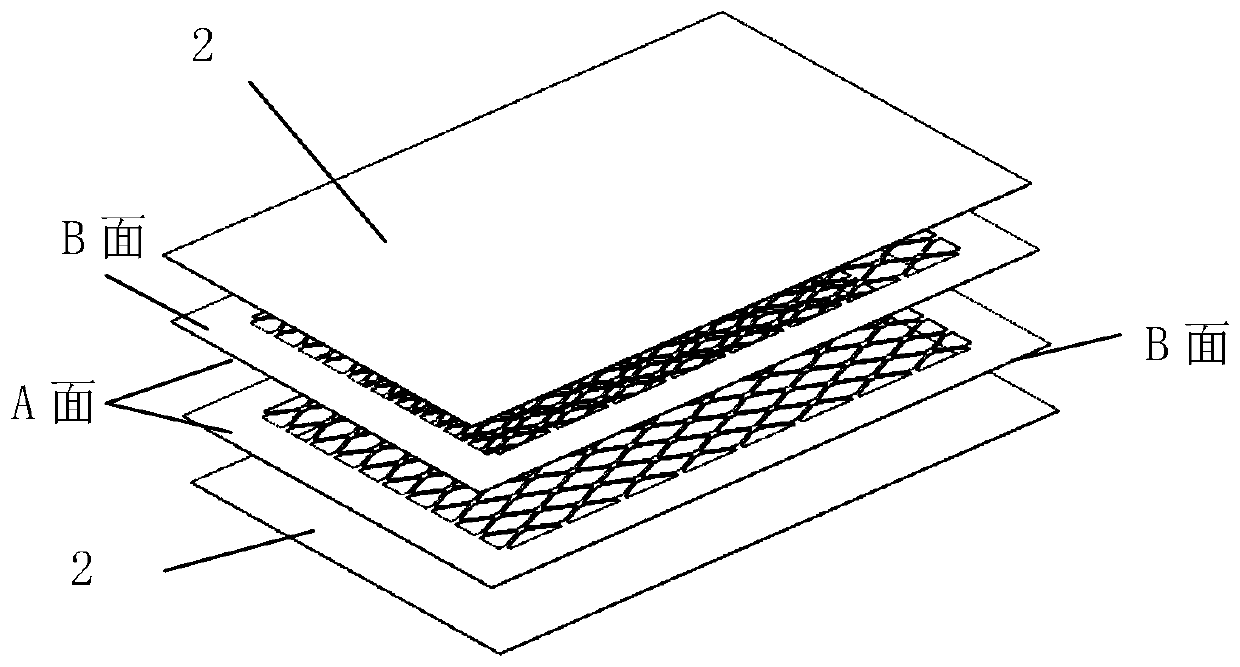

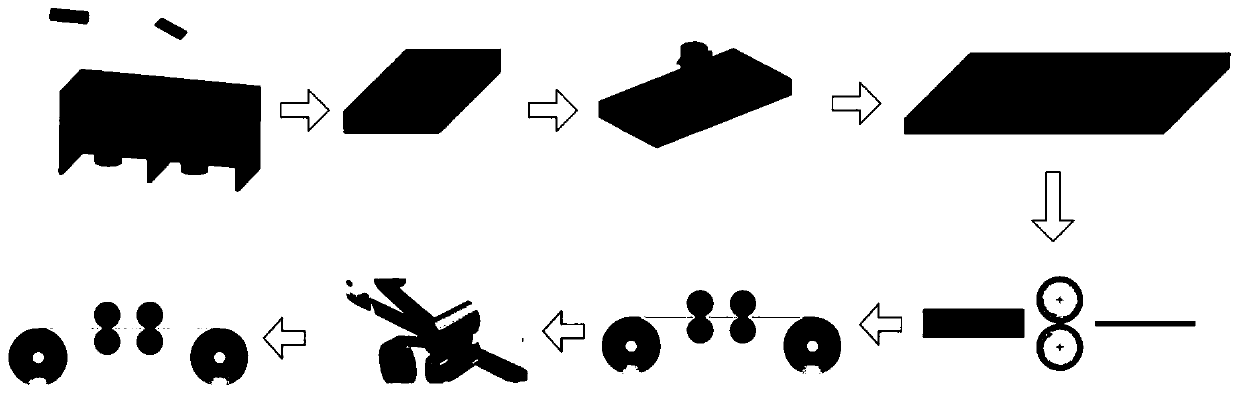

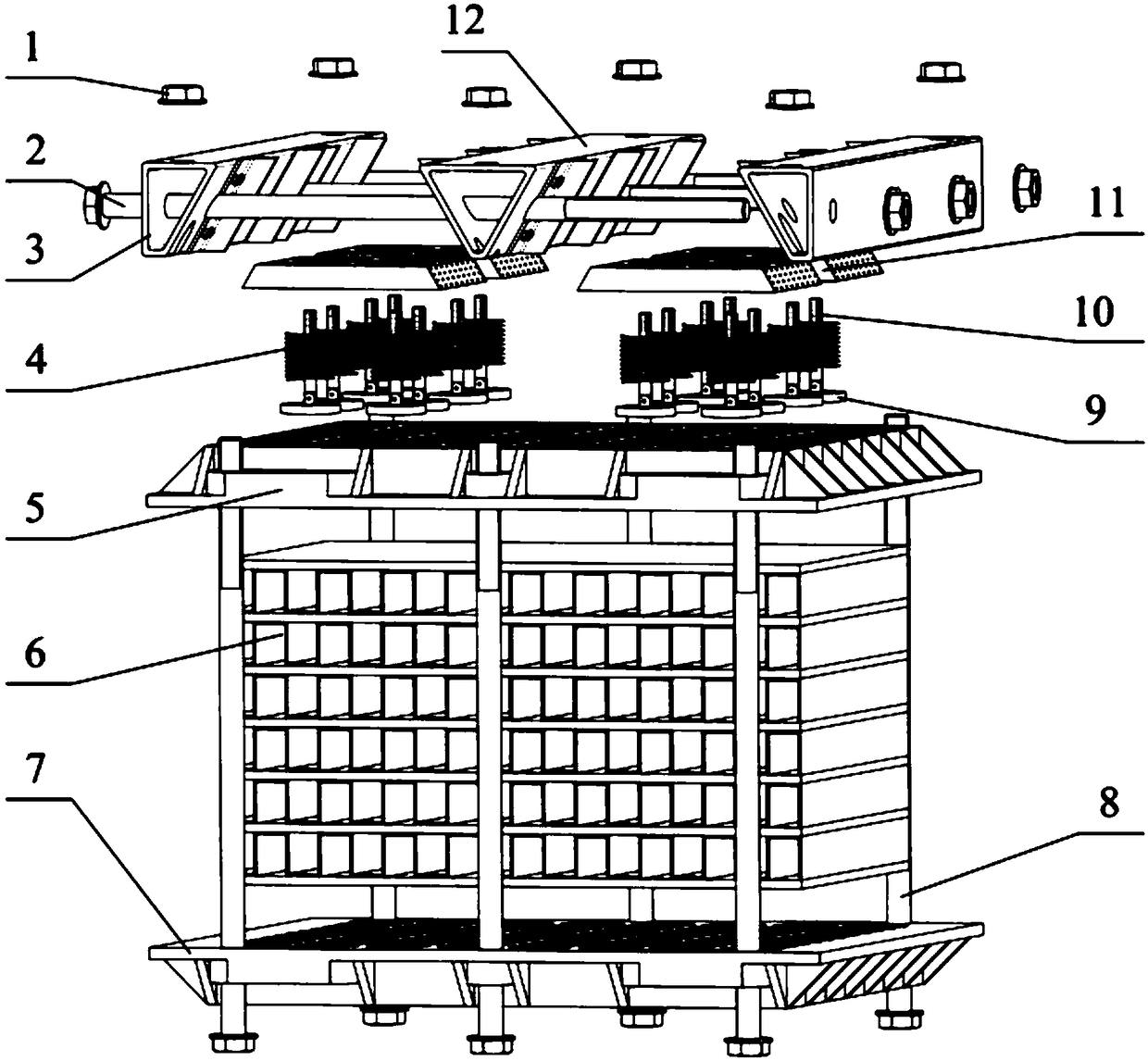

Preparation method of high-temperature alloy four-layer lattice lightweight structure

ActiveCN111069860AHigh-strength and light-weight characteristics are fully utilizedImprove stabilityNon-electric welding apparatusSurface oxidationSuperalloy

The invention provides a preparation method of a high-temperature alloy four-layer lattice lightweight structure. The preparation method comprises the steps of 1, machining hollowed-out rhombus grid structures of middle layer plates; 2, machining a skin panel; 3, removing surface oxidation films of the skin panel and the two middle layer plates through acid pickling, and cleaning acid, alkali andgreasy dirt remaining on the surface of the skin panel and the surfaces of the two middle layer plates through ethyl alcohol; 4, coating the plate surfaces of the two middle-layer plates with solder resist; 5, carrying out diffusion bonding of the skin panel and the middle layer plates; 6, performing superplastic forming; and 7, taking a formed prefabricated blank out of a superplastic forming mold, and machining the GH4169 high-temperature alloy four-layer lattice lightweight structure through a machining method. The four-layer ultrathin lattice structure rudder airfoil prepared through the method is made of GH4169 high-temperature alloy and has the advantages of good machinability and weldability, the ultrathin lattice structure has the advantage of light weight, and the four-layer rudder airfoil is high in degree of symmetry and better in mechanical property.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

