Patents

Literature

126results about How to "Reduce mud content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

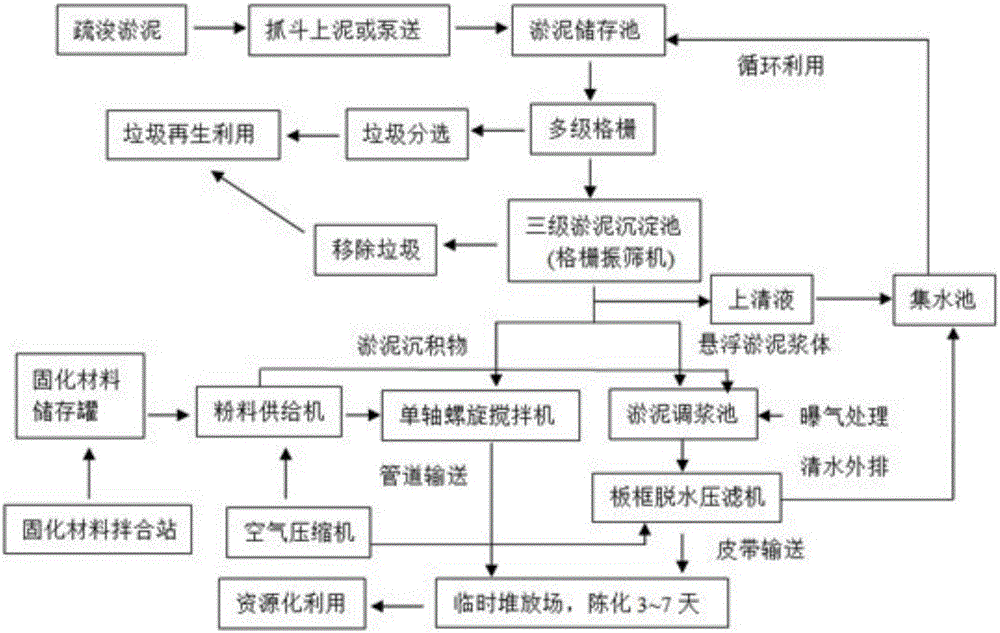

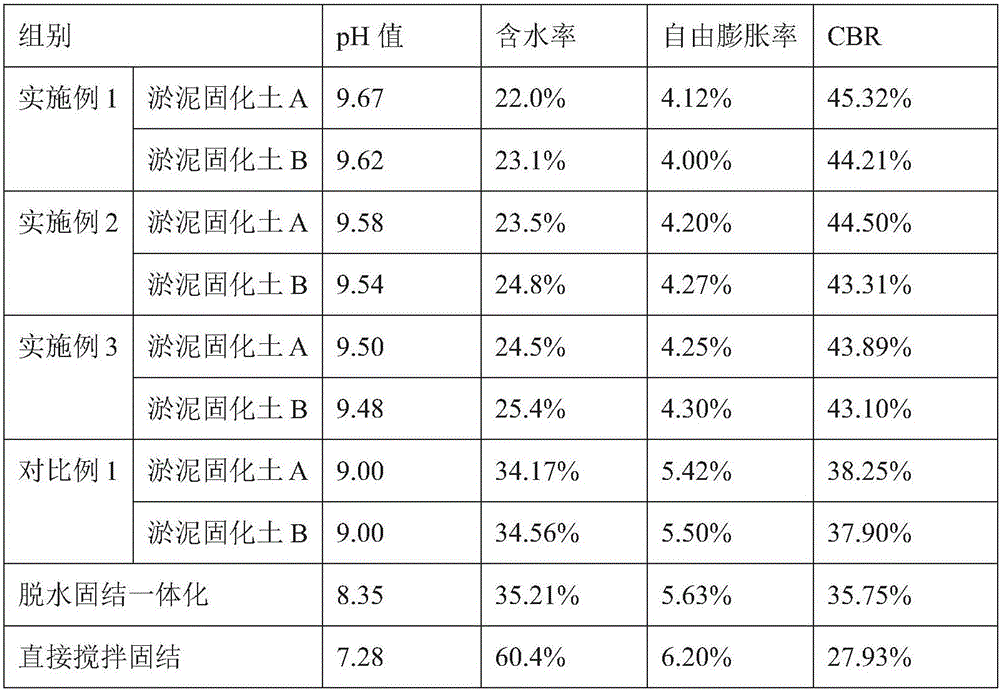

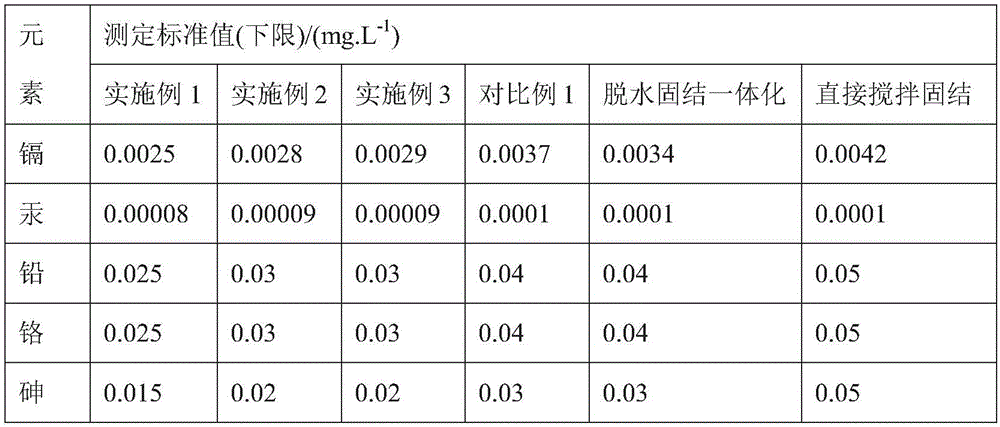

Sludge treatment process

The invention belongs to the field of environmental protection, and in particular relates to a sludge treatment process. The sludge treatment process comprises the following steps: 1) impurity removal: use multi-stage grille to filter out the garbage in the sludge; 2) pretreatment: utilize the three-stage sludge settling tank to pretreat the sludge to obtain the first, second, and The sludge in the three-stage sludge settling tank, the sludge slurry and the supernatant after being settled in the three-stage sludge settling tank; 3) solidification treatment: respectively adopt mixing solidification and dehydration solidification methods for the first, second, and third-stage sludge sedimentation The silt and silt slurry in the pond are dehydrated and solidified to obtain silt-solidified soils A and B; 4) stacking and aging: transport the silt-solidified soils A and B to a temporary storage yard and age them for 3 to 7 days to complete the treatment. The sludge treatment process of the present invention can simultaneously process particles and sludge with high viscosity and low water content, as well as sludge slurry with fine particles, organic matter and high water content, and is especially suitable for river courses with complex components, wide particle distribution, and large water content differences silt.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

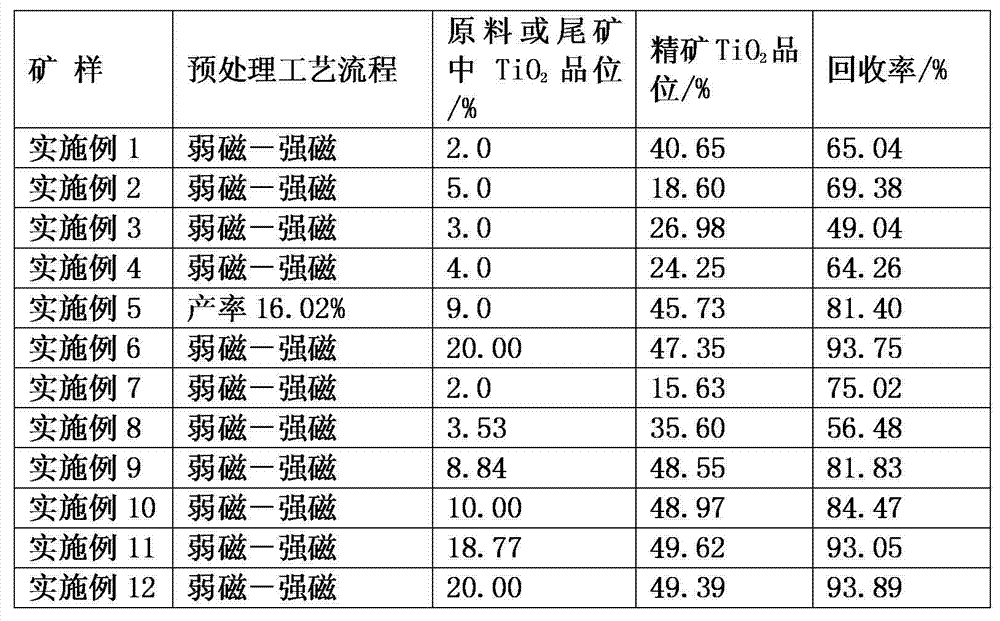

Combined mineral processing technology of low-grade laterite type weathering titanium placers

The invention relates to a combined mineral processing technology of low-grade laterite type weathering titanium placers and belongs to the technical field of mineral processing. The combined mineral processing technology includes subjecting raw materials with the titanium dioxide content of below 5% to low-intensity magnetic-high-intensity magnetic pre-treatment technologies, then gravity separation-regrinding-gravity separation, gravity separation-regrinding-flotation processing and regrinding-flotation processing. According to the combined mineral processing technology of the low-grade laterite type weathering titanium placers, by means of the low-intensity magnetic-high-intensity magnetic pre-treatment technologies, a large number of slurries which are rich in kaolin minerals can be cast, technological procedures can be simplified, obtained rough titanium concentrates have few slurries, and follow-up treatment can be easily performed, for example, the interference of the slurries is avoided when technologies such as flotation and tabling gravity separation are performed; the grade and the recovery rate of the obtained titanium concentrates are high, and high intensity magnetic separation is beneficial to recovery of fine-particle grade titanium particles; and by means of the technologies of gravity separation-regrinding-gravity separation, gravity separation-regrinding-flotation processing and regrinding-flotation processing, the recovery rate of titanium is high, simultaneously, the content of iron in mineral samples is increased, and additional values of products are improved.

Owner:KUNMING METALLURGY INST

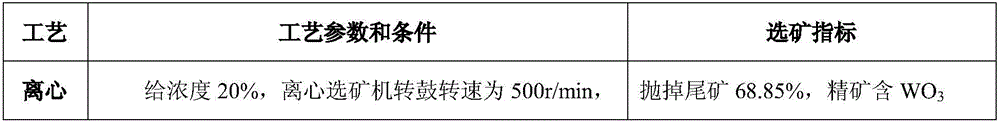

Mineral separation method for recycling wolframite from tailing

ActiveCN106669964AImprove the quality of selectionReduce the amount of oreSolid separationMechanical material recoveryGravity separationMagnetic separation

The invention discloses a mineral separation method for recycling wolframite from a tailing. The mineral separation method comprises the following steps that (1) gravity separation of a centrifugal machine is conducted for tailing discarding and preenrichment; (2) sulphide ore flotation is conducted; (3) magnetic separation is conducted and magnetic impurities are removed; (4) high-gradient magnetic separation is conducted for wolframite enrichment; (5) tabling gravity separation is conducted to obtain coarse grained wolframite; and (6) flotation is conducted to obtain fine grained wolframite. By means of centrifugation gravity separation preenrichment, the separation grade of the wolframite is improved, the ore feeding quantity and the mud content of wolframite separation are reduced, and flotation reagent dosage is saved. By means of the sulphide ore flotation and magnetic separation iron removal, the disturbance of sulphide minerals and magnetic minerals on wolframite separation is reduced. According to the mineral separation characteristics of the wolframite, the separation index of the wolframite is improved by adopting the high-gradient magnetic separation and the coarse grained and fine grained wolframite grading and separation process. Efficient recycling of the wolframite in low-grade wolframite tailing resources is achieved, and the mineral separation method is environmentally friendly, efficient and energy saving, and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

Environment-protective type plant cover concrete

InactiveCN101323517ALow water absorptionSolve the problem of stacking affecting the ecological environmentSolid waste managementEcological environmentCarboxylic acid

The invention discloses an environment-friendly plant concrete, consisting of water, cement, waste concrete aggregate, concrete antalkali and poly carboxylic acid water reducing agent. The detailed matching proportion is as follows: the ratio of water / cement / waste concrete aggregate is 0.28 to 0.32:1:5; the quantity of adopted concrete antalkali is 10 to 20 percent of the cement quantity; the quantity of the poly carboxylic acid water reducing agent is 1 to 2 percent of the cement quantity. Compared with the existing similar product of the prior technology, the invention not only can solve the contamination to ecological environment by stacked waste concrete but also can avoid the damage to ecological environment by extreme exploitation to aggregate and realize the purpose of planting plants on concrete, thus achieving the effects of recycling sources, regulating ecological balance and beautifying environment; the intensity of the concrete is high, the concrete can be pre-cast into various shapes as requirements, and the construction is convenient.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

