Patents

Literature

97results about How to "Control liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

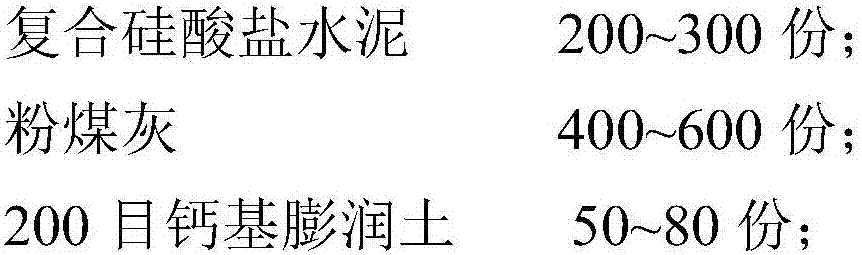

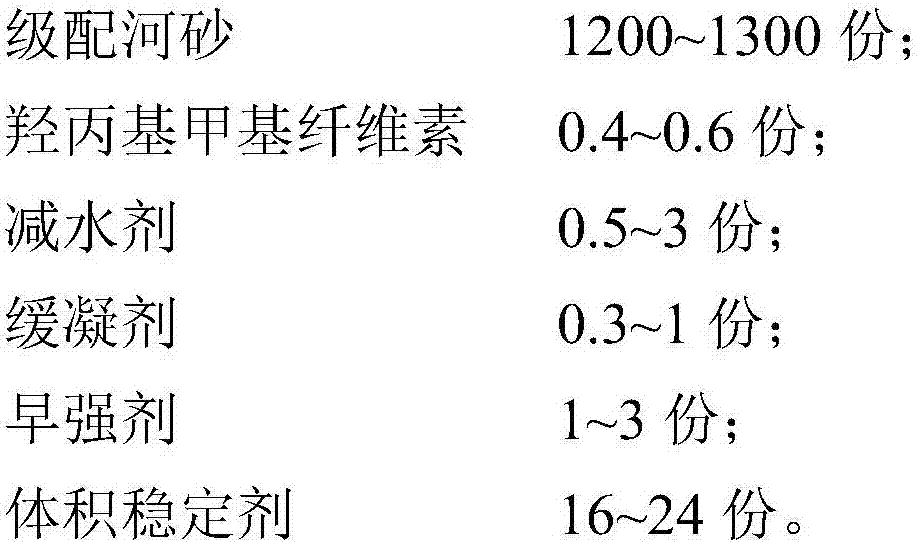

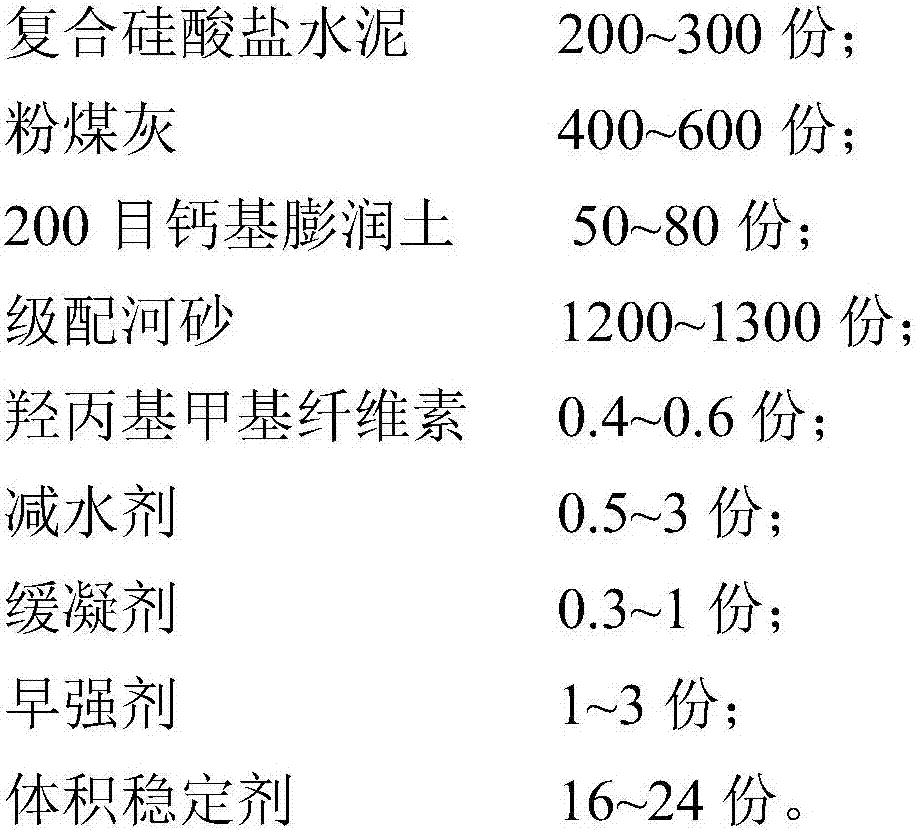

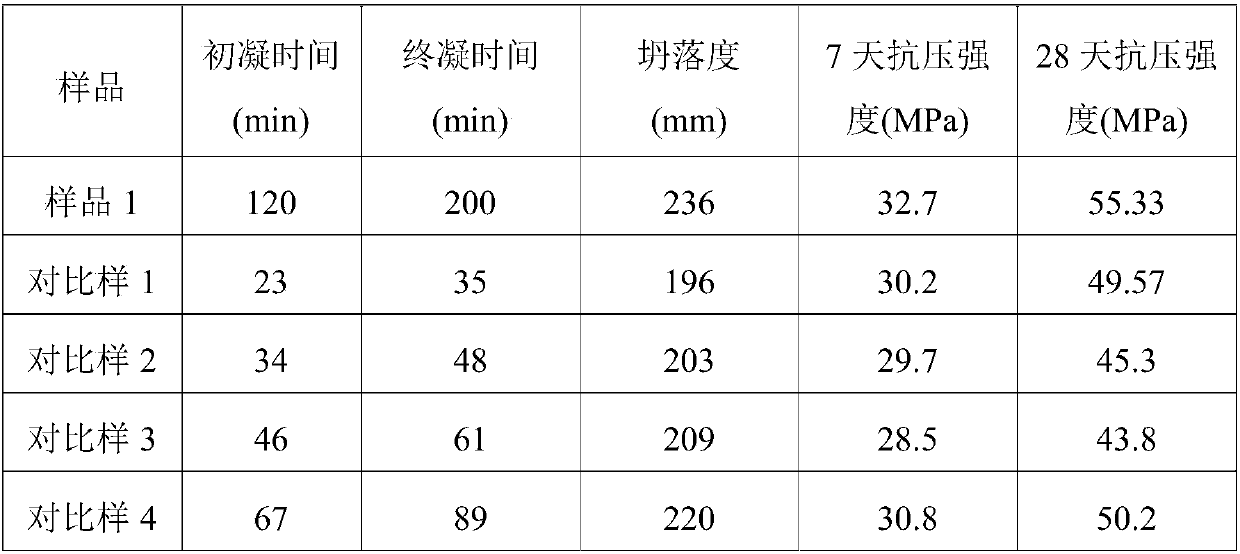

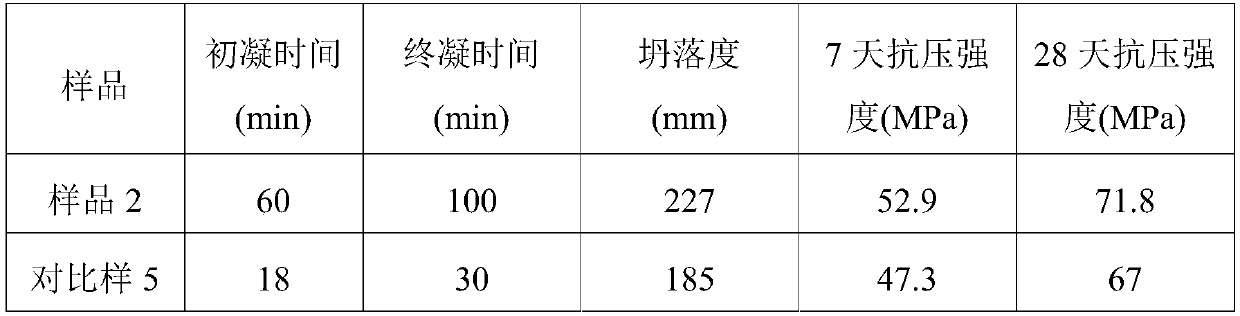

Shield synchronous grouting construction material

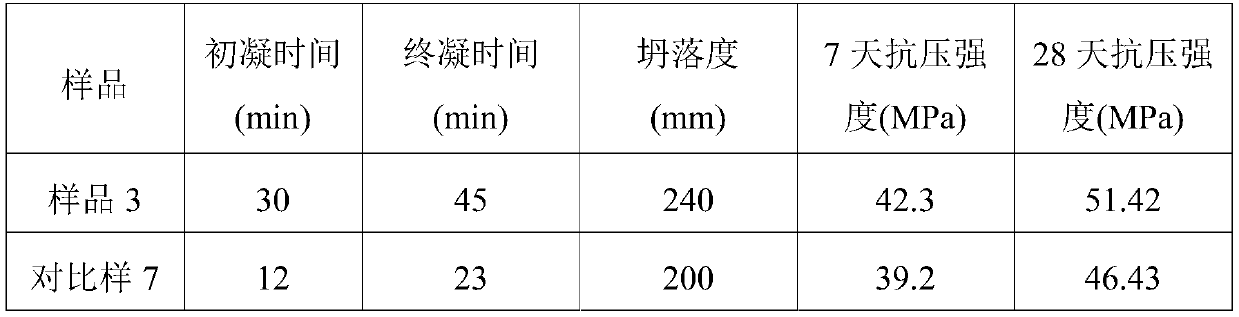

ActiveCN106946522AControl the compressive strengthControl bleeding rateSodium BentonitePortland cement

The invention discloses a shield synchronous grouting construction material including, by weight, 200-300 parts of composite Portland cement, 400-600 parts of fly ash, 50-80 parts of 200-mesh calcium based bentonite, 1200-1300 parts of grading river sand, 0.4-0.6 parts of hydroxypropylmethyl cellulose, 0.5-3 parts of a water reducer, 0.3-1 part of a retarder, 1-3 parts of an early strength agent and 16-24 parts of a volume stabilizing agent. Through reasonable adjustment of composition and content of the components, the compressive strength, bleeding ratio, setting time and flowability of the construction material are controlled, so that the construction material has long initial setting time, is quick in early strength development, is not liable to dissociation, has good volume stability, can effectively fill in gaps in buildings and prevent floatation and deformation of tunnel segments, has good flowability and anti-dispersing property, and is easy to transport and to store for a long period.