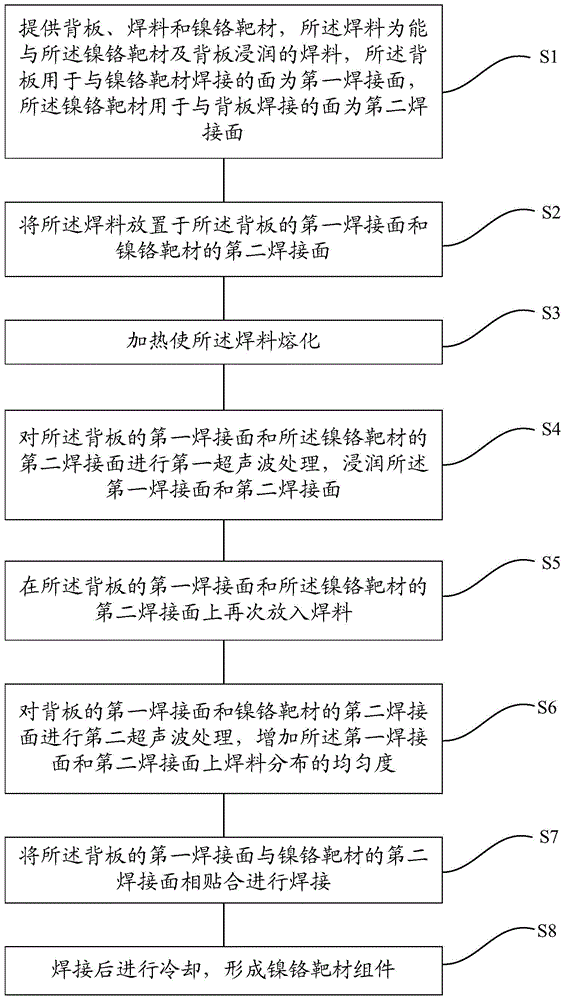

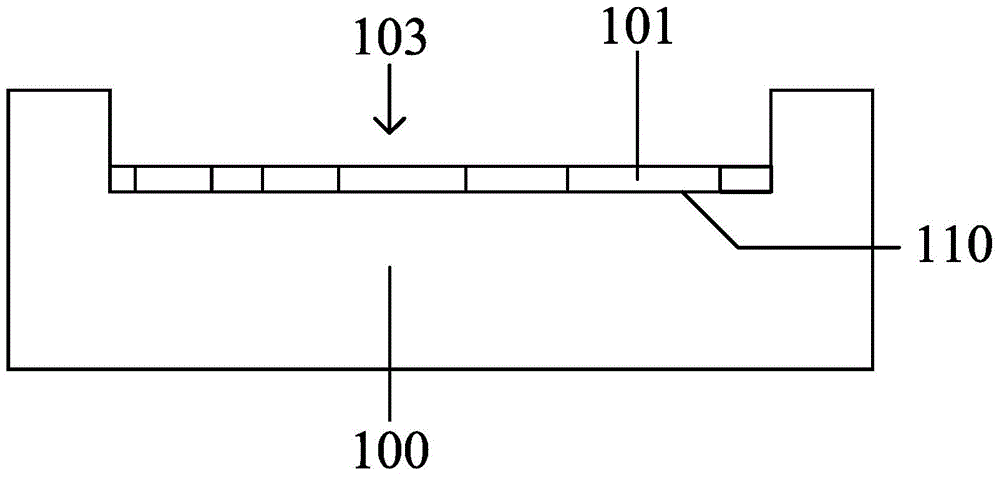

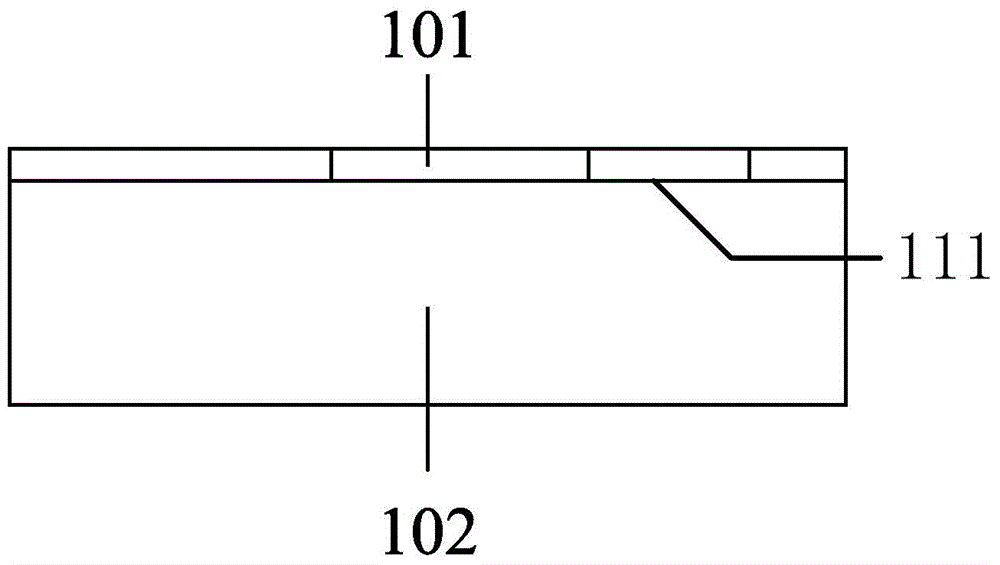

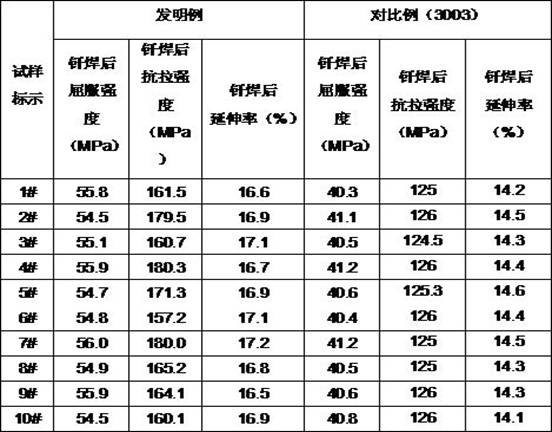

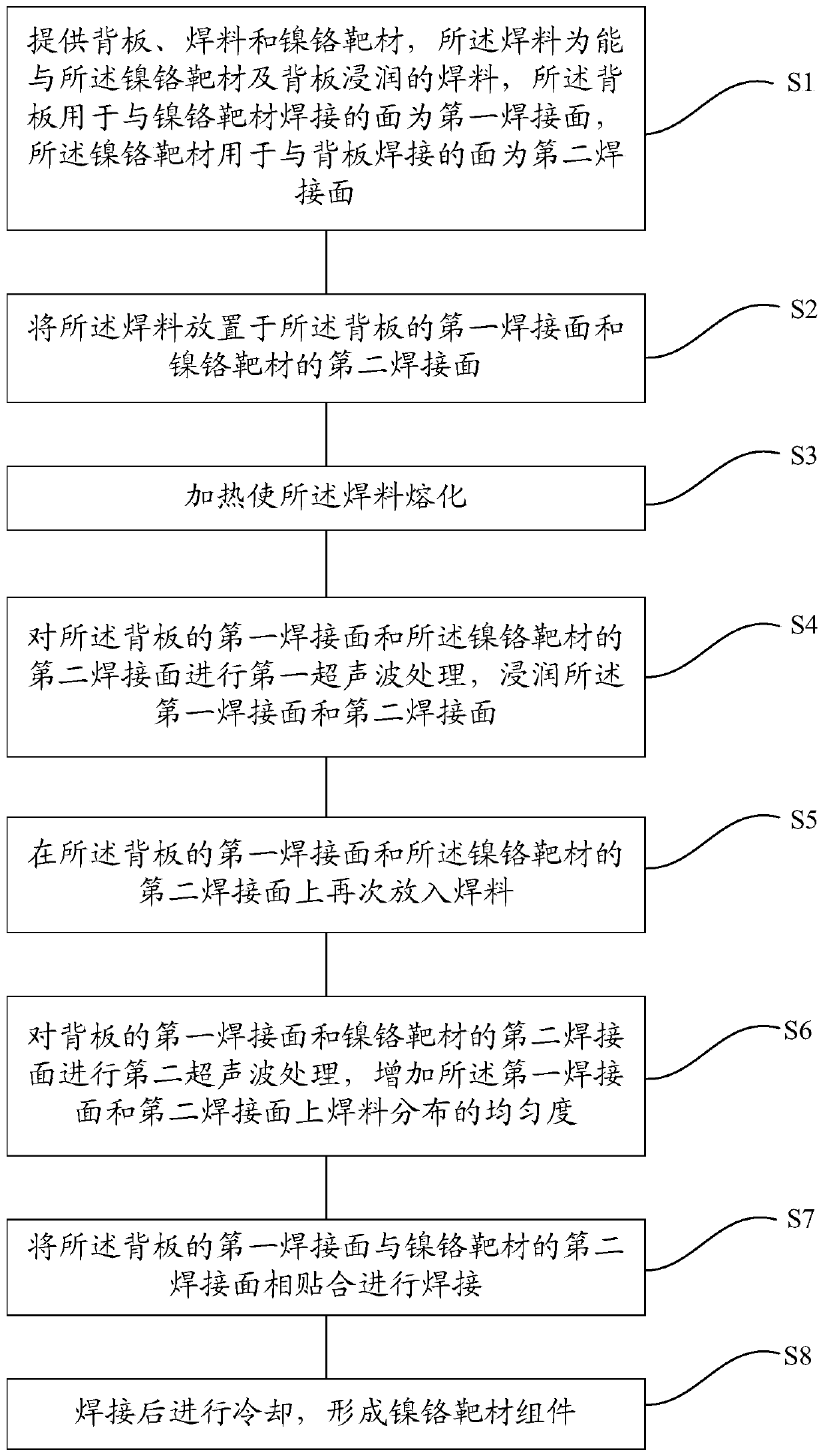

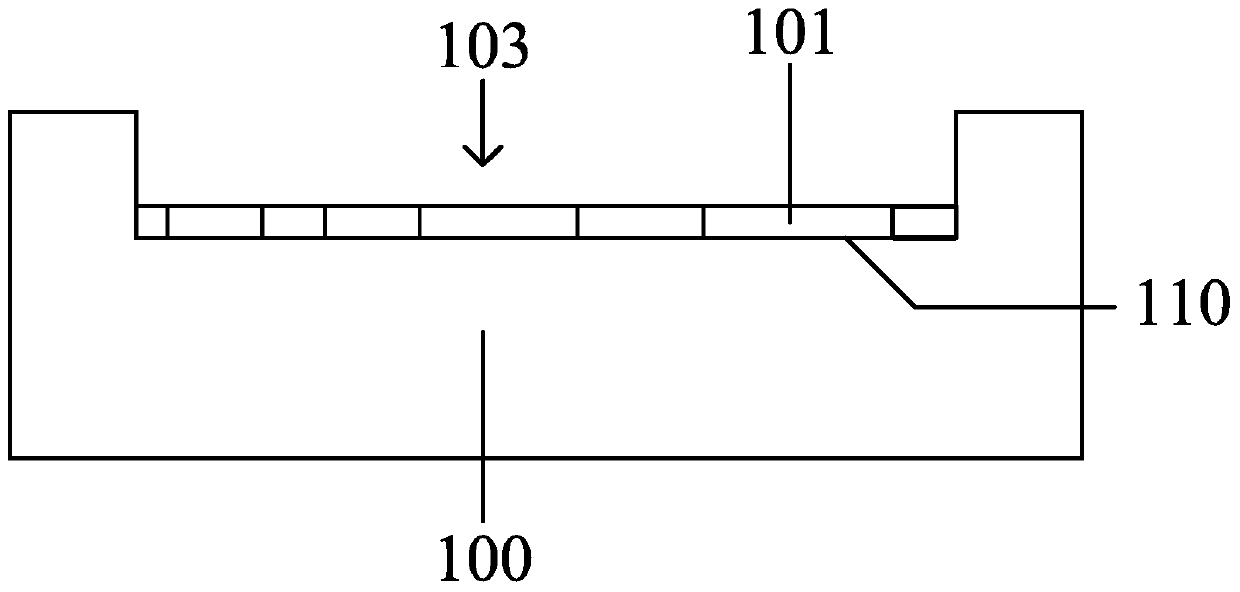

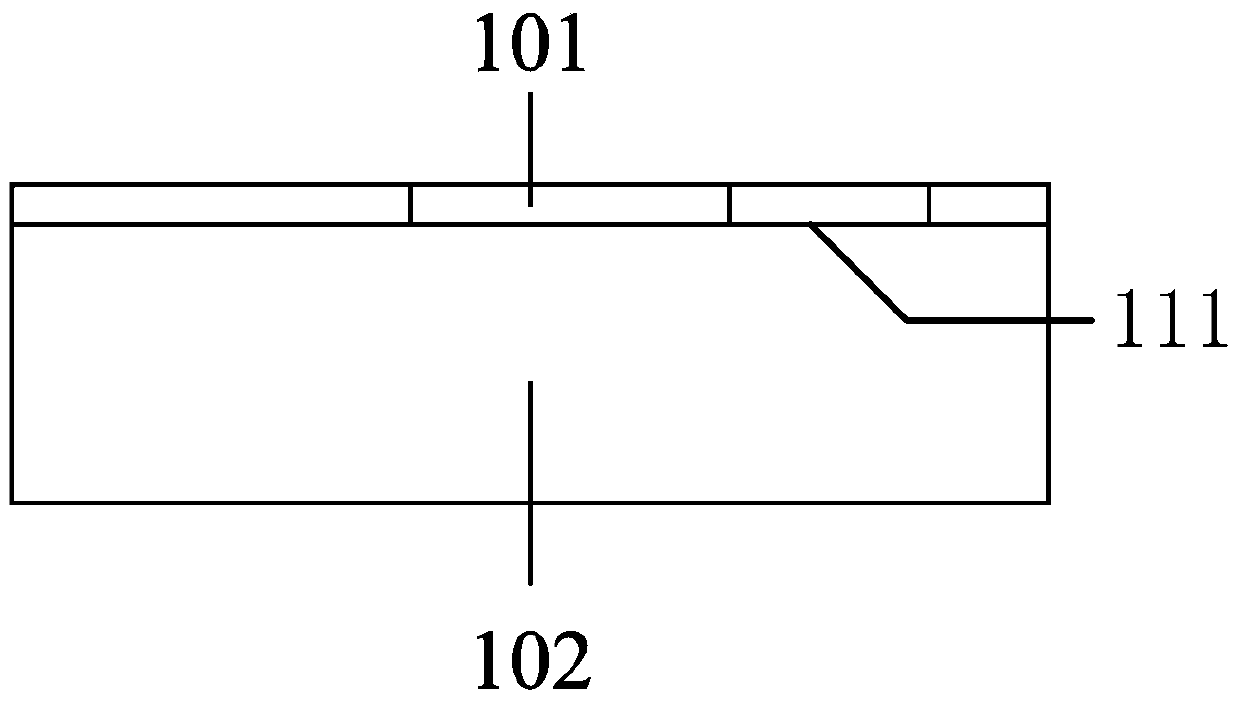

Method for manufacturing nickel-chromium target material component

ActiveCN106695109AEvenly distributedIncrease contactNon-electric welding apparatusNichromeEngineering

The invention provides a method for manufacturing a nickel-chromium target material component. The method comprises the following steps: placing a solder on welding faces of both a back panel and a nickel-chromium target material; heating to enable the solder to be molten; performing first ultrasonic treatment on the welding faces of both the back panel and the nickel-chromium target material, and soaking the welding faces; re-placing the solder on the welding face of the back panel, and performing second ultrasonic treatment on the welding faces of both the back panel and the nickel-chromium target material; laminating the welding faces of the back panel and the nickel-chromium target material and welding; and cooling after welding to form the target material component. According to the method, welding is assisted by twice ultrasonic treatment methods, twice ultrasonic treatment can enable alloy layers to form on the surfaces of the back panel and the nickel-chromium target material and can also ensure that the solder is uniformly distributed on the welding faces of both the back panel and the nickel-chromium target material, and accordingly, the high-welding-strength, high-welded-rate and low-defect-rate welding effects of the nickel-chromium target material and the back panel are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

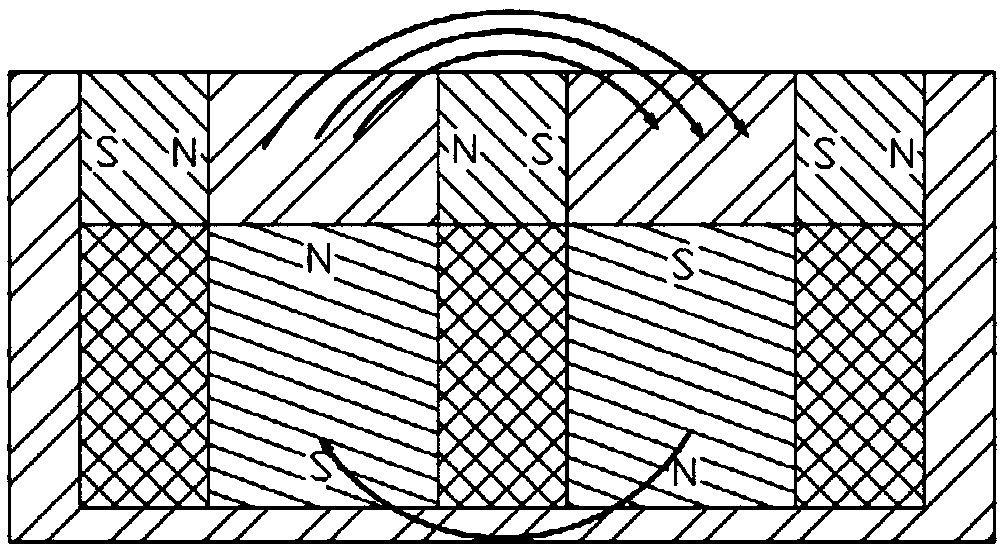

Manufacturing of composite sandwich nozzle by dynamic pressurizing transient liquid phase diffusion welding

InactiveCN101633081AAdvantages of manufacturing cycleProduction cost advantageWelding apparatusLiquid phaseDiffusion welding

The invention realizes the manufacturing of a composite sandwich structured nozzle by a dynamic pressurizing transient liquid phase diffusion welding method; the composite sandwich structured nozzle manufactured by the invention has advantages of long fatigue life, strong compression capacity, high welding rate, short manufacturing cycle, no blocking in the passageway and the like. The composite sandwich structured nozzle between materials of the same type can be manufactured by utilizing the invention, and the composite sandwich structured nozzle between materials of different types can also be manufactured, thus providing composite sandwich structured nozzle products with good performance for related industries.

Owner:北京智创联合科技股份有限公司

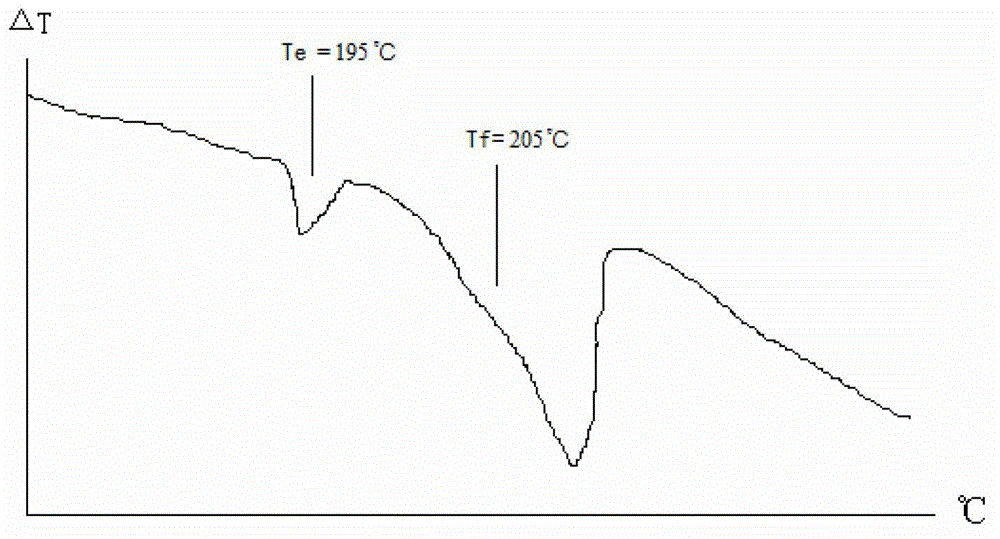

Al-Ag-Cu-Mg aluminium base alloy-state brazing filler metal and preparation method thereof

InactiveCN105364335AGood welding rateImprove welding strengthWelding/cutting media/materialsSoldering mediaAdditive ingredientFiller metal

The invention discloses an Al-Ag-Cu-Mg aluminium base alloy-state brazing filler metal and a preparation method thereof. The brazing filler metal is mainly used for vacuum brazing for aluminium alloys. The brazing filler metal is composed of the following ingredients with the following contents: 35-45wt% of Ag, 18-22wt% of Cu, 1.0-2.0wt% of Mg and the balance Al. The brazing filler metal has a low melting temperature, high brazing manufacturability, high wettability, and a high welding area ratio of greater than 90%; the brazing filler metal has a welding joint tensile strength sigma of not less than 90MPa and a shear strength tau of not less than 60MPa, and is applicable to intermediate-temperate or step vacuum brazing for many aluminium alloys of 3A21, 2A50, 6063, 6061, LF6 and the like. The preparation method comprises the steps of material preparation, intermediate alloy preparation, alloy casting, heat treatment, hot forging, rolling and the like. The preparation method is simple in method and beneficial to batch production. Foil-shaped brazing filler metal with a thickness of 0.03-2.00mm can be prepared by virtue of the method, and the brazing filler metal is more applicable to vacuum brazing for aluminium alloy members with large specifications.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Diffusion welding method of magnesium alloy and pure copper or copper alloy

ActiveCN110026669AFacilitated DiffusionStable structureNon-electric welding apparatusSolid solutionMetal

The invention discloses a diffusion welding method of a magnesium alloy and pure copper or a copper alloy. An alloy material which is not in solid solution is used as an intermediate layer material, and a vacuum diffusion welding technique is adopted to weld the magnesium alloy and the copper or the copper alloy. The alloy which is not in solid solution comprises high-melting-point component metaland low-melting-point component metal, wherein the low-melting-point component metal acts as a liquid active factor at the vacuum diffusion welding temperature, the atom diffusion process is promoted, and a good welding joint is formed. By means of the diffusion welding method, the experiment cost is reduced, the requirement for the equipment is reduced, the experiment cycle is saved, and the process is simple and effective.

