Optical glass polishing equipment

A technology of edge grinding equipment and optical glass, applied in grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problem of low utilization rate of edge grinding equipment, and achieve easy access to glass , Improve the utilization rate and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

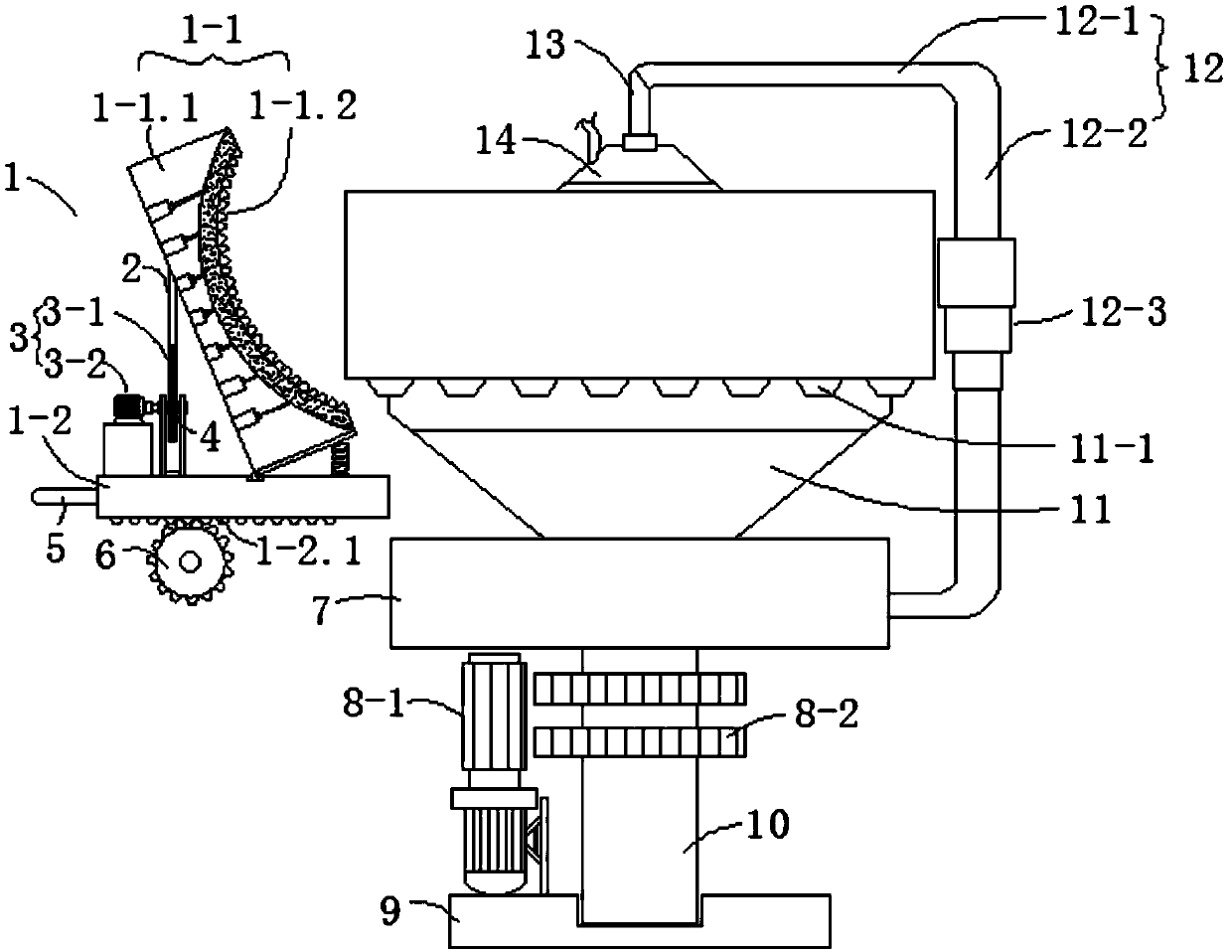

[0023] Such as figure 1 As shown, this embodiment provides an optical glass edging device, which includes a base 9 and a multi-angle mobile grinding assembly 1. A stable seat 7 is horizontally provided on the base 9, and a transmission column is connected between the base 9 and the stable seat 7. 10. A driven gear 8-2 is sleeved on the transmission column 10, and a driving gear 8-1 meshing with the driven gear 8-2 is arranged beside the driven gear 8-2, and one end of the transmission column 10 is rotated and matched with the base 9 , the other end passes through the stable seat 7 and is connected with a glass placement platform 11, the top of the glass placement platform 11 is provided with a glass adsorption disc 14 that cooperates with the glass placement platform 11, and the upper end of the glass adsorption disc 14 is rotatably connected with a vertical rod 13, and the vertical rod 13 is connected to the The multi-section telescopic mechanism 12 is connected between the s...