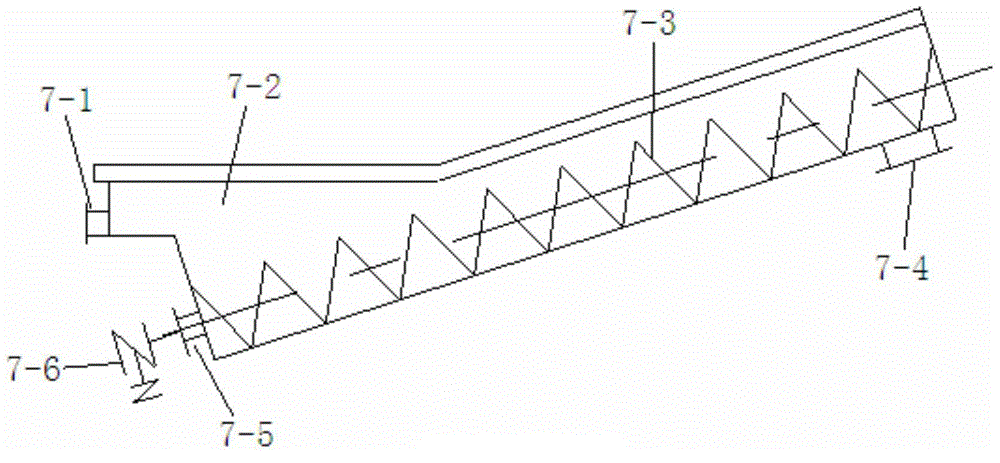

Comprehensive recycling method of waste sand in green casting

ActiveCN103128228AGood effectReduce mud contentMould handling/dressing devicesFluidized bedMagnetic separator

The invention relates to a comprehensive recycling method of waste sand in green casting, and belongs to the field of novel casting processes. The comprehensive recycling method of the waste sand in green casting is characterized in that the waste sand in green casting is recycled through the following steps: a first level of magnetic separation and smashing, a second level of magnetic separation, screening, dewatering and drying, a first level of mechanical friction demoulding, a first level of winnowing and dedusting, a second level of winnowing and dedusting, a third level of mechanical friction demoulding, a third level of boiling, dedusting and screening; and finally qualified recycled sand is obtained. A permanent magnet belt magnetic separation machine is used in the first magnetic separation of the waste sand, a three-return-stroke roller dryer is adopted during dewatering and drying, a suspension-type magnetic separation machine is adopted in the second level magnetic separation, centrifugal mechanical friction demoulding is adopted in the first level of mechanical friction demoulding and the second level of mechanical friction demoulding, streaming mode winnowing and a pulse-bag-type dedusting machine are adopted in the first level of winnowing and dedusting and the second level of winnowing and dedusting, vortex kneading demoulding is adopted in the three level of mechanical friction demoulding, and a fluidized bed and the pulse-bag-type dedusting machine are adopted in the third level of boiling and dedusting.

Owner:SHANDONG YUANTONG MASCH CO LTD

Regenerative bone material by concrete and preparing method thereof

InactiveCN1559956AHigh strengthHave physicalSolid waste managementRoad engineeringUltimate tensile strength

The invention is a concrete regenerative aggregate obtained by crushing discarded concrete and its preparing method, using the discarded concrete as raw material, and making special processes of crushing, dry-blending, screening and washing to obtain it. It has physical and mechanical properties approaching those of natural stones, a relatively ideal material for preparing regenerative concretes with low strength, medium strength, etc, able to be widely applied to road engineering, municipal engineering and houses and buildings engineering.

Owner:TONGJI UNIV

Method for preparing aggregates special for pavement asphalt from construction wastes and waste plastics

InactiveCN107445575AGood effectReduce manufacturing costIn situ pavingsRoads maintainenceEngineeringRoad surface

The invention belongs to the technical field of preparation of novel construction materials, and provides a method for preparing aggregates special for pavement asphalt from construction wastes and waste plastics. The method comprises the following steps: firstly, crushing the construction wastes to obtain the construction wastes retaining masonries, concrete, woods, plastic products and other components; then, placing in a vertical eccentric device for improving density, mechanical properties and surface properties of the aggregates so as to obtain strengthened regenerated aggregates; next, immersing in a sodium silicate solution for activating to obtain activated regenerated aggregates; finally, mixing with molten waste plastics, performing condensation, solidification and other treatments to obtain the aggregates special for pavement asphalt having good bonding property to hot melting asphalt and relatively high strength. The preparation method provided by the invention adopts the construction wastes and the waste plastics as main raw materials, have excellent environmental and social benefits, greatly reduces production costs of the aggregates and improves the properties of the pavement asphalt.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

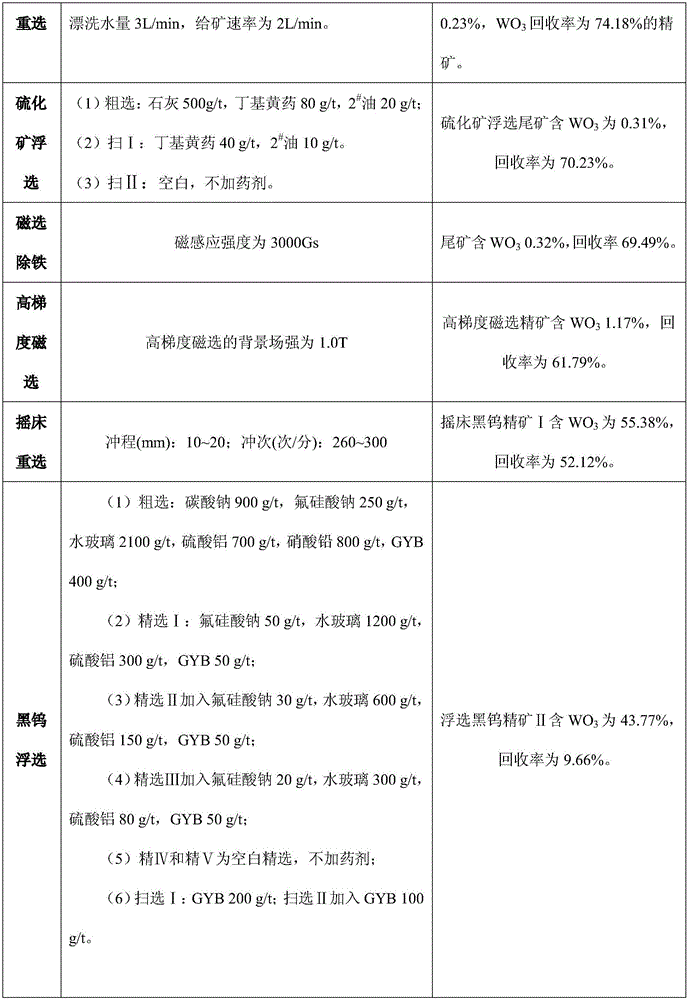

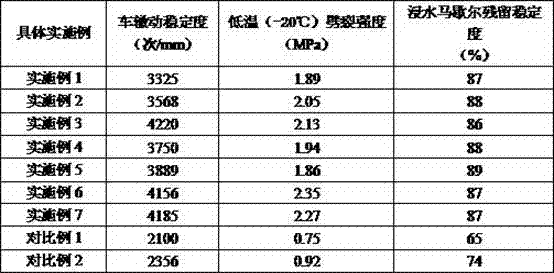

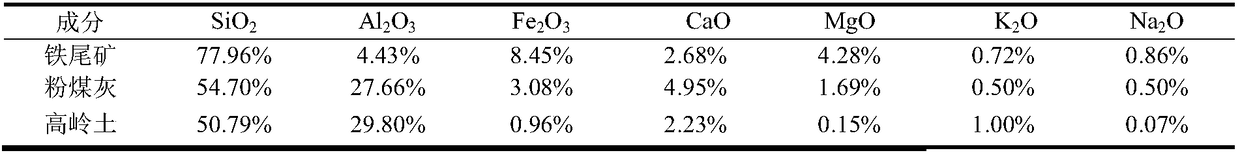

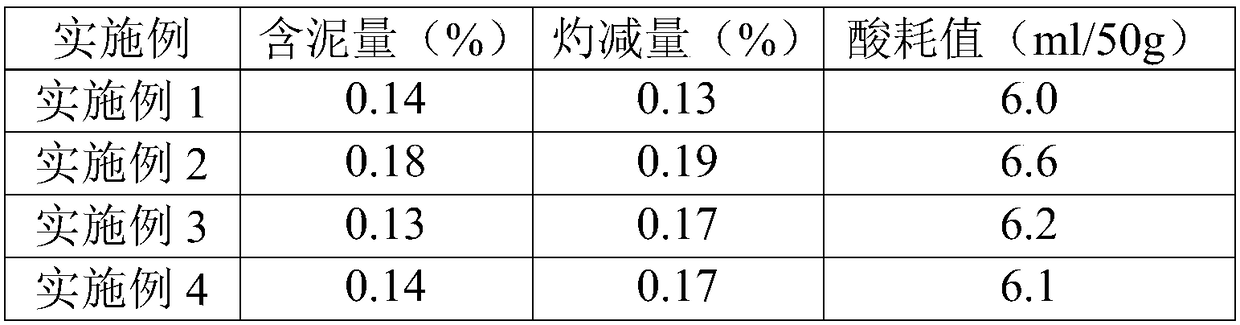

Ceramsite filter material for aerated biological filter and preparation method thereof

InactiveCN108440013ARich sourcesImprove adsorption capacityCeramic materials productionCeramicwareSolubilityEnvironmental resistance

The invention belongs to the technical field of comprehensive mineral resource utilization and sewage purification treatment, and particularly relates to a ceramsite filter material for an aerated biological filter and a preparation method thereof. According to the preparation method of the ceramsite filter material, the ceramsite filter material is prepared by using iron tailing as a main raw material, adding fly ash, a bonding agent and a pore-forming agent, mixing, granulating and then roasting. The ceramsite filter material is rough and porous in surface and large in specific surface area,a biofilm is easily formed, and adsorption and removal of pollutants in water are facilitated; moreover, the ceramsite filter material is light in weight, low in mud content and low in hydrochloric acid solubility, can withstand a hydraulic impact for a long time, has good stability, and is an excellent aerated biological filter filler for sewage treatment. The raw material sources are rich, thecost is low, the preparation method is simple, a technology is environment-friendly, the current situation of serious water pollution in China is alleviated while environment pollution caused by improper disposal of the iron tailing is reduced, treatment wastes by wastes is achieved, and a new idea is provided for combination of comprehensive iron tailing utilization and sewage treatment.

Owner:NORTHEASTERN UNIV

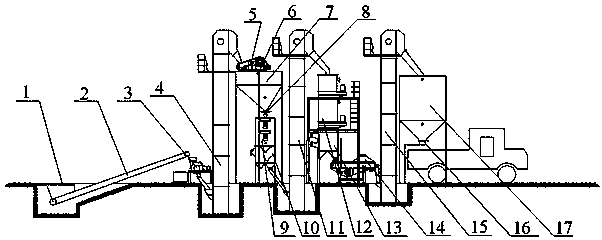

Regeneration system of used clay sand

ActiveCN103521699AReduce mud contentReduce environmental pollutionMould handling/dressing devicesLinear vibrationEngineering

The invention discloses a regeneration system of used clay sand. The regeneration system comprises a belt conveyor with a magnetic separation function, a breaker, a bucket elevator, a linear vibration sand sieving machine, a storage device, a centrifugal regenerator and an air separator, wherein a feeding opening of the breaker is connected with the tail end of the belt conveyor, and a discharging opening of the breaker is connected with a feeding opening of the bucket elevator; the linear vibration sand sieving machine is arranged under a discharging opening of the bucket elevator; the storage device is arranged under the linear vibration sand sieving machine; a feeding opening of the centrifugal regenerator is connected with a discharging opening of the storage device; the air separator is arranged under the centrifugal regenerator; the used clay sand system also comprises a vortex type regenerator; the vortex type regenerator is connected with the centrifugal regenerator through a secondary bucket elevator. Through the regeneration system of used clay sand, the clay content in the used sand is greatly reduced; the performance of the used sand is controlled stably; the performance of the molding sand is effectively improved and controlled; the full regeneration of the used clay sand is realized; the environmental pollution is reduced; the resources are saved; the casting quality and the production efficiency are improved; the production cost of castings is reduced.

