Early-strength pavement patching material and preparation method thereof

A pavement repair and admixture technology, which is applied in the field of early-strength pavement repair materials and its preparation, can solve the problems of short setting time of alkali-excited materials, difficult to control early performance, difficult construction, etc., to meet the requirements of environmental conditions without harsh, step process Short, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

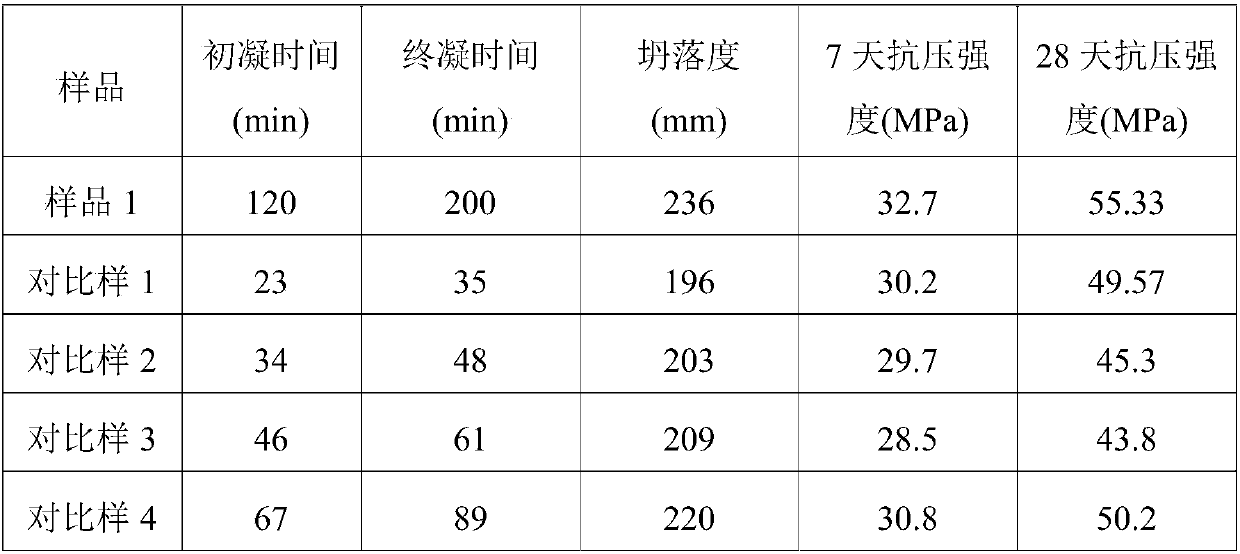

Embodiment 1

[0047] An early-strength pavement repair material, comprising the following components in parts by weight:

[0048] 30 parts of blast furnace slag, 30 parts of fly ash, 5 parts of silica fume, 5 parts of metakaolin, 35 parts of activator, 8 parts of admixtures, admixtures include powder admixtures and liquid admixtures.

[0049] Wherein, the sum of oxides of calcium, silicon and aluminum in the blast furnace slag is greater than 85wt%, and the content of calcium carbonate in the blast furnace slag is less than or equal to 10wt%. Blast furnace slag is alkaline water quenched blast furnace slag, and the ageing time should be less than 1 year. The sum of oxides of calcium, silicon and aluminum in fly ash is greater than 85 wt%. The content of active silicon oxide in the silica fume is greater than 90%. The sum of oxides of silicon and aluminum in metakaolin is greater than 90 wt%. The carbon content of metakaolin is ≤10wt%. The stimulant is sodium silicate with a modulus of 1.0 to...

