Patents

Literature

75results about How to "Fully moist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

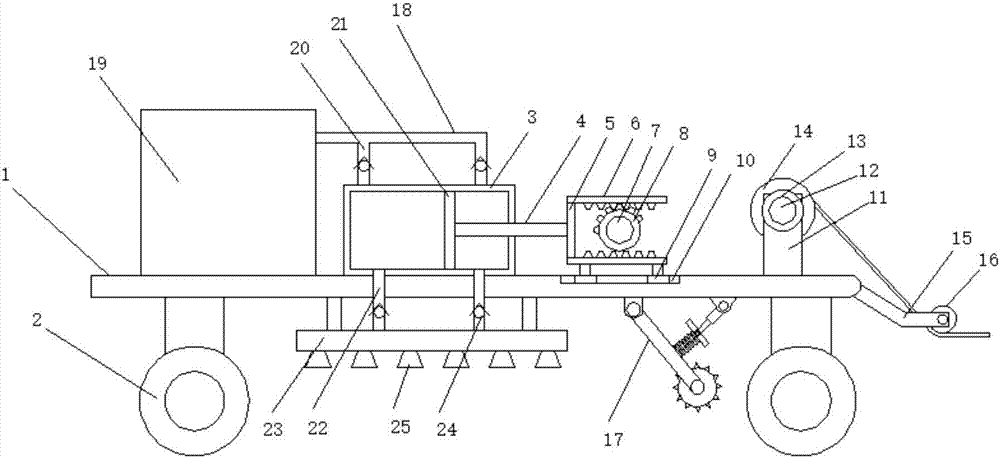

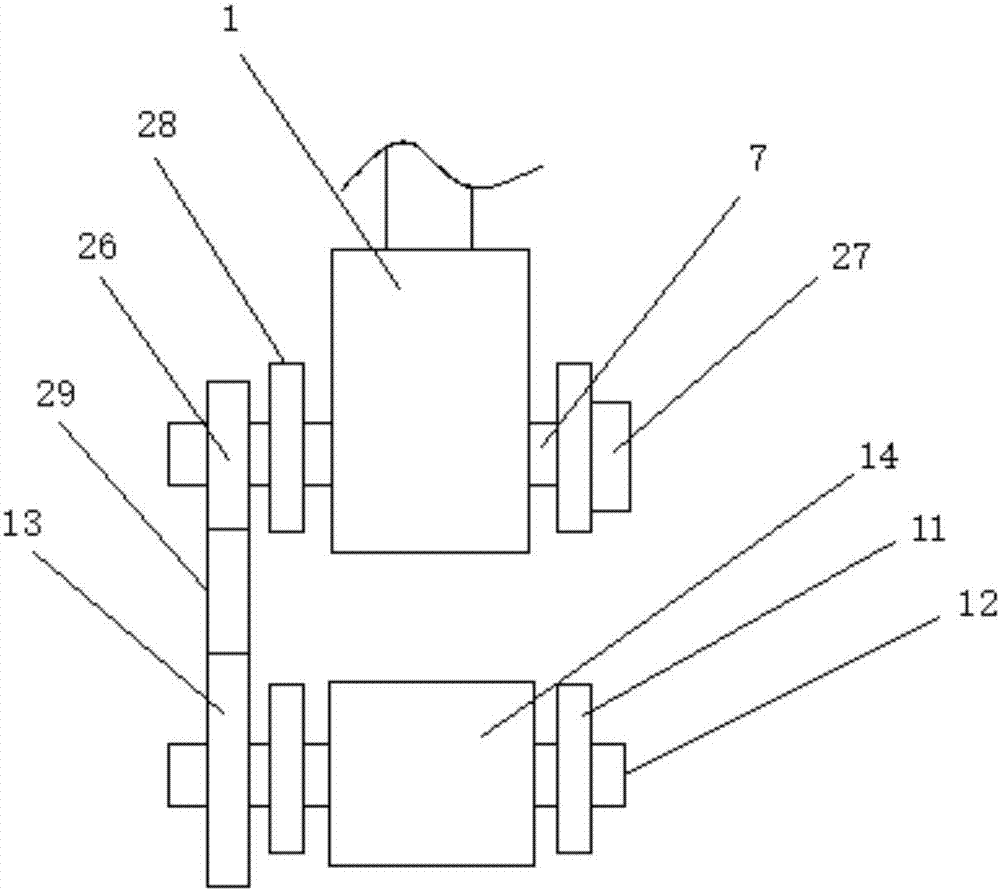

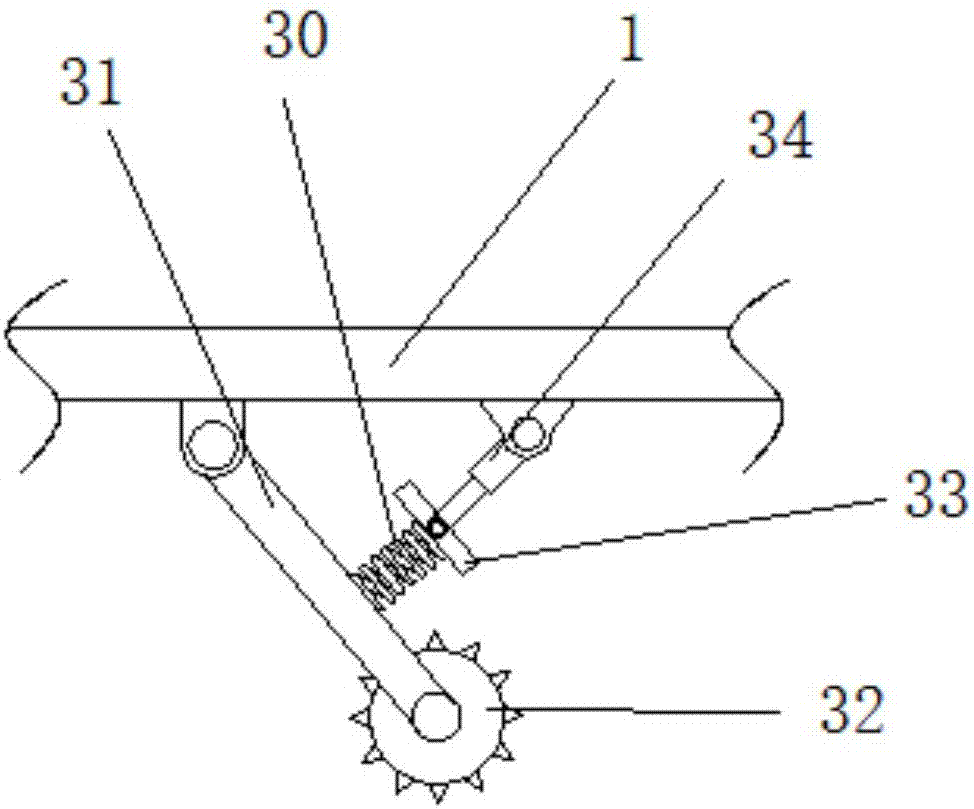

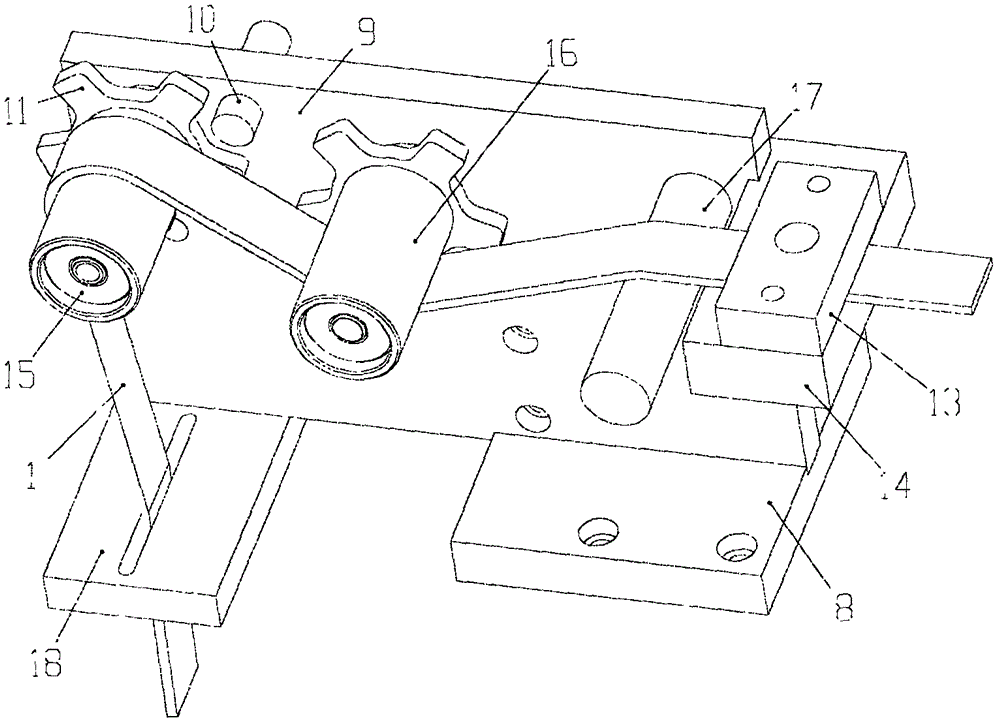

Agricultural thin-film laminating device on which water can be sprayed

InactiveCN107251821AImprove adhesionSimple structureWatering devicesCultivating equipmentsDrive motorTransverse axis

The invention discloses an agricultural thin-film laminating device on which water can be sprayed. The agricultural thin-film laminating device comprises a transverse plate, a film rolling wheel with thin film is installed on a rotary shaft, a guide roller is installed on a mounting frame, a piston is arranged inside a cylinder, a piston rod of which one end protrudes out of the cylinder is arranged at the right end face of the piston, a second support is provided with a transverse shaft, the transverse shaft is provided with a semicircular tooth gear, the semicircular tooth gear is located between two rackrs, one end of the transverse shaft is connected with a driving motor arranged on the second support, the other end of the transverse shaft is connected with one end of a conveying shaft through a conveying mechanism, the bottom ends of two water outlet pipes are connected with a spray pipe installed at the bottom of the transverse plate, the spray pipe is provided with multiple nozzles, and the water inlet branch pipes and the water outlet pipes are all provided with one-way valves; a crushing mechanism is further arranged at the lower end face of the transverse plate. The agricultural thin-film laminating device on which water can be sprayed is simple in structure, high in laminating efficiency, easy to operate and high in practicability, and can crush soil and effectively lower manual labor.