Owner:QINGDAO HEDELONG MACHINERY

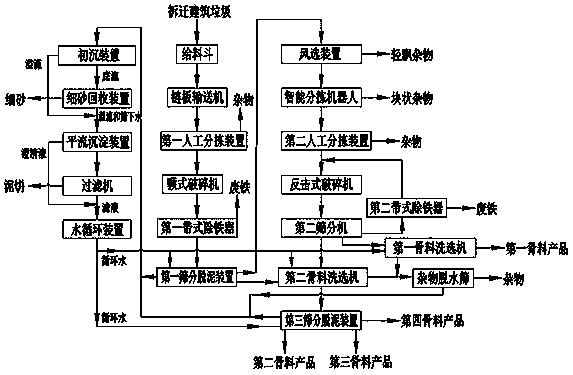

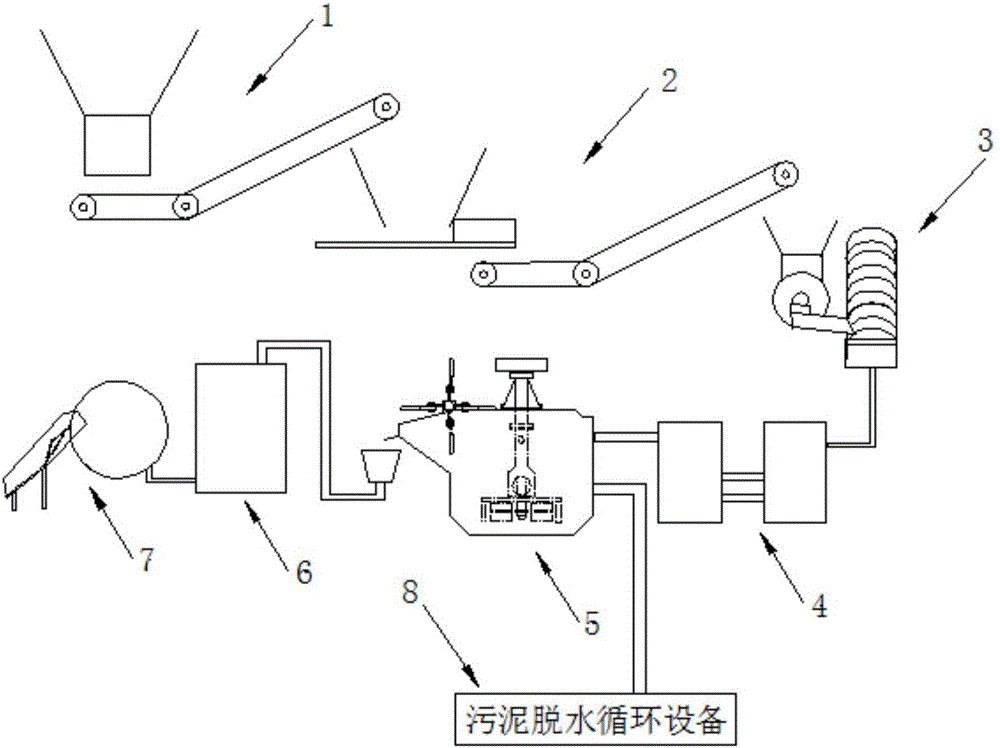

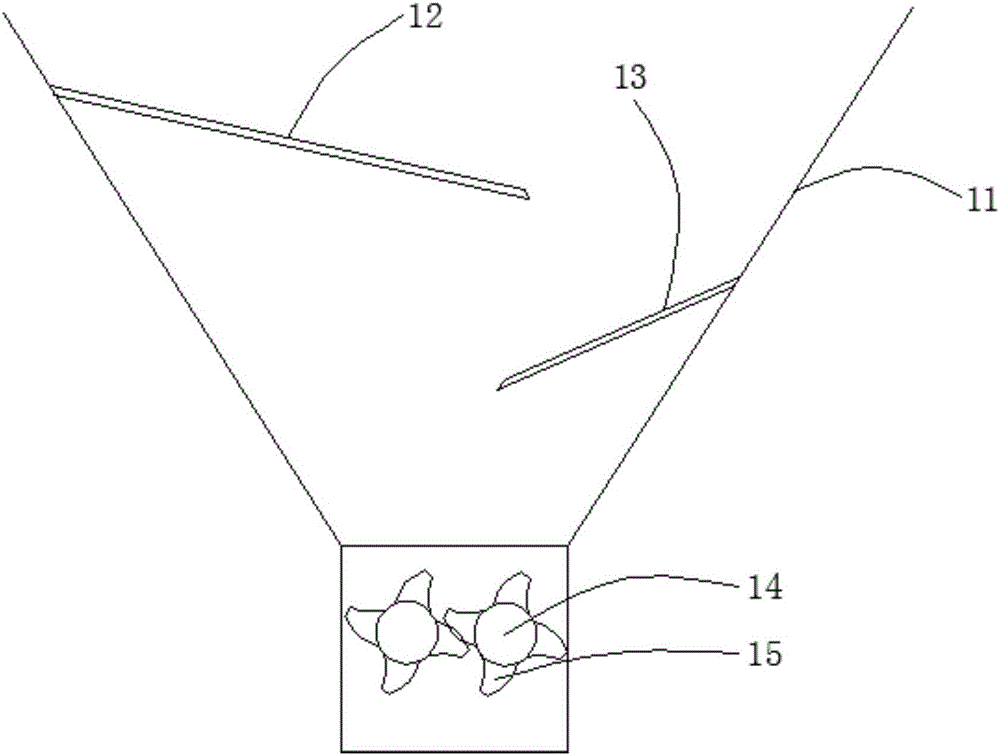

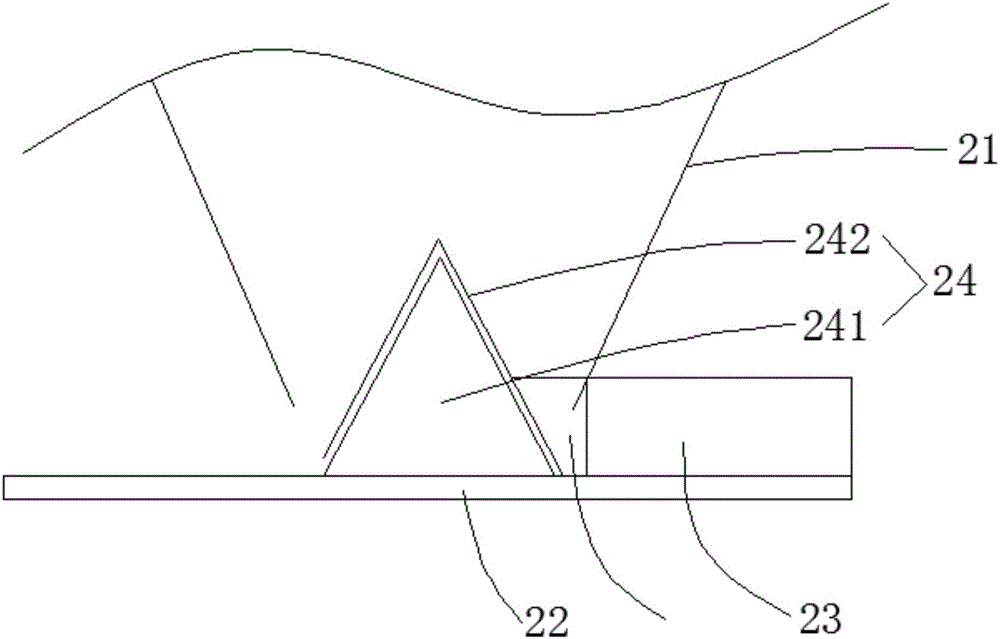

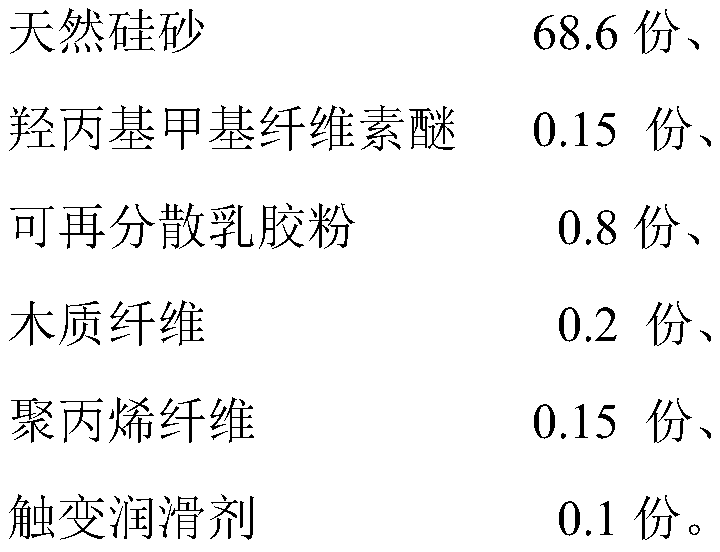

Demolished building garbage sorting system and method

ActiveCN111318548AReduce labor intensityReduce impurityConstruction waste recoverySolid waste disposalEnvironmental engineeringWater circulation

The invention discloses a demolished building garbage sorting system and method. The demolished building garbage sorting system is characterized in that a continuous feeding system, a pretreating system, a first screening-desliming device, a wind separating device, an intelligent impurity removing system, an impact crusher, a second screening device, a recycled aggregate washing-separating systemand a third screening-desliming device are sequentially connected; the first screening-desliming device, a primary settling device, a fine sand recycling device, a horizontal-flow settling device, a filter and a water circulating device are sequentially connected so as to form a circulating loop I; the recycled aggregate washing-separating system, the primary settling device, the fine sand recycling device, the horizontal-flow settling device, the filter and the water circulating device are sequentially connected so as to form a circulating loop II; and the third screening-desliming device, the primary settling device, the fine sand recycling device, the horizontal-flow settling device, the filter and the water circulating device are sequentially connected so as to form a circulating loopIII. Through the separating treatment of demolished building garbage, high-purity aggregate products and a recycled sand product can be separated, and the demolished building garbage comprehensive-treatment level can be improved.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

Unit used for machining fluorite mineral aggregate and application thereof

InactiveCN105642432AReduce shockExtend your lifeFlotationGrain treatmentsAfter treatmentEconomic benefits

The invention provides a unit used for machining fluorite mineral aggregate and application thereof. According to the processing route of the mineral aggregate, the unit comprises a crusher, a disk feeder, a levigating device, a stirring device, a flotation machine, a concentration device and a rotary drum vacuum filter in order. By the improved devices provided by the invention, the mineral aggregate is levigated after crushed, and then forms pulp. The pulp forms fine powder foam after treatment and finally forms mineral powder after dewatering and drying. The unit further comprises a sludge dewatering recycling device. Compared with the prior art, the devices provided by the invention are improved in a plurality of places. The improved devices can optimize the machining process, save raw materials, and reduce noise at the same time. Above all, the improved devices are convenient to replace if the parts are damaged so that human and material resource is greatly saved, and the waste can be turned into wealth by a sludge dewatering recycling device so that high economic benefit is achieved.

Owner:JINGDE COUNTY SHENGYU FLUORITE PROCESSING CO LTD

Variable roughness texture ornamental porcelain brick and method for producing the same

InactiveCN101245662AReduce mud contentLow dry wear resistancePolishing machinesCovering/liningsConcave surfaceMetallurgy

The invention discloses a decorative porcelain tile with changeable grains on concave surfaces and convex surfaces and a manufacturing method thereof, which is characterized in that: when powders are prepared, facing materials for patterns of sunken materials are made up for the porcelain tile; a two-level polishing and grinding treatment which comprises a hard polishing-grinding and a soft polishing-grinding in sequence is carried out after a green body is dried; a sintering temperature between 1100 DEG C and 1300 DEG C is adopted for the facing materials, as a result, obviously downward sunken materials as well as concave and convex grains in gully or pit shapes that alter along with the changes of the patterns of the fabric can be sintered for the facing materials. By adopting the manufacturing method, the concave and the convex surfaces of the decorative porcelain tile can be randomly changed, the colors, patterns and grains are naturally altered along with the changes of the concave and convex grains, and the stone imitating effect is vivid.

