Welding method of high-purity sulfur phase change alloy target

A welding method and a technology of phase change alloys, which are applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of chalcogenide alloy target cracking, high welding temperature, and inappropriateness, and ensure the thickness of the weld seam and Uniformity, waste reduction, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

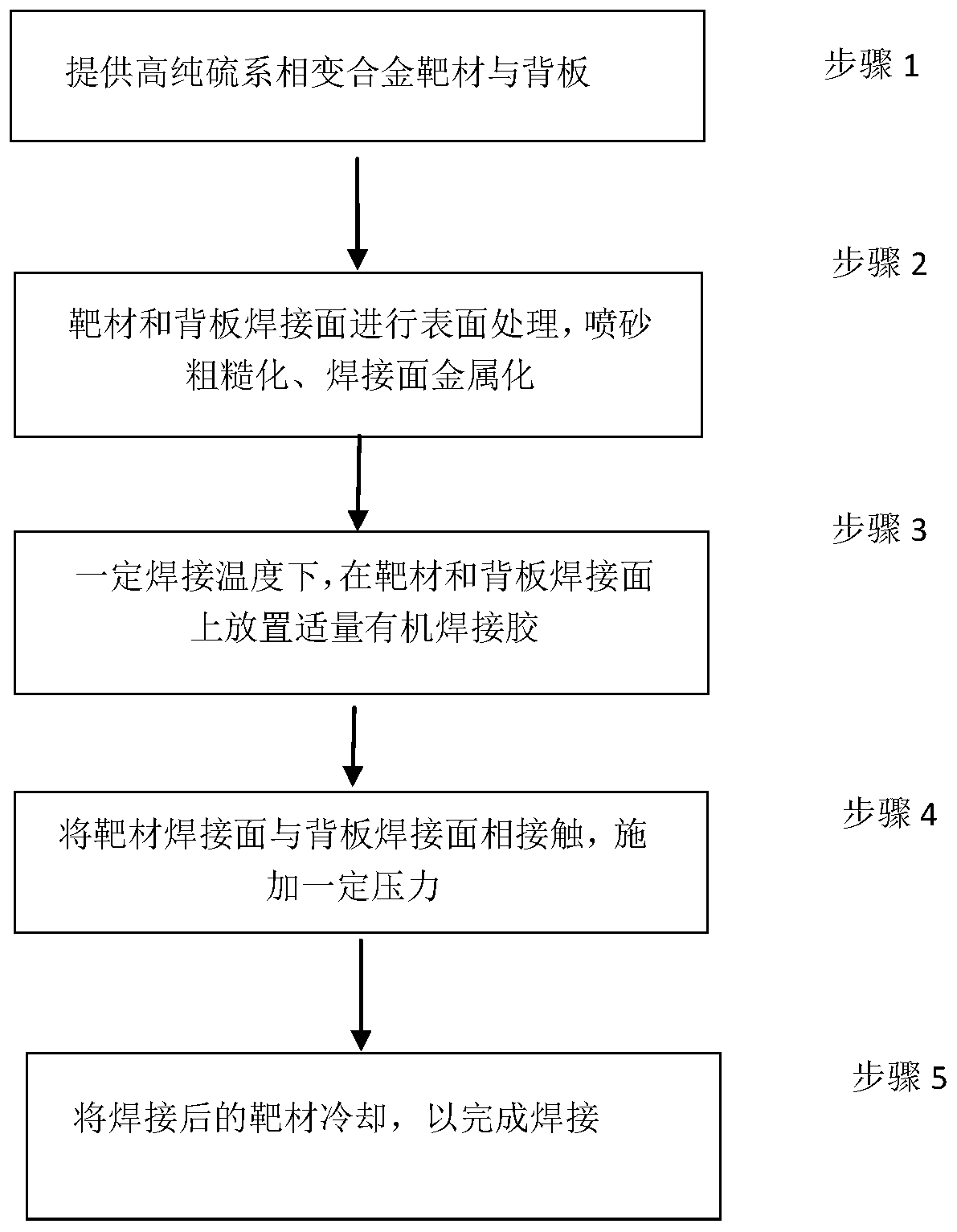

[0023] Flowchart such as figure 1 As shown, it includes the following steps:

[0024] Step 1: Provide high-purity chalcogenide phase change alloy target and back plate;

[0025] Step 2: Surface treatment of the welding surface of the target material and the back plate, sandblasting and roughening, and metallization of the welding surface;

[0026] Step 3: The welding temperature is 58°C, and an appropriate amount of organic welding glue is placed on the welding surface of the target and the back plate;

[0027] Step 4: Contact the welding surface of the target with the welding surface of the back plate, apply a pressure of 3Pa, and perform welding;

[0028] Step 5: Cool the welded target to complete the welding.

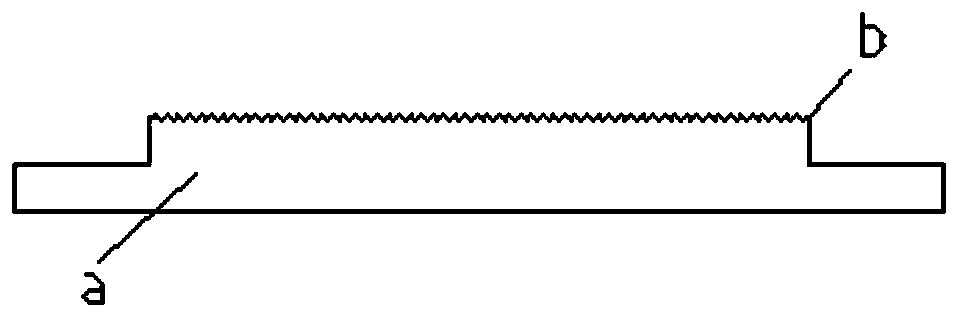

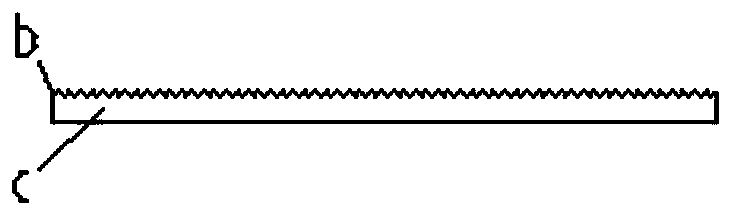

[0029] Among them, the sandblasting roughness needs to be set in combination with the characteristics of the target material, and the integrity and appearance of the target material must not be damaged. The metal material for the metallization of the target weldi...

Embodiment 2

[0031] Flowchart such as figure 1 shown, including the following steps:

[0032] Step 1: same as embodiment one, step 1;

[0033] Step 2: same as embodiment one, step 2;

[0034] Step 3: The welding temperature is 40°C, and an appropriate amount of organic welding glue is placed on the welding surface of the target and the back plate;

[0035] Step 4: same as embodiment one, step 4;

[0036] Step 5: Same as Embodiment 1, step 5.

Embodiment 3

[0038] Flowchart such as figure 1 shown, including the following steps:

[0039] Step 1: same as embodiment one, step 1;

[0040] Step 2: same as embodiment one, step 2;

[0041] Step 3: The welding temperature is 70°C, and an appropriate amount of organic welding glue is placed on the welding surface of the target and the back plate;

[0042] Step 4: same as embodiment one, step 4;

[0043] Step 5: Same as Embodiment 1, step 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com