Owner:贵港市鼎金电子产品有限公司

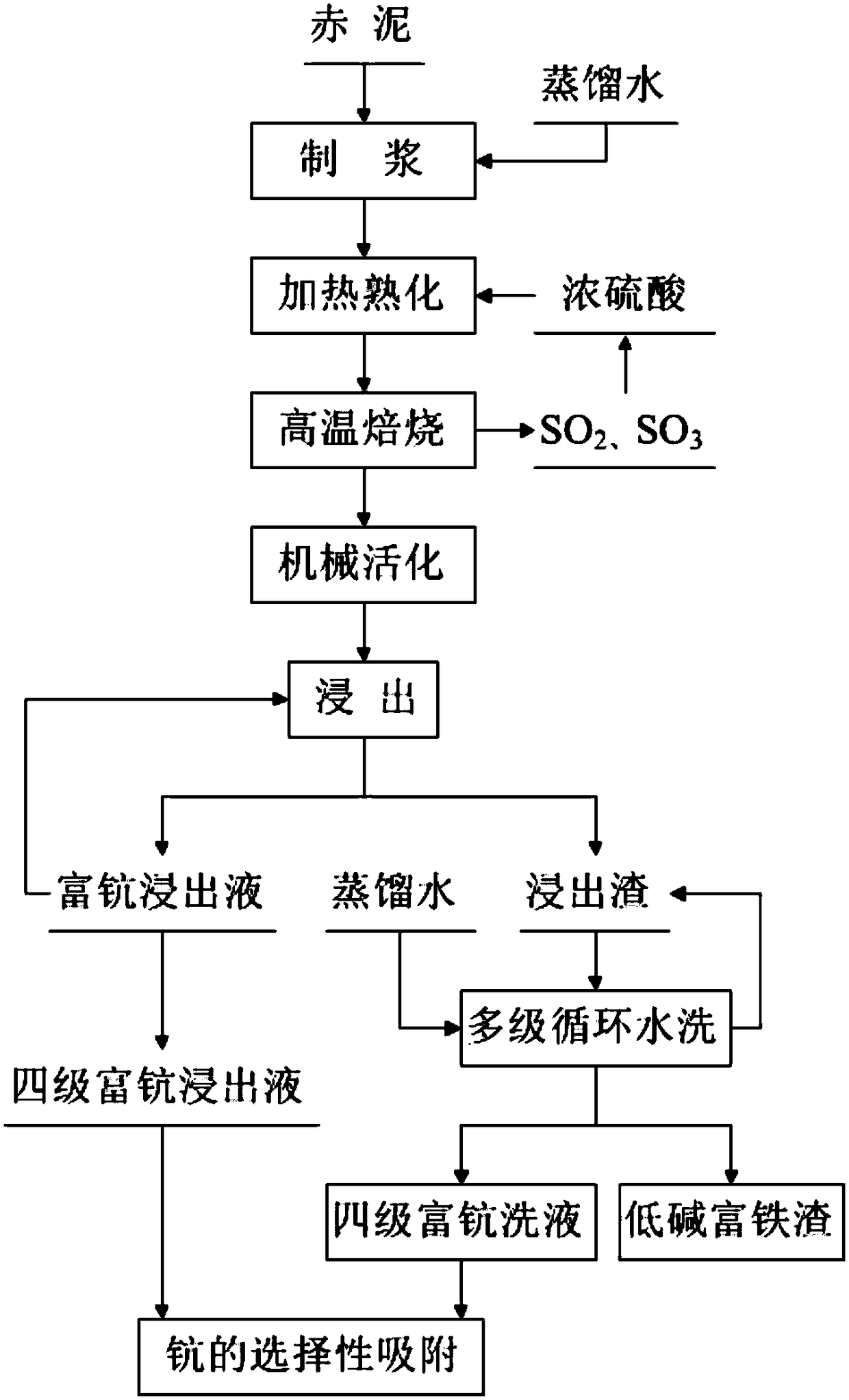

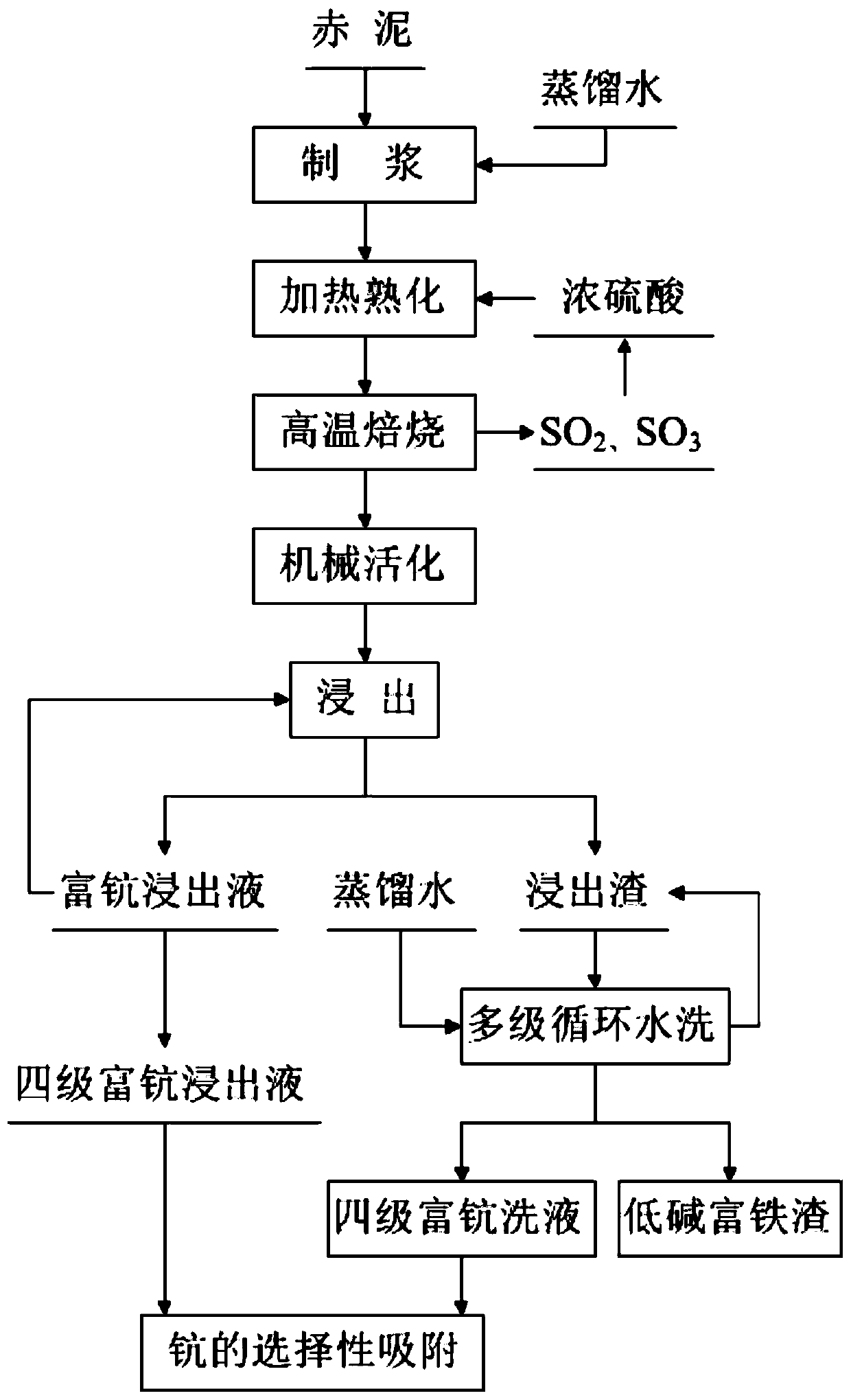

Method for selectively enriching scandium from Bayer process red mud

The invention discloses a method for selectively enriching scandium from Bayer process red mud. The method is characterized in that the Bayer process red mud is used as a raw material, the red mud isfully wet by adding an appropriate amount of water, the red mud is sulphated by using concentrated sulfuric acid and is then calcined at a high temperature, the solid calcined product is mechanicallyactivated by grinding and is then subjected to four-stage water immersion and washing, so that a scandium-rich leaching solution, scandium-rich washing liquid and low-alkali iron-rich slag are obtained. The method enables most of scandium to be leached, but the leaching rates of impurity iron and aluminum are low, and silicon and titanium are not leached substantially, so that the formation of colloidal silicate in the leaching solution is avoided, and the selective absorption and extraction of the scandium in the subsequent leaching solution are facilitated; the generated sulfur dioxide and sulfur trioxide can be reused in the preparation of sulfuric acid, so that the production of a large amount of waste acid is avoided; the pH of the low-alkali iron-rich slag is close to neutral, and can be used in the industries such as iron making, adsorbents, ceramics, construction and the like, so that a new way is provided for the extraction of the scandium and the comprehensive utilization ofthe red mud.

Owner:GUANGXI UNIV

Pinellia ternate cultivation method by means of small greenhouse covering, deep seeding and condensed planting

InactiveCN104137720AExpand artificial planting areaEffective growth periodHorticultureMedicinal herbsPinellia

The invention discloses a pinellia ternate cultivation method by means of small greenhouse covering, deep seeding and condensed planting. The pinellia ternate cultivation method includes: seed stem section and seed stem storage; land selection and land preparation; seed stem treatment; plantation including determination of planting amount and planting time, bed preparation, watering, fertilization, plantation, mulching film covering and small greenhouse covering; land management. The pinellia ternate cultivation method by means of small greenhouse covering, deep seeding and condensed planting has the advantages that acre yield, output-input ratio and drying ratio of pinellia ternate can be increased substantially, the area for artificial cultivation is enlarged, planting risks are alleviated, planting benefit of farmers is guaranteed, rural income is increased, more medicinal herbs resources are provided for the market, reliance on picking and digging of wild resources is lowered, the wide resources of the pinellia ternate can be protected and rehabilitated effectively, population of the pinellia ternate can be enlarged, and social benefits and ecological benefits are remarkable.