Owner:北京艺高世纪科技股份有限公司

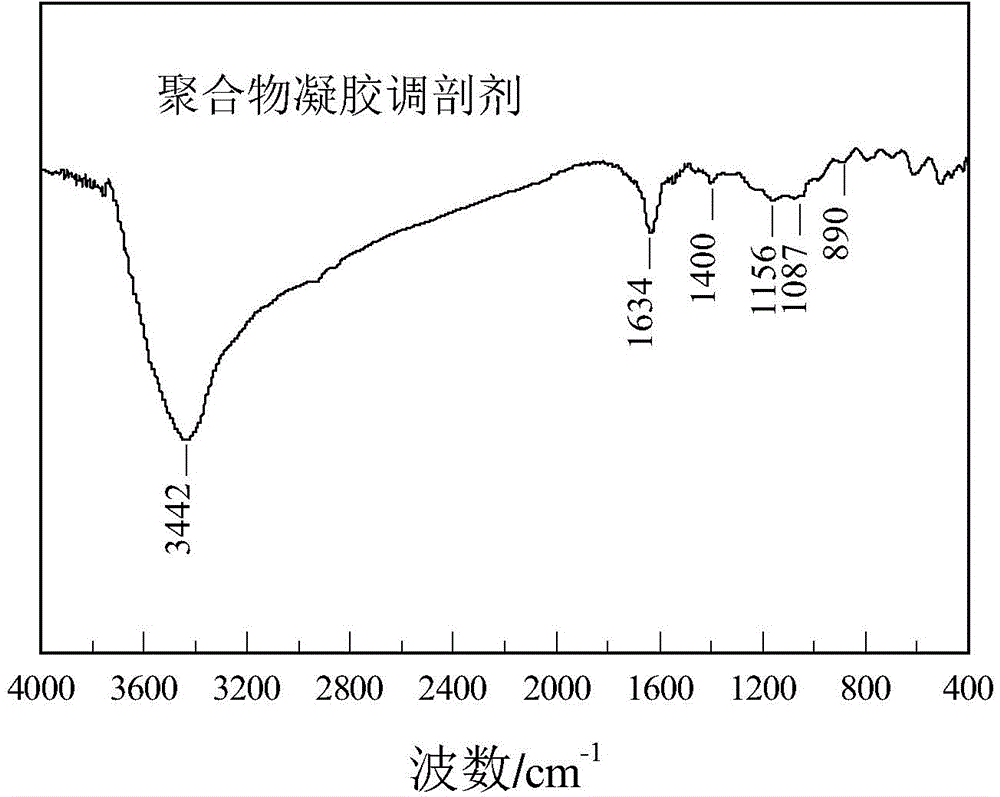

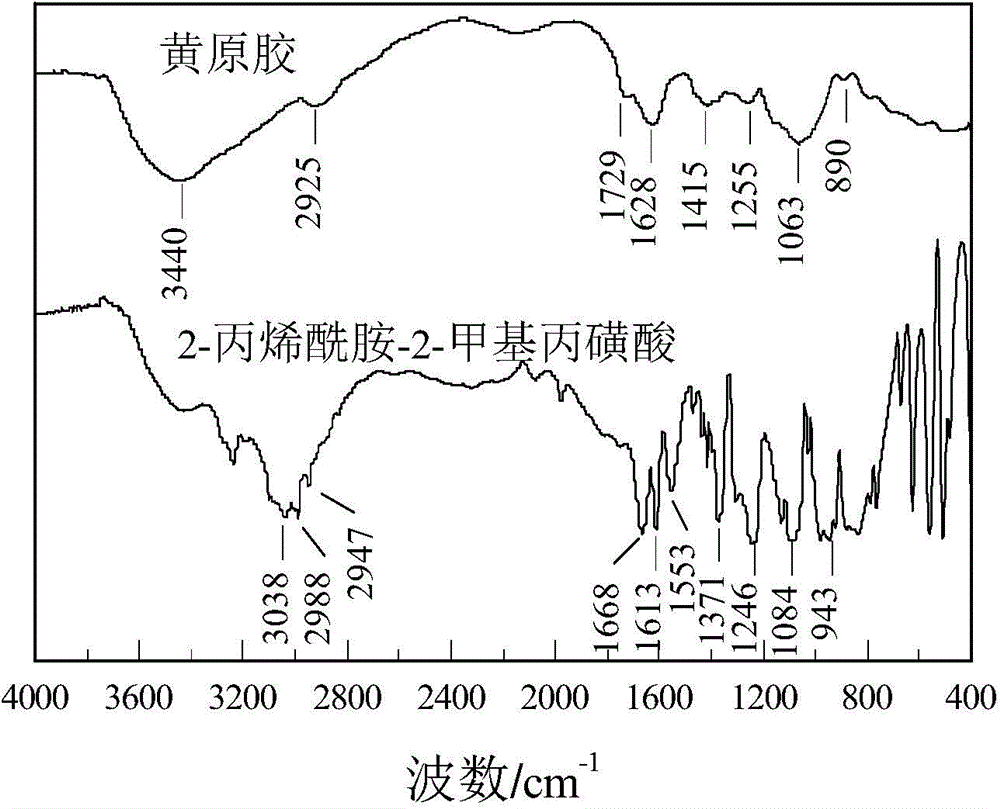

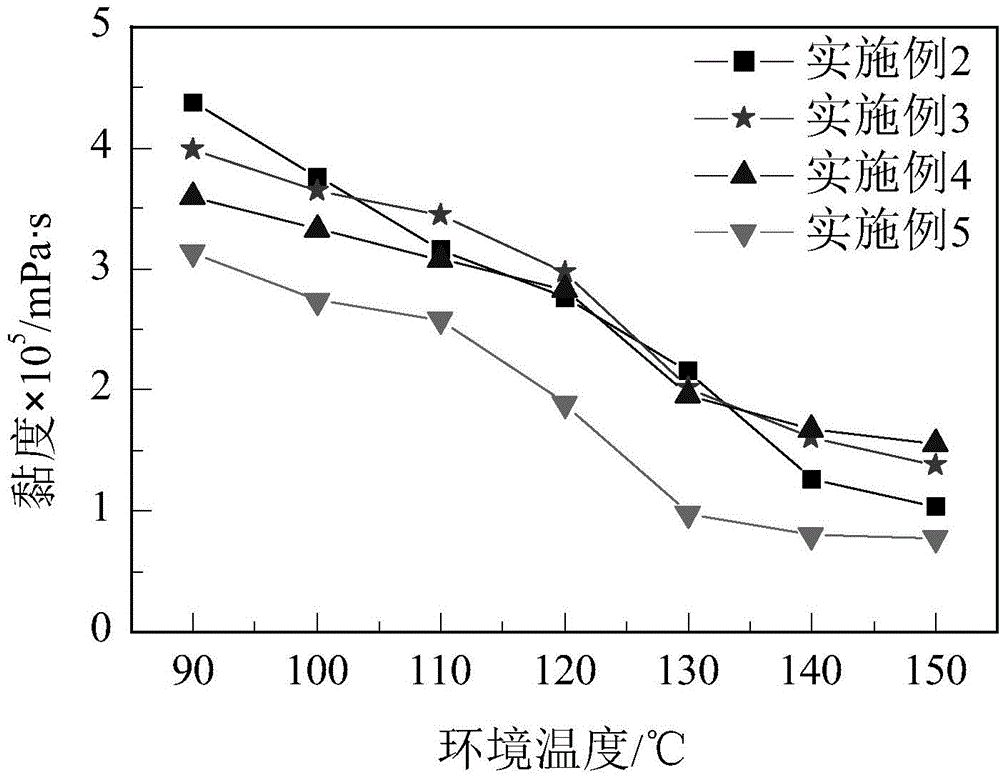

Method for preparing polysaccharide biogum polymer gel profile control agent

The invention relates to a method for preparing a polysaccharide biogum polymer gel profile control agent. The method includes the steps that polysaccharide biogum is dissolved in distilled water for allocating a solution, a monomer and a cross-linking agent are added into the solution, nitrogen is led in, the air is isolated, then an initiating agent is added, and the profile control agent is obtained through thermostatic reaction. The method for preparing the polysaccharide biogum polymer gel profile control agent has the advantages that the cost of raw materials is low, and the raw materials are wide and capable of being obtained easily; various properties such as gelling time, gelling strength, the mobility after gelling, temperature resistance and salt resistance of the profile control system can be controlled by changing the concentration of the polysaccharide biogum, the monomer, the cross-linking agent and the initiating agent in the reaction system or by changing the type and the initiating system of the cross-linking agent; certain mobility is achieved, the profile control agent can be injected under the shaft easily, and a high permeability layer in the stratum can be effectively plugged; the strength is good, and the method is suitable for oil deposit with the formation temperature being below 150 DEG C; the method is suitable for high-salt oil deposit.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

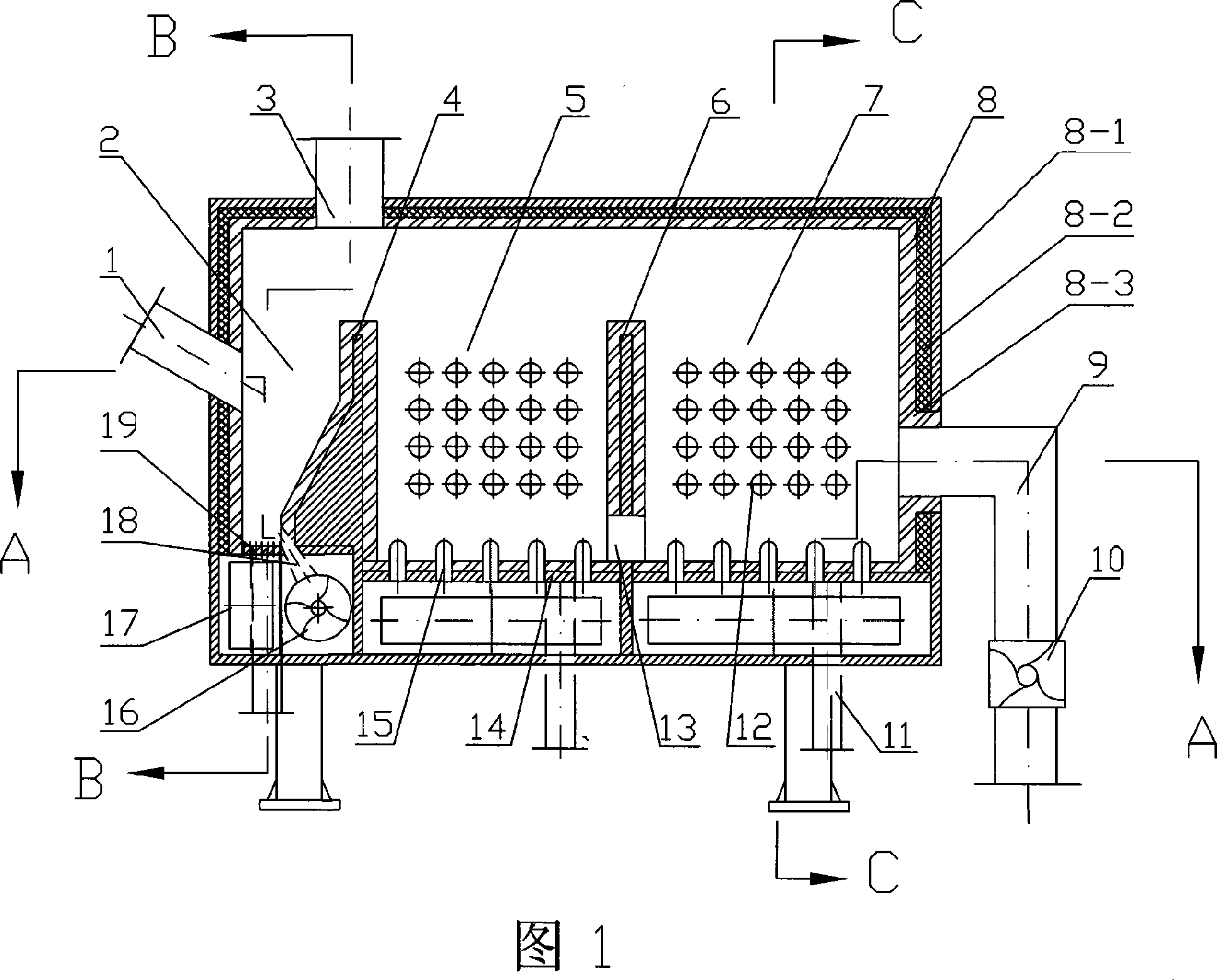

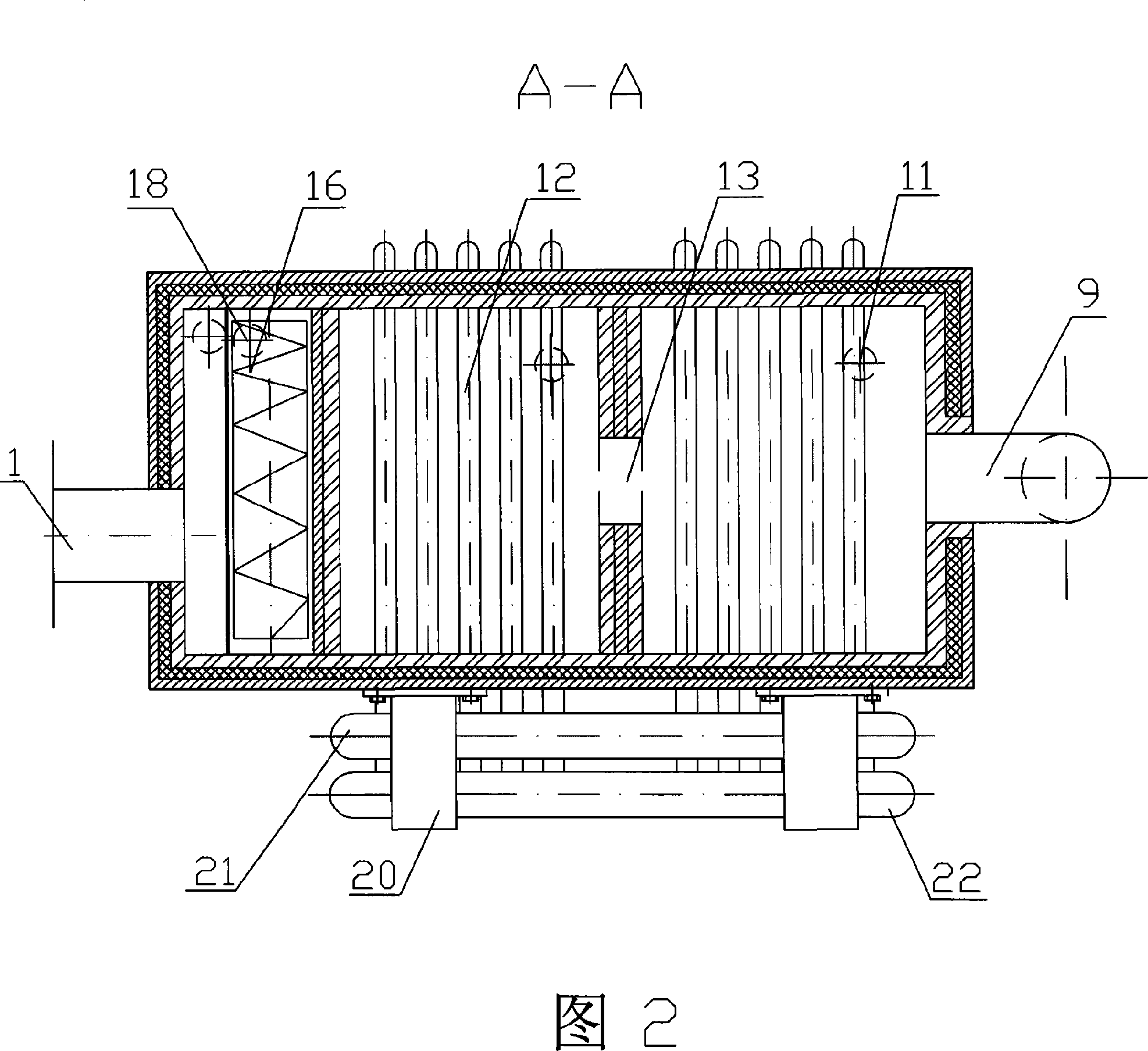

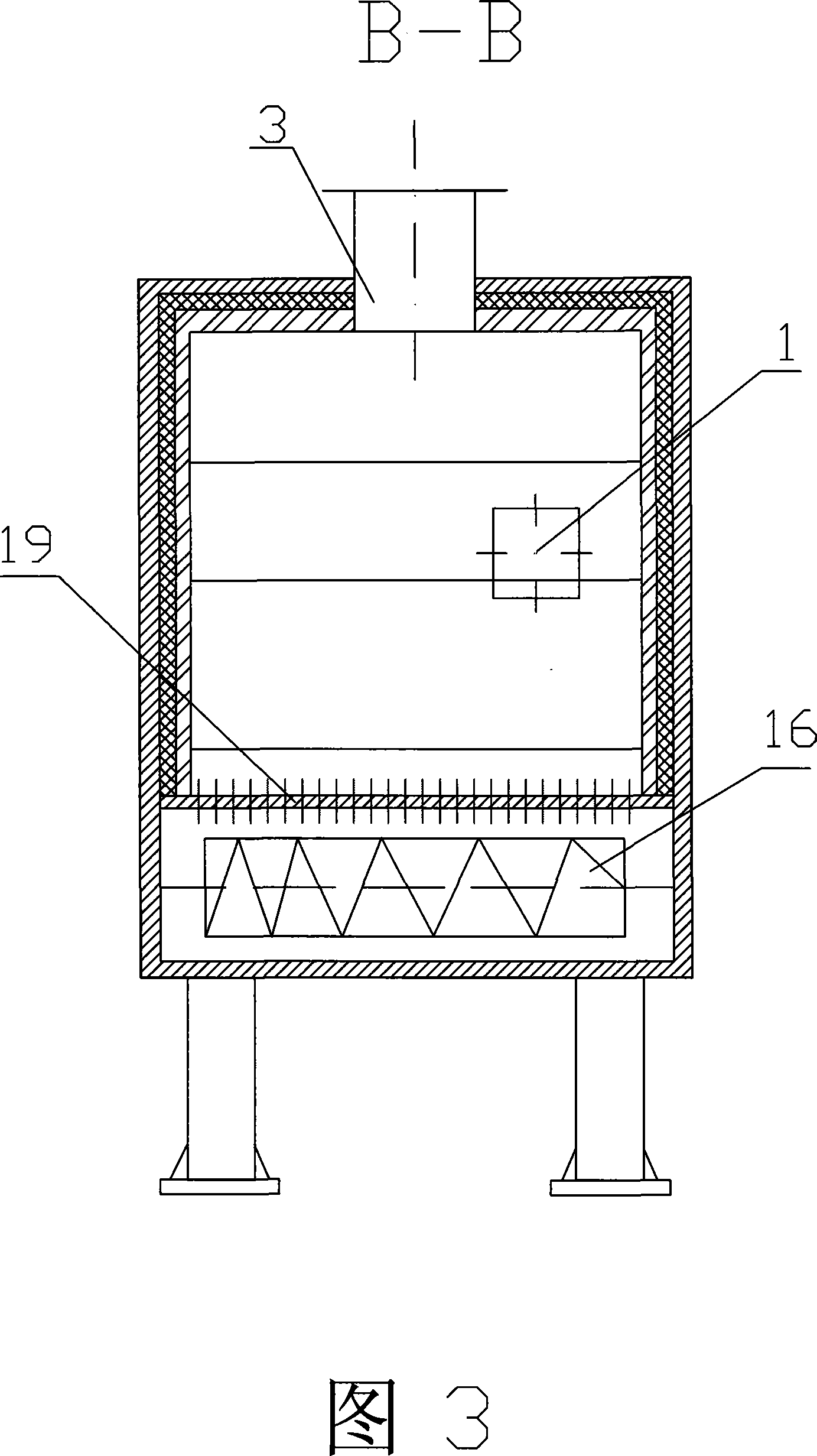

Composite type cold slag device

InactiveCN101101113ACooperate wellMeet the needs of actual operationSolid fuel combustionCombustion apparatusTechnology developmentGranularity

The invention relates to combined type cold slag device. It includes cold slag room, air chamber, and water cooling packing auger cold slag machine. The cold slag room is set two divider to divide it into three cooling room. The second divider lower is set hole. The first cooling room is spouted bed structure of which bottom is set close-hole type grid plate on which the main slag discharge pipe is set. The back two cooling rooms are set water cooling tube bank, and funnel cap type grid plate at the bottom. The invention can satisfy the demands of big feeding coal granularity, actual motion and macro-scale operations technology development for circulating fluidized bed boiler.

Owner:CHONGQING UNIV

Binary nanometer cooperative reinforcing and toughening silicon carbide ceramics and preparing method thereof

The invention discloses a method for preparing binary nanometer cooperative reinforcing and toughening silicon carbide ceramics, and silicon carbide powder, yttrium aluminum garnet, nano particles and nano crystal whickers are taken as the main raw materials. The method comprises the following steps: 1) the main raw materials, a binder and a dispersant are added into de-ionized water, after being ball-milled and mixed, water-base silicon carbide slurry is prepared; 2) the water-base silicon carbide slurry is sprayed and dried by adopting a spray granulation technology; 3) the obtained silicon carbide granulating powder is formed by adopting pre-pressing of dry pressing and final pressing of cold isostatic pressing; and 4) the obtained green body of silicon carbide is put in a vacuum non-pressure sintering furnace to be treated, thus obtaining the binary nanometer cooperative reinforcing and toughening silicon carbide ceramics. The invention also discloses the binary nanometer cooperative reinforcing and toughening silicon carbide ceramics prepared in the method. The silicon carbide ceramics have the advantages of large flexural strength, good fracture toughness and the like.