Embodiment 2

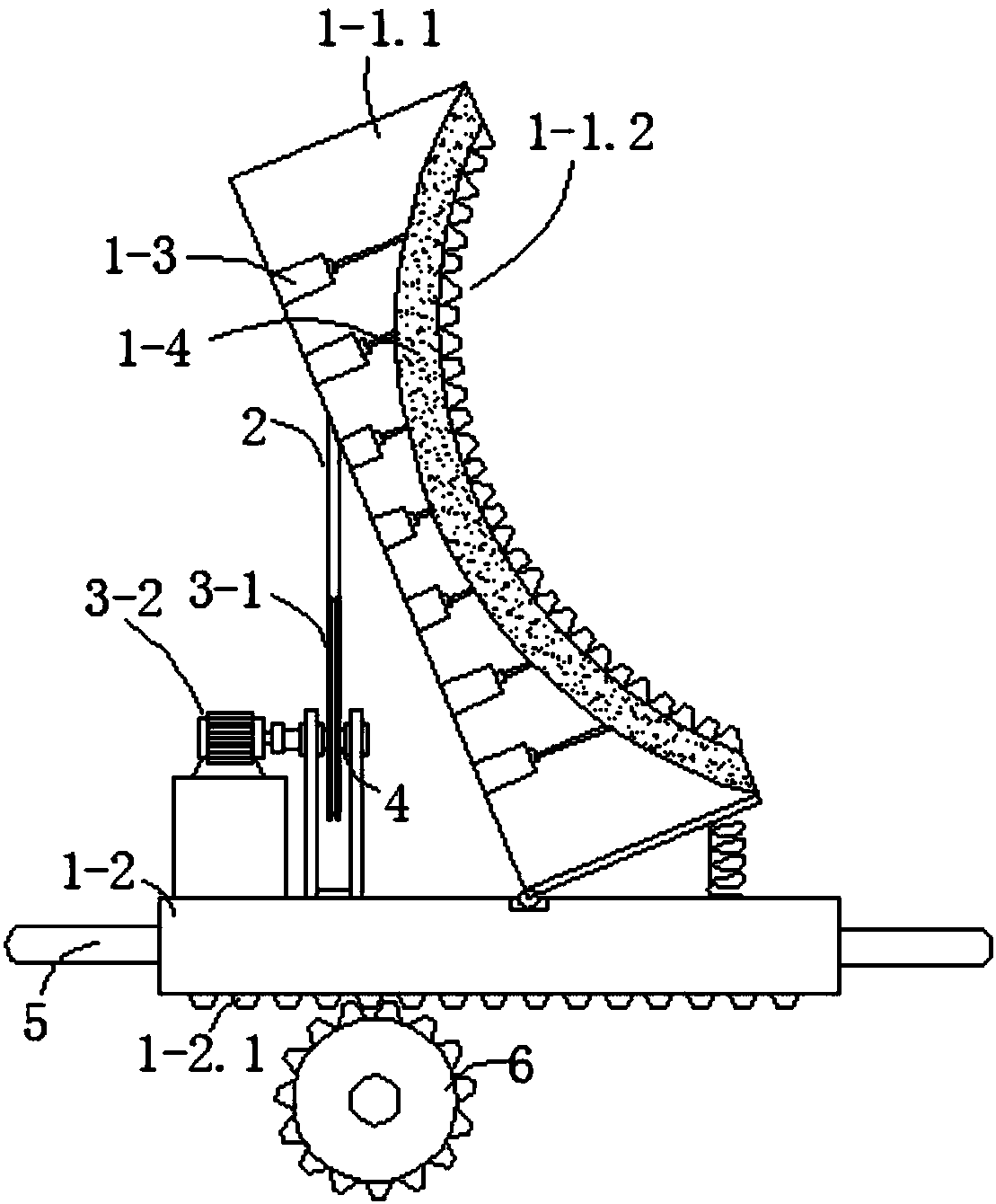

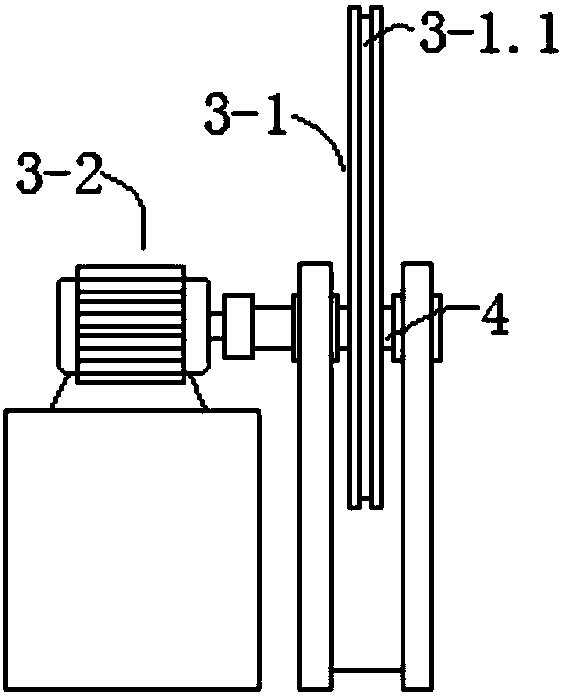

[0026] Such as figure 2 and image 3 As shown, the present embodiment is further optimized on the basis of embodiment 1, specifically:

[0027] The multi-angle mobile grinding assembly 1 includes a mobile base 1-2 and an edging assembly 1-1 arranged on the mobile base 1-2. The edging assembly 1-1 includes an installation frame 1-1.1 and an installation frame 1-1.1. 1.1 The grinding surface 1-1.2 on one side, the installation frame 1-1.1 is installed obliquely on the mobile base 1-2, and is hinged with the mobile base 1-2, and the mobile base 1-2 is provided with a connection with the installation frame 1-1.1 An inclination adjustment assembly 3, the installation frame 1-1.1 is connected with a vertical adjustment rod 2 on the opposite side of the grinding surface 1-1.2, the inclination adjustment assembly 3 includes a motor 3-2 and an eccentric wheel 3-1, and a mobile base 1 -2 is equipped with a rotating shaft 4 connected to the output shaft of the motor 3-2, the eccentric...

Embodiment 3

[0030] This embodiment is further optimized on the basis of Embodiment 2, specifically:

[0031] The bottom of the mobile base 1-2 is provided with a driving gear 6, the bottom of the mobile base 1-2 is provided with a meshing tooth 1-2.1 meshing with the driving gear 6, and a guide groove is dug inside the mobile base 1-2, and the guide groove is interspersed with There is a guide rod 5, the installation frame 1-1.1 is provided with an elastic connection layer 1-4, the grinding surface 1-1.2 is arranged outside the elastic connection layer 1-4, and a number of fine-tuning cylinders 1-4 are arranged on the installation frame 1-1.1 3. The end of the piston rod of each fine-tuning cylinder 1-3 is connected to the inner side of the elastic connecting layer 1-4, and air holes are arranged on the glass adsorption plate 14, and the air holes are connected to a vacuum generator through a connecting pipe, and the glass is placed A number of inverted vacuum chucks 11-1 are evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com