Owner:GUANGDONG DONGPENG CERAMIC CO LTD

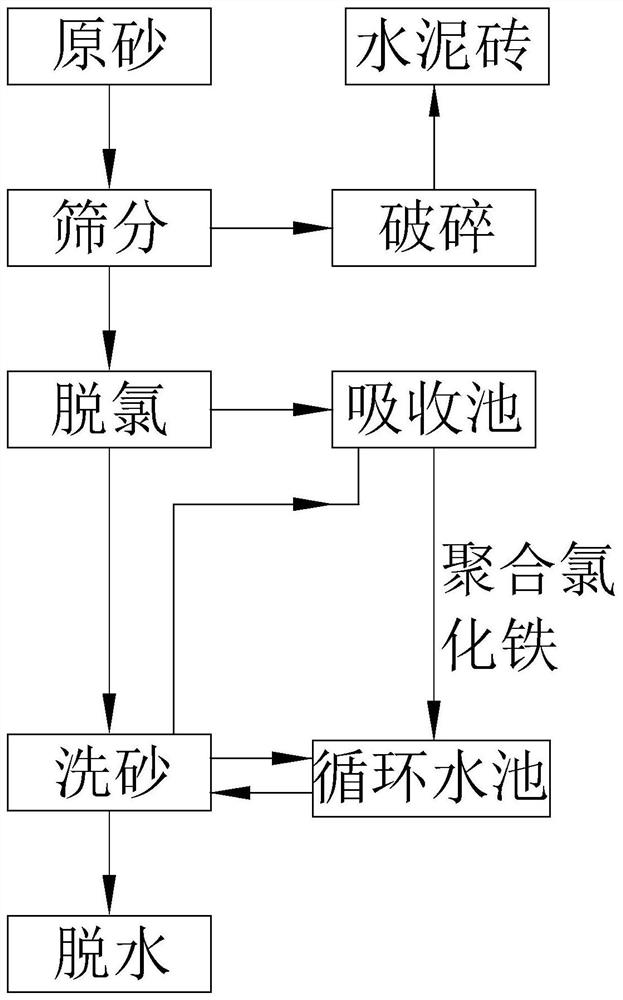

Sea sand treatment process

InactiveCN112142354AHigh dechlorination efficiencyImprove purification efficiencyIron halidesWater/sewage treatment by flocculation/precipitationSoil scienceAqueous solution

The invention relates to a sea sand treatment process, which comprises the following steps: (1) screening: removing impurities such as shells, gravels and the like in raw sand through vibration screening; (2) dechlorinating: conveying the screened sea sand, soaking the sea sand into a dechlorinating agent, and dechlorinating by adopting an ozone aqueous solution; (3) sand washing: conveying the dechlorinated sea sand to a washing pool, and washing the sea sand with washing water; and (4) dehydrating: dehydrating the cleaned sea sand to obtain finished sand. According to the invention, the strong oxidizing property of the dechlorinating agent oxidizes the chlorine ions in the sea sand into chlorine gas and discharges the chlorine gas, so that the chlorine ions are separated from the sea sand, and the dechlorinating efficiency of the sea sand is improved along with the increase of the concentration of ozone water and the increase of the dechlorinating time; and the dechlorinated sea sandis flushed by utilizing the washing water to remove residual chlorine ions and part of soil in the sea sand, so that the content of the soil and the content of mud blocks are reduced while the chlorine ions in the sea sand are further reduced, and the effects of improving the sea sand purification efficiency and reducing the water consumption are achieved.