Owner:ZHEJIANG UNIV

Casting and welding method of lead-acid storage battery busbar

InactiveCN102891278AControl liquidityImprove discharge performanceCell component detailsElectricityBusbar

The invention disclose a casting and welding method of a lead-acid storage battery busbar, which comprises the steps of: sequentially placing a battery pole plate and pole lugs on the same side in tooth sockets of a busbar clamp according to a width direction vertical to the ground; injecting molten lead in a lead melting pot into the busbar clamp, and insulating; and sequentially melting and welding the pole lugs by using a heating rod. According to the invention, when the busbar is welded, the welding and melting depth and the bonding area can be ensured, pseudo welding and over welding are not caused, and the short circuiting of the molten lead can be avoided, therefore, the welding quality of the lead-acid storage battery is ensured, the electric property of the battery is improved, and the service life of the lead-acid storage battery is prolonged.

Owner:SHUANGDENG GRP

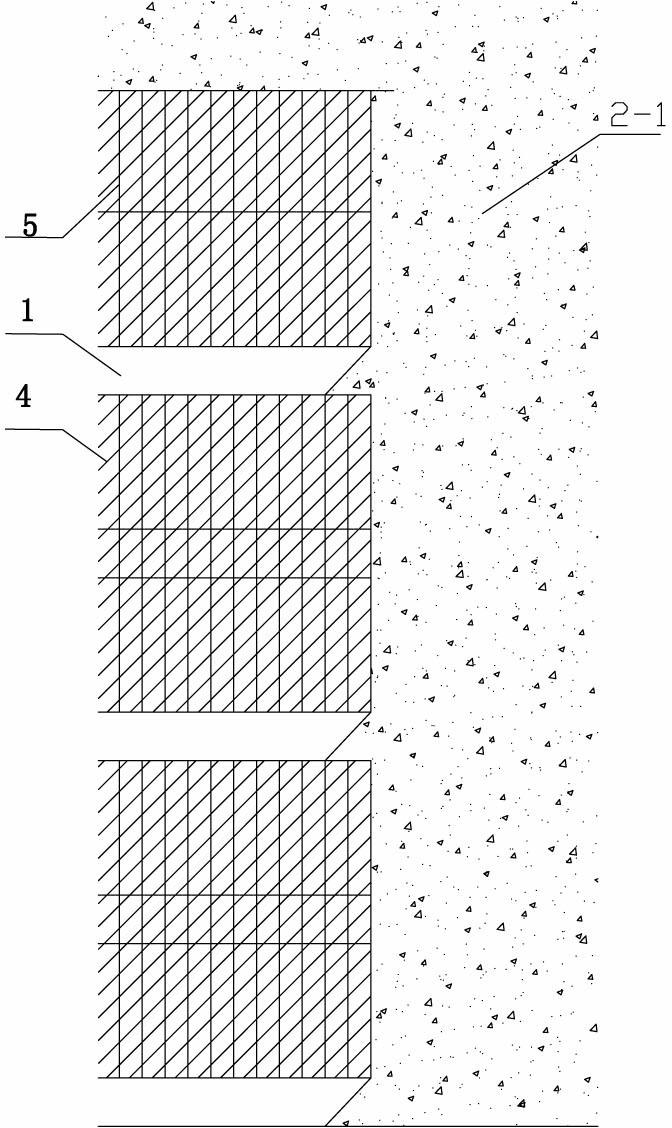

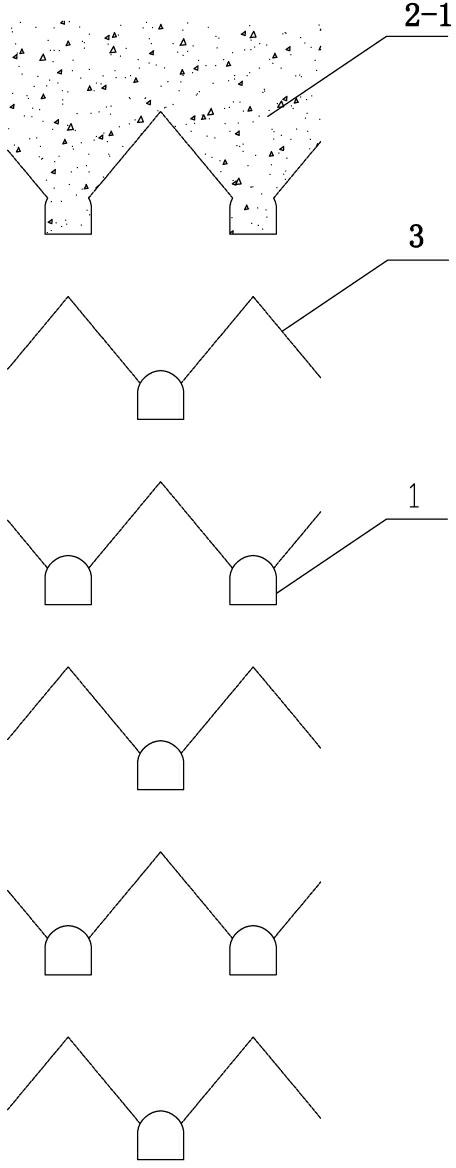

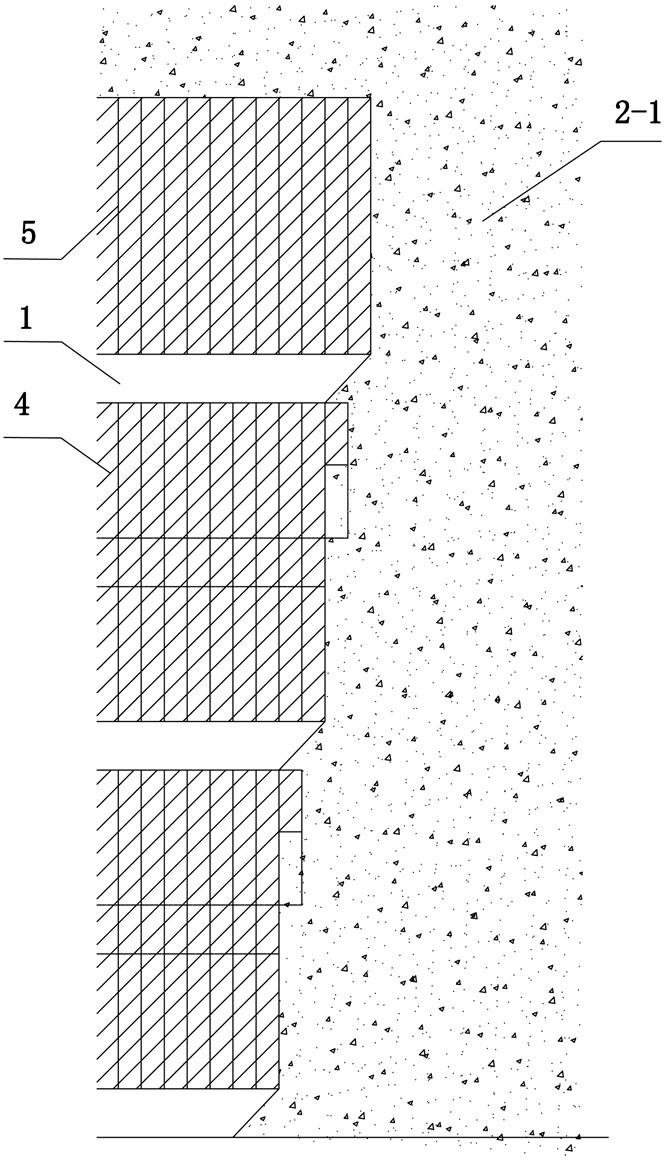

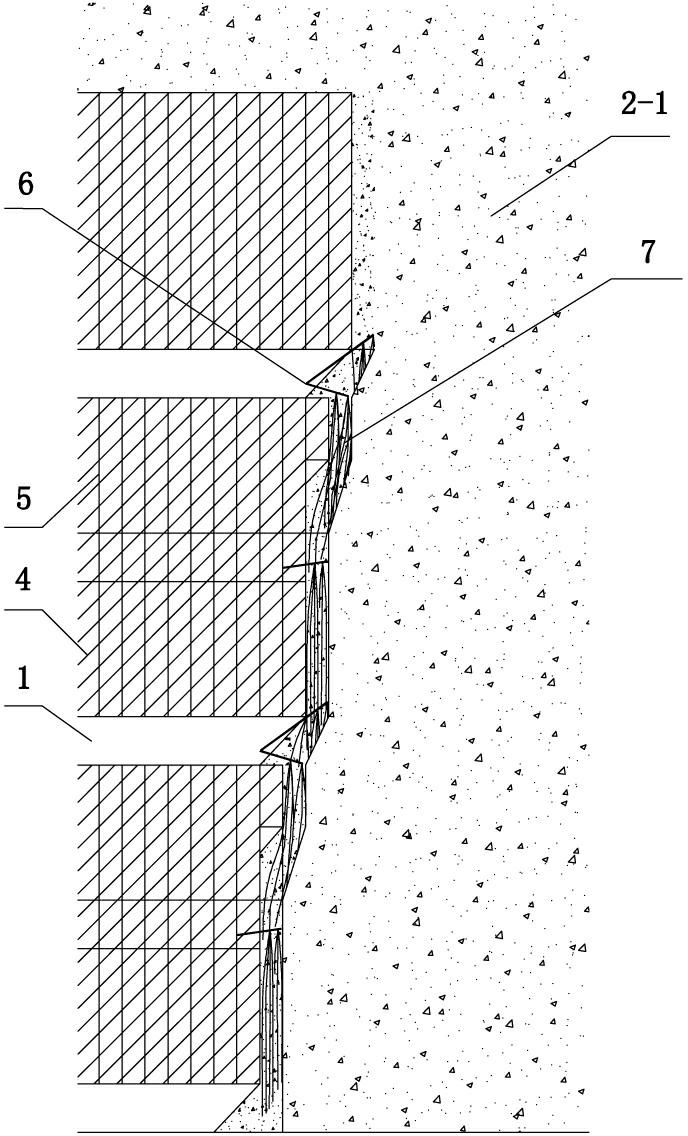

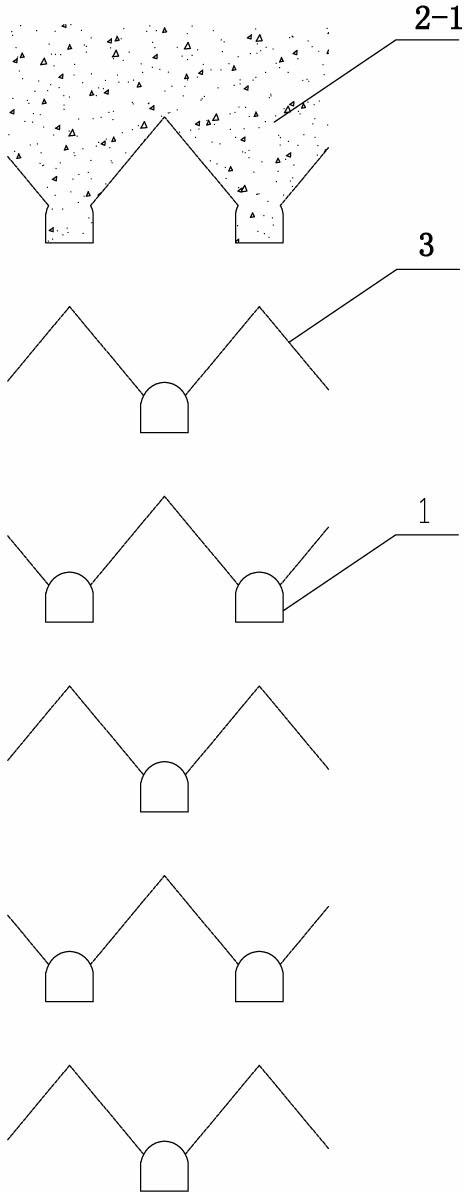

Pillarless phased caving method with top tailing crushed stone filling and sectional water injection binding

InactiveCN102635357AReduce liquidityEasy to releaseUnderground miningSurface miningCrushed stoneToxic industrial waste

The invention relates to a pillarless phased caving method with top tailing crushed stone filling and sectional water injection binding, comprising the following steps of: dividing an ore body into phases, arranging stoping gateways in the phases by means of rhombic staggering, dividing the phases into sections, and carrying out rock drilling, blasting and ore removal in a stoping tunnel. The pillarless phased caving method with the top tailing crushed stone filling and the sectional water injection binding is characterized in that ore drawing is controlled by means of water injection during a stoping process, a top gob formed during the stoping process is processed by means of the top tailing crushed stone filling, the ore drawing is controlled by means of the water injection during the stoping process, and water is injected and uniformly permeated into rocks covered around an ore drawing hole and the end wall of the stoping tunnel, and then is stood for 1-3 days. The pillarless phased caving method with the top tailing crushed stone filling and the sectional water injection binding has the following advantages: the problems of high loss and dilution and surface subsidence of the caving method are solved, and loss and dilution indexes are lower than those of an open-stope method and a filling method; the pillarless phased caving method is simple in structure, great in production capacity and high in production efficiency; and due to the filling of a tailing crushed stone in the top, a role of utilizing industrial wastes can be plaayed, and benefits to environmental protection can be realzied.

Owner:UNIV OF SCI & TECH LIAONING

Boride reinforced silicon carbide ceramics and preparation method thereof

The invention discloses a preparation method of boride reinforced silicon carbide ceramics, taking silicon carbide powder, yttrium aluminum garnet and boride micro-powder as main raw materials and comprising the following steps: 1. adding the main raw materials, binding agent and dispersant into de-ionized water followed by ball-milling and mixing to prepare water-base silicon carbide slurry; 2. spray drying the water-base silicon carbide slurry with a spray granulating technique to obtain the silicon carbide granulation powder; 3. molding the silicon carbide granulation powder by dry pre-pressing and cold isostatic final pressing to obtain high density silicon carbide green brick; and 4. placing the high density silicon carbide green brick in a vacuum pressure-free sintering furnace to be heated to 1,900-2,000 DEG C and kept for 1-1.5 hours to obtain boride reinforced silicon carbide ceramics. The boride reinforced silicon carbide ceramics prepared by the method has the characteristics of high hardness, high bending resistance, and excellent fracture toughness property, etc.

Owner:ZHEJIANG UNIV

Composite adhesive specially for heat insulating polystyrene outer-wall board

InactiveCN1403522AImprove adhesionImprove aging resistanceHydrocarbon polymer adhesivesPolymer scienceAdhesive

The composite adhesive is prepared with styrene and acrylic acid copolymer emulsion, which is inorganic silica gel and organosilicon modified and has low vitrification point and high adhesion, as main adhesive component and through adding quartzite, asbestos and other reinforcing material and some assistants. The composite adhesive has high adhesion effect, high adhesion strength, good antiaging performance, high hardness and high water resistance.

Owner:上海丰慧节能环保科技有限公司

Silicon carbide short fiber toughened and strengthened silicon carbide ceramics and preparation method thereof

The invention discloses a preparation method of silicon carbide short fiber toughened and strengthened silicon carbide ceramics, which takes silicon carbide powder, yttrium aluminum garnet and silicon carbide short fiber as the main materials and sequentially comprises the following steps of: 1) adding the main materials, a caking agent and a dispersant into de-ionized water and preparing water-based silicon carbide slurry after ball-mill mixing; 2) adopting a sponging drying technique to carry out spray drying to the water-based silicon carbide slurry; 3) adopting 160-200MPa to carry out dry pressing and shaping to the obtained strengthened silicon carbide palletizing powder to obtain a silicon carbide biscuit; and 4) arranging the silicon carbide biscuit in a vacuum pressureless sintering furnace for sintering to obtain the silicon carbide short fiber toughened and strengthened silicon carbide ceramics. The invention simultaneously provides the silicon carbide short fiber toughened and strengthened silicon carbide ceramics prepared by the method. The silicon carbide ceramics is characterized by larger fracture toughness, high mechanical strength, and the like.