Owner:陈垣

Plating auxiliary for hot dip aluminum plating and hot dip aluminum plating process for steel structural part

InactiveCN107365954APrevent oxidationQuick breakdownHot-dipping/immersion processesSurface engineeringAlloy

The invention discloses a plating auxiliary for hot dip aluminum plating and a hot dip aluminum plating process for a steel structural part and belongs to the technical field of metal corrosion prevention surface engineering. The plating auxiliary is characterized by being composed of the following components, by weight, of 1.5%-3% of NaCl, 3.8%-5.2% of KF, 1.8%-2.5% of ZnCl2 and the balance water. The plating auxiliary and the hot dip aluminum plating process are adopted for steel part surface aluminum plating, the plating is smooth and bright, generation of plating leakage and convex points is avoided on the surface of the plating, the thickness of the plating is more than 140 [mu]m, and the thicknesses of the plating and an alloy layer are even. After steel part assisted plating, the plating auxiliary forms a uniform covering layer, iron salt and oxides remaining on the workpiece surface can be removed, a workpiece can be prevented from being oxidized before dipping in a melting alloy, and the workpiece can be quickly decomposed or melted when meeting the melting alloy again, it is guaranteed that the molten metal fully wets the workpiece, and strong corrosion inhibition and plating assisting effects are achieved.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

Cleaning device for inner tubes of solar vacuum tubes

InactiveCN104438240AFully moistEasy to applySolar heating energySolar heat devicesMoistureWater saving

The invention relates to a cleaning device for inner tubes of solar vacuum tubes. The cleaning device comprises a cleaning tank, a partition plate is arranged in the cleaning tank and partitions the cleaning tank into a cleaning cavity and a drying cavity, a cleaning drum is transversely arranged in the middle of the cleaning cavity, two ends of the cleaning drum penetrates out of the left side wall of the cleaning cavity and the partition plate respectively, a wiping through hole is longitudinally formed in the center of a drying block which is arranged in the middle of the drying cavity, and the right side wall of the drying cavity is provided with an inner pipe outlet. At least one water nozzle is arranged at the edge of the upper opening of the cleaning tank and aligned to the cleaning drum, and the bottom of the cleaning tank is provided with at least one drainage outlet. The cleaning device for the inner tubes of the solar vacuum tubes is simple in structure and high in cleanliness, water can be saved while complete moisture of flexible cleaning strips is guaranteed by adopting the nozzles for spraying; owing to drying blocks, a drying function can be realized during cleaning.