Owner:SOUTHWEST JIAOTONG UNIV

Collecting chamber, production method of collecting chamber, automobile radiator, and production method of automobile radiator

ActiveCN104236372ASimple structureSimple manufacturing processStationary conduit assembliesHeat exchanger casingsWeld seamHeat spreader

The invention discloses a collecting chamber, a production method of the collecting chamber, an automobile radiator, and a production method of the automobile radiator, which belong to the technical field of automobile radiators. The invention aims to reduce welding seams and improve one-time welded rate of a product. The invention adopts the technical scheme that the collecting chamber comprises a collecting chamber main body and block boards, wherein the collecting chamber main body is a square pipe; a plurality of collecting holes are formed in the bottom surface of the collecting chamber body; a transverse cut-through welding seam is formed in the top surface of the collecting chamber body; the block boards are sealed and fixed on two ends of the collecting chamber body; a water inlet and outlet hole is formed in the side face of the collecting chamber main body. The production method of the collecting chamber comprises the following steps of blanking, stamping to form at the first time, stamping bulges to form the collecting holes, stamping the water inlet and outlet hole, stamping to form at the second time, and fixing the block boards. The automobile radiator is provided with the collecting chamber. The production method of the automobile radiator comprises the following steps of assembling the automobile radiator into a whole, and putting into a brazing furnace for welding at one step.

Owner:山东厚丰汽车散热器有限公司

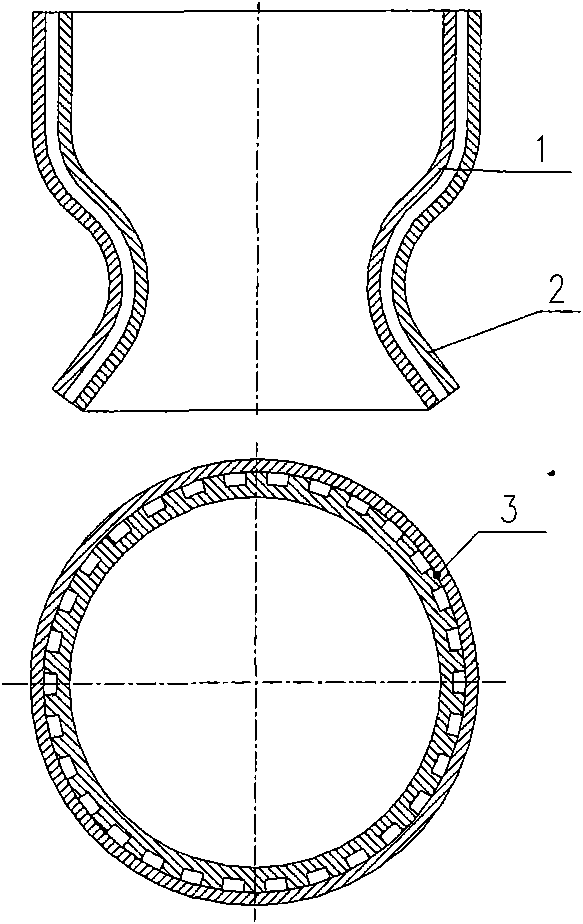

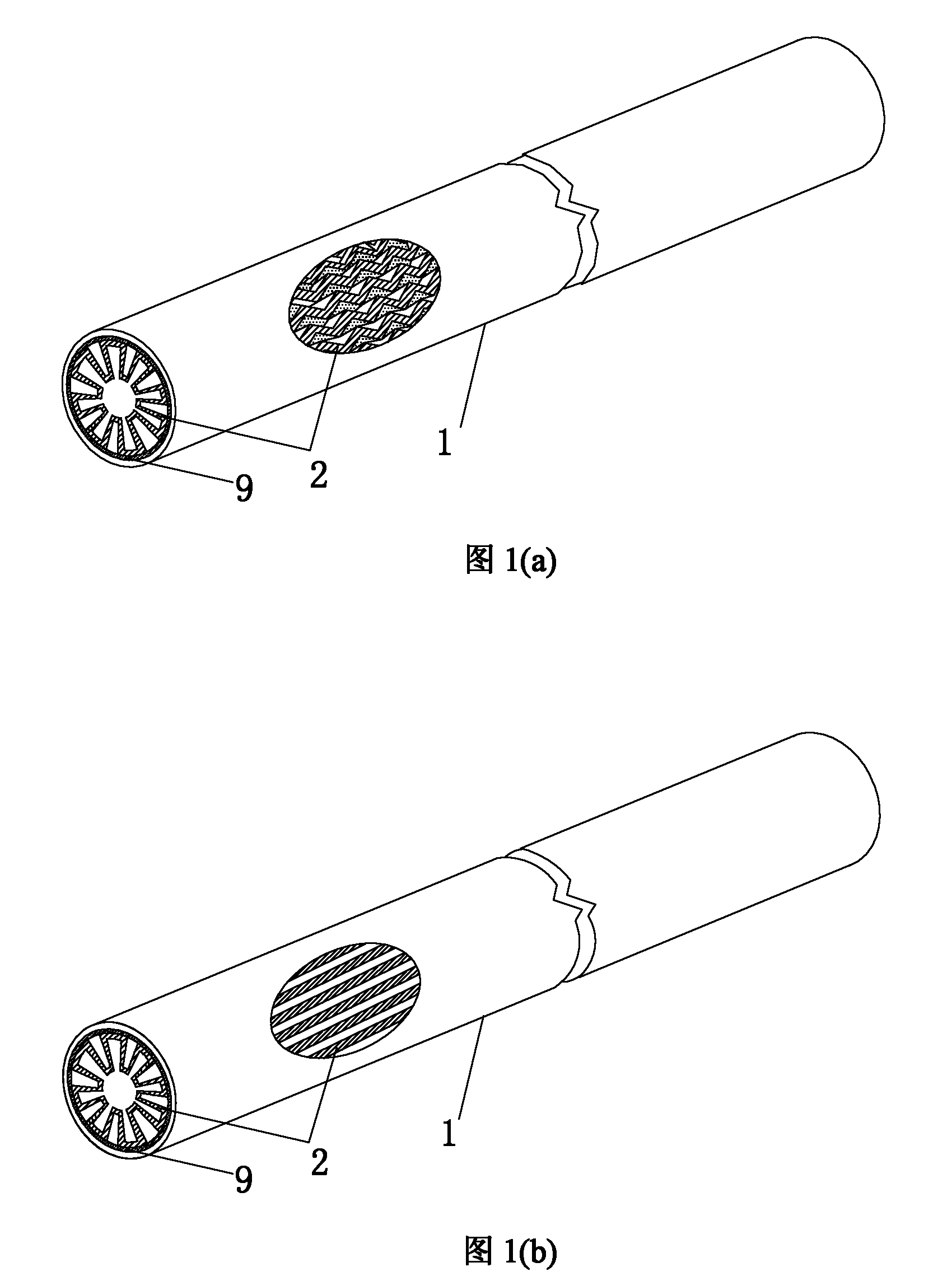

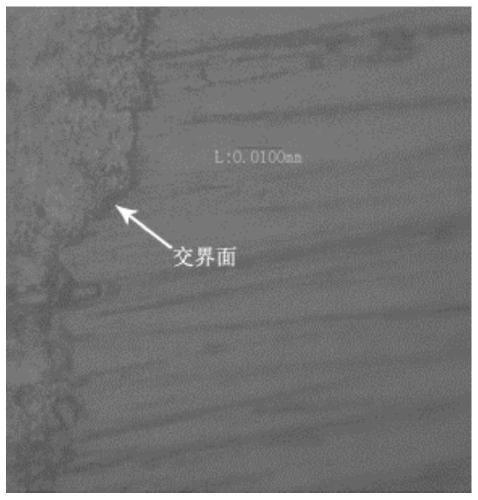

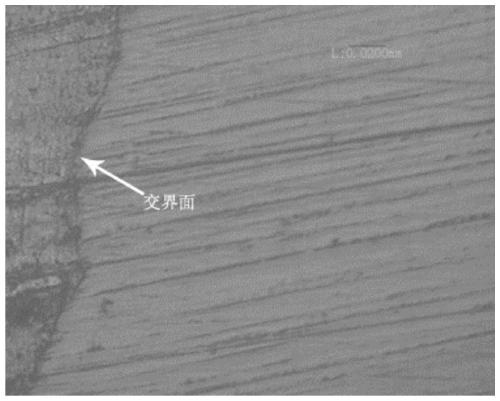

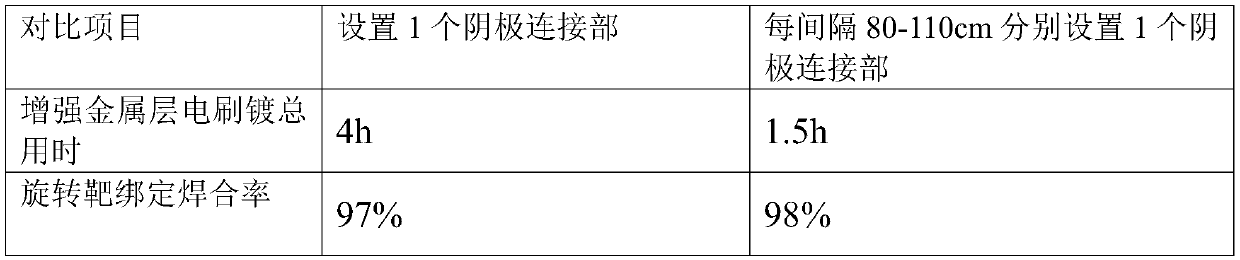

Magnetron sputtering rotary target material binding method

InactiveCN110218983AImprove welding rateAvoid uneven distributionSoldering apparatusVacuum evaporation coatingSputteringSand blasting

The invention discloses a magnetron sputtering rotary target material binding method. The method comprises the following steps that the inner surface of a rotary target pipe is metallized by means ofan ultrasonic surface treatment mode; the outer surface of a stainless steel pipe is roughed by adopting a sand blasting treatment means, and then welding flux is brushed to the outer surface of the stainless steel pipe by adopting a steel brush; and the stainless steel pipe is erected, the rotary target pipe sleeves the exterior of the stainless steel pipe, it is guaranteed that the temperature of the rotary target pipe is constant at 180-300 DEG C, the temperature of the stainless steel pipe is controlled to be kept at 180-300 DEG C, after the temperatures of the rotary target pipe and the stainless steel pipe are consistent, molten welding flux is poured into a gap between the inner surface of the rotary target pipe and the outer surface of the stainless steel pipe, the rotary target pipe and the stainless steel pipe are cooled to the room temperature simultaneously with the cooling speed being 1-5 DEG C / min after air in the gap is exhausted, and thus, a bound rotary target materialis obtained. The method has the advantages that heating is uniform, and the yield is high.

Owner:杨晔

Sn-Zn-Ag-Ni alloy lead-free solder and preparation method thereof

ActiveCN104002058AModerate melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaSolderingAluminium alloy

Disclosed are a Sn-Zn-Ag-Ni alloy lead-free solder and a preparation method thereof. The Sn-Zn-Ag-Ni alloy lead-free solder is mainly applied to low-temperature soldering of pure aluminum and aluminum alloy. The Sn-Zn-Ag-Ni alloy lead-free solder is composed of, by weight percentage, 8.0-10.0% of Zn, 0.5-1.5% of Ag, 0.5-1.2% of Ni and Sn as balance. The Sn-Zn-Ag-Ni alloy lead-free solder is low in melting temperature, good in soldering technological property and high in lubricity, achieves a welding deposition rate higher than 75% and a welding line tensile strength sigma b higher than or equal to 50 MPa, and is applicable to low-temperature soldering of the pure aluminum and various aluminum alloys such as 3A21, 6063 and 6061.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Welding process of superconductive cable and box type copper connector in large high temperature superconductive current lead

ActiveCN110181138AReduce the probability of cloggingUniform welding thicknessConductorsMetal working apparatusElectrolysisShielding gas

The invention discloses a welding process of a superconductive cable and a box type copper connector in a large high temperature superconductive current lead. The welding process of the superconductive cable and the box type copper connector in the large high temperature superconductive current lead includes the following steps: (1) sequentially performing an armor removal process on the surface of the superconductive cable, performing a nickel removal process on the surface of the superconductive cable by using an anti-electrolysis method, and performing a silver coating brushing process on the surface of the superconductive cable; (2) performing the silver coating brushing process on a copper face on the inner surface of the box type copper connector, and then installing three layers ofSn63Pb37 tin sheets 0.1mm in thickness and 183 DEG C in melting point on the inner surface of the box type copper connector; (3) installing the superconductive cable in the box type copper connector,and then installing a box cover on the box type copper connector; and (4) applying certain force onto the box cover, inflating a box body with protective gas, and completing a tin soldering process after heating. The welding process of the superconductive cable and the box type copper connector in the large high temperature superconductive current lead reduces the plugging rate of the superconductive cable, obtains a uniform sliver coating, obtains uniform welding thickness for the superconductive cable and the box type copper connector, achieves the high welding rate and high welding strengthfor the first layer cable, and is simple to operate and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