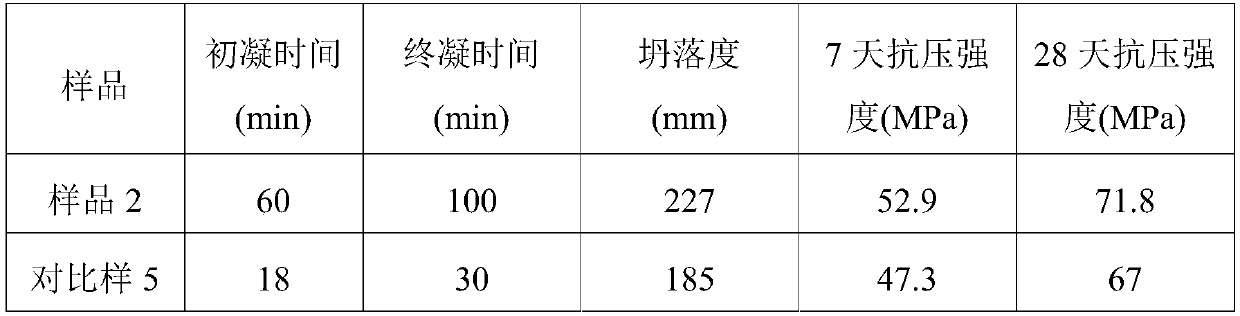

Embodiment 2

[0051] An early-strength pavement repair material, comprising the following components in parts by weight:

[0052] 70 parts of blast furnace slag, 70 parts of fly ash, 40 parts of silica fume, 40 parts of metakaolin, 120 parts of activator, 16 parts of admixtures, admixtures including powder external admixtures and liquid admixtures.

[0053] Wherein, the sum of oxides of calcium, silicon and aluminum in the blast furnace slag is greater than 85wt%, and the content of calcium carbonate in the blast furnace slag is less than or equal to 10wt%. Blast furnace slag is alkaline water quenched blast furnace slag, and the ageing time should be less than 1 year. The sum of oxides of calcium, silicon and aluminum in fly ash is greater than 85 wt%. The content of active silicon oxide in the silica fume is greater than 90%. The sum of oxides of silicon and aluminum in metakaolin is greater than 90 wt%. The carbon content of metakaolin is ≤10wt%. The stimulant is sodium silicate with a mo...

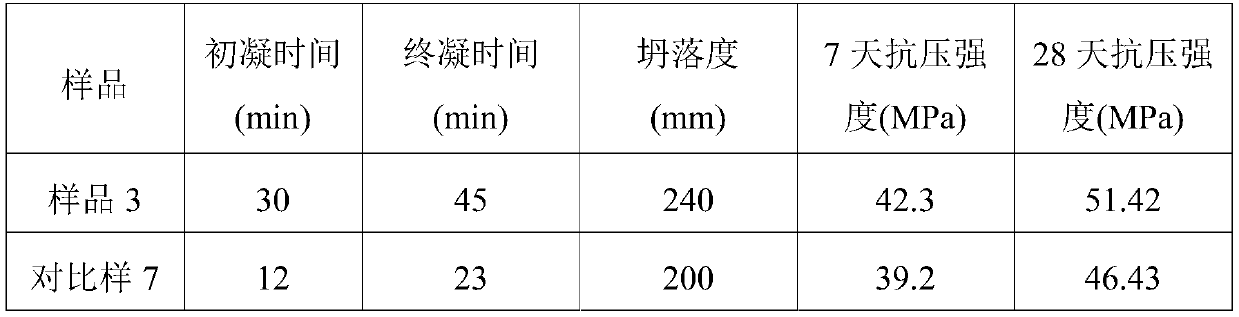

Embodiment 3

[0055] An early-strength pavement repair material, comprising the following components in parts by weight:

[0056] 50 parts of blast furnace slag, 40 parts of fly ash, 20 parts of silica fume, 20 parts of metakaolin, 65 parts of activator, 12 parts of admixtures, admixtures include powder admixtures and liquid admixtures.

[0057] Wherein, the sum of oxides of calcium, silicon and aluminum in the blast furnace slag is greater than 85wt%, and the content of calcium carbonate in the blast furnace slag is less than or equal to 10wt%. Blast furnace slag is alkaline water quenched blast furnace slag, and the ageing time should be less than 1 year. The sum of oxides of calcium, silicon and aluminum in fly ash is greater than 85 wt%. The content of active silicon oxide in the silica fume is greater than 90%. The sum of oxides of silicon and aluminum in metakaolin is greater than 90 wt%. The carbon content of metakaolin is ≤10wt%. The stimulant is sodium silicate with a modulus of 1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com