Owner:重庆鸿沥金属材料有限公司

Sweet potato vermicelli processing method and processing unit thereof

The invention discloses a sweet potato vermicelli processing method and a processing unit thereof, relating to a sweet potato deep-processing technology in the technical field of processing of agricultural products. The sweet potato vermicelli processing method disclosed by the invention comprises the following steps: 1, preparing raw materials; 2, pasting, namely (1), pasting acidic sweet potato starch; and (2), pasting alkali sweet potato starch; 3, stirring slurry, namely (1), stirring slurry of acidic sweet potato starch; and (2), stirring slurry of alkali sweet potato starch; 4, mixing slurry; 5, pumping slurry in vacuum; 6, curing preliminarily; 7, rapidly cooling and aging; 8, curing; 9, humidifying and aging; 10, blowing for aging; 11, drying; and 12, packaging. Sweet potato vermicelli prepared by the processing method disclosed by the invention is good in mouth feel, soft and flexible during eating; the production process is environment-friendly; furthermore, the sweet potato vermicelli is free from any food additive; and the sweet potato vermicelli processing method disclosed by the invention is not only capable of processing sweet potato vermicelli by using sweet potato starch as the raw material but also capable of processing vermicelli by using rice or other grains, such as millet, red rice, black rice, sorghum, oat, wheat germ, soybean, mung bean, red bean, petits pois, black soya bean, purple sweet potato, Chinese yam and potato, as the raw materials.

Owner:湖南吉祥食品有限公司

Water-oil universal color paste and preparation method thereof

The invention relates to the field of coatings and provides a water-oil universal color paste prepared by a reasonable dispersant system. A hydrophilic nonionic surfactant is used as a first dispersant, and a second dispersing agent synergistically interacting with the first dispersing agent is adopted, so that a pigment can be sufficiently dispersed in a water-oil system. At the same time, wateris adopted as a main solvent, and the paste is environmentally friendly and free of toxicity. The color paste production cost is reduced. A preparation method of the water-oil universal color paste isfurther provided. The process is simple and feasible and easy to popularize.

Owner:MINGHAI CHEM ENTERPRISE

Chinese medicinal preparation for treating cold stuffy nasal obstruction

InactiveCN102949700AFully moistRelieve painRespiratory disorderPlant ingredientsIllicium verumEphedra herb

The invention discloses a Chinese medicinal preparation for treating cold stuffy nasal obstruction. The Chinese medicinal preparation is prepared from the following raw material medicaments in parts by weight: 3-15 parts of lonicera japonica, 3-15 parts of weeping forsythiae capsule, 5-10 parts of houttuynia cordata, 3-5 parts of ephedra herb, 2-6 parts of ginger, 8-12 parts of burdock, 5-15 parts of divaricate saposhnikovia root, 1-3 parts of Cherokee rose fruit, 1-3 parts of illicium verum, 3-8 parts of azalea, 10-40 parts of mung beans, and 2-4 parts of tuber onion seed. Through clinical application and observation, the Chinese medicinal preparation for treating the cold stuffy nasal obstruction has the advantages of quick response, good curative effective, complete cure and no toxic and side effects.

Owner:郑松林

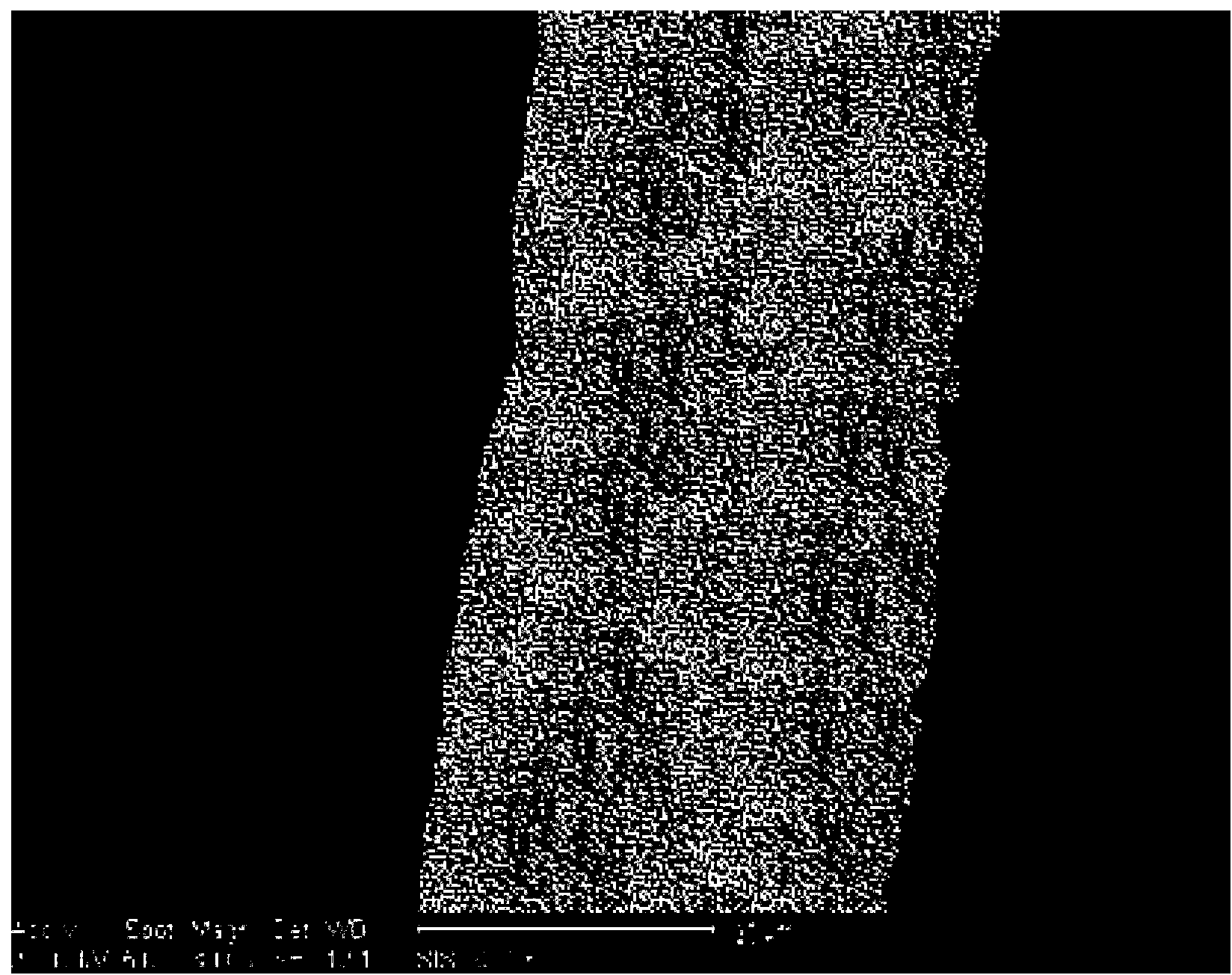

Preparation method of modified coating of carbon fiber surface

InactiveCN103061111AImprove surface roughnessHigh surface energyCatalyst carriersOther chemical processesFiberCarbon coating