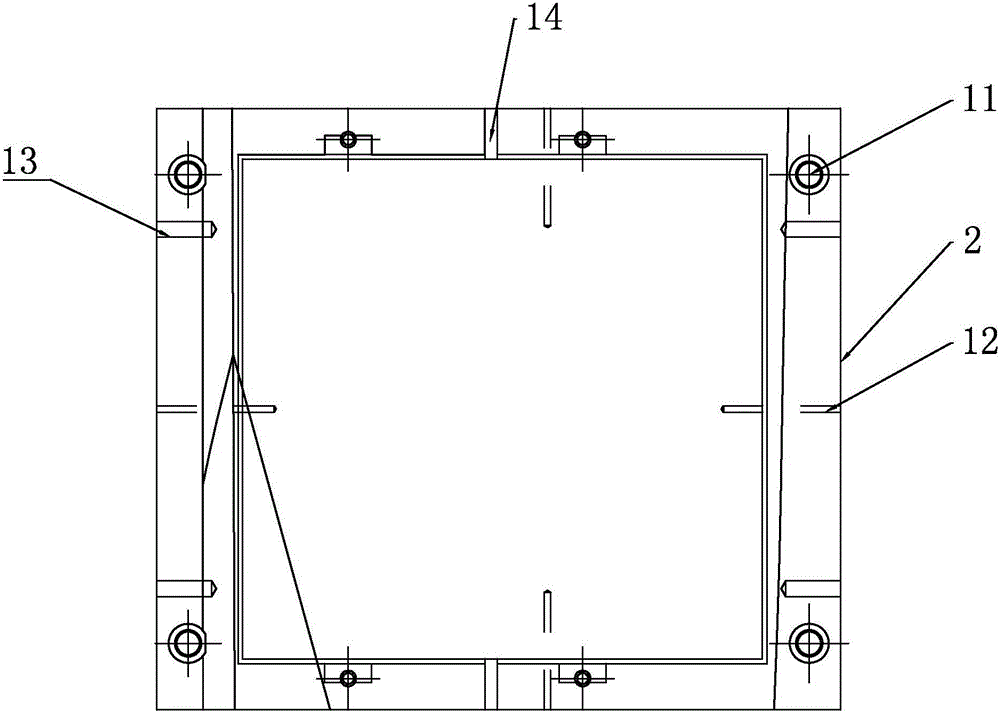

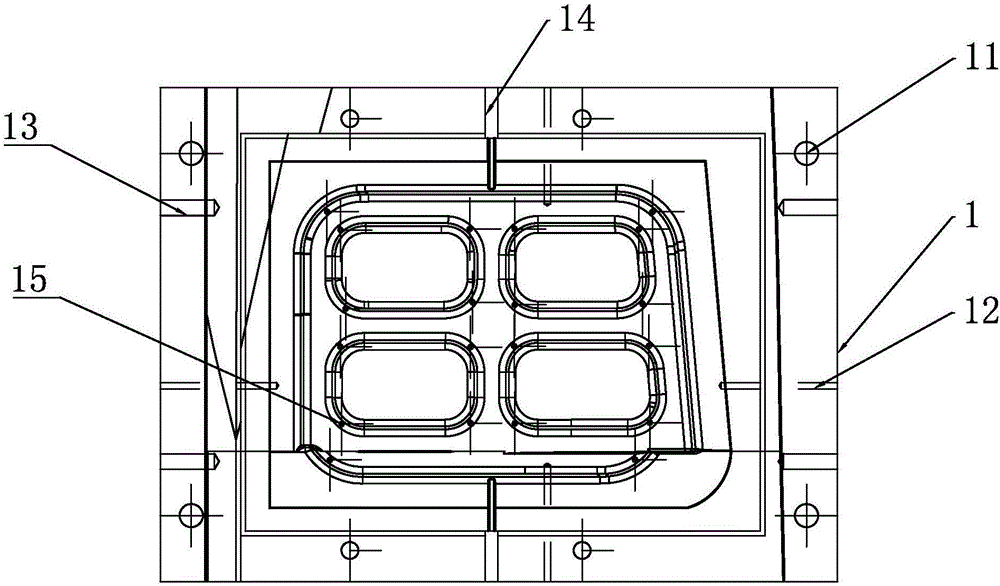

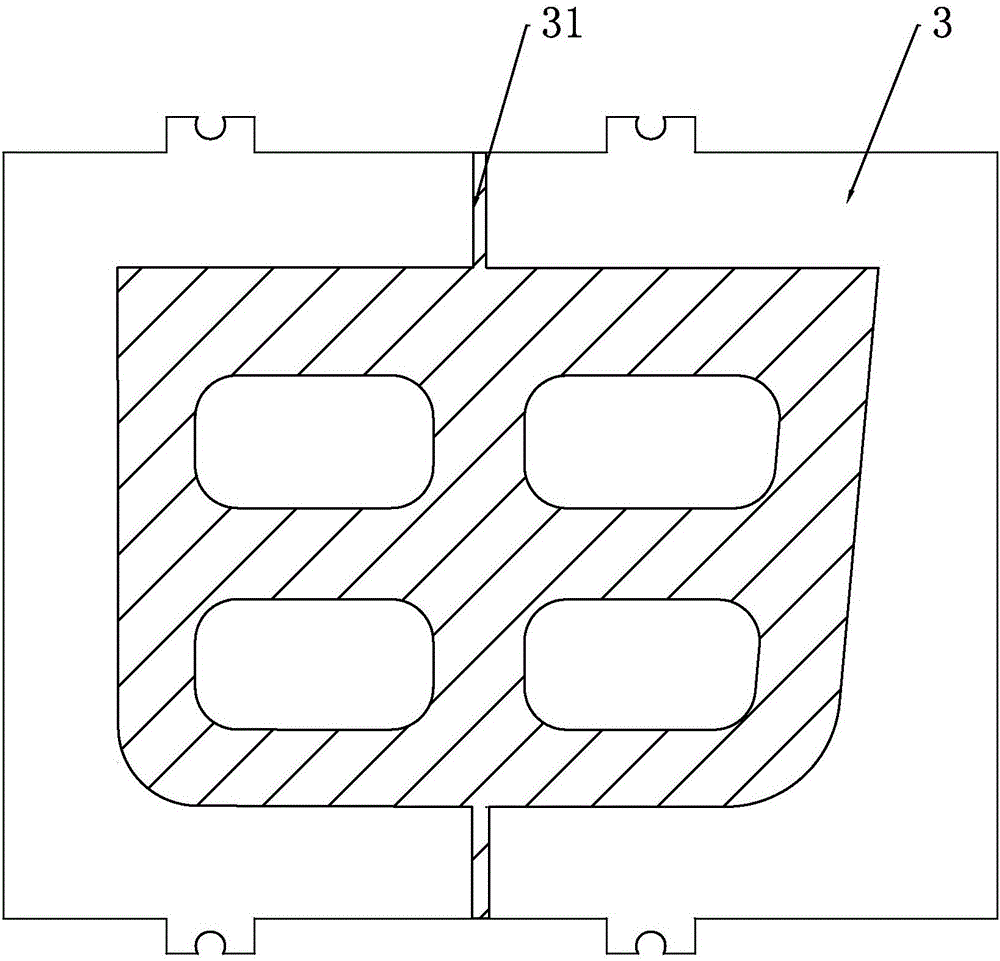

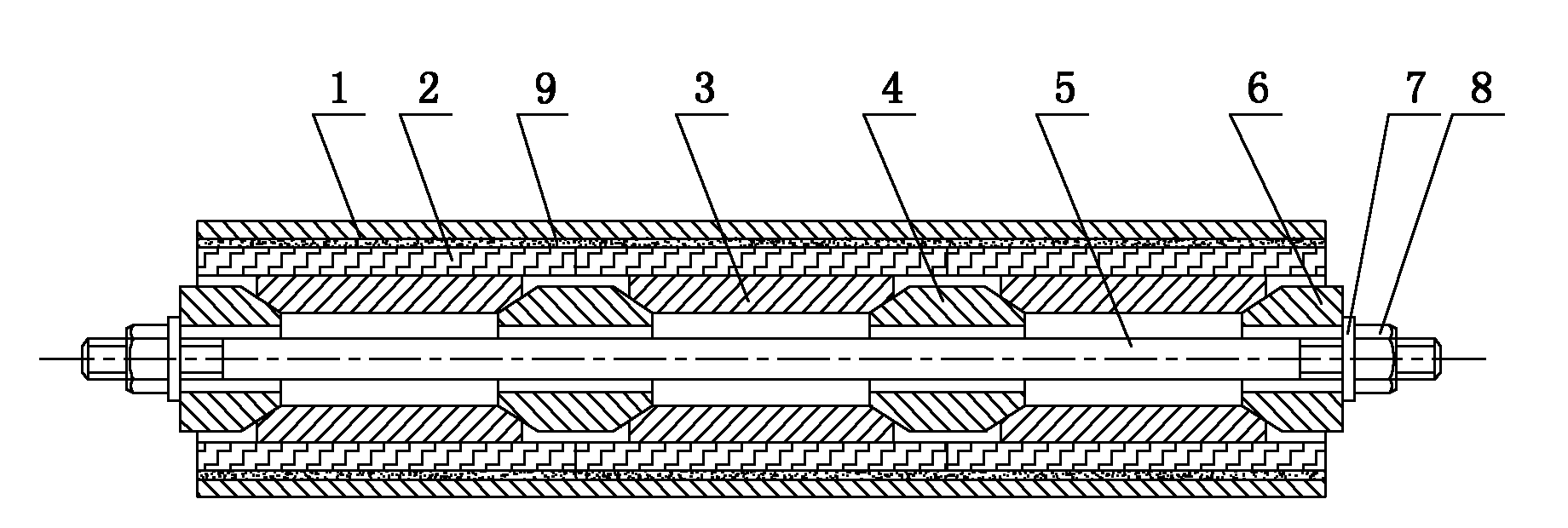

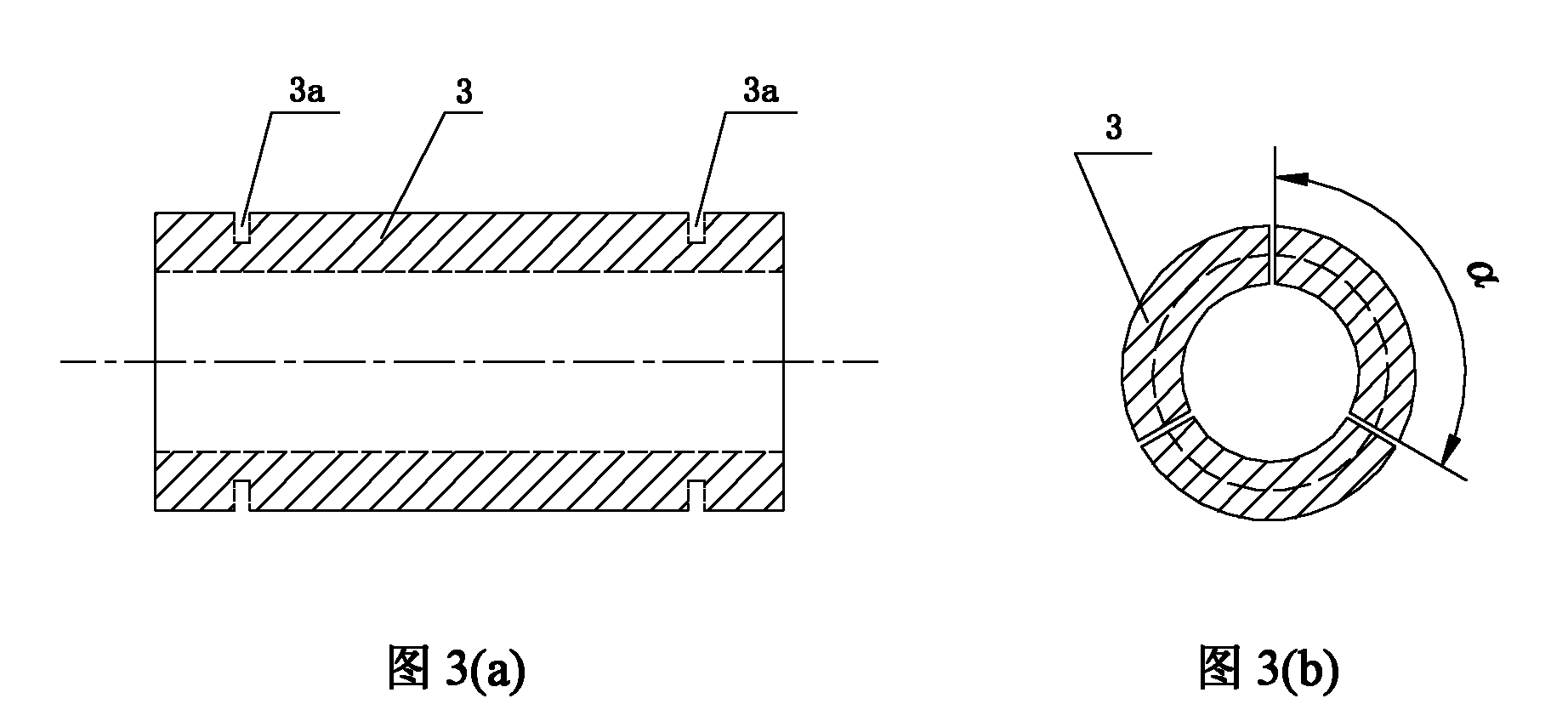

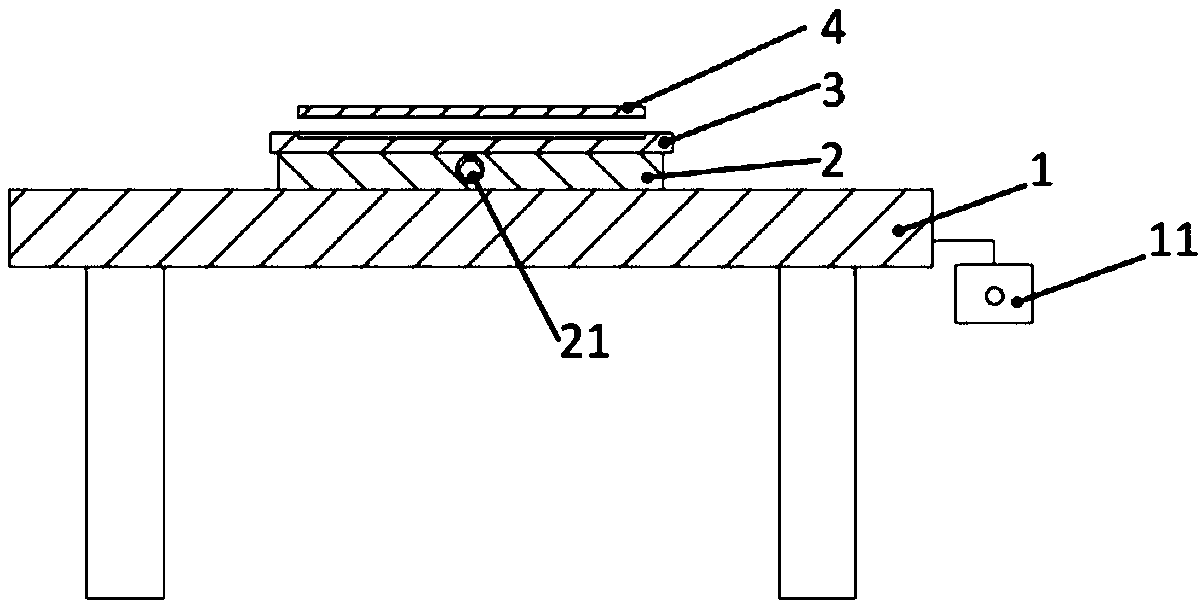

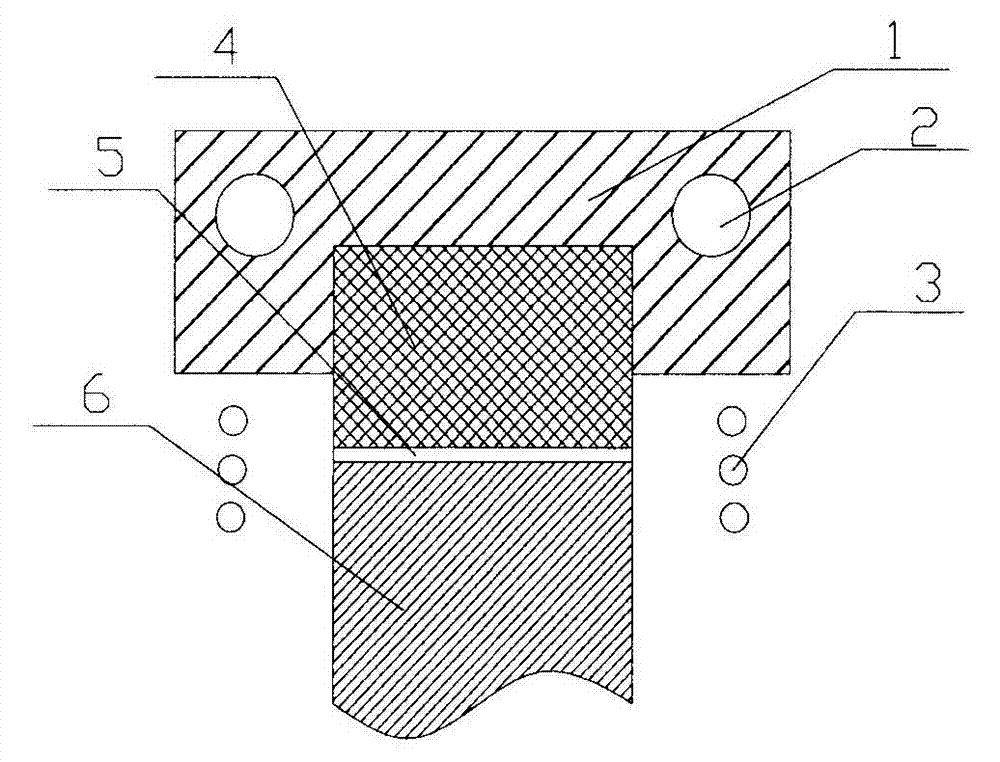

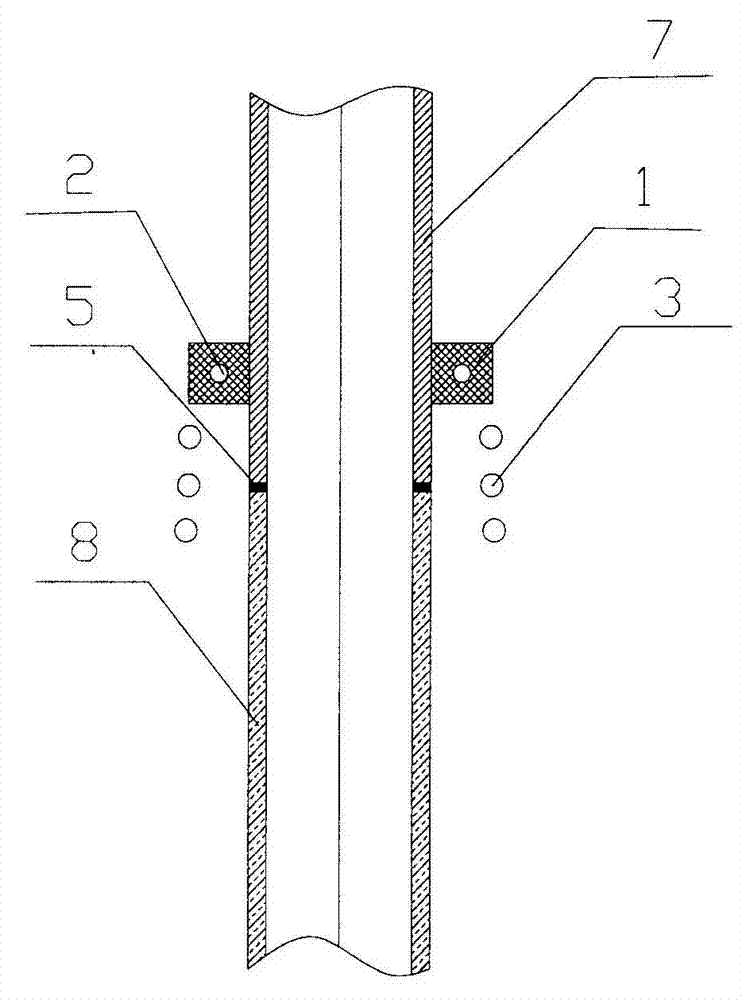

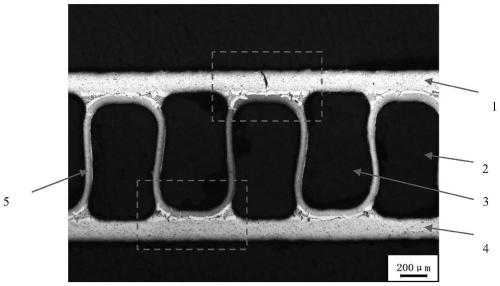

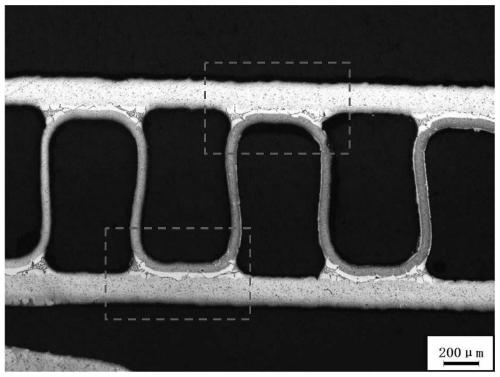

High temperature vacuum brazing clamp for internally finned tube

InactiveCN101829827AReduce weld distanceImprove welding rateSoldering auxillary devicesBrazingHeat exchanger

The invention relates to a high temperature vacuum brazing clamp for an internally finned tube. The clamp consists of a supporting guide tube, an inner supporting cone, a core tube, an end head supporting cone, a gasket and a nut, wherein the supporting guide tube consists of a plurality of tube segments which are formed by uniformly cutting a circular tube along the axial direction; when an external force is applied to the nut, the supporting guide tube can move along the inclined planes of the inner supporting cone and the end head supporting cone so as to uniformly stretch the tube segments of the supporting guide tube along the radial direction; and inner fins can be gradually and closely attached to the inner wall of an outer tube under the action of the uniform tension of the supporting guide tube. The clamp of the invention can apply uniform tension to the internally finned tube during the high temperature brazing process, reduce the distance for the weld joint, improve the ratio of welding area, improve the strength and the plasticity of the brazing joint and reduce the thermal contact resistance so as to meet the requirements for the use of the internally finned tube in a high temperature heat exchanger; and meanwhile, the clamp has a simple structure and convenient assembly and is suitable for large-scale industrial production.

Owner:XI AN JIAOTONG UNIV

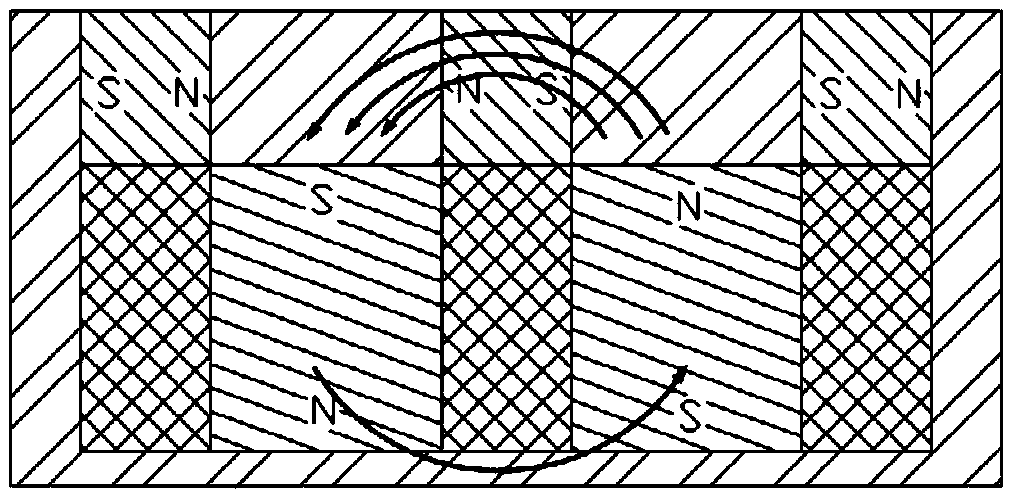

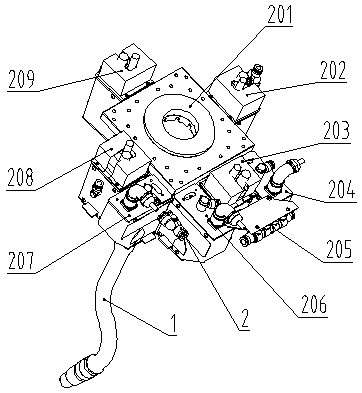

Welding method and device for large-area ferromagnetic target material

ActiveCN109590560AImprove welding rateImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesMagnetic effectFerromagnetism

The invention discloses a welding method and device for a ferromagnetic sputtering target material. According the welding method, through the magnetic effect of a permanent magnet chuck platform on the ferromagnetic sputtering target material, the target material, a solder and a backing plate are uniformly combined to improve the welding quality of the large-area ferromagnetic sputtering target material, so that the welded rate of the target material is high and the thickness uniformity of the target material is good. The welding method is easy to operate and has strong repeatability; the high-quality welding of the large-area ferromagnetic sputtering target material can be achieved by using a magnetic platform welding device; and the sputtering performance of the target material is significantly improved.

Owner:GRIKIN ADVANCED MATERIALS

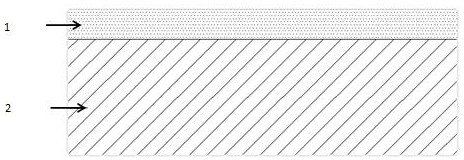

Induction brazing temperature field control method with selective wetting effect

ActiveCN102784986AImprove uneven wettabilityImprove welding rateSoldering auxillary devicesFiller metalCopper alloy