Owner:ZHEJIANG UNIV

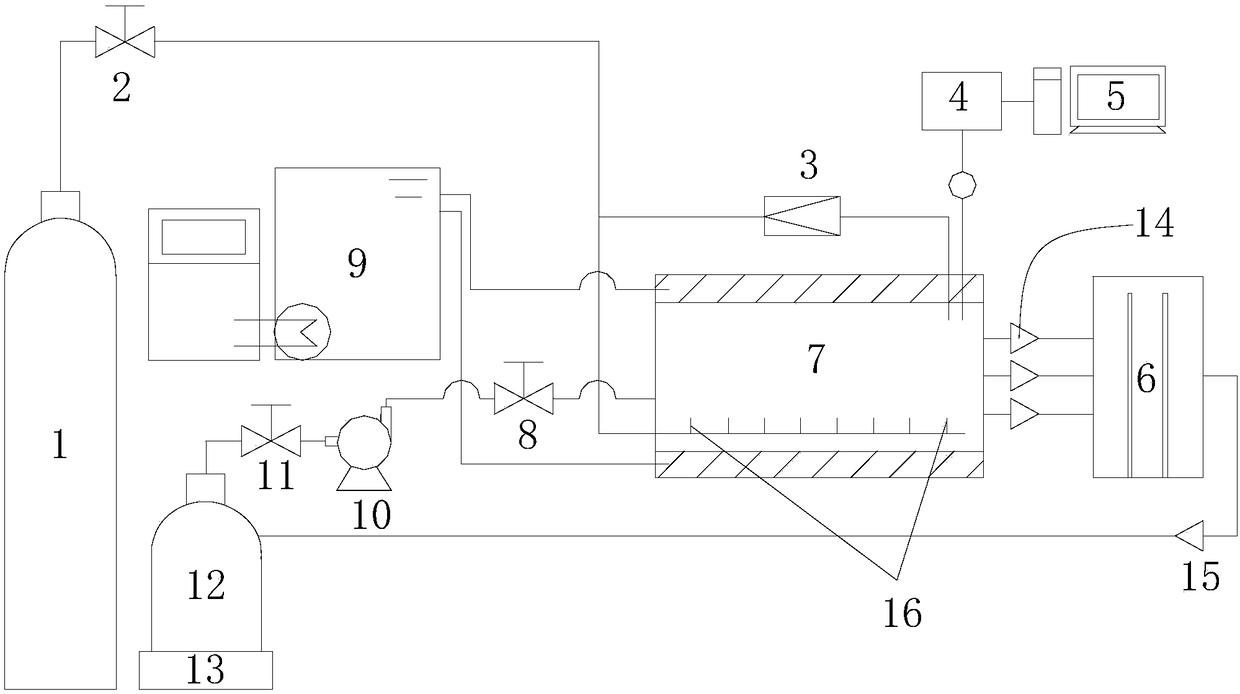

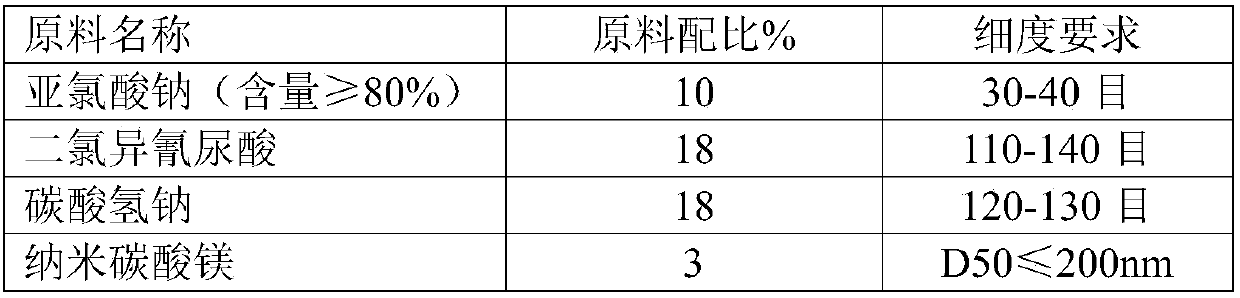

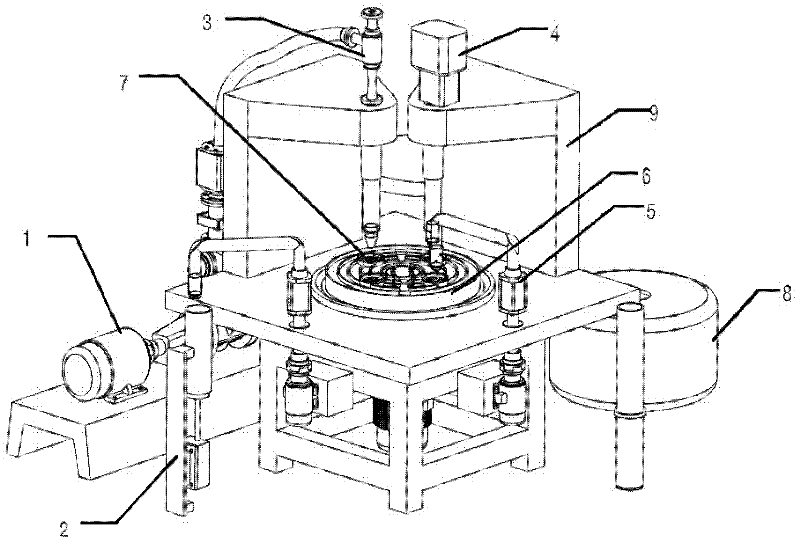

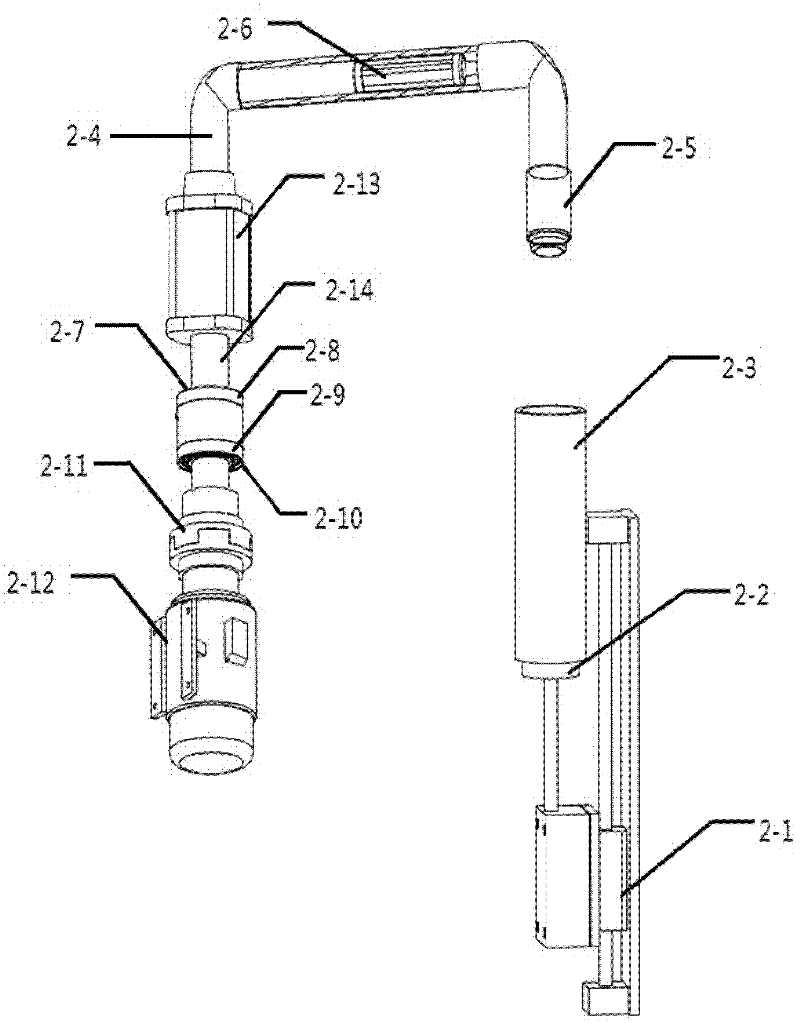

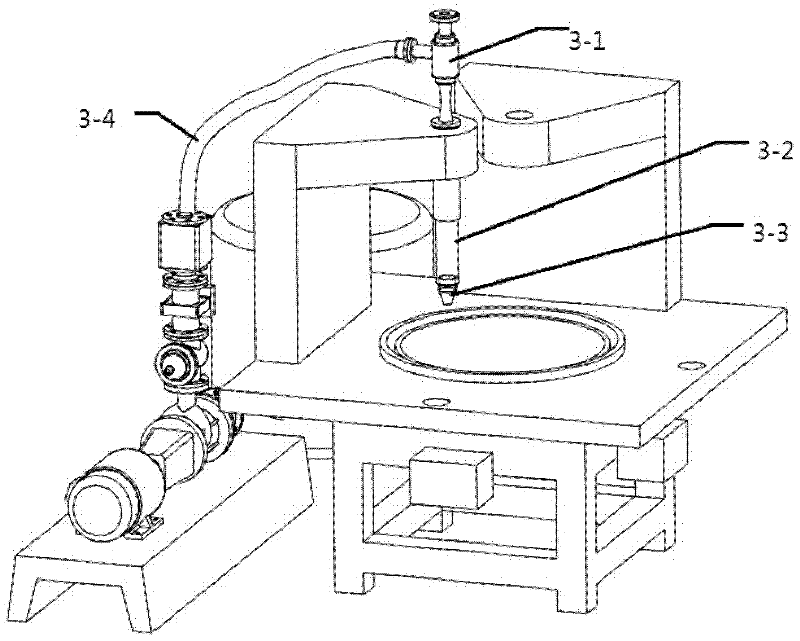

Device for rapidly and continuously preparing gas hydrate

InactiveCN108160003AImprove the efficiency of storage and transportationControl generationPressure vessel componentsPressure vessels for chemical processTemperature controlData acquisition

The invention discloses a device for rapidly and continuously preparing a gas hydrate. The device comprises a reactor with an outer water jacket, a gas supply unit for supplying a gas source to the reactor, an ice liquid supply unit for supplying an ice liquid to the reactor, a temperature control unit for controlling the temperature of the outer jacket, a hydrate filtering and collecting unit connected to the reactor and used for filtering and collecting produced hydrate crystals, and a data acquisition and processing unit for acquiring and recording the temperature and pressure data of the reactor. The rear end of the hydrate filtering and collecting unit is connected to the ice liquid supply unit through a quick-connecting valve. The device solves the problem that the conventional hydrate formation device has no a complete hydrate formation process, produces internal retention in the stirred slurry or on a magneton and has no a continuous reaction process. The experimental device issimple and economical, is easy to operate, produces a complete and uniform gas hydrate and improves the efficiency of gas storage and transportation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

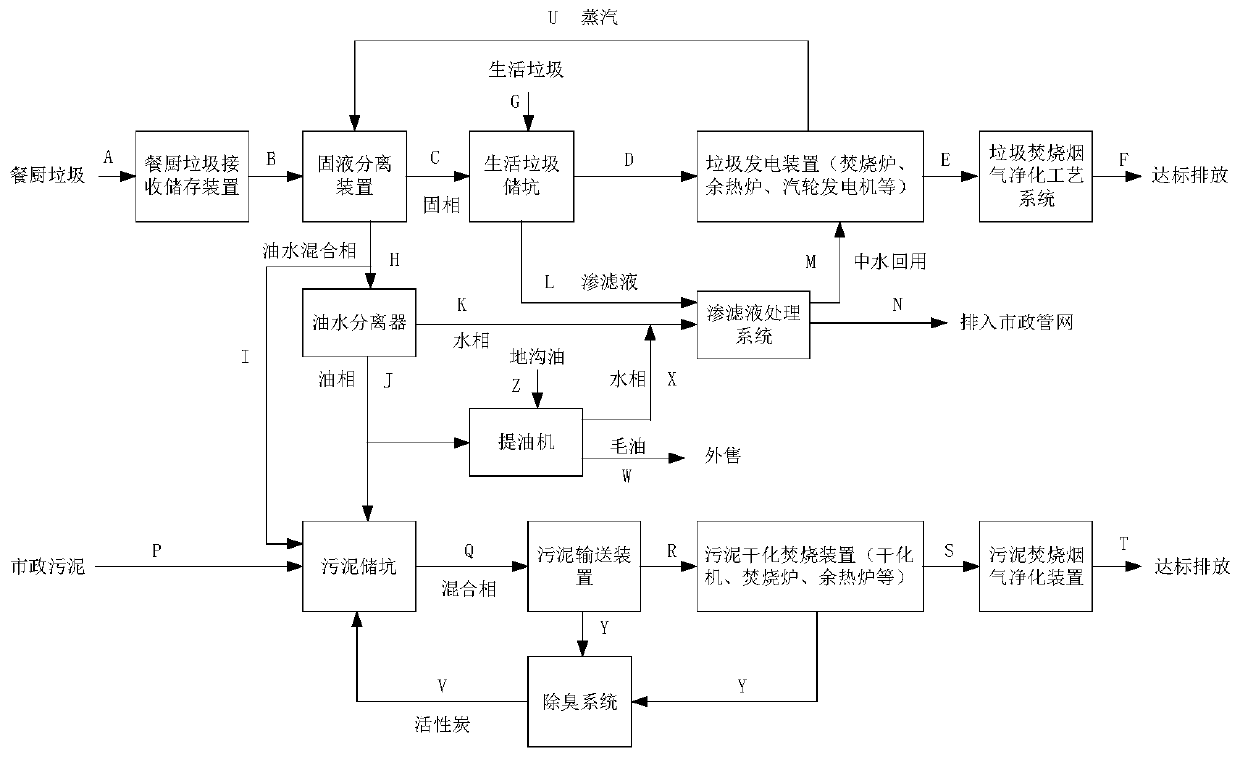

Method for cooperative treatment of kitchen waste, household waste and sewage plant sludge

InactiveCN111036643AControl calorific valueControl liquiditySolid waste disposalTransportation and packagingOil and greaseFluid phase

The invention discloses a method for cooperative treatment of kitchen waste, household waste and sewage plant sludge. Solid-phase material obtained after solid-liquid separation of the kitchen waste is subjected to a household waste incineration step, so that the solid-phase material of the kitchen waste is subjected to incineration power generation together with the household waste; and oil-watermixed liquid obtained after solid-liquid separation of the kitchen waste is selectively mixed with the sludge, so that the heat value and the fluidity of a sludge mixture are effectively controlled,and the sludge is ensured to be smoothly dried and incinerated. The heat value of the sludge is improved, the use amount of natural gas for sludge drying and incinerating can be saved, and the energy-saving effect is achieved; and meanwhile, the problem that a leachate membrane is blocked due to kitchen and household waste mixed fermentation grease is solved, and moreover, water phases obtained after grease is separated from kitchen waste liquid phases is good in biodegradability, so that cooperative treatment together with leachate of the household waste is facilitated. The oil-water mixed liquid separated from the kitchen waste through a solid-liquid separation device is subjected to dry combustion to be removed after being mixed with the sludge, anaerobic fermentation treatment is not needed, and water resources are effectively saved.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG +1

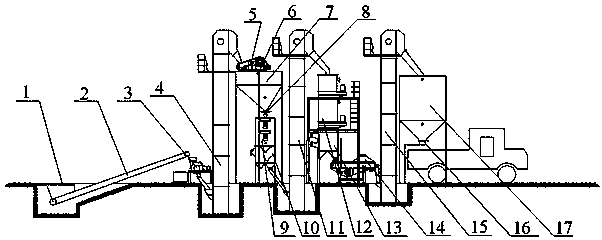

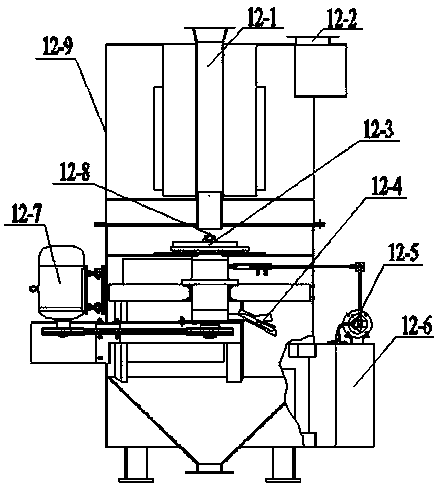

Regeneration system of used clay sand

ActiveCN103521699AReduce mud contentReduce environmental pollutionMould handling/dressing devicesLinear vibrationEngineering

The invention discloses a regeneration system of used clay sand. The regeneration system comprises a belt conveyor with a magnetic separation function, a breaker, a bucket elevator, a linear vibration sand sieving machine, a storage device, a centrifugal regenerator and an air separator, wherein a feeding opening of the breaker is connected with the tail end of the belt conveyor, and a discharging opening of the breaker is connected with a feeding opening of the bucket elevator; the linear vibration sand sieving machine is arranged under a discharging opening of the bucket elevator; the storage device is arranged under the linear vibration sand sieving machine; a feeding opening of the centrifugal regenerator is connected with a discharging opening of the storage device; the air separator is arranged under the centrifugal regenerator; the used clay sand system also comprises a vortex type regenerator; the vortex type regenerator is connected with the centrifugal regenerator through a secondary bucket elevator. Through the regeneration system of used clay sand, the clay content in the used sand is greatly reduced; the performance of the used sand is controlled stably; the performance of the molding sand is effectively improved and controlled; the full regeneration of the used clay sand is realized; the environmental pollution is reduced; the resources are saved; the casting quality and the production efficiency are improved; the production cost of castings is reduced.