The invention discloses a preparation method of a modified coating of a carbon fiber surface, relating to the field of preparation of carbon fiber. The invention aims at solving the problem of a weak interface between the carbon fiber and resin matrix in the existing carbon fiber composite material. The invention comprises the following operations of 1. prepolymerization of phenolic resin slurry; 2. coating of phenolic resin slurry; 3. curing of phenolic resin; and 4. carbonization of phenolic resin. The interlayer shearing strength of the full-carbon coating of the carbon fiber surface prepared by the preparation method is improved by 12-15%; the fiber absorption ability is obviously improved and the full-carbon coating is a good catalyst carrier. The carbon fiber full-carbon coating structure disclosed by the invention is controllable, and can provide different functions to the carbon fiber or can be applied to different varieties of resin matrix composite materials by adjusting the chemical ingredients and ingredient proportions of phenolic aldehyde. According to the preparation method disclosed by the invention, the simplicity, high efficiency and good effect are realized and industrial production is easy. The preparation method is applied to the fields such as aviation, spaceflight, military affairs, buildings and the like.

Owner:HARBIN INST OF TECH

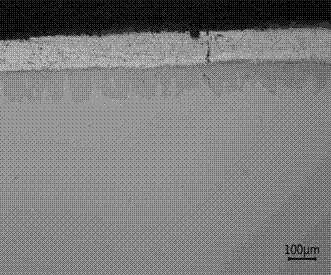

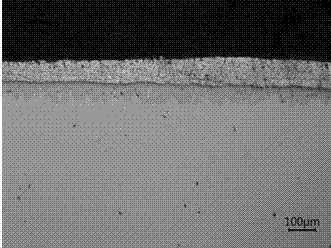

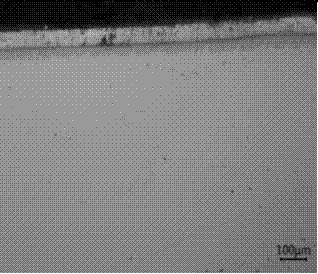

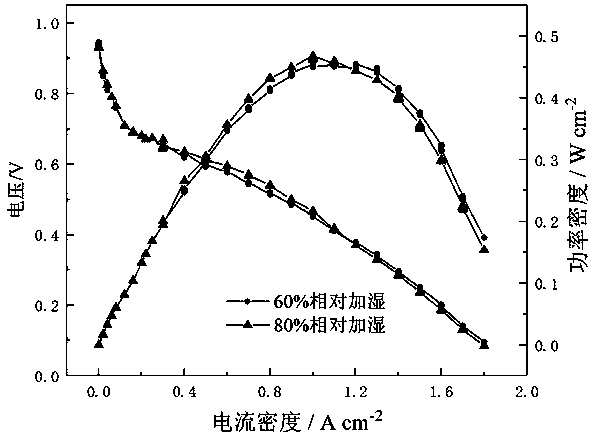

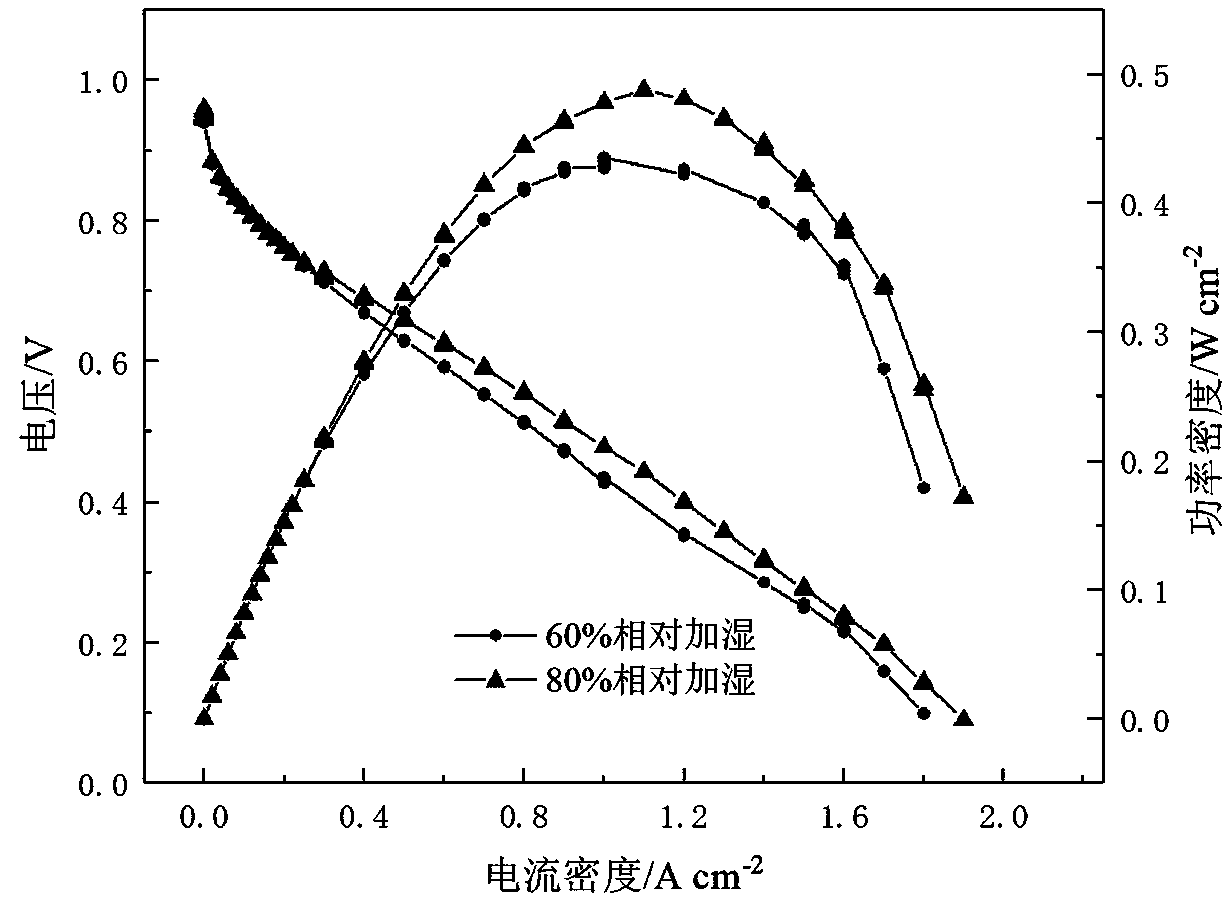

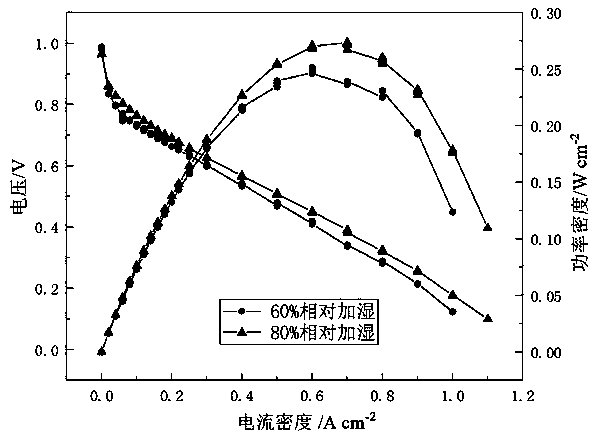

Preparation method of self-humidifying membrane electrode for fuel cell

The invention relates to a preparation method of a self-humidifying membrane electrode for a fuel cell. The preparation process of the membrane electrode comprises the following steps: pretreating a proton exchange membrane; preparing an anode hydrophilic catalytic layer; preparing a cathode catalyst layer; respectively laminating gas diffusion layers to prepare the self-humidifying membrane electrode; wherein the anode hydrophilic material chitin can play a good role in water retention, moisture generated by reaction in the cathode catalyst layer is absorbed and retained, the proton exchange membrane is fully wetted, and good proton conduction capability of the proton exchange membrane is kept; the self-humidifying membrane electrode can have excellent performance under a low-humidity condition, the influence of adding hydrophilic substances on the electrical conductivity and resistance of the electrode is reduced, and the preparation process of the membrane electrode is simplified.