The invention discloses an induction brazing temperature field control method with a selective wetting effect. The control method comprises the following steps: washing a workpiece prior to welding; coating preset solder and welding flux and assembling the workpiece at a connector welding area; putting a welding area of the workpiece to be welded at a center part of an induction ring of a high frequency induction brazing machine; clamping a copper alloy cooling clamp at one end of a base metal of which the brazing temperature needs to be reduced in a mechanical fastening mode; starting a power supply of the high frequency induction brazing machine and opening a switch of the cooling clamp clamped on the workpiece at the same time; adjusting the flow of a cooling medium and heating the workpiece to be welded for 5-60 seconds; keeping the temperature for 5-30 seconds after a brazing filler metal is melted and spread out; closing the power supply of a sensing welding machine and closing a cooling clamp circulating system after the welding; and taking out the workpiece when the workpiece is cooled. By controlling the gradient temperature fields at two ends of the base metal of the connector, the temperature of the base metal at one side with better brazing filler metal wetness is 20-50 DEG C lower than the temperature of the other side, so that the wetness difference of the brazing filler metal at the substrate of the base metal, and the welding-on rate and the performance of the connector are improved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Multi-directional laser vision tracking device and tracking and controlling method thereof

ActiveCN110153602AReduces splash and interferenceSmall overall structureWelding/cutting auxillary devicesAuxillary welding devicesSteel platesEngineering

The invention discloses a multi-direction laser vision tracking device and a tracking and controlling method thereof. The device comprises a laser vision sensor, a special-shaped welding gun and a computer control system, wherein the laser vision sensor is arranged at the tail end of a mechanical arm, and the special-shaped welding gun is arranged at the lower end of the center of the laser visionsensor. The laser vision sensor comprises a flange frame, four cameras, three lasers, an integrated pipeline. The four cameras are uniformly arranged around the upper end of the welding gun, whereinthe first camera and the third camera are arranged in a paring mode with the first laser and the third laser on the inclined opposite sides of the flange frame for measuring and tracking weld joints in the front, in the rear and in the side, and the fourth camera is arranged in the other direction for observing and monitoring the weld joints. According to the multi-direction laser vision trackingdevice and the tracking and controlling method thereof, the measuring and tracking of the crossed welding joints can be achieved, thus realizing the switching and tracking of the welding joints in thelongitudinal direction, the transverse direction and the vertical direction; in addition, the welding method solves the problems that due to the fact that a steel plate well-shaped structure, a corrugated plate and other complex structures are limited in space and easy to interfere with the starting end and the tail end,