Owner:QINGDAO HEDELONG MACHINERY

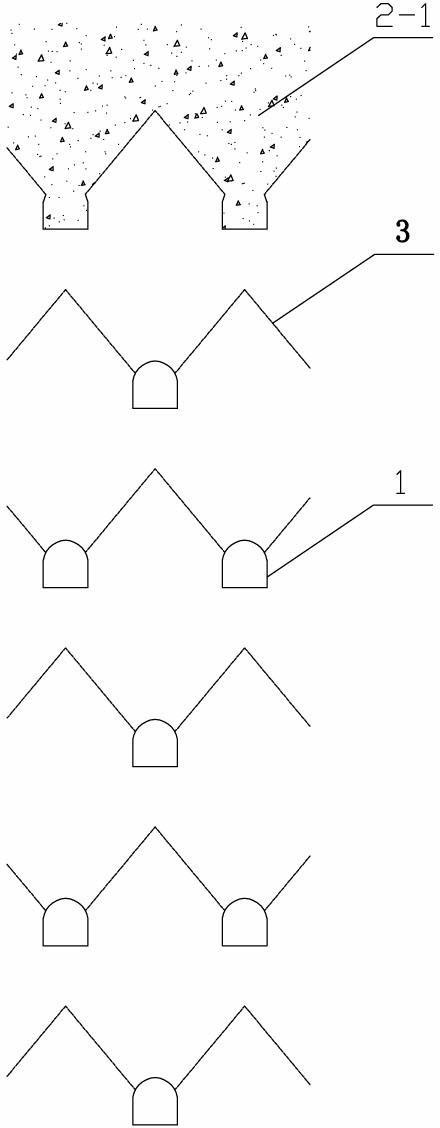

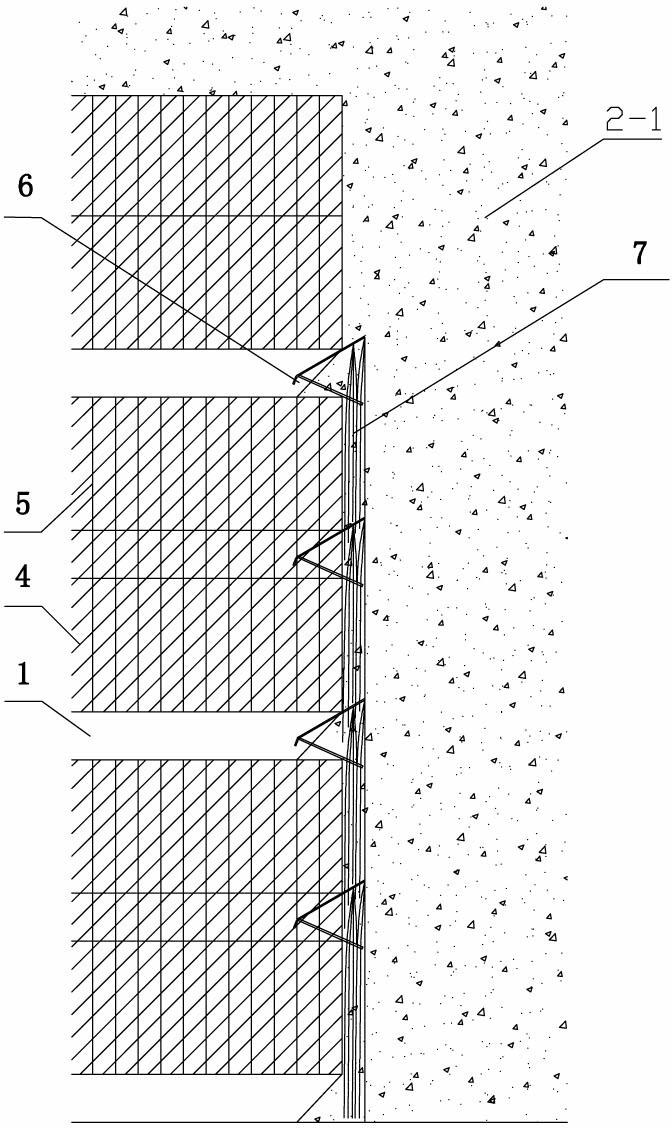

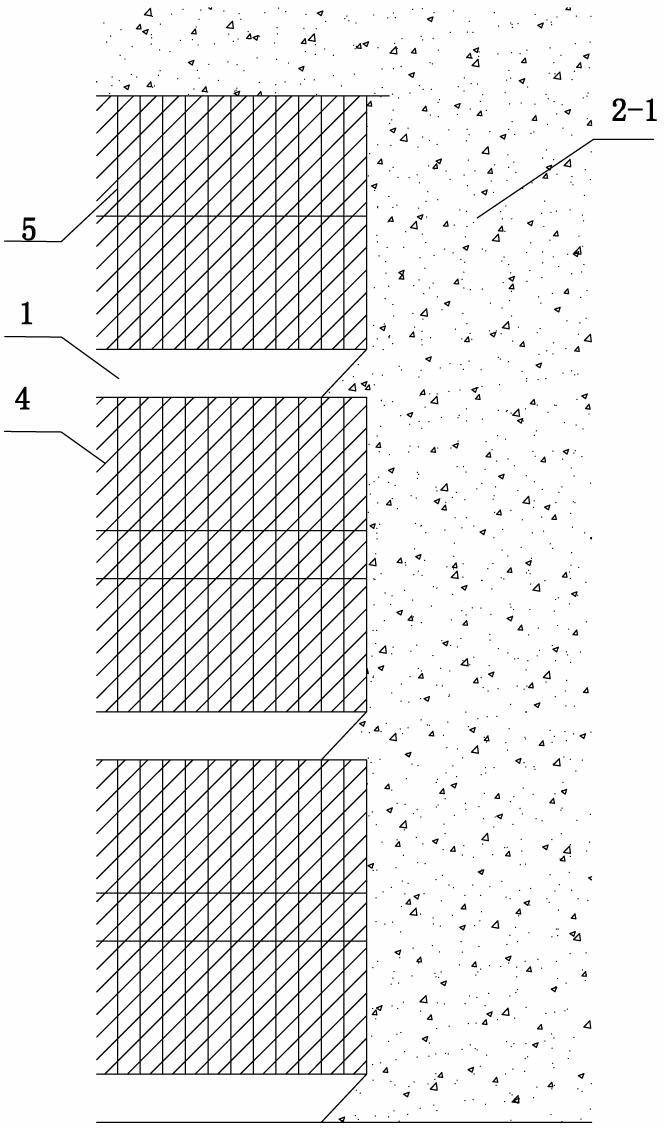

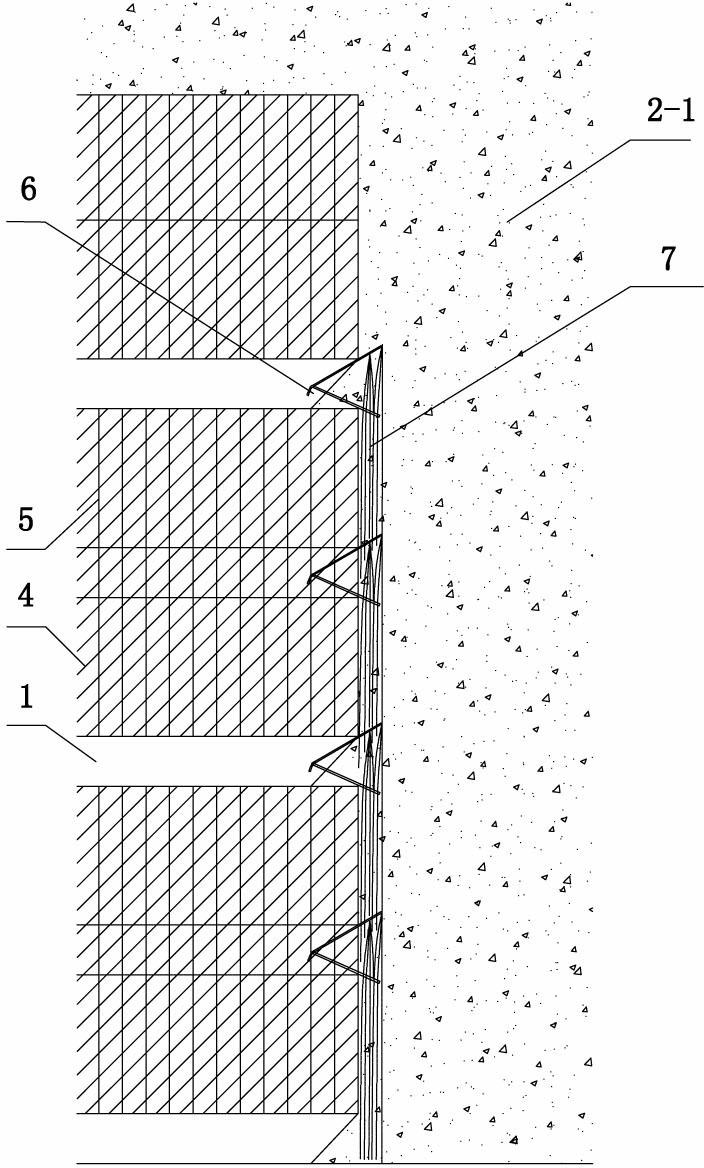

Top-filled pillarless cornice end-wall sublevel caving method extraction technique

ActiveCN102619514APrevent collapseControl liquidityUnderground miningSurface miningLiquid mediumCrushed stone

The invention relates to a top-filled pillarless cornice end-wall sublevel caving method extraction technique. The pillarless cornice end-wall sublevel caving method is characterized by comprising the following steps of: (1) after ore drawing is completed, stretching a grouting tube deep into overlaying rocks by using a grouting device at both sides and front part of the end part of a mining roadway besides the lowest sublevel roadway, injecting and permeating one liquid medium into overlaying rocks surrounding the ore drawing port and the end wall, laying aside for 1-3 days, eliminating excessive water in the overlaying rocks, and performing blasting and actual mining in the next ore caving step; and (2) filling tailings and broken stone into the top of a gob so as to prevent surface subsidence. Compared with the traditional underground extraction method, the pillarless cornice end-wall sublevel caving method solves the problems of great loss dilution and surface subsidence of the caving method, has lower loss dilution index than the open-stope method and the filling method and also has the advantages of simple structure, large production capacity and high production efficiency.

Owner:ANSTEEL GRP MINING CO LTD

Top-filled pillarless vertical end-wall sublevel caving method extraction technique

InactiveCN102619516APrevent land subsidenceGood economic benefitsUnderground miningSurface miningEngineeringSubsidence

The invention relates to a top-filled pillarless vertical end-wall sublevel caving method extraction technique. The pillarless vertical end-wall sublevel caving method is characterized by comprising the following steps of: (1) after ore drawing is completed, stretching a grouting tube deep into overlaying rocks by using a grouting device at both sides and front part of the end part of a mining roadway besides the lowest sublevel roadway, injecting and permeating one liquid medium into overlaying rocks surrounding the ore drawing port and the end wall, laying aside for 1-3 days, eliminating excessive water in the overlaying rocks, and performing blasting and actual mining in the next ore caving step; and (2) filling tailings and broken stone into the top of a gob so as to prevent surface subsidence. Compared with the traditional underground extraction method, the pillarless vertical end-wall sublevel caving method solves the problems of great loss dilution and surface subsidence of the caving method, has lower loss dilution index than the open-stope method and the filling method and also has the advantages of simple structure, large production capacity and high production efficiency.

Owner:ANSTEEL GRP MINING CO LTD

Sandwich adhesive for high-strength aramid fibre paper honeycomb and preparation method thereby

ActiveCN103254862AImprove high temperature resistanceRegular extrusion processNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesElastomerPolymer science

The invention discloses a sandwich adhesive for a high-strength aramid fibre paper honeycomb and a preparation method thereof, and relates to an adhesive and a preparation method thereof. The sandwich adhesive disclosed by the invention is higher in strength and toughness compared with the existing product, thus solving the problem of honeycomb node cracking during a manufacturing and drawing process for the high-strength aramid fibre paper honeycomb. The sandwich adhesive disclosed by the invention is prepared from matrix resin, a rubber elastomer, nuclear shell rubber, a curing agent, inorganic filler, a rubber cross-linking agent, a silane coupling agent and a solvent. The preparation method for the sandwich adhesive disclosed by the invention comprises the following steps of: 1, preparing B-stage resin; 2, preparing a mixed adhesive sheet; and 3, adding the mixed adhesive sheet, the B-stage resin and the silane coupling agent in the solvent, dissolving and uniformly mixing in a stirring state, and then preparing the sandwich adhesive for the high-strength aramid fibre paper honeycomb. The sandwich adhesive disclosed by the invention has the characteristics of high strength and high toughness, and is mainly used for preparing the high-strength aramid fibre paper honeycomb.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Special foam concrete for exterior wall external thermal insulation system engineering

InactiveCN108314378AImprove crack resistanceGood flexibilityCeramicwareThermal insulationSetting time

The invention provides a special foam concrete for exterior wall external thermal insulation system engineering. The special foam concrete comprises the following components in parts by weight: 100 parts of a cementing material, 0-50 parts of an admixture, 2-10 parts of a high polymer, 0.5-2 parts of fiber, 2-10 parts of a foaming agent and 2-15 parts of an additive. According to the special foamconcrete provided by the invention, other components are introduced into the common foam concrete, so that the special foam concrete has the characteristics of good fluidity, crack resistance, light weight, good affinity with a thermal insulation material, high bonding strength, adjustable setting time, function of repairing defects of a base wall, and the like, and the special foam concrete is filled between the insulation board and the base wall to play the role of bonding and repairing.

Owner:SHAANXI ACAD OF ARCHITECTONICS

Copper alloy for precision casting of artwork, and preparation method and method for precision casting

InactiveCN103834845ASmall mechanical propertiesIncrease surface tensionFoundry mouldsFoundry coresPrecision castingCopper alloy

The invention discloses a copper alloy for precision casting of artwork, and a preparation method and a method for precision casting, and belongs to the field of precision casting. The copper alloy comprises the following components by mass percent: 45.0-49.0% of Cu, 3.5-3.9% of Sb, 1.3-1.7% of Fe, 3.0-4.0% of Bi, 0.5-1.5% of Ni, 0.2-0.5% of Te and the balance of Zn, wherein the sum of Sb and Te is smaller than or equal to 4.2%. The mobility of the alloy disclosed by the invention is greatly improved, and the method is applicable to casting of cultural artifacts. The artwork of which the minimal diameter is about 1mm can be cast, the casting accuracy is improved, and the application field of the casting technique is expanded. A processing method of the copper alloy for precision casting of the artwork and a method for precision casting are also disclosed by the invention.