Owner:南通市展成商品混凝土有限公司

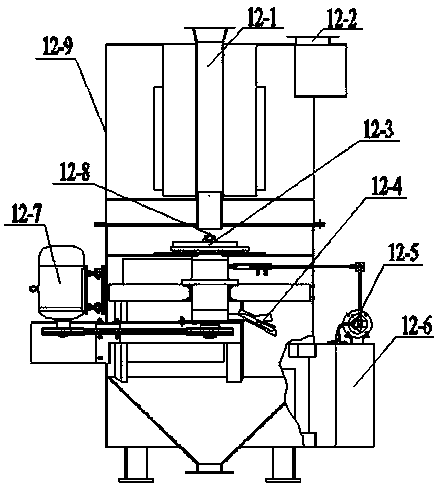

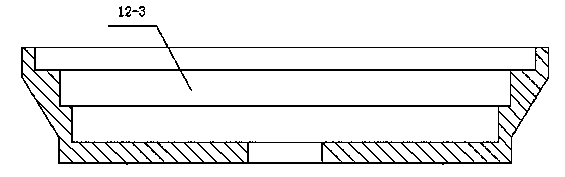

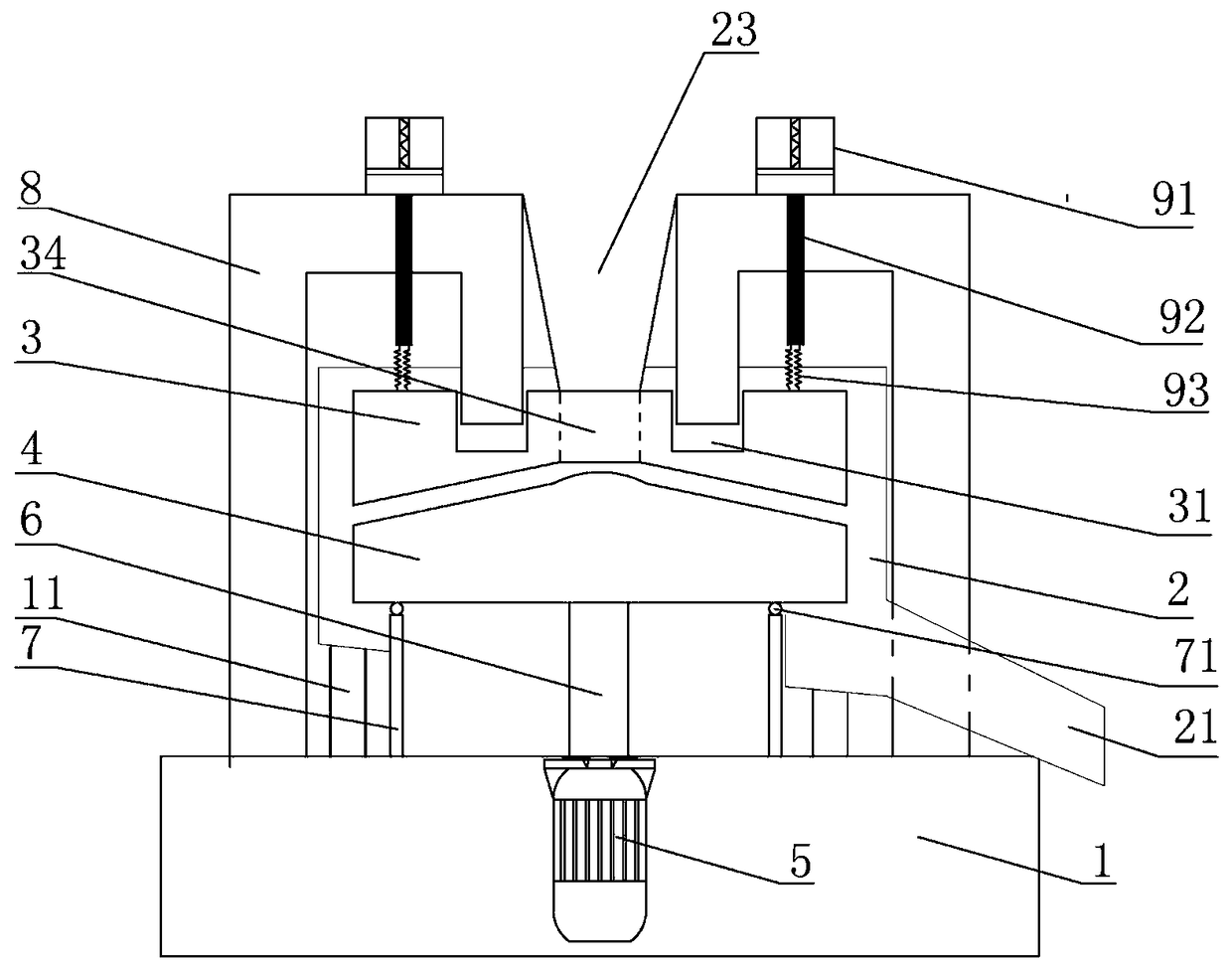

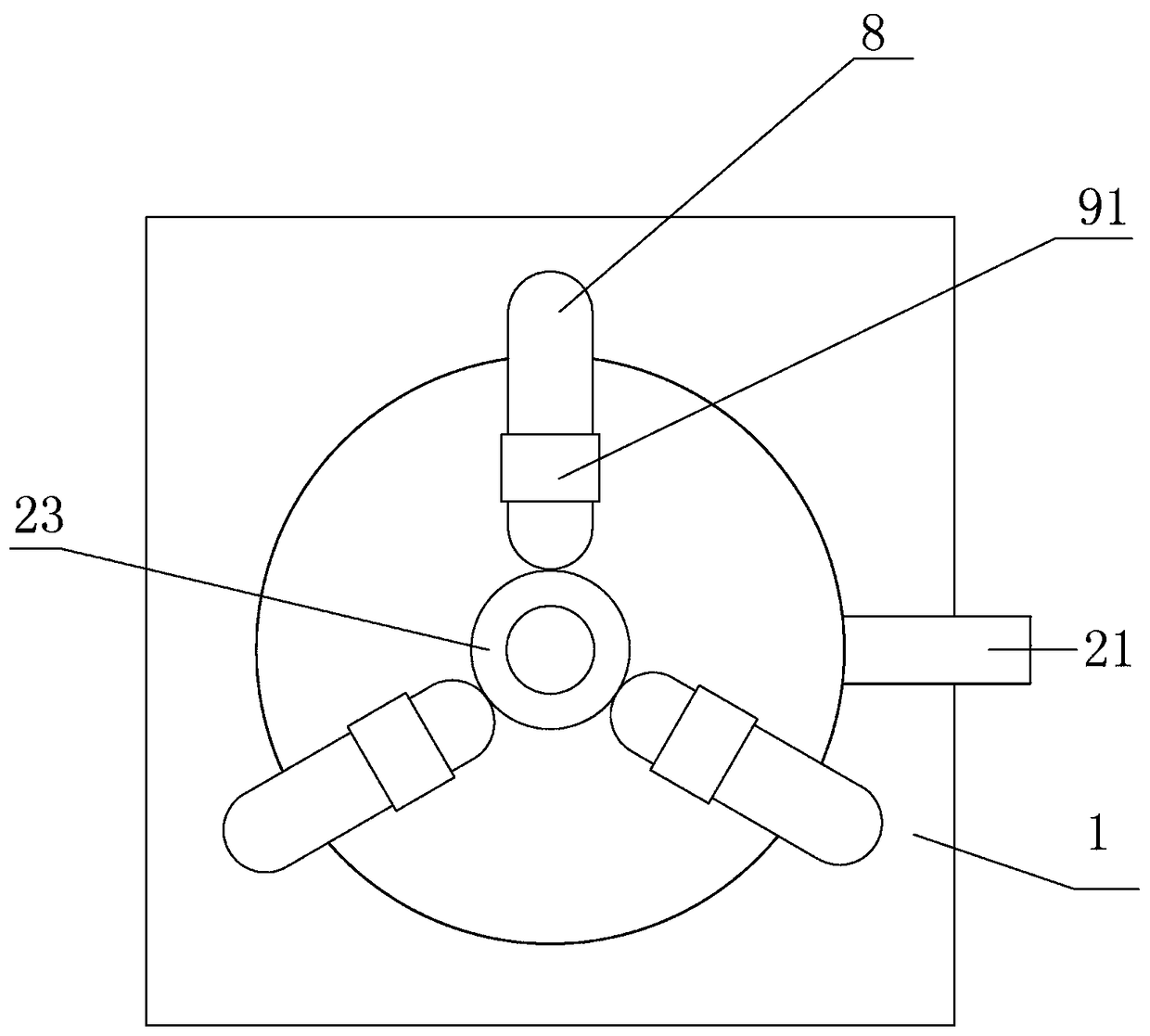

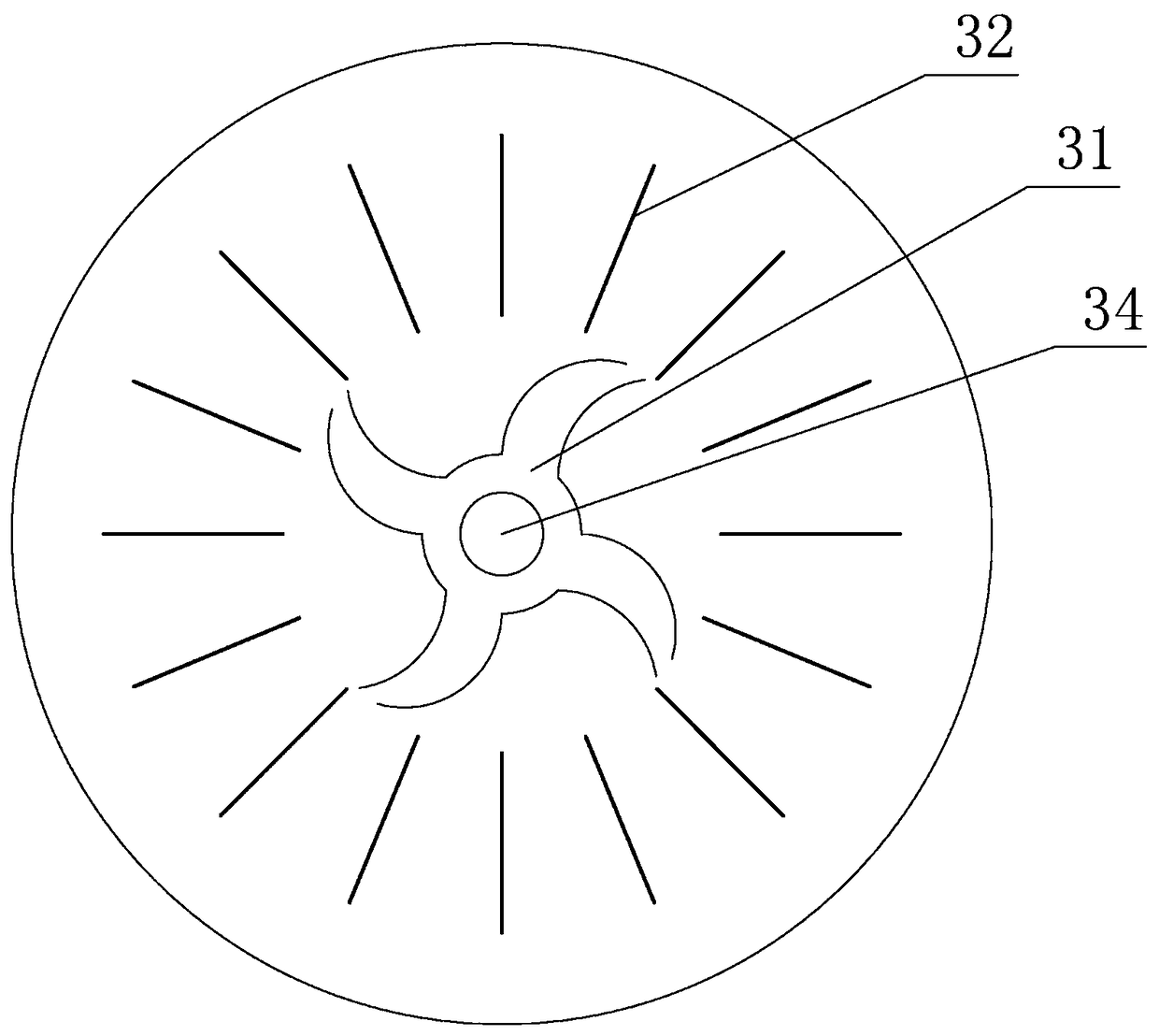

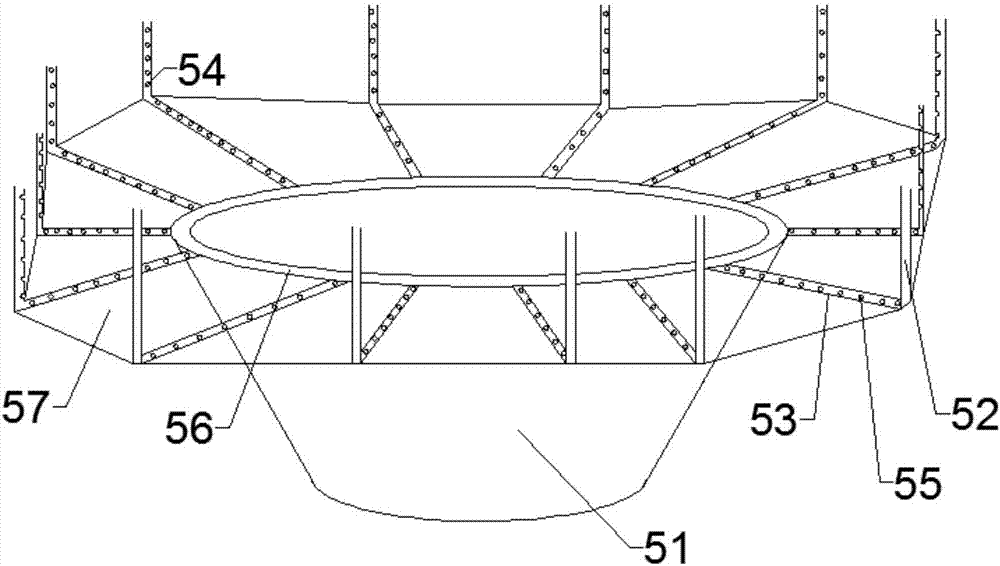

Cone-disc type waste concrete regenerated coarse aggregate mortar stripping device

ActiveCN109012867AWeaken protruding cornersReduce mud contentCocoaGrain treatmentsMetallurgyConstruction aggregate

The invention discloses a cone-disc type waste concrete regenerated coarse aggregate mortar stripping device. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device comprises a base, a material collection bin and a cone-disc type grinding disc, wherein the cone-disc type grinding disc is composed of an upper grinding disc and a lower grinding disc, the grinding surface of the lower grinding disc is of a convex cone type, the grinding surface of the upper grinding disc is of a concave cone type, and the grinding surface of the upper grinding disc is in fit with that of the lower grinding disc; the base is provided with a plurality of reverse-hook-shaped supports, the disc surface of the upper grinding disc is correspondingly provided with position-limiting holes, and reverse hooks of all the reverse-hook-shaped supports penetrate into the corresponding position-limiting holes to restrict the upper grinding disc to be only capable of sliding up and down; ahydraulic force transmitting device is arranged between the upper grinding disc and all the reverse-hook-shaped supports, and ascending and descending of the upper grinding disc are controlled through stretching and contracting adjustment of the hydraulic force transmitting device; and the center of the upper grinding disc is provided with a material inlet, the material inlet penetrates out of the top of the material collection bin, and the lower portion of the material collection bin is provided with a material outlet. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device is simple in structure, the aggregate mortar stripping effect is good, and the original particle size of coarse aggregate can be maintained to make the performance of the coarse aggregate be close to natural aggregate, so that the workability, strength and durability of freshly-mixed waste concrete are improved.

Owner:CHINA UNIV OF MINING & TECH

Recycled aggregate freezing and thawing cycle pretreatment method

InactiveCN108675662AReduce physical damageHigh bulk densitySolid waste managementPretreatment methodFreeze and thaw

The invention relates to a recycled aggregate freezing and thawing cycle pretreatment method which specially comprises the following steps: primarily breaking, removing impurities, soaking, performingfreezing and thawing cycle, secondarily breaking, performing cleaning and polishing, performing sieving and the like. Through the freezing and thawing cycle pretreatment, expansion pressure generatedwhen water is frozen on inner walls of concrete holes is utilized to make concrete generate cracks from the inner weak positions; after ice melts into water, the water can go deep into the interior of a structure through the cracks without taking extra trouble. Through certain times of freezing and thawing cycles, many fine and small cracks can be generated at the weak positions inside the structure of concrete which has low compressive strength and not compact internal structure; when being broken again, the concrete can be broken along the structural cracked positions to form the recycled coarse aggregate which has the advantages of high strength, small holes, large crushing index and low silt content.

Owner:ANHUI UNIV OF SCI & TECH

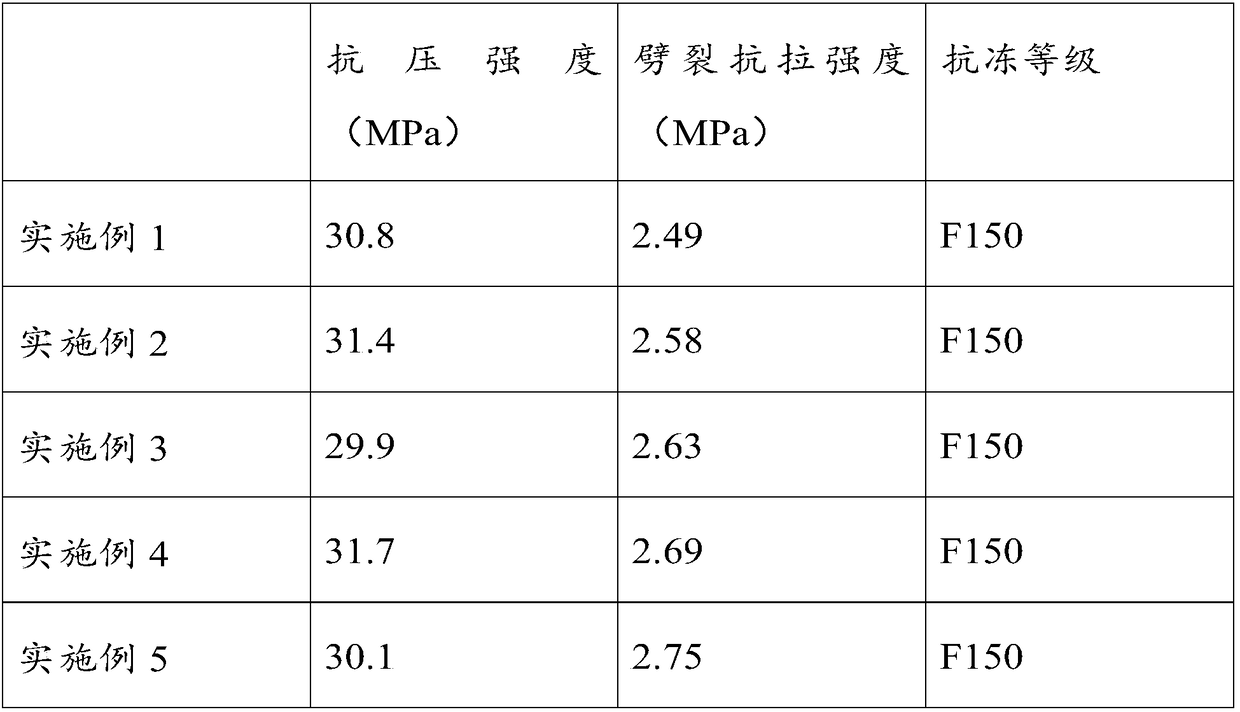

Concrete containing electrolytic manganese slag, preparation method thereof, and concrete pavement

The invention relates to concrete containing electrolytic manganese slag, a preparation method thereof, and a concrete pavement and relates to the field of materials. The concrete is prepared by mixing raw materials including, by weight, 130-200 parts of grading electrolytic manganese slag calcined material; 13-20 parts of cement, 5-10 parts of silica fume, 10-15 parts of fly ash, 0.5-0.8 parts ofa dispersant, 0.7-1 part of a water reducing agent, and 10-15 parts of water; the grading electrolytic manganese slag calcined material is prepared by calcining electrolytic manganese slag at 800-1000 DEG C, and crushing and grading the product. The concrete has good anti-freezing performance and high strength, is suitable for pavement, can effectively save sand and stone, and improves utilization rate of the electrolytic manganese slag. The preparation method is simple, is convenient to carry out and is free of pollution, and can effectively increase performance of the concrete containing electrolytic manganese slag. Meanwhile, by applying the concrete containing electrolytic manganese slag to a concrete pavement, the pavement has good anti-freezing performance and high strength and is long in service life.