Owner:芜湖行健智能机器人有限公司 +1

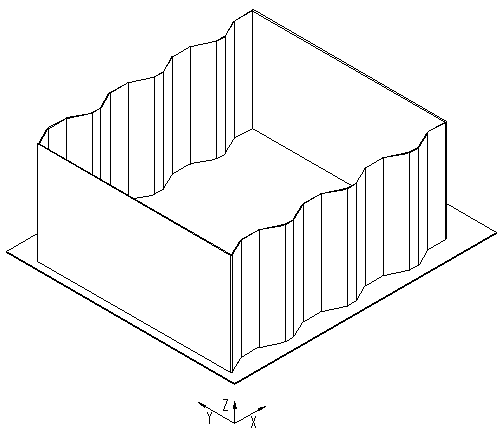

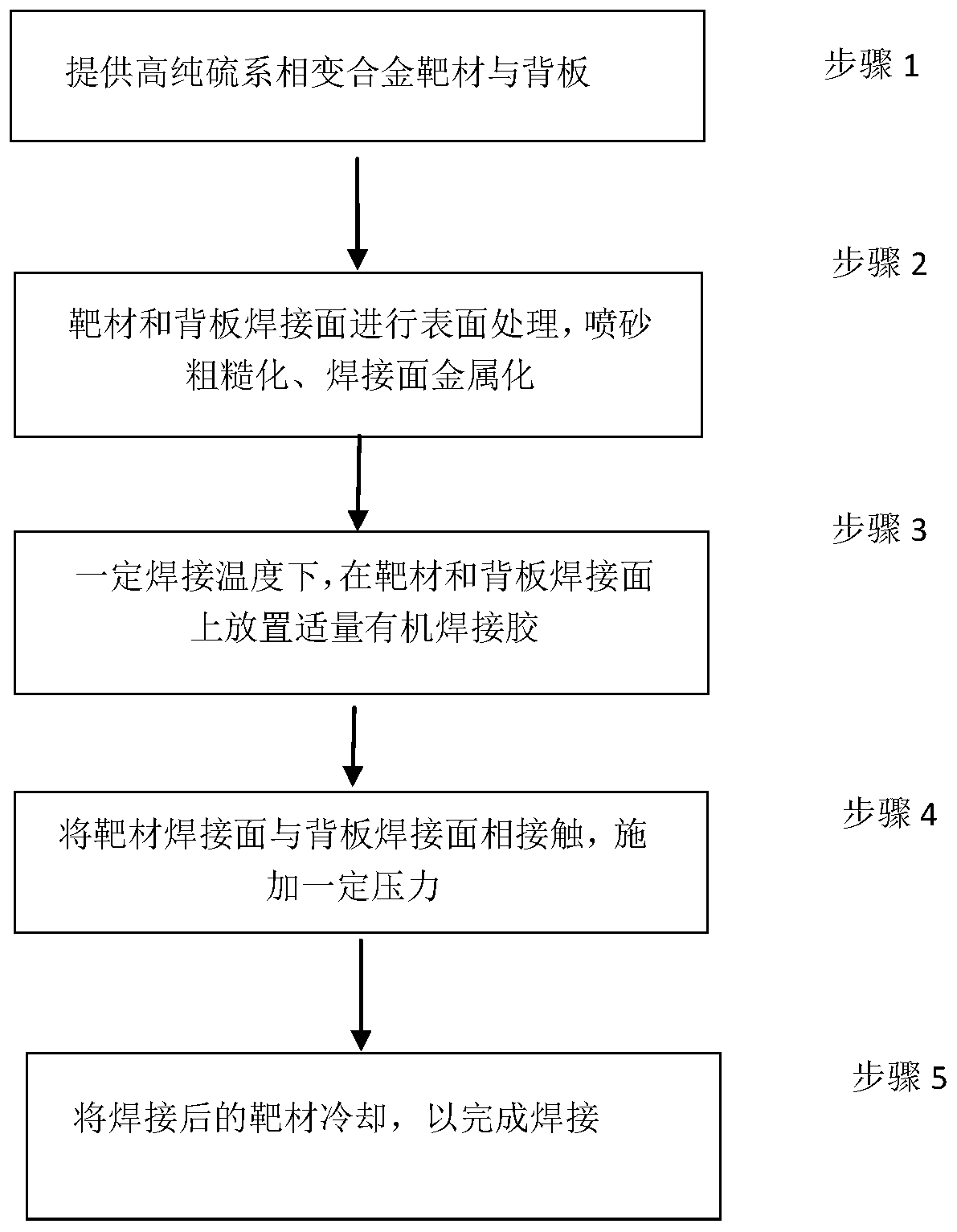

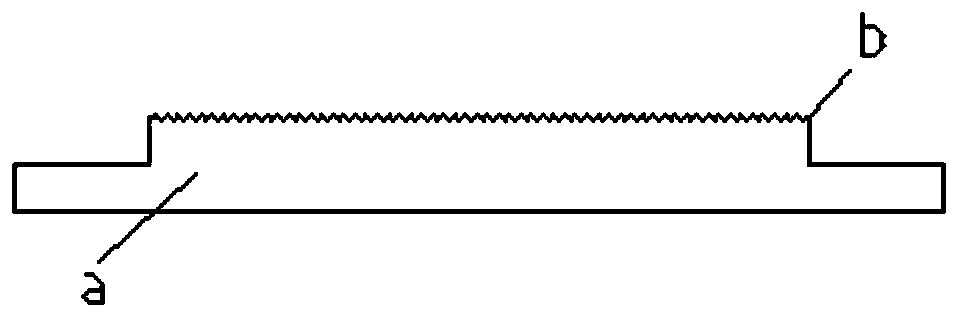

Welding method of high-purity sulfur phase change alloy target

The invention discloses a welding method of high-purity sulfur phase change alloy target. The welding method comprises the following steps of 1, providing the high-purity sulfur phase change alloy target and a back plate; 2, carrying out surface treatment of the welding surfaces of the target and the back plate; 3, placing appropriate amount of organic welding adhesives on the welding surfaces ofthe target and the back plate; 4, contacting the welding surface of the target with the welding surface of the back plate, and applying a certain pressure for welding; and 5, cooling the welded targetto complete welding. According to the welding method of the high-purity sulfur phase change alloy target, by optimizing the surface state of the welding surfaces of the target and the back plate, thetarget and the back plate are wetted with the organic welding adhesives, so that the welding area is increased, and the welding effect is improved, that is, the welded rate is improved; and at the same time, the welding temperature and the welding pressure are controlled, so that the fluidity of the welding adhesives is controlled, the amount of the welding adhesives is reduced and the thicknessof welding seams is controlled, and therefore, the requirements of the customers for the target performance are met.

Owner:有研新材料股份有限公司

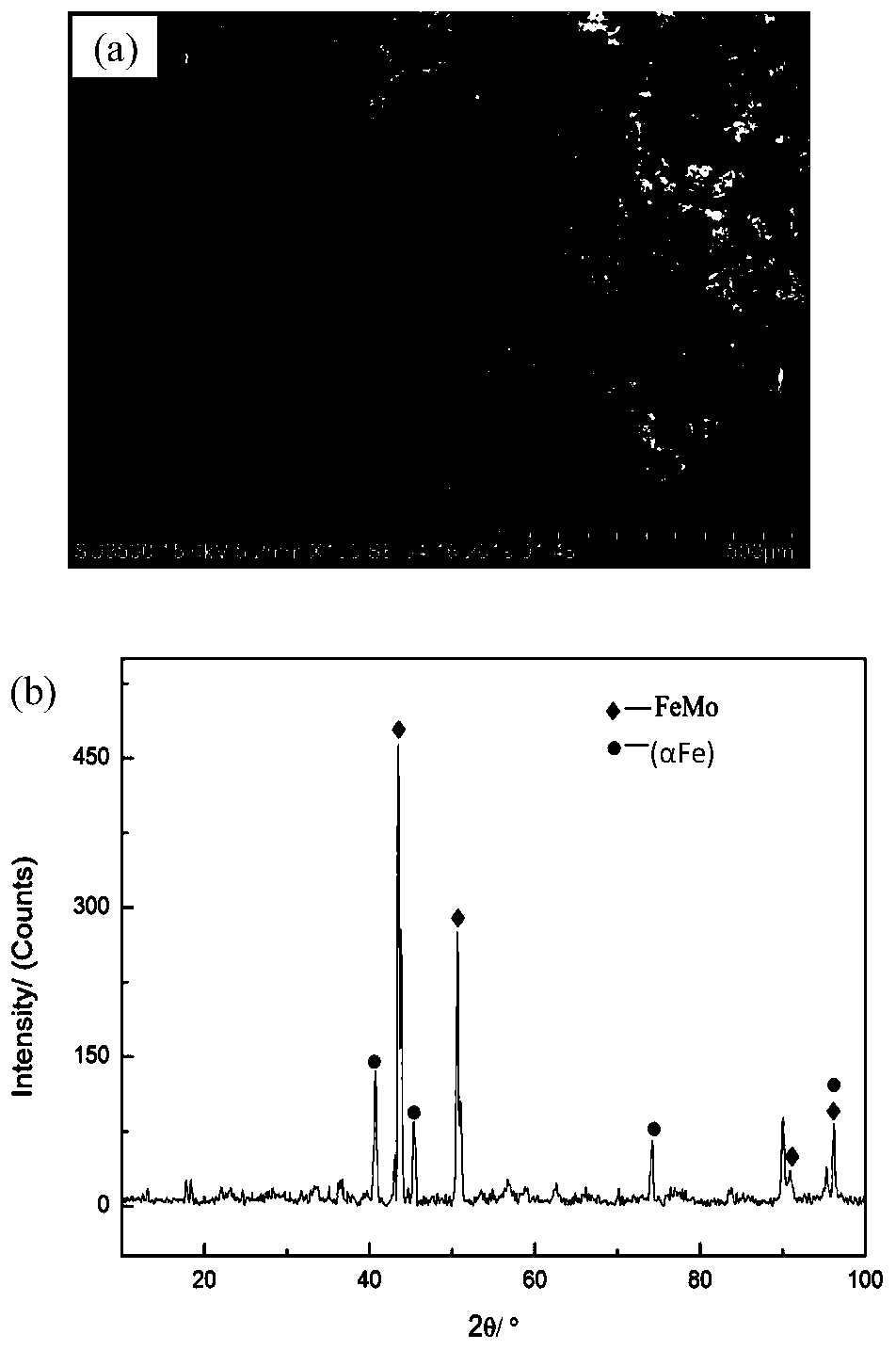

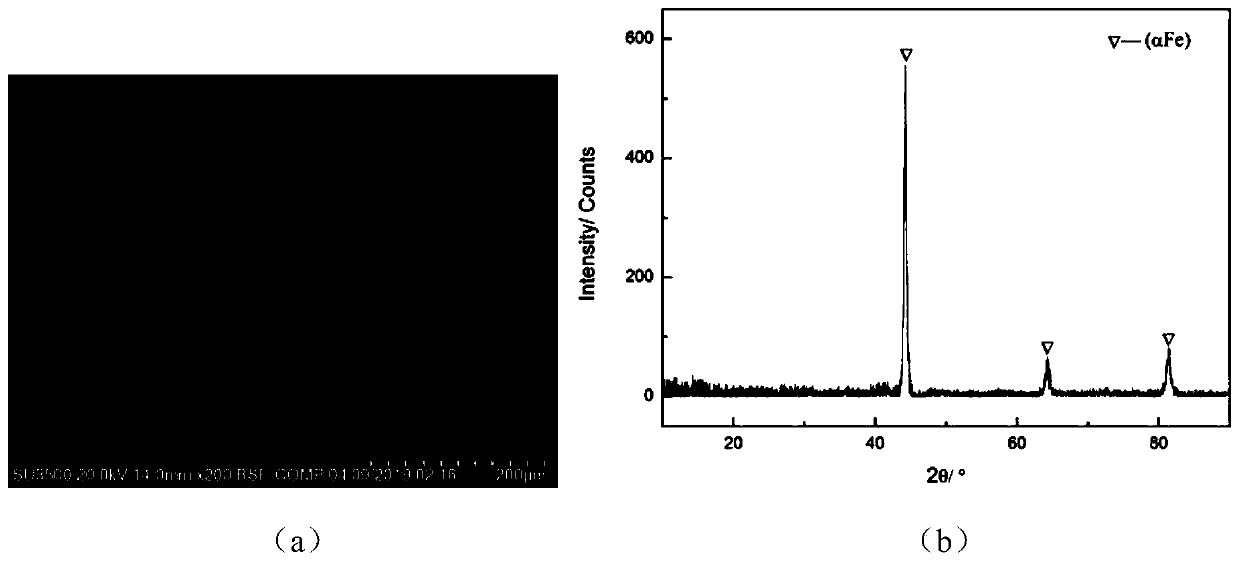

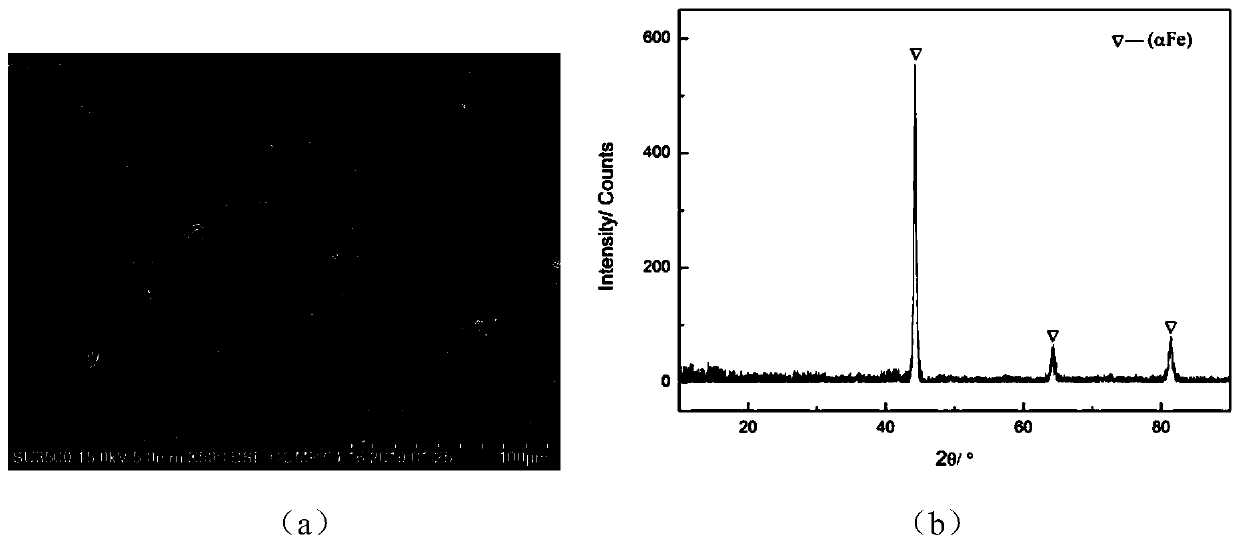

Fe-based multi-element active high-temperature solder for carbon fiber reinforced ceramic matrix composite

ActiveCN111085796ASmall coefficient of thermal expansionImprove high temperature resistanceWelding/cutting media/materialsSoldering mediaThermal dilatationCarbon fibers

The invention designs a Fe-based multi-element active high-temperature solder for a carbon fiber reinforced ceramic matrix composite. Stainless steel with low expansion coefficients is mainly used asa master alloy, melting point depressant elements are not added, and a liquid phase is obtained by a mode of eutectic reaction between Fe and carbon fibers in the solder in soldering so that the non-metallic carbon fibers can be rapidly wetted, a melting point of the solder, the soldering temperature and the service temperature of a joint can be improved favorably, and a brittle intermetallic compound formed by the melting point depressant elements can be avoided favorably; due to the fact that the stainless steel master alloy and an added refractory element Mo both have the advantages of being small in thermal expansion coefficient and high in heat resistance, an obtained soldering seam has the advantages of small in thermal expansion coefficient, resistant in oxidation corrosion and highin heat resistance, which is beneficial to reducing the thermal stress and improving the service temperature of the joint and improving the comprehensive performance of the joint; and the solder hasthe advantages of being low in price, high in soldering temperature, fast in wetting reaction, short in soaking time and high in room-temperature / high-temperature strength of the soldered joint.

Owner:咸阳瞪羚谷新材料科技有限公司

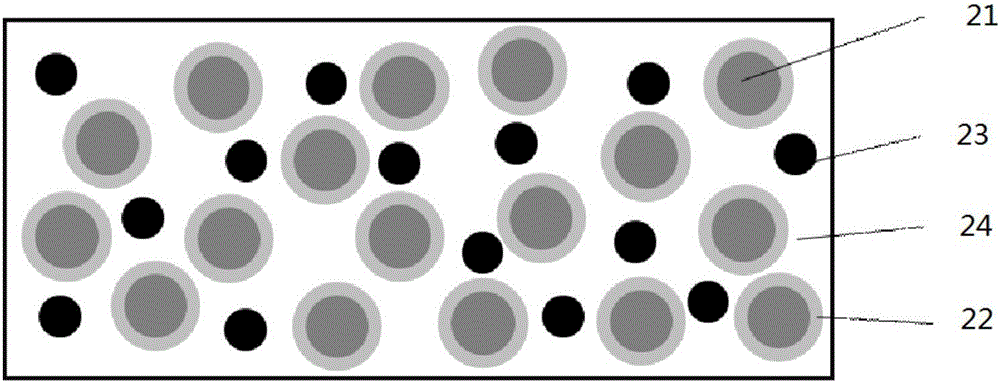

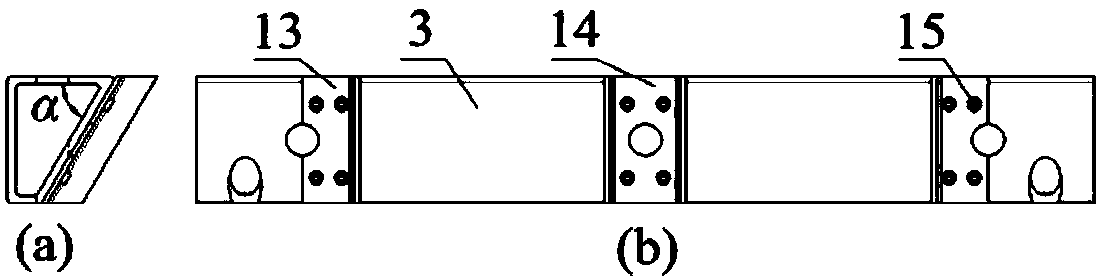

Composite board and preparation method thereof

ActiveCN111331962AEliminate residueRemove oil spotsLaminationLamination apparatusIngotComposite plate

The invention discloses a composite board and a preparation method thereof. The method comprises the following steps: preparing a core material cast ingot, a filling layer alloy plate and a covering layer alloy plate; hot-rolling the composite core material cast ingot and the filling layer alloy plate to obtain an alloy coiled material; and cold-rolling the composite coating alloy plate and the alloy coiled material. The composite board comprises a core material, a filling layer and a covering layer which are stacked in sequence, the covering layer is prepared from the following aluminum alloycomponents in percentage by weight: 5.0 to 12.6 percent of Si, less than or equal to 0.8 percent of Fe, less than or equal to 0.25 percent of Cu, less than or equal to 0.1 percent of Mn, less than orequal to 0.1 percent of Zn, 0.05 to 0.2 percent of Bi, less than or equal to 0.1 percent of Sr, less than or equal to 0.1 percent of Eu and less than or equal to 0.1 percent of Yb; the filling layeraluminum alloy comprises the following components in percentage by weight: 7.0-15.0% of Si, less than or equal to 0.8% of Fe, less than or equal to 0.3% of Cu, less than or equal to 0.15% of Mn, lessthan or equal to 0.15% of Zn, 0.05-0.5% of Mg, 0.05-0.2% of Bi, less than or equal to 0.1% of Sr and less than or equal to 0.1% of Gd; the core material is one of series 1, series 3, series 5, series6, and series 7 aluminum alloys. The composite board is used as a soldering flux-free brazing material for the finned tube in the automobile condenser, and the welding rate reaches up to 95% or above.