Owner:ANHUI HOULIN SHENDIAO METAL ARTWORK

Large-flow state light foamed mixed soil

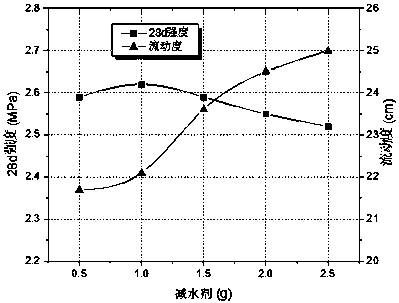

The invention provides large-flow state light foamed mixed soil which comprises the following components by mass: 1.5-3.5kg of cement, 1.0-2.5kg of an admixture, 0-2.5kg of clay, 0.5-2.5kg of sand, 1.5-3.5kg of water, 150-300g of a foam group, 0.5-2.0g of a water reduction agent, 0-2.0g of a sedimentation shrinkage reduction agent and 0-1.5g of a foam stabilizer, wherein the foam group is made byfoaming a high-performance animal protein modification foaming agent. The light foamed mixed soil has the characteristics of being high in flowability, high in strength, high in stability, low in shrinkage deformation, high in durability, low in cost, convenient to construct, and the like, the flowability of the light foamed mixed soil can be increased by 30-50% when being compared with that of common foamed light soil, the stability is improved by 50-100%, and the light foamed mixed soil is particularly applicable to fields such as backfill of complex parts such as brokebacks of bridge platforms, pipe galleries / pipelines, tunnels and coal mines, and heat preservation and water resistance of lining layers and roofs in municipal administration and road engineering, and belongs to novel, light, large-flow state foamed light mixed soil with excellent properties.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

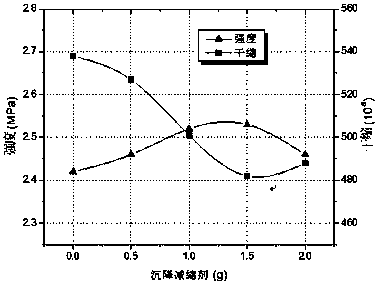

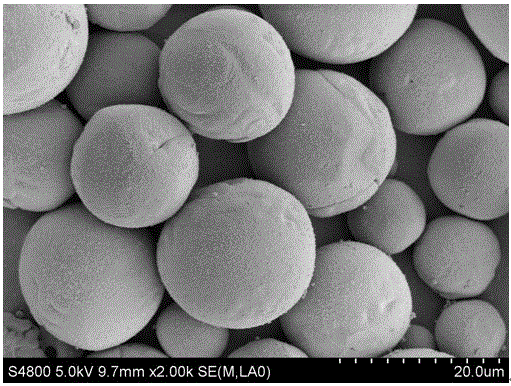

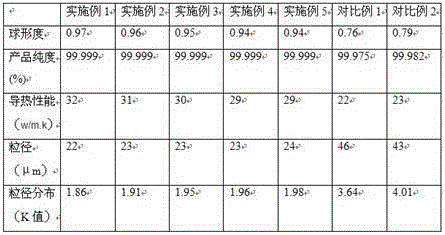

Preparation method of high-purity heat-conducting spherical aluminum oxide

ActiveCN106315647AImprove thermal conductivityDoes not affect transparencyNon-macromolecular adhesive additivesAluminates/aluminium-oxide/aluminium-hydroxide purificationCombustion chamberHeat conducting

The invention relates to a preparation method of high-purity heat-conducting spherical aluminum oxide. The method is characterized by comprising the following steps: high-purity gamma-aluminum oxide powder is added into a hopper; an oxyhydrogen combustor is connected with a gas feeder and is ignited, the volume flow rate of the hydrogen gas inlet to the oxygen gas inlet is regulated to (14.6-15.4):7, and heating of the furnace chamber of the furnace body is started; when the temperature in the furnace chamber rises to 1850-1890 DEG C, the volume flow rate of the material-carrying oxygen to the oxygen is (1.2-1.3):7, the aluminum oxide powder enters the combustion chamber of the oxyhydrogen combustor through an oxygen nozzle so as to be sintered; and the material is sintered through the oxyhydrogen flame of the nozzle, passes through the furnace chamber along with the gas flow, falls onto a high-purity aluminum oxide carrier of a conveyor belt, is cooled on the conveyor belt, and finally enters a storage bin. The technical process is simple, and is suitable for mass production. The technique is stable, and can ensure the product quality. The product has favorable particle size distribution and adjustable particle size. The product has the advantages of favorable sphericity, high purity and favorable heat-conducting property.

Owner:晶鑫晶体(内蒙古)科技有限公司

Preparation method of shear thickening gel, and application of gel in anti-break fabric

The invention discloses a preparation method of a shear thickening gel, and an application of the gel in an anti-break fabric, and belongs to the field of composite materials. The shear thickening gelcomprises, by weight, 80-120 parts of hydroxyl silicone oil, 5-10 parts of borate ester, 0.5- 5 parts of kenaf core short fibers, and 10-40 parts of modified silica. The borate ester is adopted to substitute boric acid in conventional methods, so the problem of too fast reaction of boric acid and hydroxyl silicone oil is inhibited and solved; and silicon-boron polymers with different viscositiescan be obtained in a high temperature state by changing the addition amount of the borate ester, so the problem of production in a kneader due to the great increase of the viscosity of most conventional silicon-boron polymers in the high temperature state is solved.

Owner:董小琳

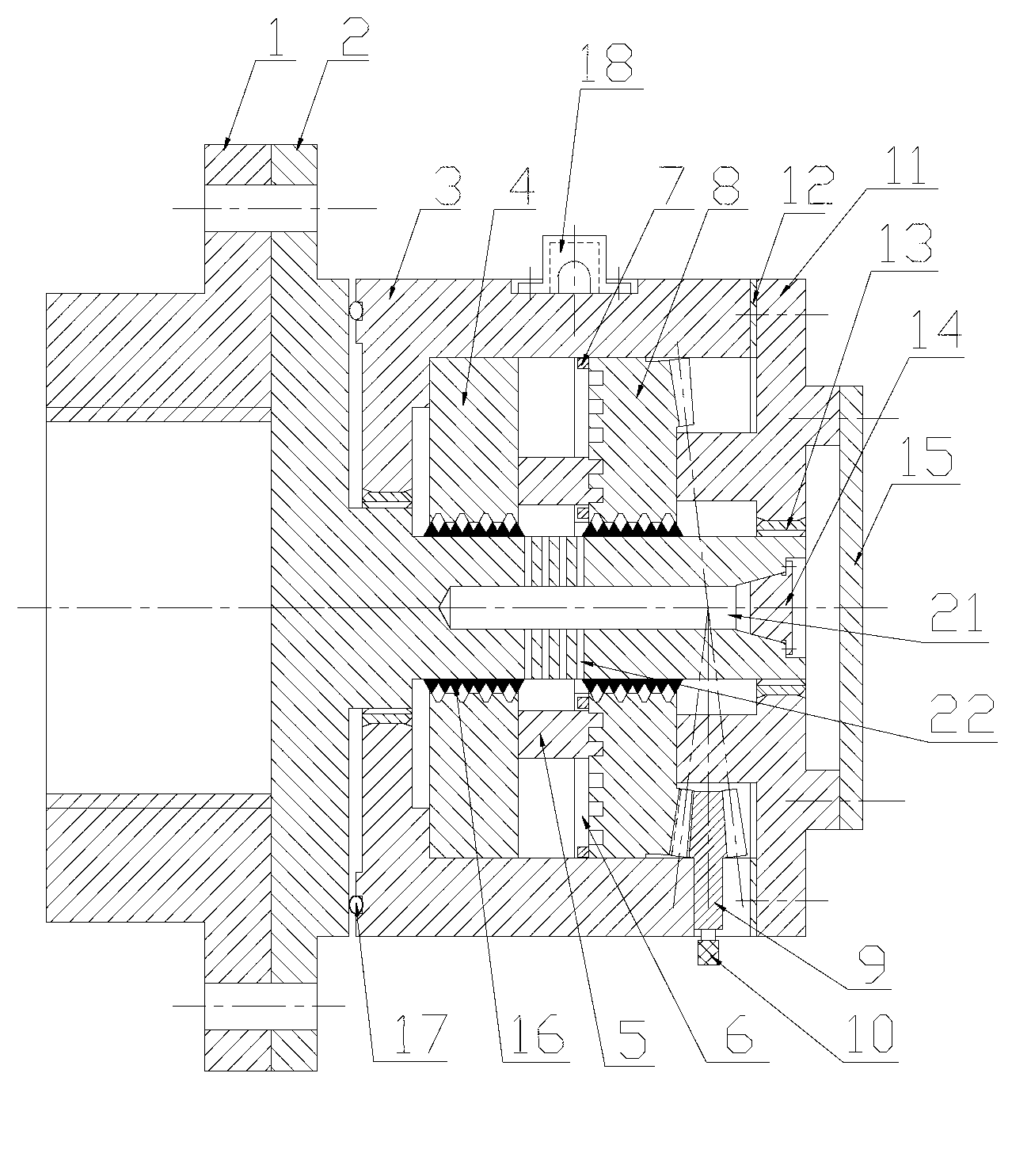

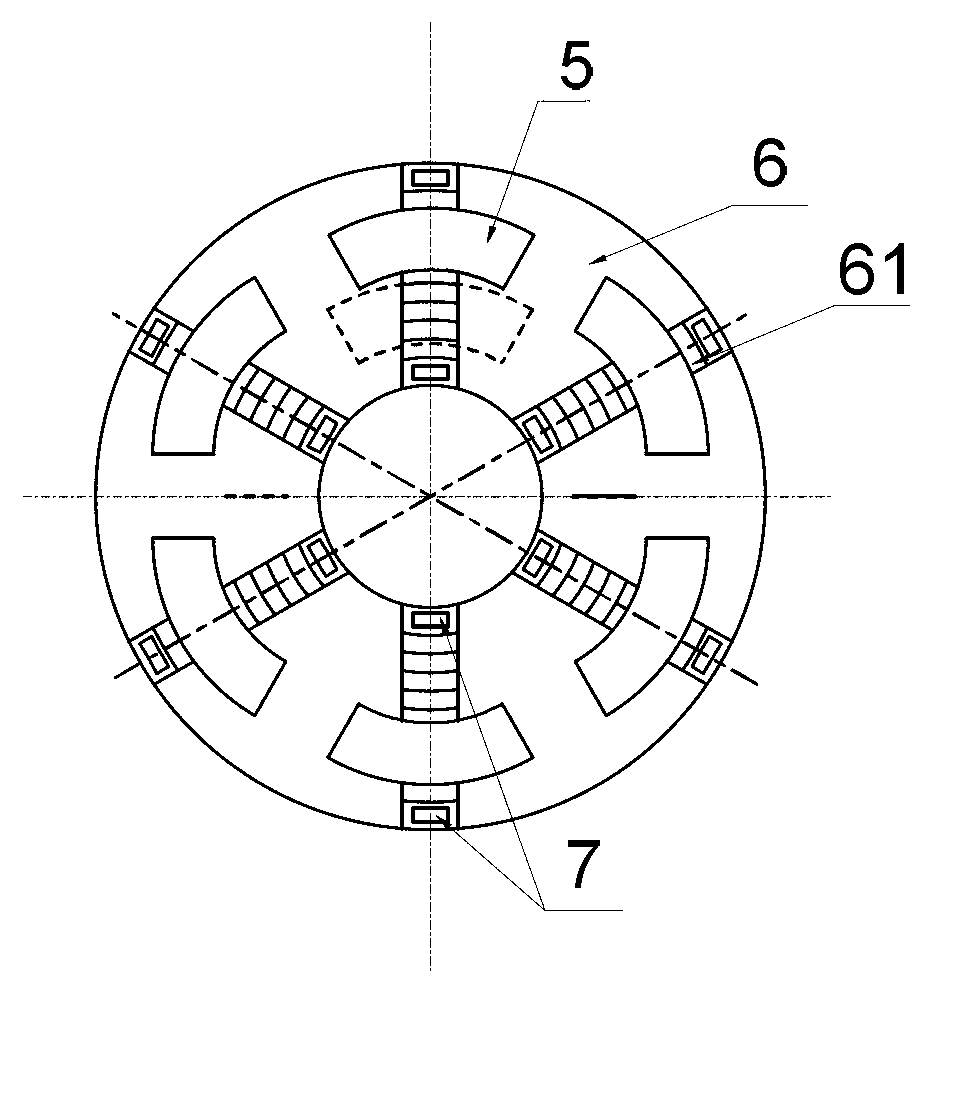

Grinding wheel grinding sound emission monitoring device

InactiveCN103273423AReduce uncertaintyHigh shear yield strengthGrinding feed controlMagnetic rotationMagnetic poles

The invention discloses a grinding wheel grinding sound emission monitoring device, and relates to a sound emission monitoring device. The grinding wheel grinding sound emission monitoring device comprises a locking flange, a magnetic rotation shaft, a shell, an annular magnetic pole, a permanent magnet, a magnetic slide plate, a limited block, an annular conical surface magnetic pole, a bevel gear, a handle, a retainer ring, a plug, an end cover, magnetorheological fluids, a sound emission sensor seat, a sound emission sensor and a detection circuit, the locking flange is locked with an external grinder grinding wheel, the left end of the magnetic rotation shaft is connected with the locking flange, the magnetic rotation shaft is provided with a hollow hole, the plug is arranged at an opening end of the hollow hole, the magnetorheological fluids are stored in the hollow hole, the hollow hole is communicated with the outer surface of the magnetic rotation shaft, the shell is sleeved on the magnetic rotation shaft, both the annular magnetic pole and the annular conical surface magnetic pole are positioned in the shell and are sleeved on the magnetic rotation shaft, the left end of the annular conical surface magnetic pole is connected with the magnetic slide plate, the left end of the magnetic slide plate is connected with the permanent magnet in a threaded manner, the right end of the annular conical surface magnetic pole is meshed with the bevel gear, and the detection circuit is arranged outside the shell and is electrically connected with the sound emission sensor.