Owner:TONGREN UNIV

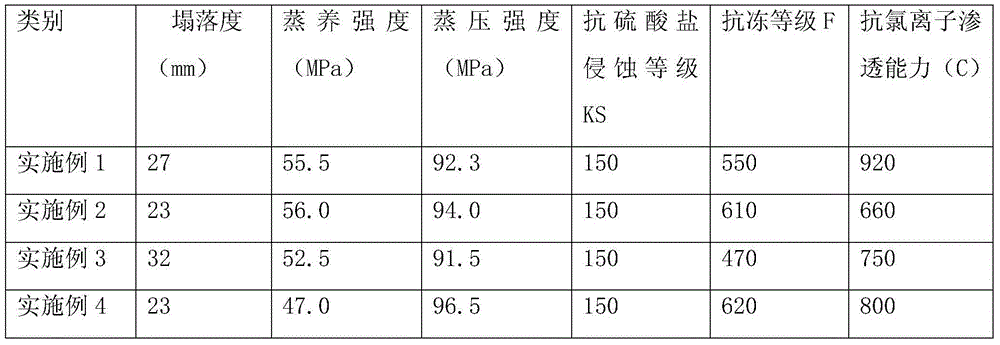

Concrete prefabricated pile and production method thereof

The invention discloses a concrete prefabricated pile, the concrete prefabricated pile is prepared by filling of concrete into a mold provided with steel reinforcement cage skeleton, die assembly, stretch-draw, centrifugal shaping, atmospheric pressure steam curing, demoulding and high pressure steam curing, the concrete includes the raw materials of a cementing material, fine aggregate, coarse aggregate, an additive and water, the content of the cementing material is 350-550 kg / m<3>, the cementing material comprises 55wt%-95wt% of cement and 5wt%-45wt% of an admixture, the admixture is silica powder; the fine aggregate is machine-made sand or a machine-made sand and natural sand mixture, the machine-made sand is prepared from mineral tailings, industrial waste slag and other stone raw materials by mechanical crushing, grading, sieving and dust removal processing; the invention also discloses a production method of the concrete prefabricated pile. The machine-made sand adopts various kinds of abandoned mineral resources, the production is not affected by the climate and season, not only the problem of environmental pollution is solved, the utilization rate of resources is improved, and the production cost of the concrete prefabricated pile is reduced.

Owner:QINGDAO XINGHE BUILDING MATERIAL

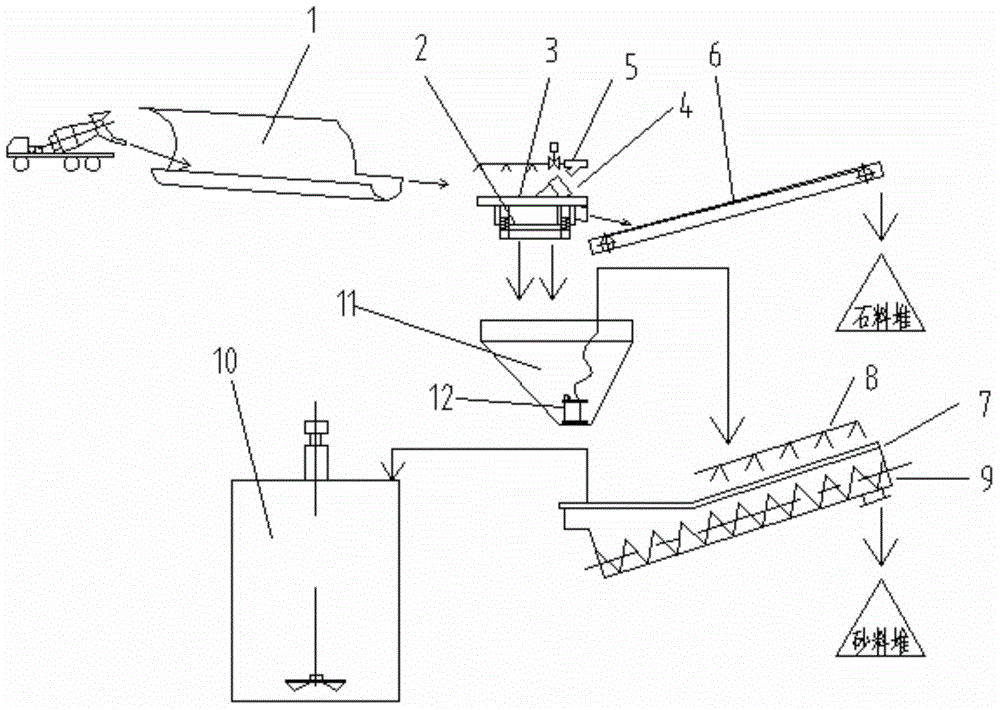

Novel device and method for separating sand and stone from concrete

The invention relates to a novel device and method for separating sand and stone from concrete. The separating device comprises a vehicle washing tank, a vibrating screen, a spiral sand separator, a mortar pool, a water pump and a stirring pool. The device is characterized in that the vehicle washing tank is connected with the vibrating screen; the residual concrete in a stirring vehicle is discharged to be put in the vehicle washing tank, and flows onto the vibrating screen through the vehicle washing tank; the vibrating screen is positioned over the mortar pool; the water pump is placed in the mortar pool; the discharging outlet of the water pump is connected with the spiral sand separator; the water outlet of the spiral sand separator is connected to the stirring pool; a vibrating motor and a screen are arranged on the vibrating screen. According to the separating method disclosed by the invention, through the high-efficiency vibration of the vibrating screen, the sand and the stone in the concrete can be thoroughly separated out, and the separated sand and the separated stone are washed by a high-pressure washing device, so that the low mud containing rate and the low water containing rate of the sand and the stone are guaranteed so as to conform with the standard of sand and stone aggregates for construction concrete; the rest paste can be directly recycled, so that zero discharge of waste residues and waste water in a concrete stirring station is really realized.

Owner:SHANTUI CHUTIAN CONSTRUCTION MACHINERY CO LTD

Sandstone separator for directly separating mixed sandstone according to different granule diameters

InactiveCN106862053AReduce mud contentFast separationSievingScreeningPore diameterPulp and paper industry

The invention discloses a sand-stone separator which directly separates the sand-stone mixture into different particle sizes. , a third sieve and a fourth sieve, the lower ends of the first, second, third and fourth sieves are respectively erected with a discharge port, the upper end of the first sieve is connected to a feed port , the apertures of the first, second, third and fourth screens gradually decrease in sequence. The fully graded sand and gravel separator of the present invention combines four screens with different apertures on one separator, the apertures gradually decrease from top to bottom, and can separate fine sand (0.1~5mm) to block stones ( 300~500mm), aggregates of different particle sizes roll down from the outlets of the screens under the action of vibrators and springs for classification, and add water spray at the feeding port The device is used to facilitate full flushing and reduce the mud content of the aggregate, which not only improves the separation speed of the aggregate, but also improves the quality.

Owner:青岛星锐机械有限公司

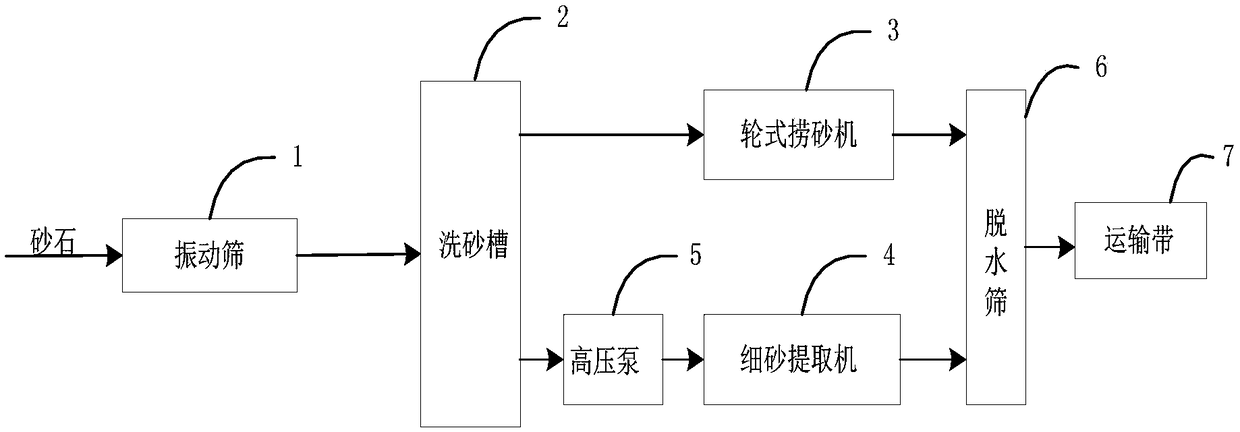

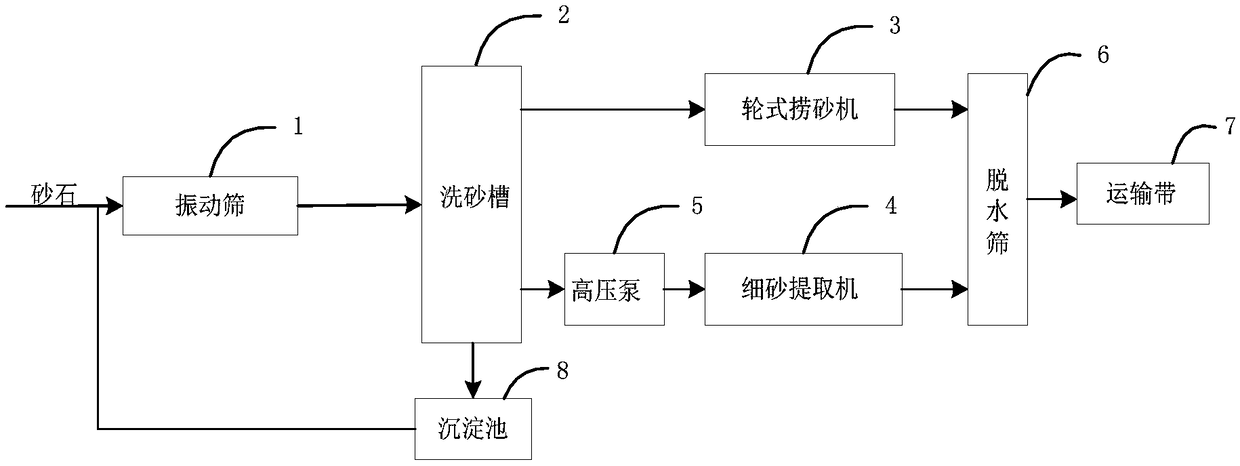

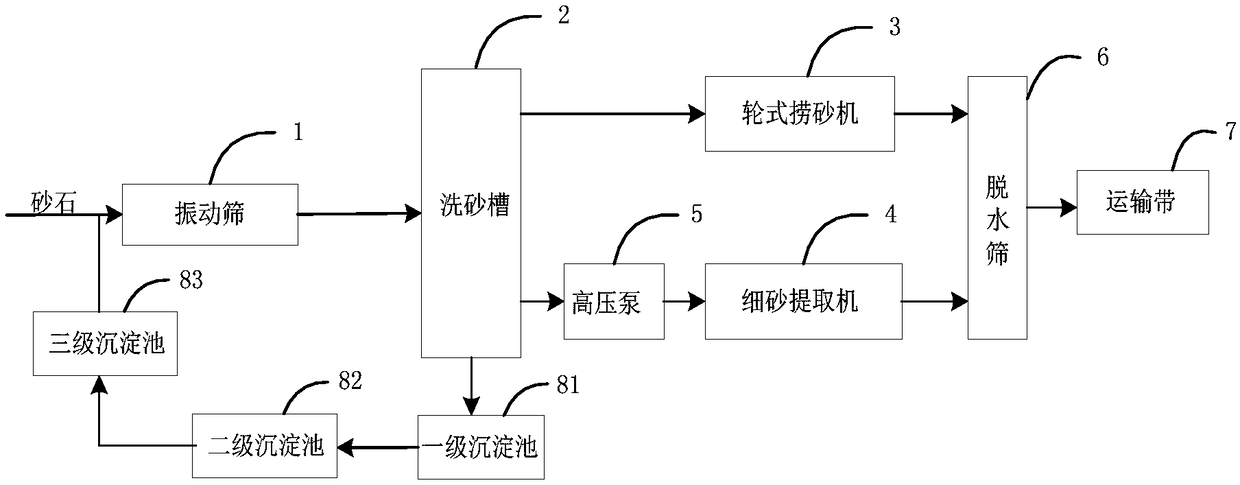

Sand washing system and debugging method

The invention relates to the technical field of sand making, in particular to a sand washing system and debugging method. The sand washing system comprises a vibrating screen, a sand washing tank, a wheel type bailing machine, a fine sand extracting machine, a high pressure pump, a dewatering screen and a conveyor belt. A discharge hole of the vibrating screen is connected to a feed inlet of the sand washing tank, and the wheel type bailing machine is disposed on the sand washing tank. The fine sand extracting machine is connected with the sand washing tank through the high pressure pump, anddischarge holes of the wheel type bailing machine and the fine sand extracting machine are separately connected with the dewatering screen. A discharge hole of the dewatering screen is connected withthe conveyor belt. According to the sand washing system and debugging method, medium sand and fine sand in the sand washing tank are correspondingly extracted by the wheel type bailing machine and thefine sand extracting machine so as to avoid the massive loss of the fine sand, and the effective control over the fineness modulus of mechanism sand is realized; and the mechanical sand is subjectedto dewatering by the dewatering screen to enable the moisture content of the mechanical sand to meet the engineering requirements.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Regeneration method of ceramsite used sand, regenerated ceramsite sand and products of regenerated ceramsite sand

ActiveCN108941448AReduce acid consumptionReduce Ignition LossMould handling/dressing devicesImpurityMaterials science

The invention provides a regeneration method of ceramsite used sand, regenerated ceramsite sand and products of the regenerated ceramsite sand, and relates to the technical field of foundry waste sandregeneration. The regeneration method of the ceramsite used sand comprises the following steps that broken ceramsite used sand molds are sequentially subjected to roasting, pickling and physically removing of impurities to obtain the regenerated ceramsite sand; and the mesh of the broken ceramsite used sand molds is 30-200 mesh. The regeneration method of the ceramsite used sand solves the technical problem of lacking of a regeneration method of the ceramsite used sand in the prior art which uses the ceramsite used sand to recover and regenerate the higher-quality regenerated ceramsite sand and has a high regeneration rate. The regenerated ceramsite sand and the products of the ceramsite used sand are obtained through recycle and regeneration by using the regeneration method of the ceramsite used sand.