Owner:YINBANG CLAD MATERIAL

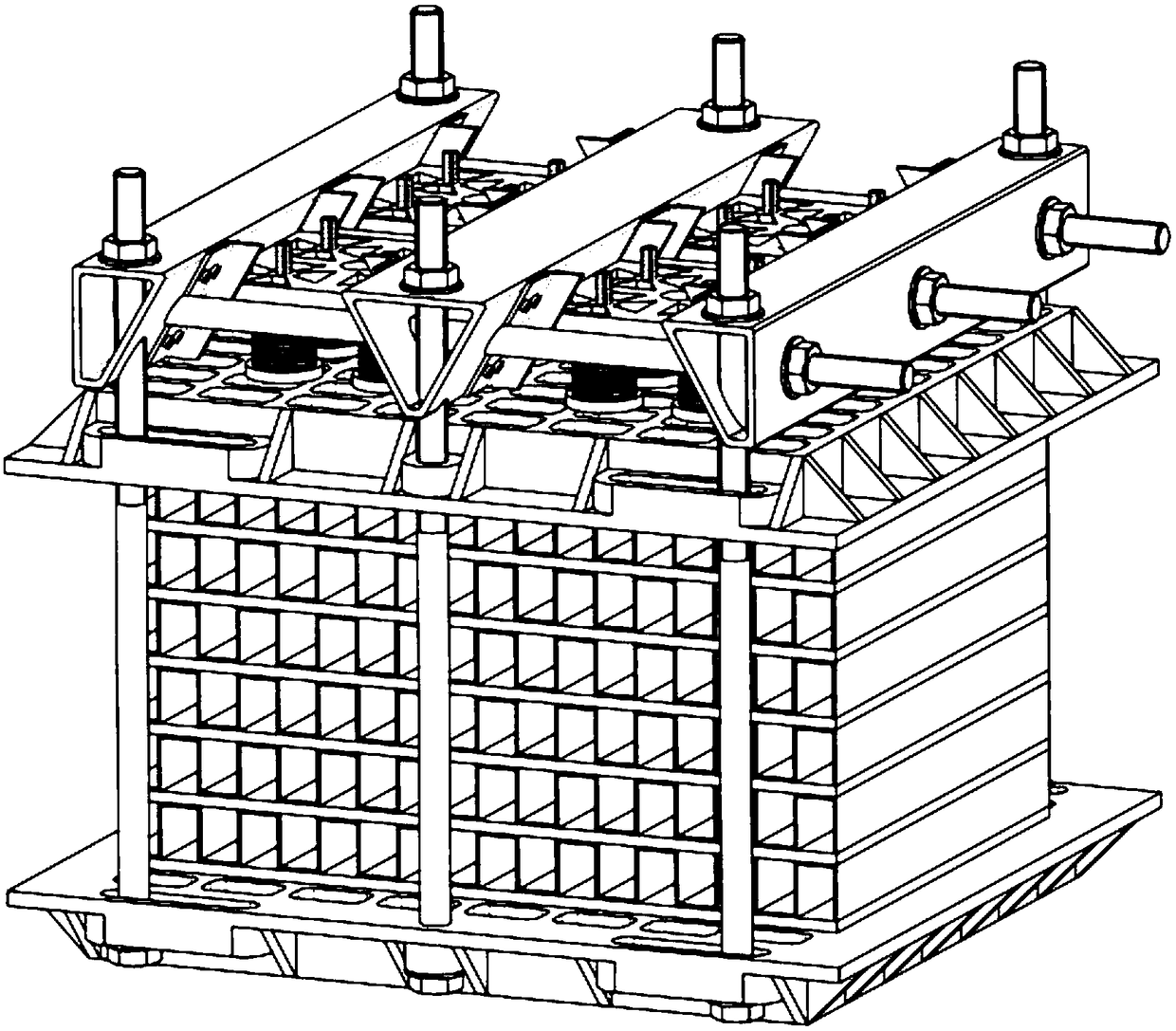

Braze welding clamp of plate-fin type heat exchanger

ActiveCN108637421AHigh strengthImprove plasticitySoldering auxillary devicesWeld seamHeat transfer efficiency

The invention discloses a braze welding clamp of a plate-fin type heat exchanger. The clamp consists of a nut, a top bolt, a side top bar, a spring, an upper cover plate, a plate-fin structure, a lower bottom plate, a vertical bolt, a supporting plate, a measuring rod, a pressure plate, a middle top bar, a side guide sheet, a middle guide sheet, a bolt, a rolling ball and a pin, wherein the pressure plate is additionally arranged between the side top bar and the middle top bar; the measuring rod is inserted into the pressure plate in a through hole; the spring is placed between the supportingplate and the pressure plate; the supporting plate is placed on the upper cover plate; the plate-fin structure is positioned between the upper cover plate and the lower bottom plate; a part among thepressure plate, the upper cover plate and the lower bottom plate is of a hollow-out structure; the side top bar is assembled with the middle top bar through matching of a bolt and a nut; and each topbar is assembled with the lower bottom plate through matching of a bolt and a nut. The braze welding clamp can apply uniform pressure to the plate-fin structure in a vacuum braze welding process, so that distance among welding seams is reduced, a welding rate is increased, welding defects are reduced, and strength and plasticity of a braze welding joint are improved; and moreover, the clamp is high in heat transfer efficiency, is convenient in dismounting, and can shorten a braze welding period.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-strength and high-ductility power station fin material and processing technology thereof

InactiveCN111645380AImprove welding rateEliminate internal stressLamination ancillary operationsLaminationPower stationAlloy

The prepared material is composed of a core material and a skin material, and the core material alloy is prepared from 0.7 wt%-1.0 wt% of Si, 0.3 wt%-0.6 wt% of Fe, 1.3 wt%-1.8 wt% of Mn, 1.3 wt%-1.6wt% of Zn, 0.1 wt%-0.2 wt% of Zr and the balance aluminum and inevitable impurity elements; the skin material alloy comprises, by weight, 6.8%-7.8% of Si and the balance aluminum and inevitable impurity elements. According to the chemical components, a composite aluminum strip obtained through the procedures of fusion casting, saw cutting, surface milling, compounding, heating, hot rolling, cold rolling, annealing, tension leveling and slitting has the forming performance, the strength and corrosion resistance after brazing are superior to those of a composite aluminum strip material with 3003as the core material, and the use requirement of fins for brazing of a power station cooling system is met.

Owner:DALISHEN ALUMINUM

Manufacturing method of nickel-chromium target assembly

The invention provides a method for manufacturing a nickel-chromium target material component. The method comprises the following steps: placing a solder on welding faces of both a back panel and a nickel-chromium target material; heating to enable the solder to be molten; performing first ultrasonic treatment on the welding faces of both the back panel and the nickel-chromium target material, and soaking the welding faces; re-placing the solder on the welding face of the back panel, and performing second ultrasonic treatment on the welding faces of both the back panel and the nickel-chromium target material; laminating the welding faces of the back panel and the nickel-chromium target material and welding; and cooling after welding to form the target material component. According to the method, welding is assisted by twice ultrasonic treatment methods, twice ultrasonic treatment can enable alloy layers to form on the surfaces of the back panel and the nickel-chromium target material and can also ensure that the solder is uniformly distributed on the welding faces of both the back panel and the nickel-chromium target material, and accordingly, the high-welding-strength, high-welded-rate and low-defect-rate welding effects of the nickel-chromium target material and the back panel are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Pre-treatment improving target material binding method

ActiveCN110359021AEnhanced binding effectGuaranteed uniformityWelding/cutting auxillary devicesVacuum evaporation coatingPre treatmentMetal

The invention discloses a pre-treatment improving target material binding method which comprises the following steps: a, a step before pre-treatment; b, a step of pre-treatment of a back tube; c, a step of pre-treatment of a metal target tube; and d, a binding step. According to the pre-treatment improving target material binding method provided by the invention, the pre-treatment effect before binding a rotary target is improved effectively, and the binding quality of the rotary target is improved.

Owner:东莞市欧莱溅射靶材有限公司

Cadmium-free silver-based brazing filler metal

InactiveCN106514042AEnhance welding rate and welding strengthLow melting pointWelding/cutting media/materialsSoldering mediaMelt temperatureCorrosion

The invention provides cadmium-free silver-based brazing filler metal which is prepared from, by weight, 28-38% of Ag, 20-30% of Zn, 1-3% of Mg, 2-4% of Sn, 0.6-1.3% of Ni, 0.04-0.16% of NaF, 0.3-1.2% of P and the balance Cu. The cadmium-free silver-based brazing filler metal is low in silver content, contains no cadmium element, is low in melting temperature, high in corrosion resistance and good in machining performance, is the multi-element silver brazing filler metal and is used for brazing red copper, brass and stainless steel.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

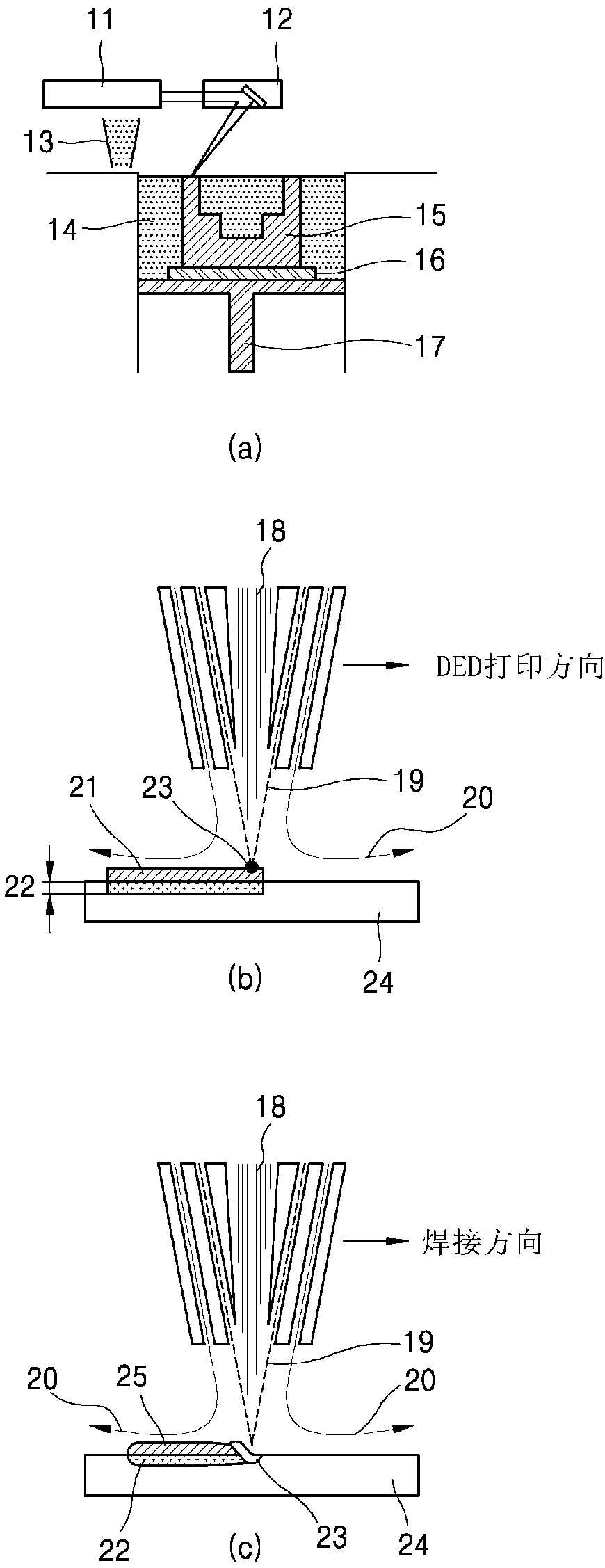

Ded arc three-dimensional alloy metal powder printing method and apparatus using arc and alloy metal powder core wire

InactiveCN108349002AEffective and high-speed workReasonable priceAdditive manufacturing apparatusArc welding apparatusPotential differenceElectrode Contact

Disclosed are a DED arc three-dimensional alloy metal powder printing method using an arc and an alloy metal powder core wire, and an apparatus therefor. A DED arc three-dimensional alloy metal powderprinting method, according to an embodiment of the present invention, comprises the steps of: (a) connecting a three-dimensional printing part mold with a first electrode via a ground line, contacting a second electrode, in which an electrode contact tip is tapped on a peripheral surface of an alloy metal powder core wire, with a part of the surface of the printing part of the mold, and then generating an arc by a potential difference between the first electrode and the second electrode to melt the front end of the alloy metal powder core wire and the surface of the printing part at the sametime; (b) forming a monolayer by mixing and coagulating the melt of the alloy metal powder core wire and the melt of the surface of the printing part; and (c) stacking the monolayer by continuously performing a monolayer overlay.

Owner:BEES INC

Copper-molybdenum electrode welding method

ActiveCN108237278AEnsure welding strength is qualifiedSolve difficult problemsSoldering apparatusPower flowButt joint

The invention discloses a copper-molybdenum electrode welding method. An copper-molybdenum electrode is formed through welding of a copper-molybdenum head and a copper seat, wherein the copper-molybdenum head is made of copper-molybdenum material; and the copper seat is made of pure copper or copper alloy. The copper-molybdenum electrode welding method comprises the following steps: cleaning a to-be-welded surface; smearing brazing flux on the to-be-welded surface, and then carrying out butt joint and clamping to enable the to-be-welded surface to be horizontal; smearing a stop-off agent in the welding line on the periphery of the to-be-welded surface to separate the welding line into an air exhausting area accounting for 25%-40% and a brazing filler metal adding area accounting for 15%-30%; enabling the welding line positions of the brazing filler metal adding area and the air exhausting area to be opposite; mounting a to-be-welded piece and a clamp into high-frequency induction heating equipment; placing a proper amount of brazing filler metal in the brazing filler metal adding area; quickly heating to fuse the brazing filler metal; adjusting induced current for heat preservation; shutting down the heating equipment until fused brazing filler metal on the entire air exhausting area; and cooling to obtain the copper-molybdenum electrode. According to the copper-molybdenum electrode welding method, the stop-off agent restrains fused brazing filler metal to flow in the welding line on the periphery; the fused brazing filler metal flows in the brazing filler metal adding areaand flows out of the air exhausting area to squeeze the air in the gap out, so that the problem about discharging of the air in the gap when a large-specification copper-molybdenum electrode is brazed is solved; and the brazing rate is remarkably increased to be 80% or above.

