Method for preparing polysaccharide biogum polymer gel profile control agent

A technology of biological glue and profile control agent, which is applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as adverse effects on environmental construction personnel, and achieve the effects of good strength, lower production costs and less environmental impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve xanthan gum in distilled water to form a 0.1% solution, and add 10% 2-acrylamido-2-methylpropanesulfonic acid and 0.16% N,N'- Methylene bisacrylamide, blowing nitrogen to isolate the air, adding potassium persulfate accounting for 0.025% of the mass fraction of the reaction system, and reacting at a constant temperature at 70°C to prepare the profile control agent.

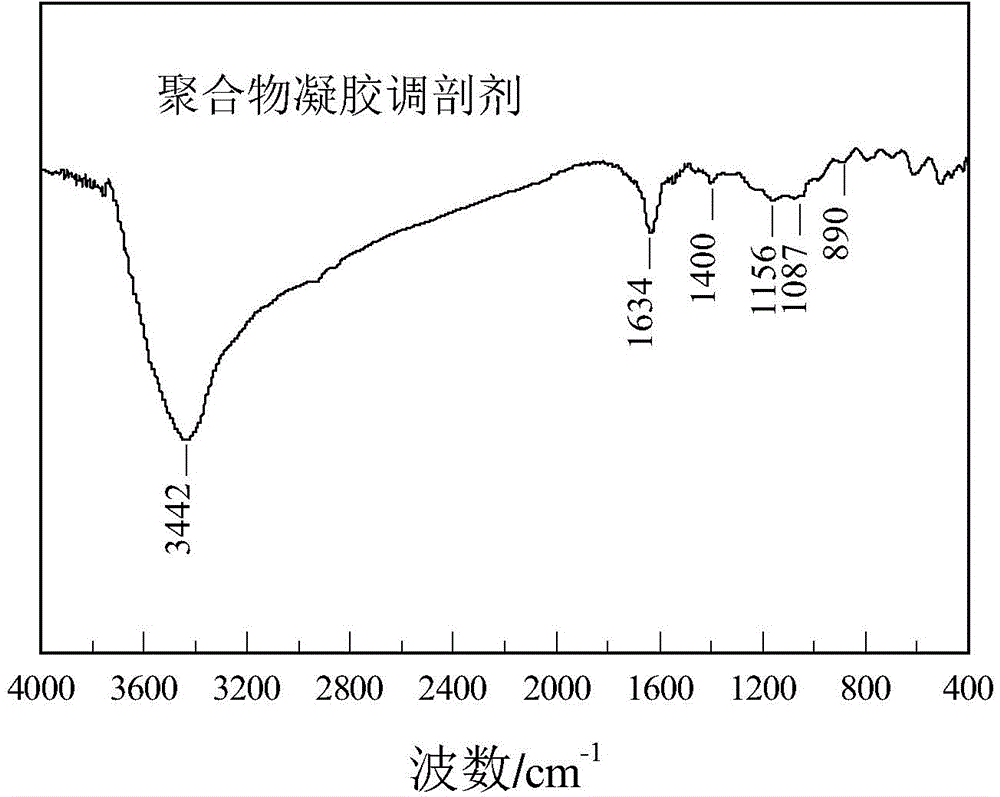

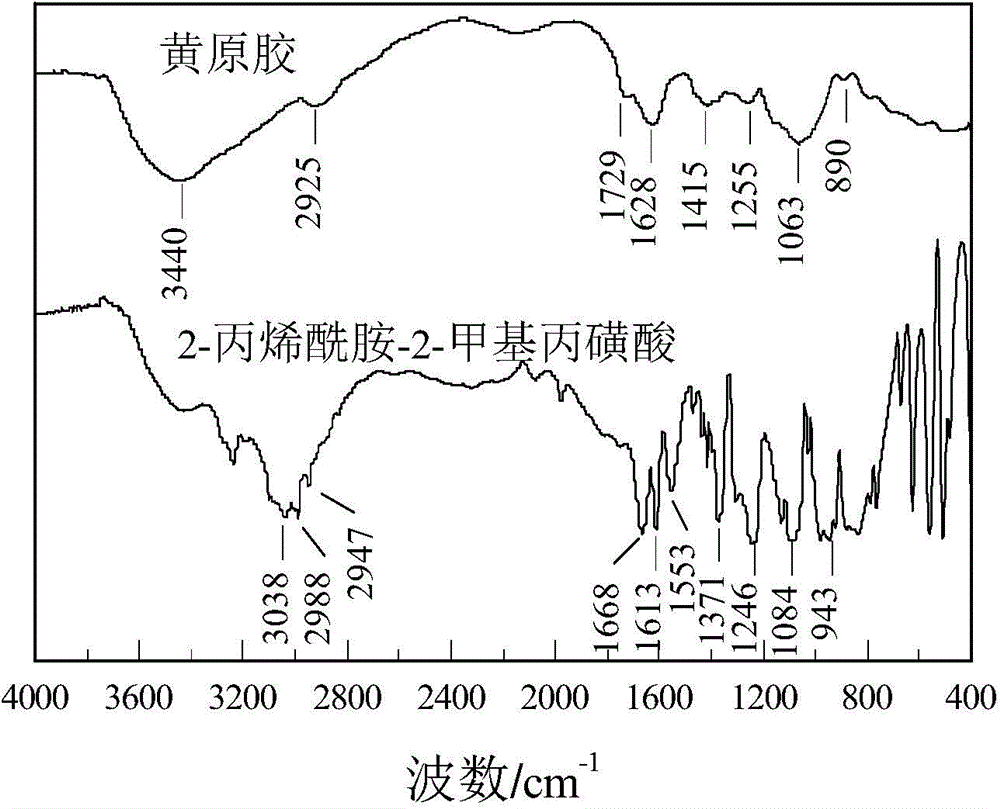

[0026] The profile control agent prepared by this method is soaked in a large amount of distilled water, taken out and dried, then soaked in ethanol, dried and extracted with acetone in a Soxhlet extractor for 24 hours, and the purified polymer profile control agent is obtained after complete drying. The purified and dried polymer profile control agent, xanthan gum, and 2-acrylamido-2-methylpropanesulfonic acid were tested by infrared spectrum, and the infrared spectrum obtained was shown in the attached figure 1 And attached figure 2 shown.

[0027] In the spectrum of the polymer gel profile co...

Embodiment 2

[0029] Dissolve xanthan gum in distilled water to form a 5% solution, add 15% 2-acrylamido-2-methylpropanesulfonic acid and 1% polyethylene glycol disulfonic acid to the solution Acrylic ester, blowing nitrogen gas to isolate the air, adding potassium persulfate accounting for 1% of the mass fraction of the reaction system, and reacting at a constant temperature at a temperature of 70°C to prepare the profile control agent.