Owner:南阳仁创砂业科技有限公司

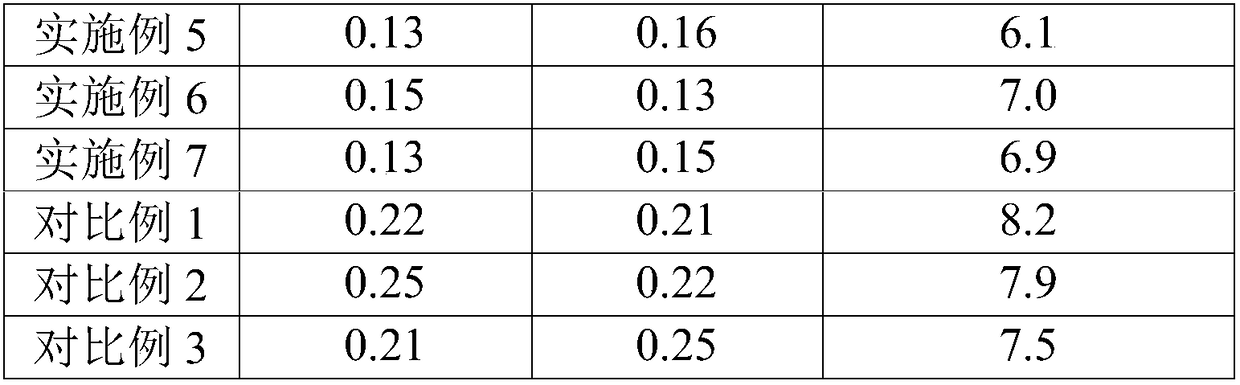

Method for simultaneously removing insoluble organic matter, total cyanogen and total nitrogen in wastewater of industrial park

InactiveCN107010782ASimple processSmall footprintWater treatment parameter controlTreatment using aerobic processesCyanideCatalytic oxidation

The invention relates to a method for simultaneously removing insoluble organic matter, total cyanogen and total nitrogen in wastewater of an industrial park. The method comprises the following steps: wastewater enters a high-efficiency coagulated decyanation reactor to remove total cyanogen in the wastewater removed from the coagulated decyanation reaction; effluent from the coagulating reaction enters an aeration biofilter, ammonia and nitrogen in the wastewater is oxidized into nitrate nitrogen or nitrite nitrogen, and partial organic matters are oxidized and removed; effluent from the aeration biofilter flows into a denitrification filter tank, and nitrate nitrogen and nitrite nitrogen in the wastewater are denitrified into nitrogen and removed; effluent from the denitrification filter tank is filtered in a V-shaped filter tank and then enters an ozone catalytic oxidation tank, and insoluble organic matters are oxidized into small-molecular organic matters or mineralized in the presence of a catalyst. The method can be used for oxidizing and degrading organic matters while removing total cyanogen and total nitrogen in the wastewater to ensure that treated effluent can be emitted in standard, thus having an excellent market prospect.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL TECH RES INST CO LTD

Cleaning and impurity removing device for recycling construction waste

InactiveCN105598068AAchieve separationEasy to separateCleaning using liquidsWet separationHigh pressureImpurity

The invention relates to a cleaning and impurity removing device for recycling construction waste. The lower end of a belt conveyor is arranged in a water tank; an aggregate dewatering sieve is arranged below a higher end of the belt conveyor; a retaining hopper and a nozzle group are arranged above the lower end of the belt conveyor; a sundry collecting device is fixed to one side of the water tank; a light substance dewatering sieve is arranged below the outlet of the sundry collecting device; the high-pressure nozzle group is aligned with materials on the belt conveyor. The cleaning and impurity removing device is safe and environmentally friendly, and can be used for forcibly cleaning aggregate and efficiently separating light substances.

Owner:郝志付

Foundation pile hole drilling construction process

InactiveCN104141300AEasy to moveIncrease drilling speedExcavationsBulkheads/pilesEngineeringFoundation engineering

The invention discloses a foundation pile hole drilling construction process, which comprises the following technical flow processes of construction preparation, field flattening, pile position lofting, protection tube burying, drilling machine place taking, drilling, hole cleaning, hole forming quality checking, steel bar cage and catheter mounting, catheter mounting, secondary hole cleaning, underwater concrete filling, protection tube pulling and removing and pile forming quality checking. The foundation pile hole drilling construction process has the advantages that the construction time of the foundation engineering is shortened, the construction period pressure of a lower part structure is reduced, and in addition, a part of labor, machine and material investment is reduced, so the total construction cost of the project is reduced.

Owner:LUOYANG GUANGXIN CONSTR GRP

Anti-cracking mortar powder for thin plastering and leveling of inner walls and preparation method of anti-cracking mortar powder

The invention relates to anti-cracking mortar powder for thin plastering and leveling of inner walls and a preparation method of the anti-cracking mortar powder. The anti-cracking mortar powder for thin plastering and leveling of inner walls is prepared from the following raw materials: in parts by weight, 17-25 parts of a cementing material, 0-10 parts of active filler, 0-5 parts of inert filler,70-75 parts of aggregate, 0.1-0.2 part of a water-retaining thickener, 0-0.8 part of an adhesive, 0-0.5 part of a binder, 0.2-0.3 part of a water-conducting thickener, 0.05-0.15 part of crack-resistant fiber, 0-0.5 part of a slipping agent and 0-0.1 part of a thixotropic agent. The mortar powder has good water resistance, high strength, no easy cracking, no indoor environmental pollution and goodworkability.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP +1

Air blowing and mud collecting type air floatation tank

ActiveCN107032431ARapid responseIncrease profitEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationMotor driveContact zone

The invention discloses an air blowing and mud collecting type air floatation tank. The air blowing and mud collecting type air floatation tank comprises a reaction tank and a contact separation tank, wherein the reaction tank comprises an agent guiding device, the agent guiding device comprises a main vertically arranged pipe, multiple groups of branch pipes fixed to the outer side wall of the main pipe at intervals from top to bottom and a first motor driving the main pipe to rotate, the lengths of the multiple groups of branch pipes are decrease sequentially and progressively from top to bottom, and multiple agent outlet holes are uniformly formed in the multiple groups of branch pipes and the main pipe. The contact separation tank is located at the downstream of the reaction tank, the lower side of the contact separation tank is communicated with the reaction tank, a partition plate is vertically arranged in the contact separation tank and divides the contact separation tank into an upstream contact zone and a downstream separation zone, and the separation zone comprises a residue removal component, a swing component, an air blowing and mud collecting component and a water outlet component. The air blowing and mud collecting type air floatation tank has the advantages of accelerating coagulant and raw water reaction, improving the coagulant utilization rate, removing floating residues at the dead corner position of a residue guiding plate and at the position below the separation zone in time, collecting the floating residues decomposed into sinking mud in a centralized mode, greatly decreasing the mud content of clear water and ensuring the quality of outlet clear water.

Owner:新疆中泰创新技术研究院有限责任公司

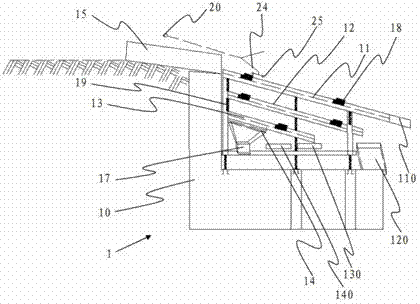

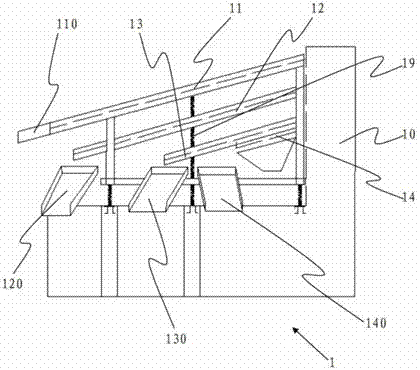

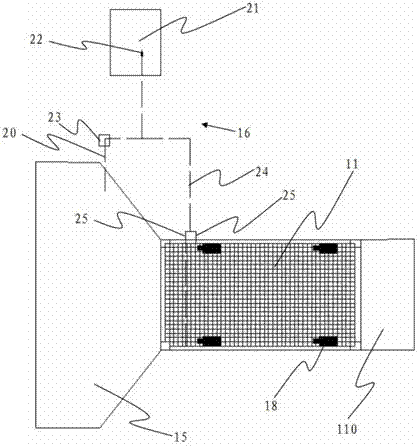

Production method of recycled aggregate of engineering waste soil

ActiveCN109824290AReduce mud contentNo emissionsSolid waste managementAutomatic controlEnvironmental effect

The invention relates to the technical field of recycling of engineering waste soil, in particular to a production method of recycled aggregate of engineering waste soil. The method is based on dry operation and zero water consumption, and the water content of the engineering waste soil can meet the demand of process water after the engineering waste soil is separated; large-scale equipment such as a sand washer and a sedimentation tank are not needed, the process flow is based on automated control, the occupied area is small, and the influence on the surrounding environment is small; no slurry is discharged; the efficiency of separating mud is high, the mud content of the separated engineering waste soil is lower than 3%, and muddy powder does not contain aggregate granules, and the comprehensive treatment cost is low.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