Owner:桂林金格电工电子材料科技有限公司

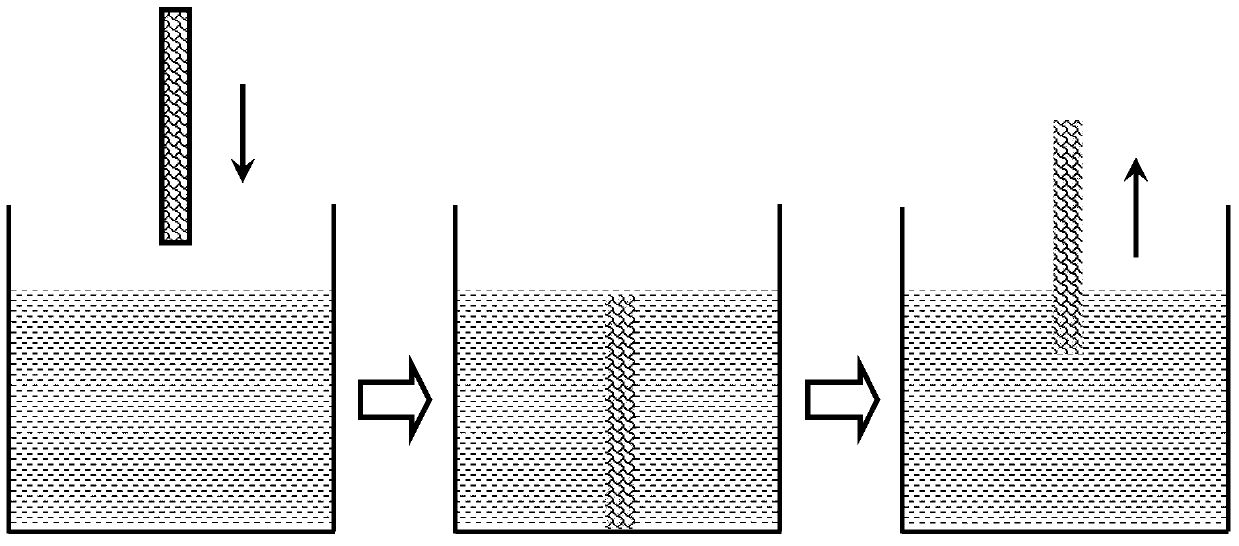

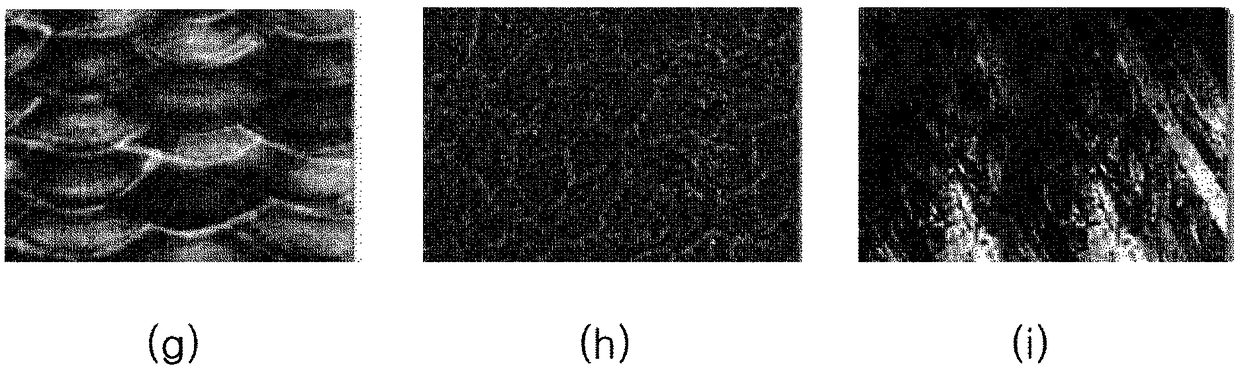

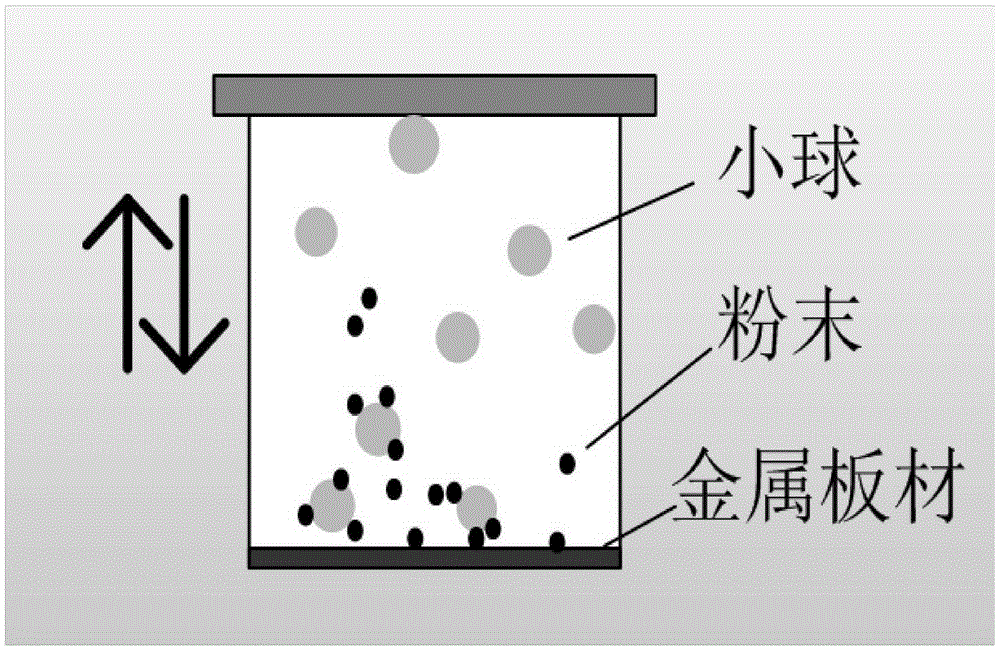

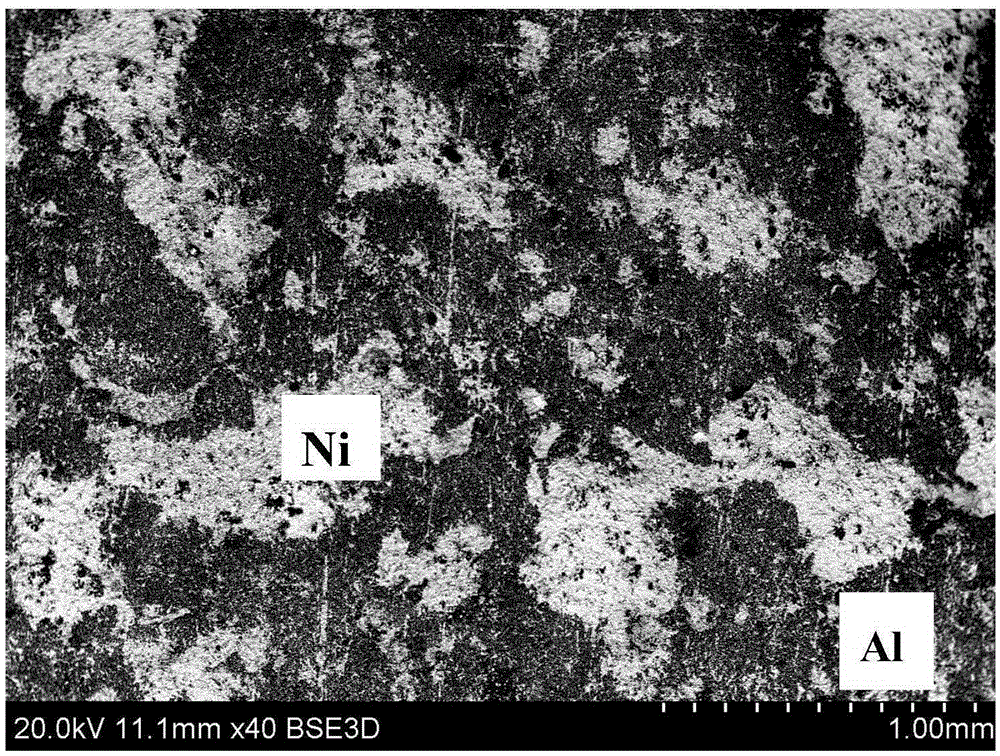

Pure aluminum surface treatment method for aluminum/nickel diffusion bonding

ActiveCN105252138ADiffuse fullyReduce gapNon-electric welding apparatusBond qualityTherapeutic effect

The invention relates to pure aluminum surface treatment methods, in particular to a pure aluminum surface treatment method for aluminum / nickel diffusion bonding. According to the pure aluminum surface treatment method, a pure aluminum base material surface treatment method is a mechanical vibration treatment method, small stainless steel balls bonded with nickel powder constantly collide with a pure aluminum base material subjected to softening annealing treatment, and crushing of oxide films on pure aluminum surfaces is facilitated; cold welding is constantly conducted through energy rise caused by collision between the nickel powder and the pure aluminum base material, and part of nickel is inlaid in the pure aluminum base material; and finally, a coating nonuniform in thickness can be formed, so that the surface treatment effect is achieved. According to the method, diffusion bonding is conducted on the pure aluminum base material subjected to mechanical vibration surface treatment and the nickel, the oxide films on the aluminum surfaces are crushed more easily, and nickel-and-nickel bonding occurs, so that atomic diffusion is more sufficient, the number of gaps is smaller, the welding rate is increased significantly, and bonding quality is improved remarkably.

Owner:HARBIN INST OF TECH

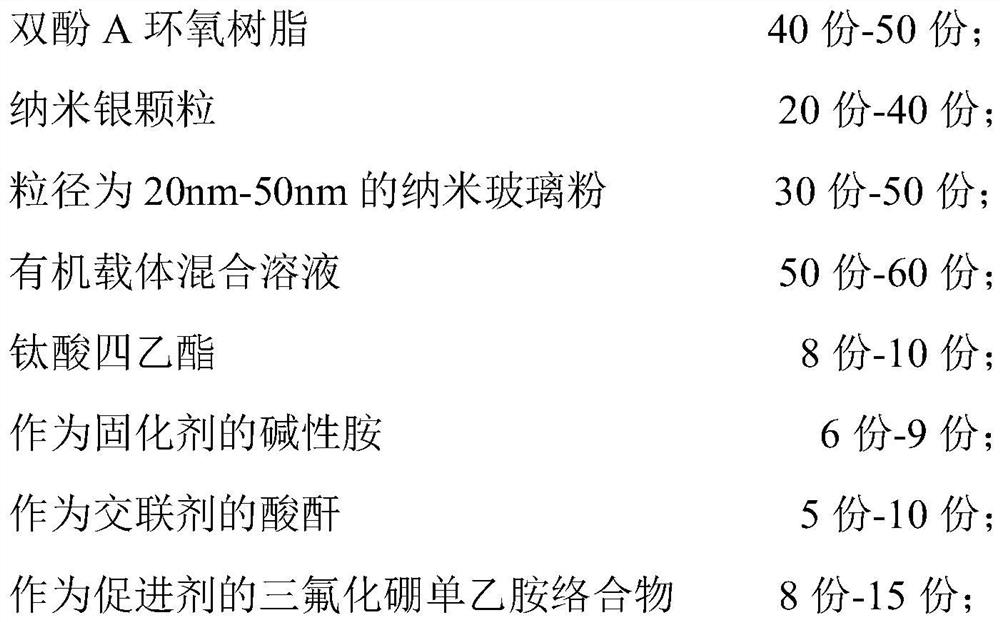

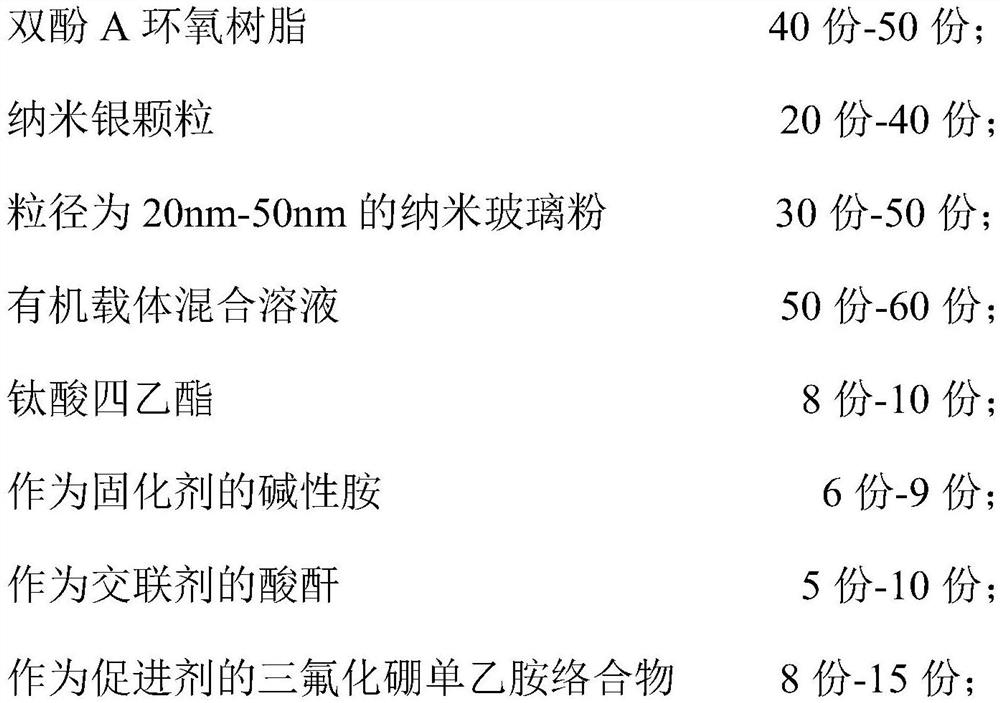

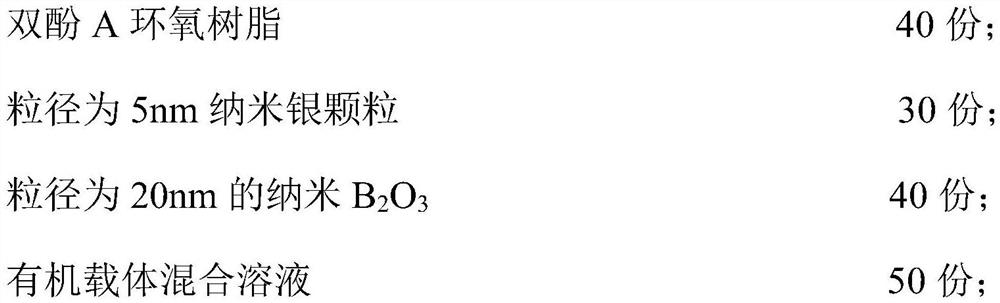

Solar cell front conductive silver paste and preparation method thereof

PendingCN114464338AImprove control effectExcellent thin line ink penetration abilityNon-conductive material with dispersed conductive materialCable/conductor manufactureEngineeringSolar cell

The invention provides solar cell front conductive silver paste and a preparation method thereof, and the conductive silver paste is prepared from the following materials in parts by weight: 40-50 parts of bisphenol A epoxy resin; 20 to 40 parts of nano silver particles; 30 to 50 parts of nano glass powder; 50-60 parts of an organic carrier mixed solution; 8 to 10 parts of tetraethyl titanate; 6-9 parts of alkaline amine; 5 to 10 parts of anhydride; 8 to 15 parts of a boron trifluoride monoethylamine complex; the organic carrier mixed solution comprises organic acid doped conductive organic polymer / epoxidized soybean oil with the mass fraction concentration of 15%-20% and a high-boiling-point solvent with the mass fraction concentration of 80%-85%. According to the invention, the contact between the inorganic powder and the screen cloth material can be effectively wetted, the more excellent fine line ink penetration capability is provided, the method is suitable for the high-speed printing of the ultra-fine grid of the current large-area silicon wafer, the fine grid line width control capability is excellent, and the better electrode height-width ratio can be formed.

Owner:DK ELECTRONICS MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com