Owner:XIAMEN UNIV

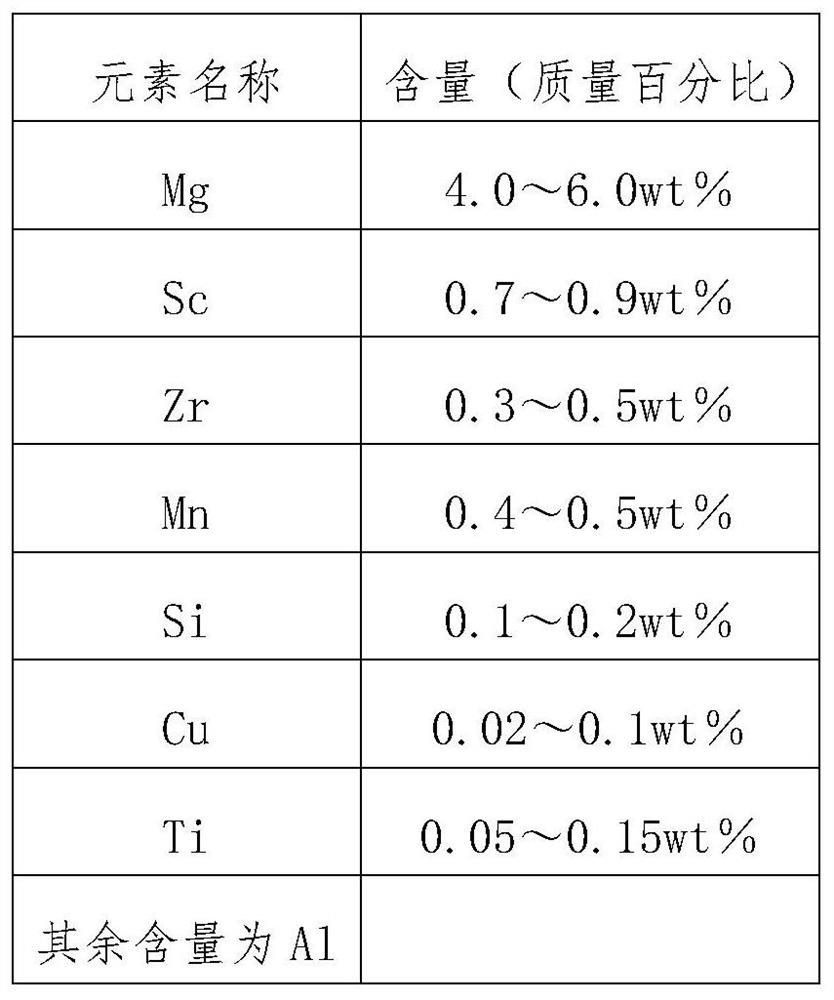

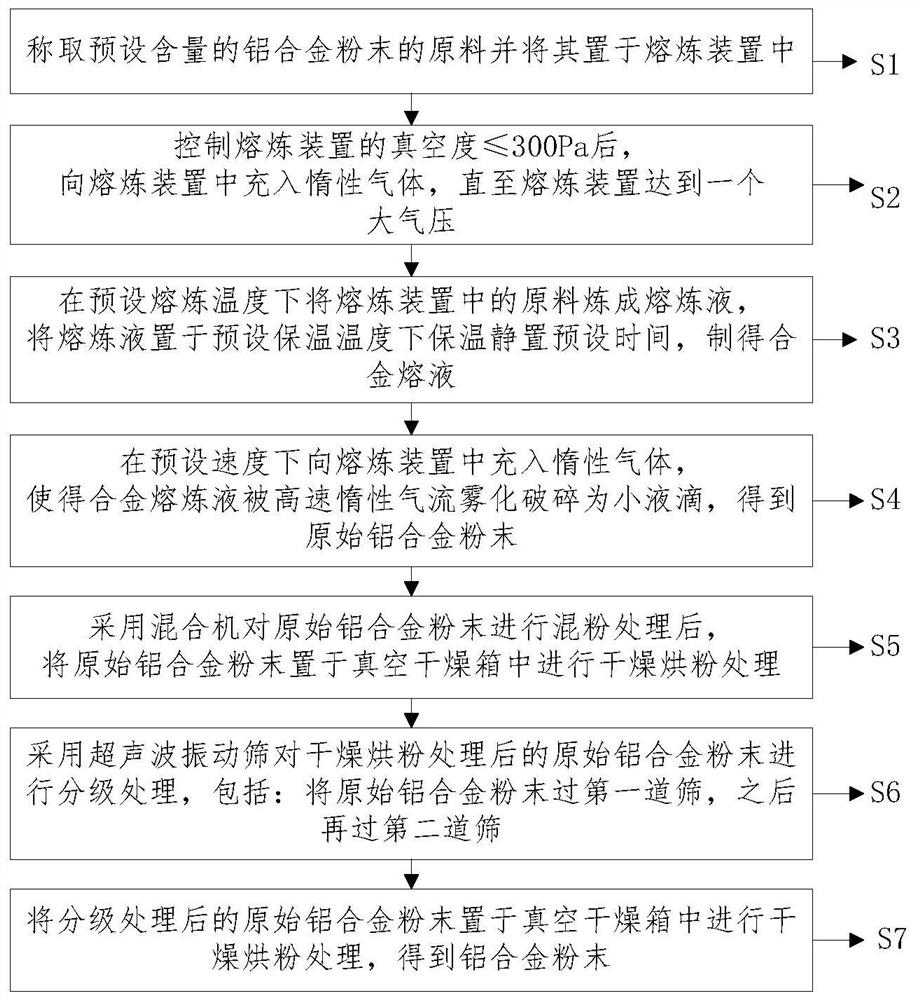

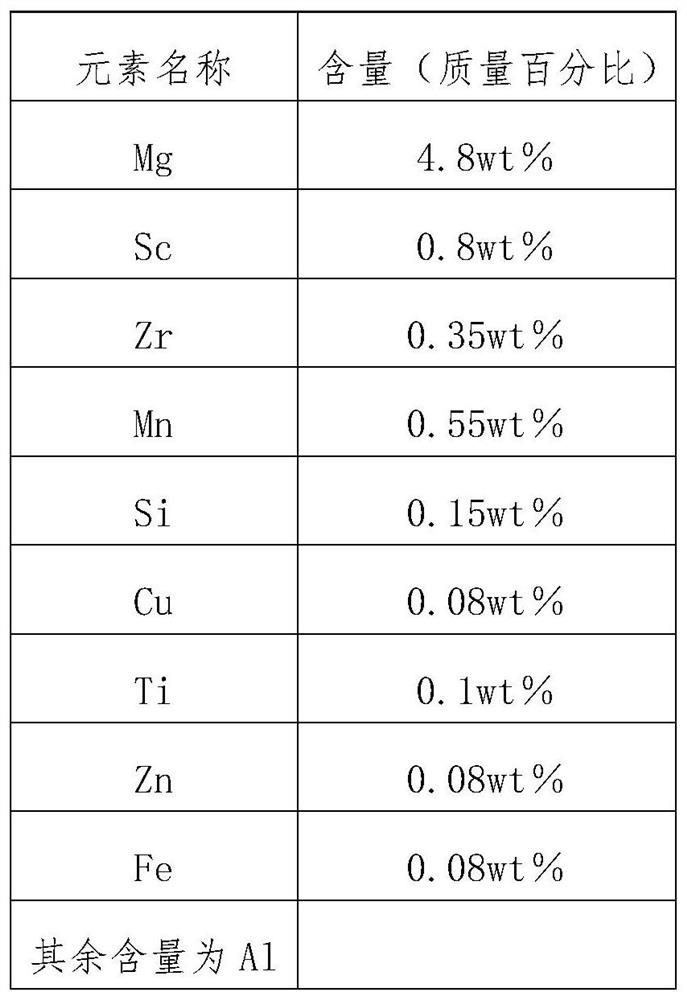

Aluminum alloy powder material for aviation additive manufacturing, preparation method and 3D printing method

ActiveCN113020606AReduce laser reflectivitySolving Hot Crack PropensityAdditive manufacturing apparatusTransportation and packagingHigh reflectivityUltimate tensile strength

The invention provides aluminum alloy powder for aviation additive manufacturing, a preparing method and a 3D printing method. The aluminum alloy powder comprises 4.0 wt%-6.0 wt% of Mg, 0.7 wt%-0.9 wt% of Sc, 0.3 wt%-0.5 wt% of Zr, 0.4 wt%-0.5 wt% of Mn, 0.1 wt%-0.2 wt% of Si, 0.02 wt%-0.1 wt% of Cu, 0.05 wt%-0.15 wt% of Ti, smaller than 0.1 wt% of Zn or smaller than 0.1 wt% of Fe and the balance Al. By doping elements with different components, the material has very high strength and toughness, the material characteristics of the aluminum alloy can be compensated, the high reflectivity of the aluminum alloy powder material to laser during laser forming is reduced, meanwhile, the problem of hot cracking of the aluminum alloy powder material is solved, and he aluminum alloy powder can be used for an additive manufacturing method in the aviation field.

Owner:BEIJING BAOHANG ADVANCED MATERIALS CO LTD

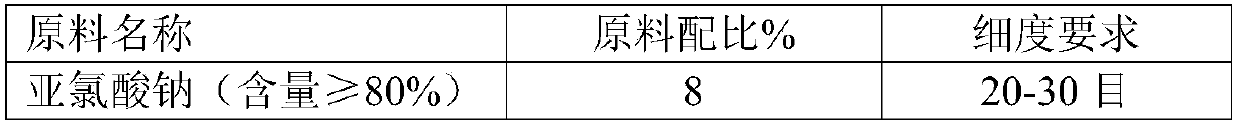

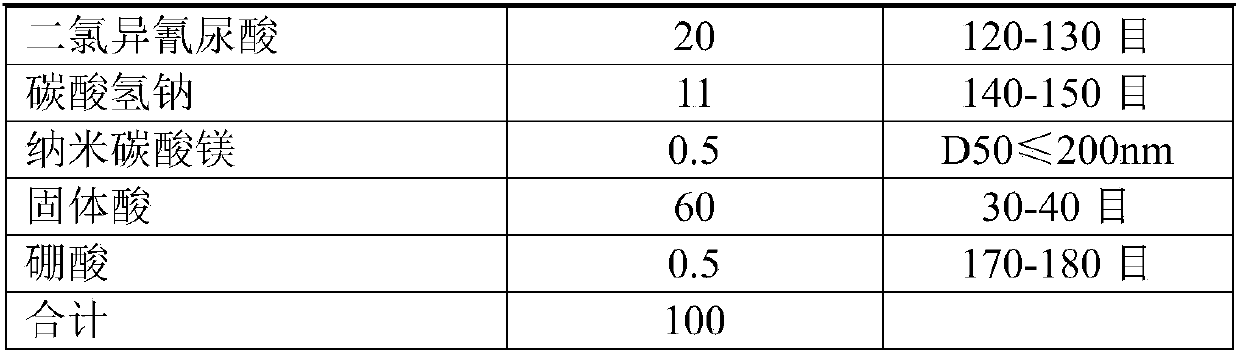

Compound disinfection tablet and preparation method thereof

InactiveCN107593720ARapid bactericidal effectReduce environmental pollutionBiocideDisinfectantsChemical disinfectionChemistry

A compound disinfection tablet belongs to the technical field of chemical disinfection and comprises the following components by weight percent: 8-31% of sodium chlorite, 5-20% of dichlord isocyanurice acid, 10-20% of sodium bicarbonate, 0.5-3% of nanometer magnesium carbonate, 25-60% of solid acid and 0.5-1.0% of boric acid. The invention also discloses a preparation method of the compound disinfection tablet. The preparation method is simple, the prepared disinfection tablet is uniform in ingredient, can produce various disinfection ingredients including chlorine dioxide, hypochlorous acid and active oxygen after being dissolved in water, and is improved in sterilization and disinfection performance, the solution is good in stability and small in corrosivity, and the product using cost is lowered. The compound disinfection tablet is mainly used for sterilization and disinfection of swimming pool water, industrial circulating water, aquaculture water, daily life and the like.

Owner:河北冀衡化学股份有限公司

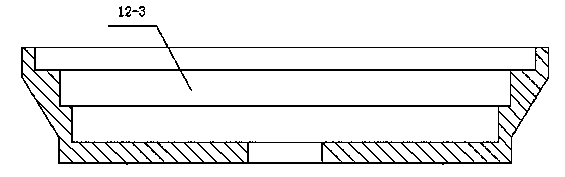

Fiber metal laminated plate forming device and method

InactiveCN107570585ASupport pressure is the sameImprovement accuracy is not highShaping toolsMetal-working feeding devicesTemperature controlNumerical control

The invention provides a fiber metal laminated plate forming device and method. A fiber metal laminated plate is processed by means of the hydraulic supporting and auxiliary heating numerical controlincremental forming technology. On a numerical control incremental forming machine tool, a forming tool head controlled through a mechanical program is arranged above a frame-shaped upper forming fixture and a frame-shaped lower forming fixture in advance. A box with an upward opening is additionally arranged in a cavity of the lower forming fixture. The laminated plate is clamped between the upper forming fixture and the lower forming fixture. The box is connected with a pressure control system and a temperature control system through a pipeline. In the process of incremental forming, a hydraulic control system is used for controlling ingoing, outgoing, heating and cooling of hydraulic oil to guarantee that the pressure and temperature borne by the laminated plate to be uniform and constant in the forming process. Accordingly, the good mechanical performance of the laminated plate is guaranteed, and the forming quality of products is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sheet material micro-forming device by use of high-pressure water jet

InactiveCN102527809ALow costImprove cooling effectMetal-working feeding devicesPositioning devicesHigh pressure waterEngineering

The invention provides a sheet material micro-forming device of a high-pressure water jet, comprising a high-pressure system, wherein the high-pressure system is connected with a jet flow forming system; the high-pressure system is used for providing high-pressure water to the jet flow forming system; an charging system, the jet flow forming system, a drying system, a fetching system and a worktable are mounted on a bracket; the charging system and the fetching system work by utilizing a pneumatic adsorption way; an upper rotary disc performs 90-degree rotation at intervals since a movable material cylinder is put on a fixed bracket; the time interval between two times of rotation is one period and each period is divided into two stages, including an upper rotary disc rotating stage and an upper rotary disc non-rotating stage; in the upper rotary disc rotating stage, the charging system, a sheet material edge pressing system, the jet flow forming system, the drying system and the fetching system do not work; in the upper rotary disc non-rotating stage, the charging system, the sheet material edge pressing system, the jet flow forming system, the drying system and the fetching system start to work. The micro-forming device provided by the invention reduces the manufacturing cost and can realize automatic production on a large scale.

Owner:XI AN JIAOTONG UNIV

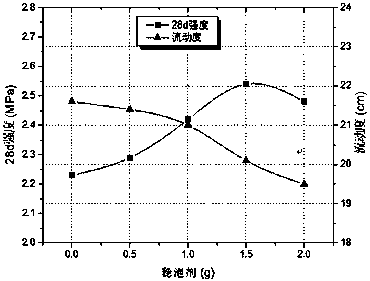

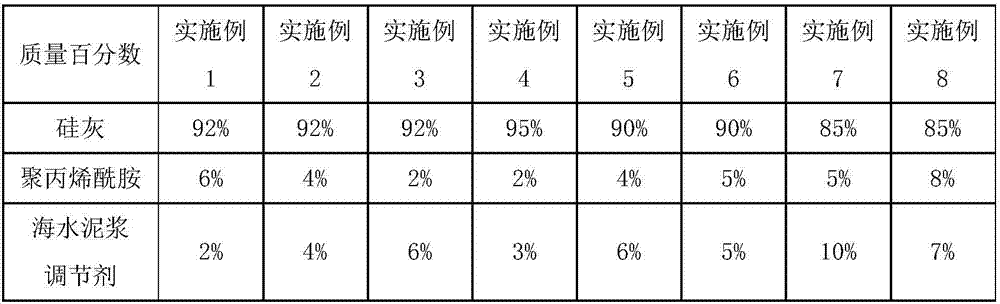

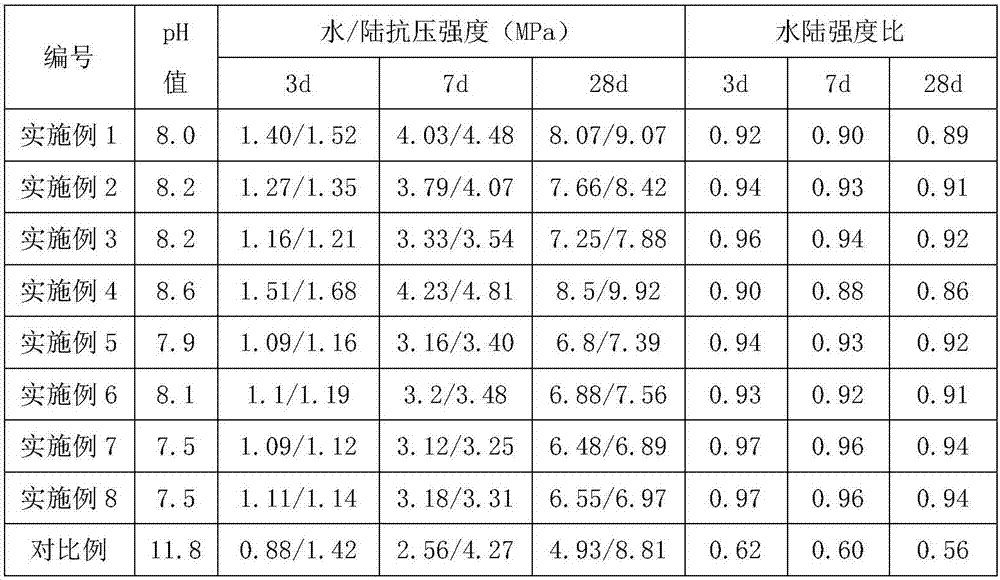

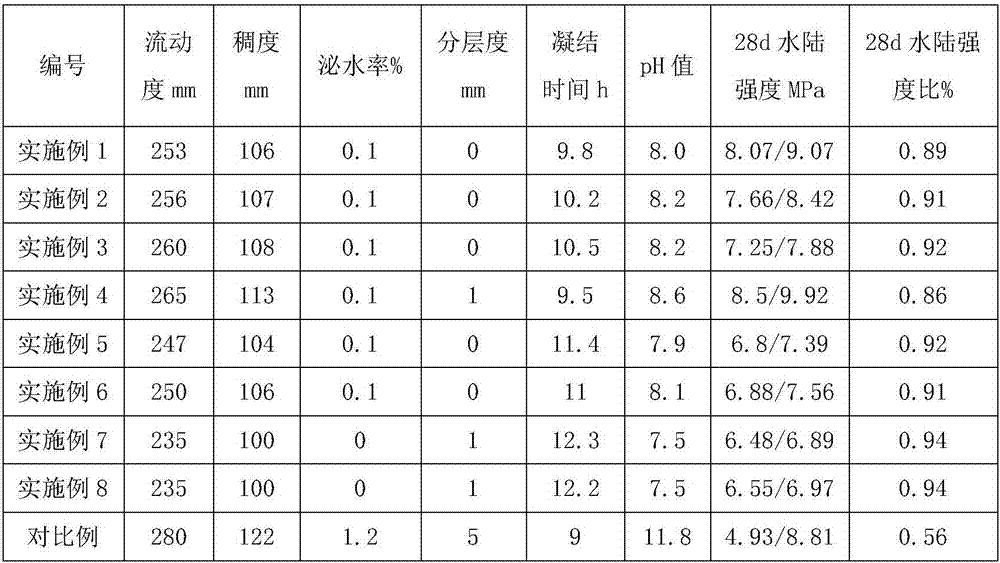

Shield synchronous grouting material special tackifier

The invention discloses a shield synchronous grouting material special tackifier characterized by comprising the following components by the mass percentage: 85-95% of silica fume; 2-8% of polyacrylamide; and 2-10% of a seawater slurry regulator, wherein the sum of the mass percentages of the components is 100%. The tackifier can greatly improve the anti-water dispersity of a shield synchronous grouting material, reduces the water bleeding rate and the stratification degree of the material, prevents strong duct piece floating ability, improves the stability of the material, improves the comprehensive performance of the material, makes the 28 d land and water strength ratio of a synchronous grouting liquid reach 90% or more, and can well adapt to conditions of high-pressure water-rich strata.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