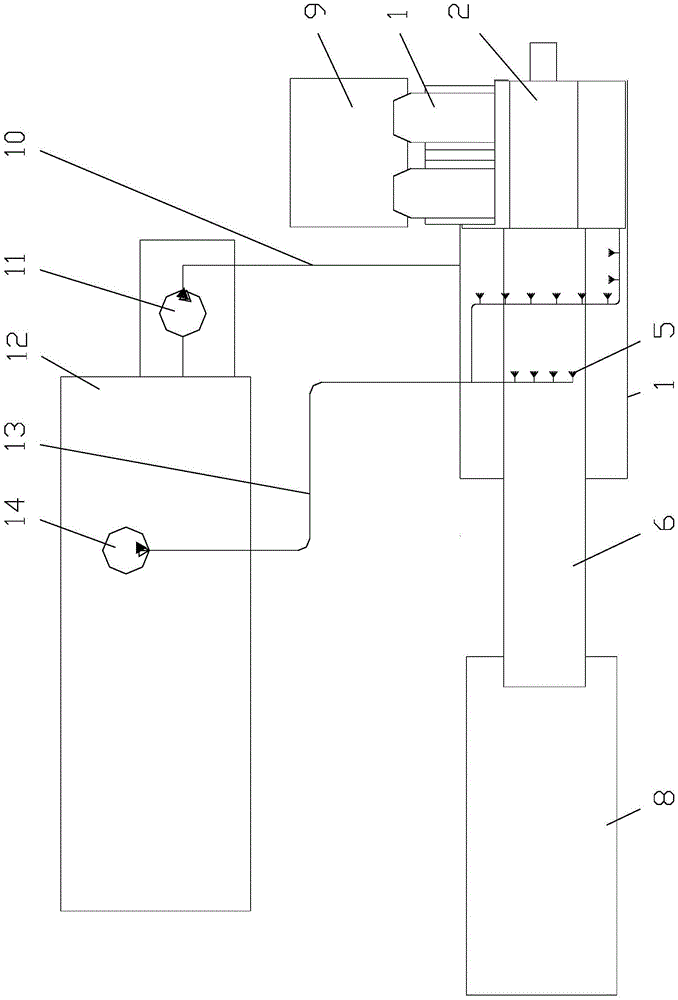

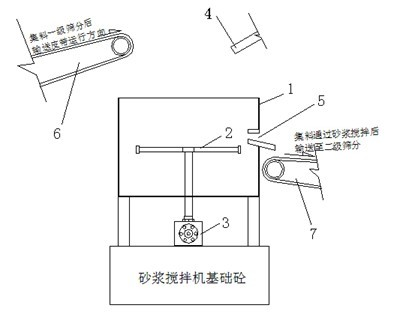

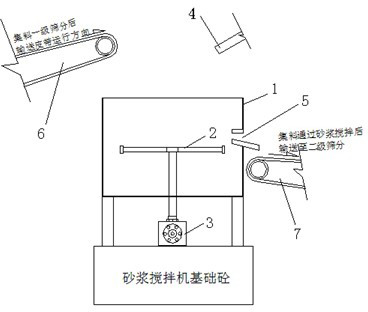

Method and device for cleaning sand gravel

The invention discloses a method and a device for cleaning sand gravel. The method for cleaning the sand gravel comprises the following steps of: allowing fine aggregate which is fed by primary sieving conveying equipment (6) to fall into a mortar mixer (1), injecting clean water from a water filling nozzle (4), rotating a stirring arm (2) under the drive of a drive motor (3) to stir and extrude the fine aggregate in water, and fully wetting and dissolving soil adhered to the sand gravel in water; and extruding from a discharge hole (5) when the fine aggregate is stacked to the height of the discharge hole (5), and allowing the fine aggregate to fall onto secondary sieving conveying equipment, and sieving and washing. In the device for cleaning the sand gravel, the primary sieving conveying equipment (6) is arranged above the left side of the mortar mixer (1), the water filling nozzle (4) is formed above the right side of the mortar mixer (1), the discharge hole (5) is formed on the right side of a machine body of the mortar mixer (1) and above the stirring arm (2), and the secondary sieving conveying equipment (7) is arranged below the discharge hole (5).

Owner:CHINA RAILWAY NO 5 ENG GRP +1

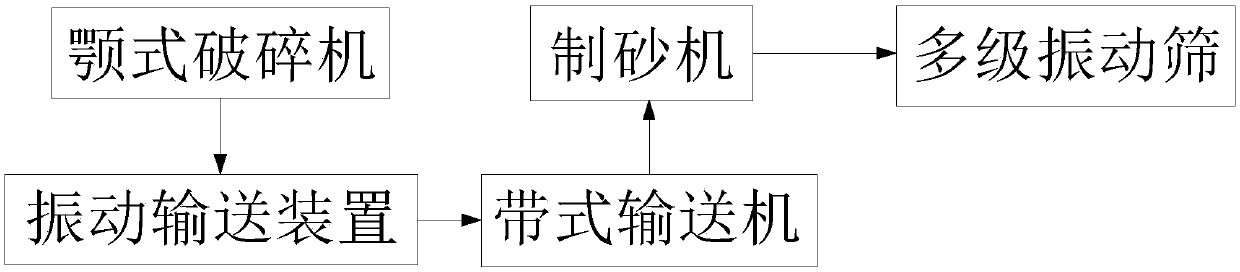

Dry-method sand making production line and method

The invention discloses a dry-method sand making production line and method. The dry-method sand making production line comprises a jaw crusher, a vibration conveying device, a sand making machine anda multi-stage vibrating screen, wherein a discharge port of the jaw crusher is connected to a feeding hopper of the vibration conveying device; a belt conveyor is used for feeding wet broken stones into the sand making machine; the sand making machine is used for finely crushing the broken stones; a discharge port of the sand making machine is located above the multi-stage vibrating screen; and the finely crushed broken stones are graded by the multi-stage vibrating screen. A special vibration conveying device, that is, the vibration conveying device is designed for the dry-method sand makingproduction line and can adjust the pose of the broken stones on the one hand, and sprays water onto the broken stones on the other hand, thereby reducing the mud content of the material entering thesand making machine, increasing the humidity of the material entering the sand making machine, greatly reducing dust generated by the sand making machine when the broken stones are crushed in the sandmaking machine, and improving the quality of machine-made sand.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

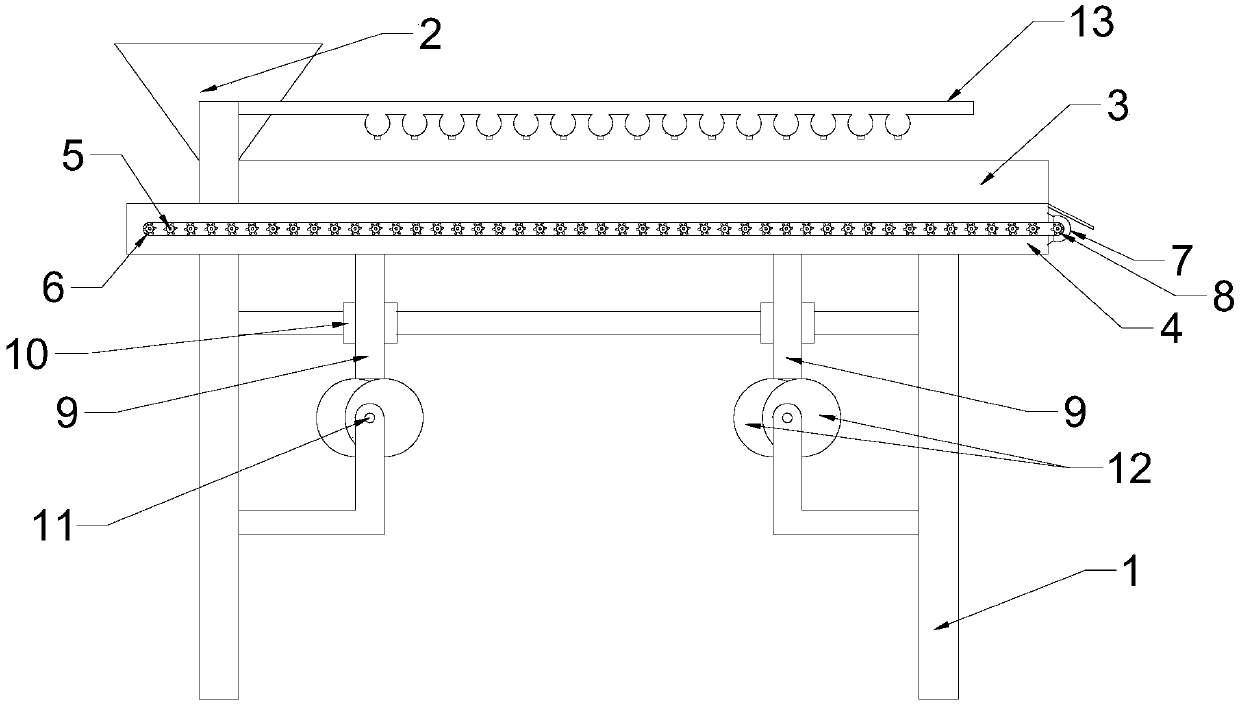

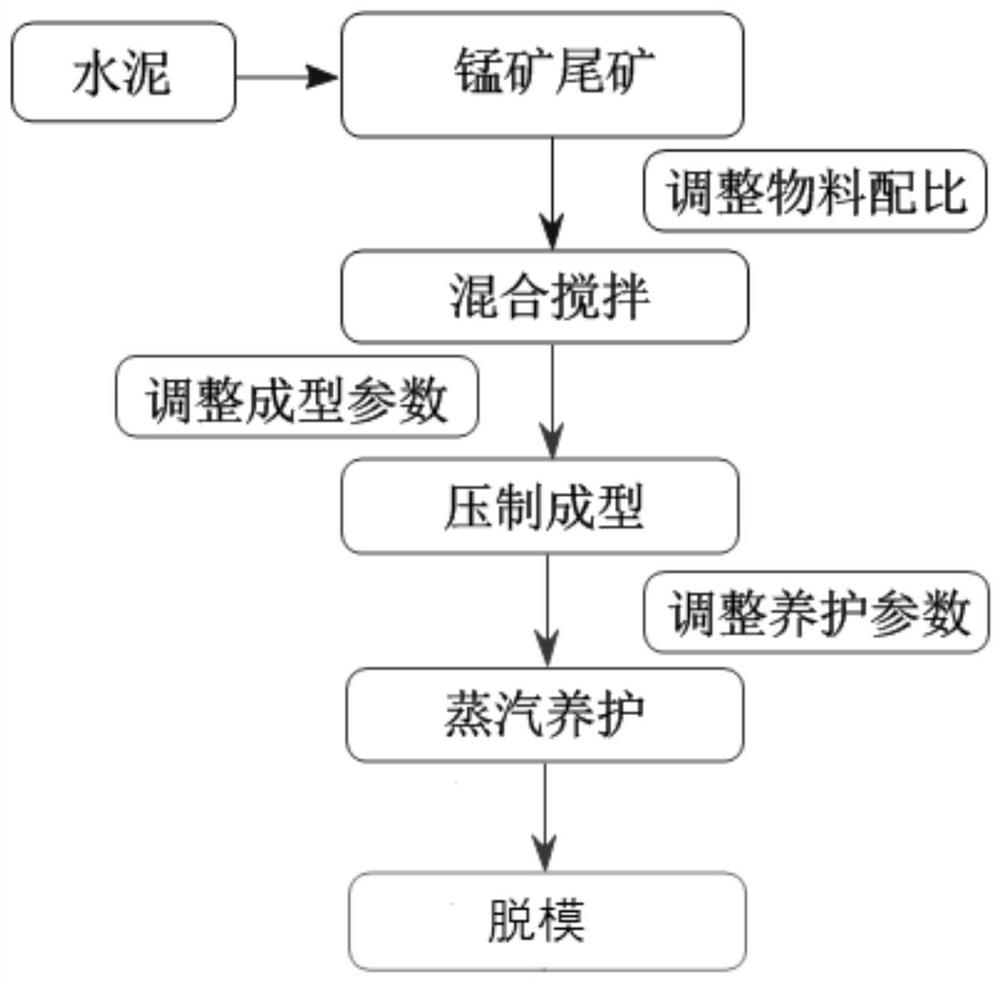

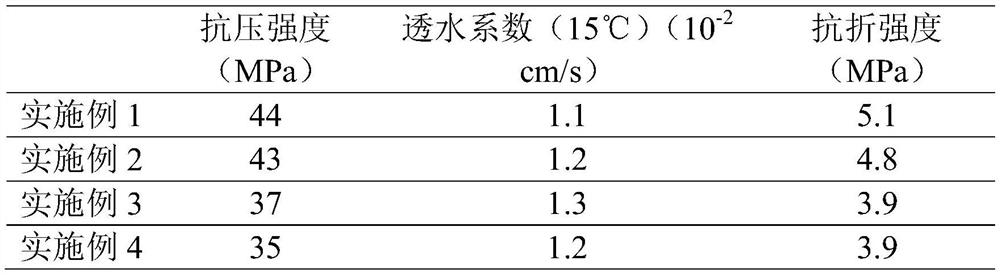

Manganese tailing water permeable brick and preparation method thereof

InactiveCN111635174AMeet the needs of constructionHigh content of manganese tailingsSolid waste managementCeramicwareCompression moldingBrick

The invention discloses a manganese tailing water permeable brick and a preparation method thereof. The manganese tailing water permeable brick comprises a base layer and a facing layer, and a base layer blank comprises the following raw materials in parts by mass: 40-60 parts of manganese tailings, 10-15 parts of cement, 15-20 parts of water and 0.135-0.38 part of a pore forming agent; the facinglayer blank is prepared from the following raw materials in parts by mass: 35 to 50 parts of manganese tailings, 10 to 15 parts of cement, 15 to 20 parts of water and 0.12 to 0.34 part of pore forming agent. The components such as SiO2 and Al2O3 in the tailings have potential gelling activity; under the action of cement, the gelling property can be exerted and the basic conditions for making bricks can be met; manganese ore is used as a main raw material, a small amount of cement is used as a cementing material, a pore-forming agent is added for uniform mixing and stirring, the water permeable brick is prepared through compression molding and maintenance, the raw materials are easy to obtain, the preparation process is simple, a high-temperature sintering process is avoided, energy consumption is greatly reduced, meanwhile, the raw material cost is reduced, and industrialization is facilitated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com