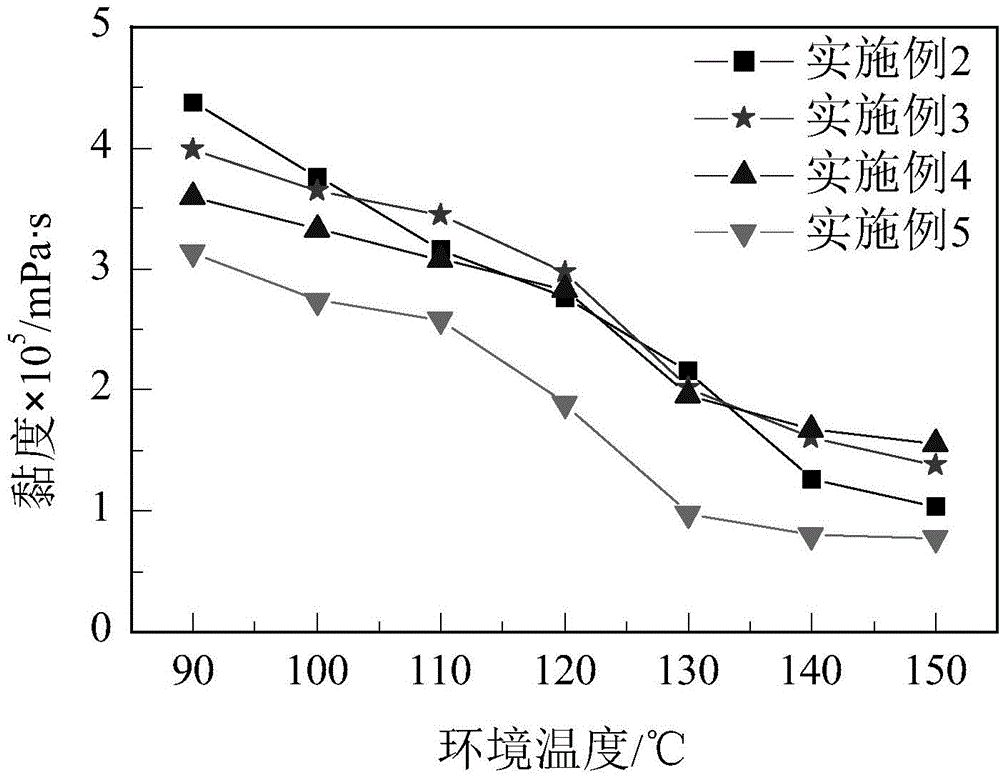

[0030] During the test, the viscosity of the gel was measured with an NDJ-8S viscometer, and the temperature and salt resistance properties are shown in the attached image 3 And attached Figure 5 shown.

[0031] attached image 3 Among them, it can be seen from the temperature resistance performance test curve of specific example 2 that the viscosity gradually decreases with the increase of temperature, and its downward trend gradually becomes gentle at 140°C-150°C, and when the ambient temperature reaches 150°C , its viscosity is still 1.04×10 5 mP...

Embodiment 3

[0034] Dissolve xanthan gum in distilled water to form a 2% solution, and add 15% of 2-acrylamido-2-methylpropanesulfonic acid and 1% of N-methylol propanesulfonic acid and 1% of the reaction system to the solution For acrylamide, pass nitrogen gas to isolate the air, add ammonium persulfate accounting for 0.5% of the mass fraction of the reaction system, and react at a constant temperature at a temperature of 80°C to prepare the profile control agent.

[0035] During the test, the viscosity of the gel was measured with an NDJ-8S viscometer, and the temperature and salt resistance properties are shown in the attached image 3 And attached Figure 5 shown.

[0036] attached image 3 Among them, it can be seen from the temperature resistance performance test curve of specific example 3 that its viscosity gradually decreases with the increase of temperature, and its downward trend gradually becomes gentle at 130°C-150°C, and when the ambient temperature reaches 150°C , its vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com