Early-strength pavement patching material and preparation method thereof

PendingCN110482972AHigh degree of controllabilityImprove interfacial adhesionAlkali activatedRepair material

The embodiment of the invention provides an early-strength pavement patching material and a preparation method thereof. The early-strength pavement patching material comprises the following components: blast furnace slag, fly ash, silica fume, metakaolin, an excitant and an additive; by compounding the several ash body components, a reaction is carried out under an alkaline condition to generate amaterial with high strength; then an additive is added for regulating and controlling the product, so that the problems that the alkali-activated material is too fast in early coagulation, relativelylarge in gas content and relatively large in shrinkage are solved. Different ash bodies are subjected to a composite reaction and an additive is added, so that the setting time, the fluidity, the mechanical strength development and the matrix pore content of the alkali-activated matrix material can be effectively regulated; the prepared pavement repair material has advantages of high regulation degree, good interface adhesion with old concrete, good compatibility, effective road durability improving, effective road service life prolonging, and suitableness for promotion and use. Another embodiment of the invention also provides a preparation method of the early-strength pavement patching material.

Owner:GUANGZHOU UNIVERSITY

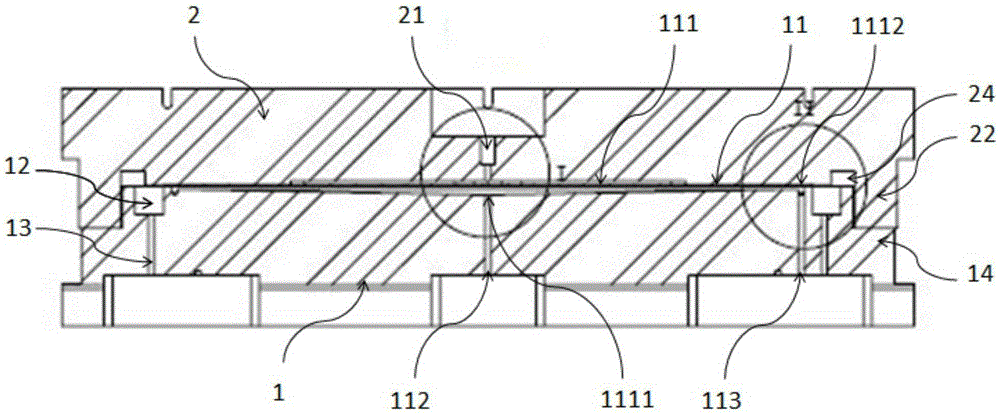

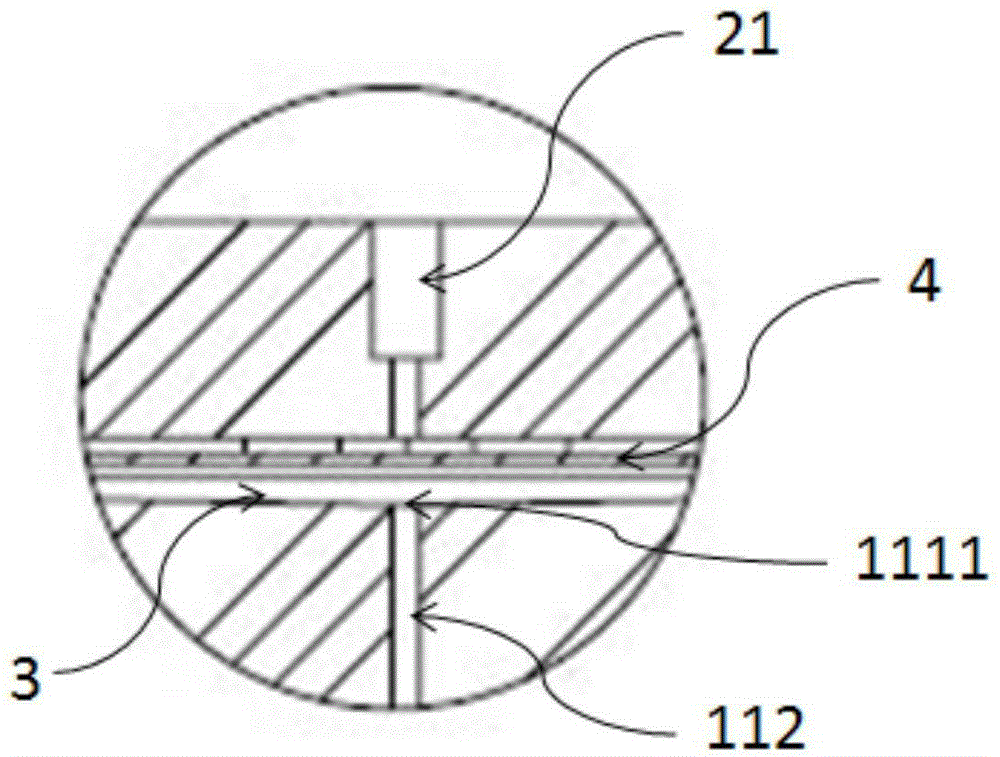

Semiconductor processing device and method thereof

ActiveCN106803477AControl liquidityControl flow speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical reactionEngineering

The invention discloses a semiconductor processing device and a method thereof, which relate to the technical field of semiconductors. The semiconductor processing device comprises a body and at least one semiconductor processing unit formed on the body, wherein each semiconductor processing unit comprises a recessed part formed on the upper end surface of the body, a first channel and a second channel, the bottom wall of the recessed part is provided with at least position, a fall trend is presented from the position to the edge of the bottom wall along a gravity direction or a rise trend is presented from the position to the edge of the bottom wall along a direction opposite to the gravity direction, the first channel is opened in each position of the bottom wall and communicated with the recessed part, the second channel is opened in the body at the edge of the bottom wall of the recessed part and communicated with the recessed part, and the first channel and the second channel can be used as outlets and / or inlets of fluid. Through controlling the flowing direction of the fluid on the surface of a substrate, the fluid is contacted with the surface of the substrate during a process of flowing the recessed part and a physical and / or chemical reaction happens, and process processing is carried out on the surface of the substrate.

Owner:WUXI HUAYING MICROELECTRONICS TECH CO LTD

Soaking and degreasing device of front mesh enclosure of fan

The invention discloses a soaking and degreasing device of a front mesh enclosure of a fan. The soaking and degreasing device comprises a base plate, wherein the base plate is provided with supporting pillars; the end parts of the supporting pillars are provided with a degreasing tank; the bottom of the degreasing tank is provided with a guide pipe; the base plate is provided with a driving motor; the guide pipe is internally sleeved by a driving pipe; the driving pipe is connected with a driving motor; the degreasing tank is internally provided with a rotary vane which is arranged on the end part of the driving pipe; the base plate is provided with a supporting plate; the end part of the support plate is provided with a guide pipeline; the guide pipeline is provided with supporting rods; the end parts of the supporting rods are provided with guide wheels; pull wires are wound on the guide wheels; one ends of the pull wires are free ends, and the other ends of the pull wires are provided hooks; the hooks are arranged in the degreasing tank. According to the invention, the soaked front mesh enclosure of the fan can be pulled out from the degreasing tank by the pull wires, and is dried naturally; the soaking and degreasing device is high in degreasing efficiency.

Owner:启东福平达机械设备有限公司

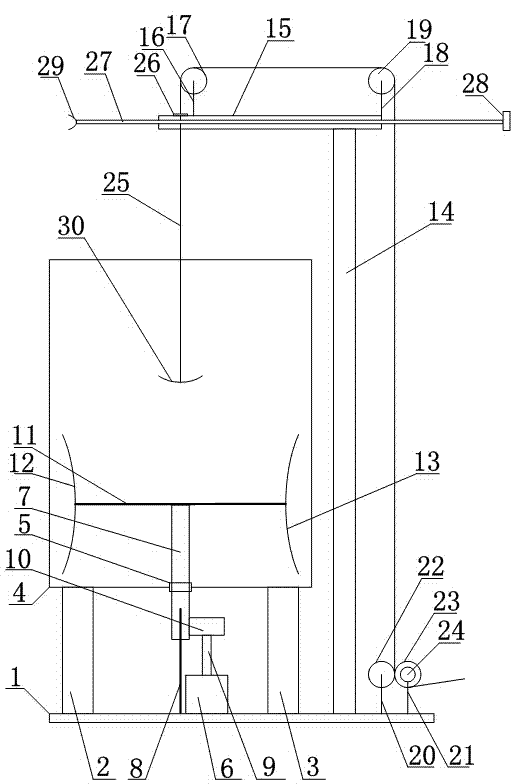

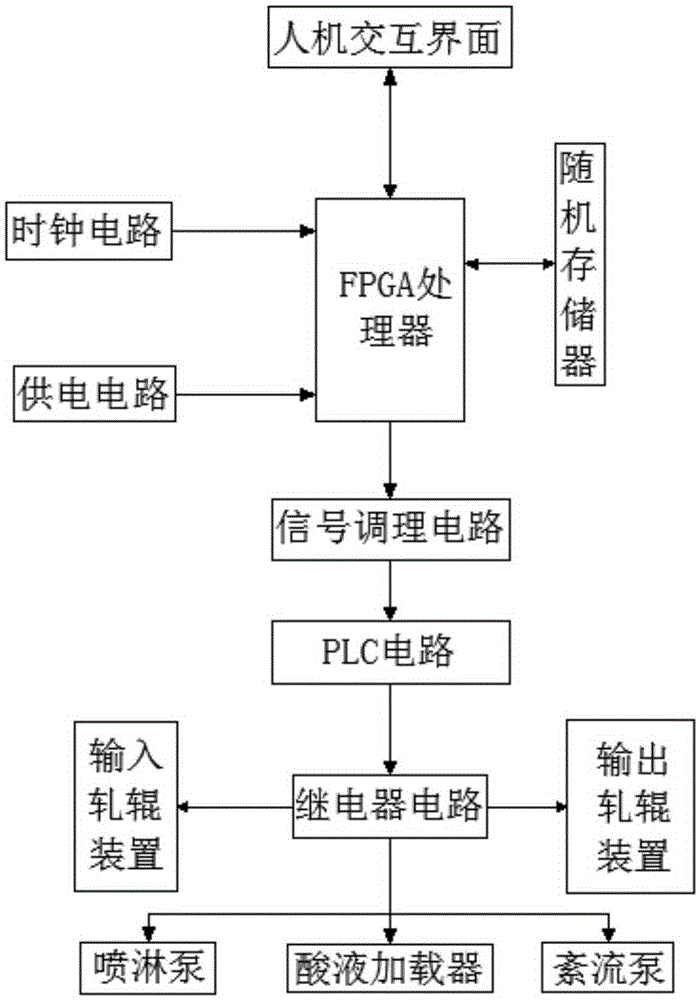

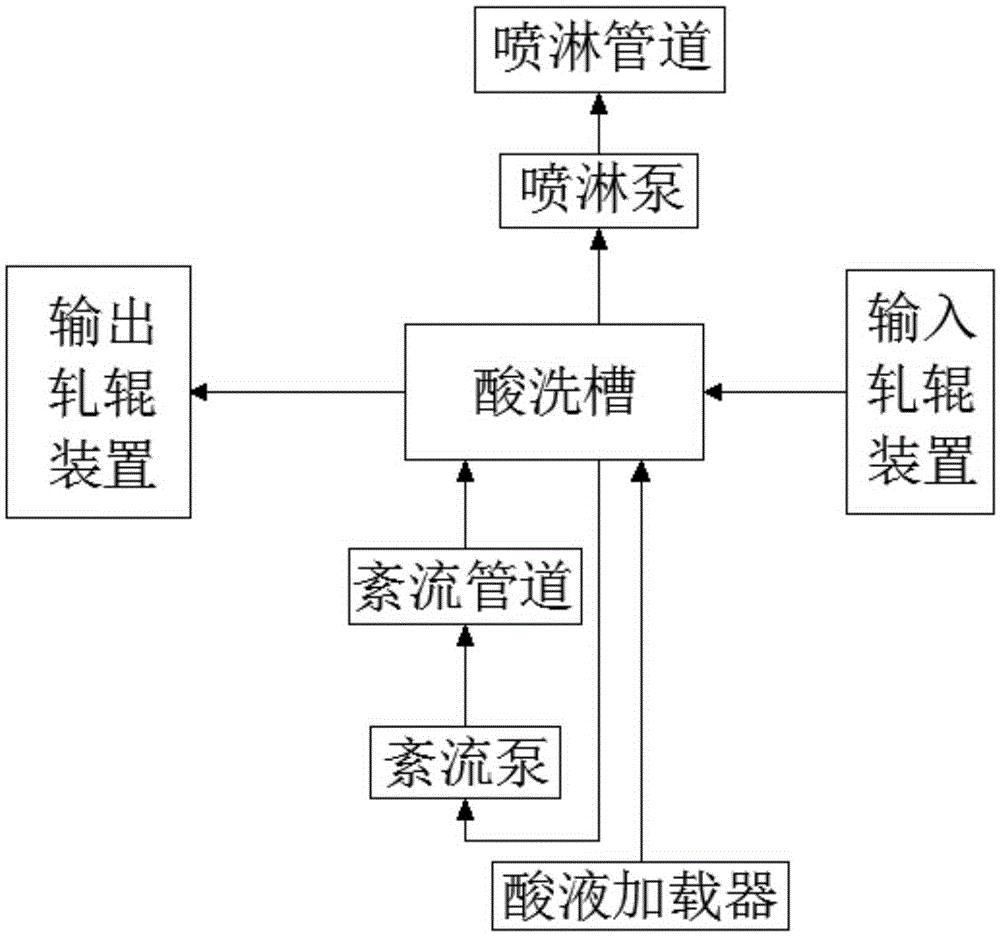

Strip steel pickling system with spraying system

The invention discloses a strip steel pickling system with a spraying system. The strip steel pickling system with the spraying system comprises a strip steel pickling device and a control system connected with the strip steel pickling device. A field programmable gate array (FPGA) processor, a power supply circuit, a storage circuit and a signal processing circuit are arranged in the control system. The FPGA processor is connected with the power supply circuit, the storage circuit and the signal processing circuit. The signal processing circuit is connected with the strip steel pickling device. Strip steel is pickled by combining the spraying system with a turbulent flow system so that the surface state of the surface, in an acid tank, of a steel plate can be improved, iron oxide skin on the surface of the steel plate can be fully pickled, no iron oxide skin exists on the surface of the pickled steel plate, the surface of the plate is bright, and the quality is stable; in addition, the intelligent control system is used for controlling the pickling process and the fluidity of acid liquor in the pickling tank, the pickling process and the operation of the strip steel are managed synchronously, and the strip steel is pickled optimally.

Owner:CHONGQING GUANGJI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com