Owner:江苏乾景新能源产业技术研究院有限公司

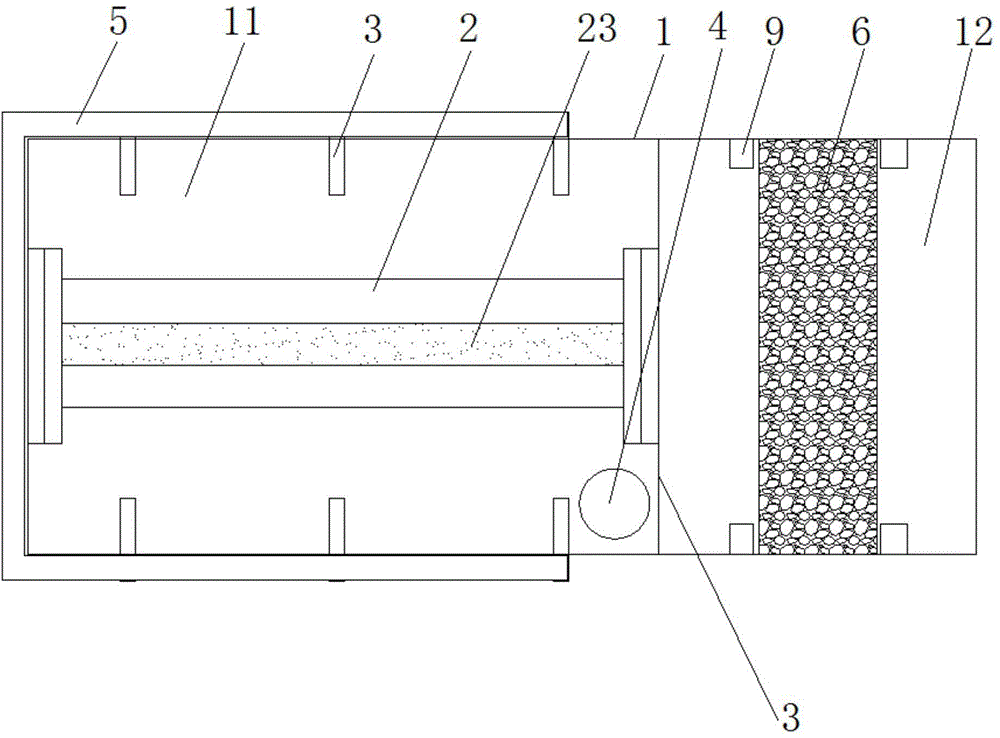

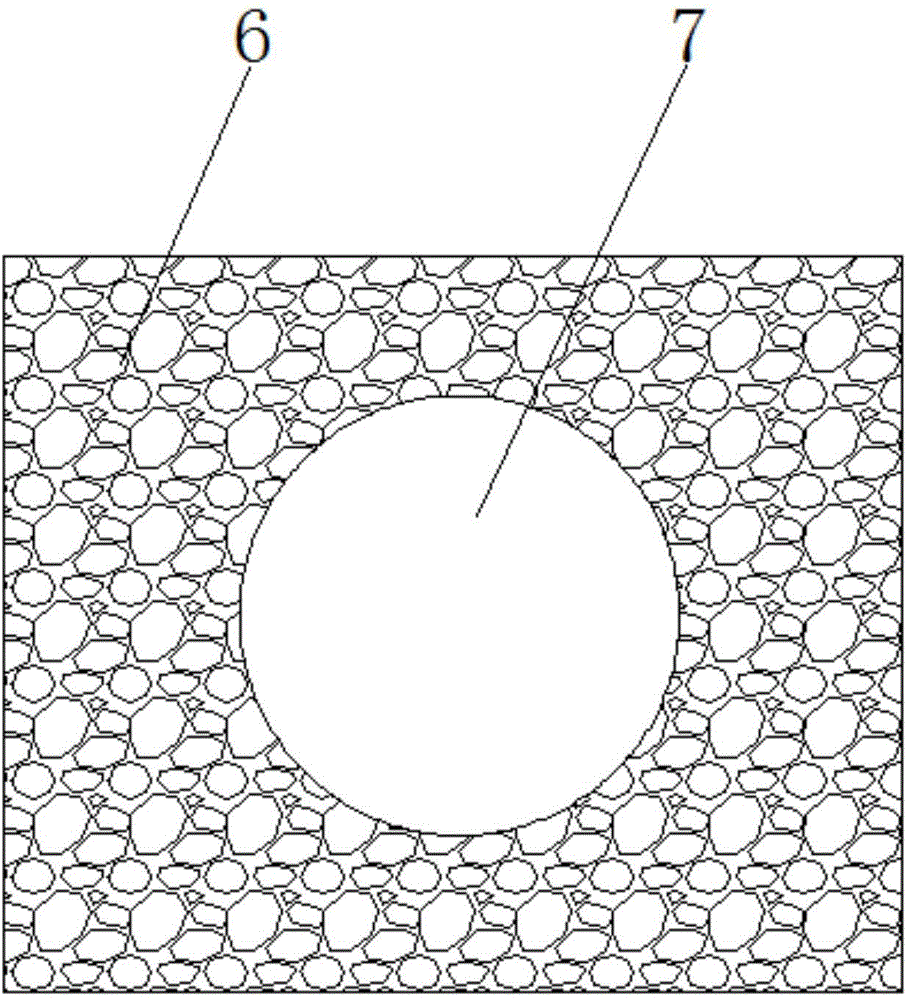

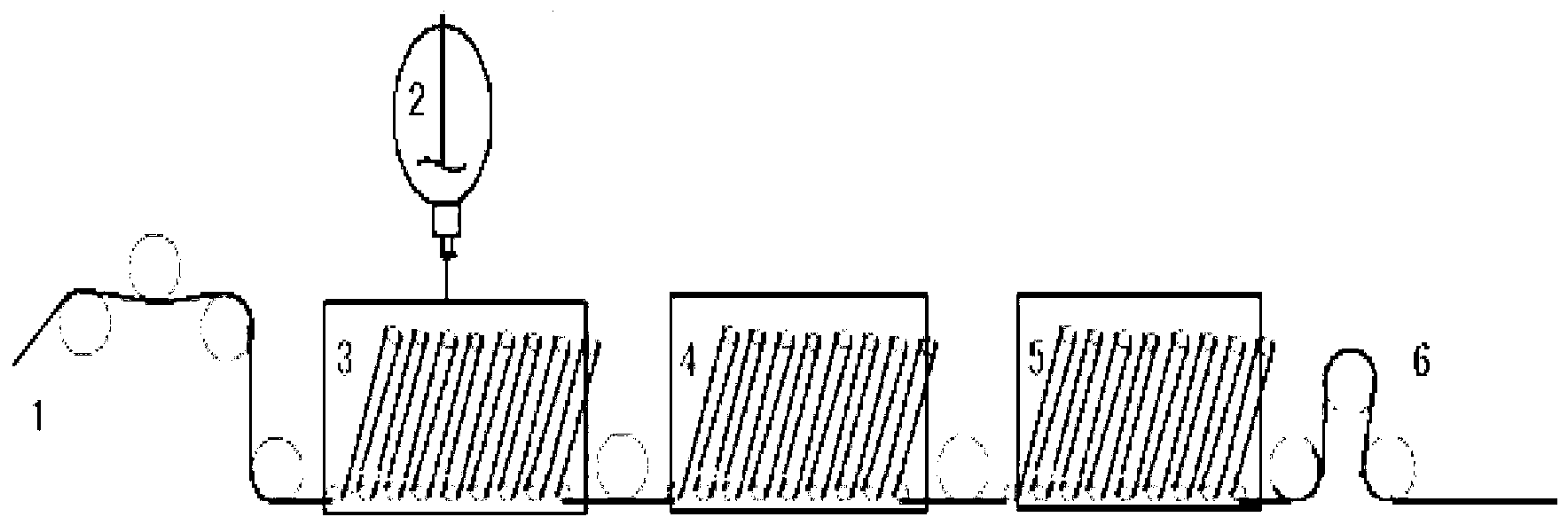

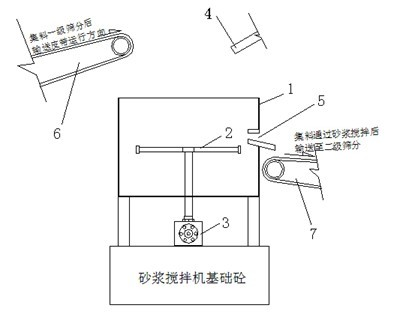

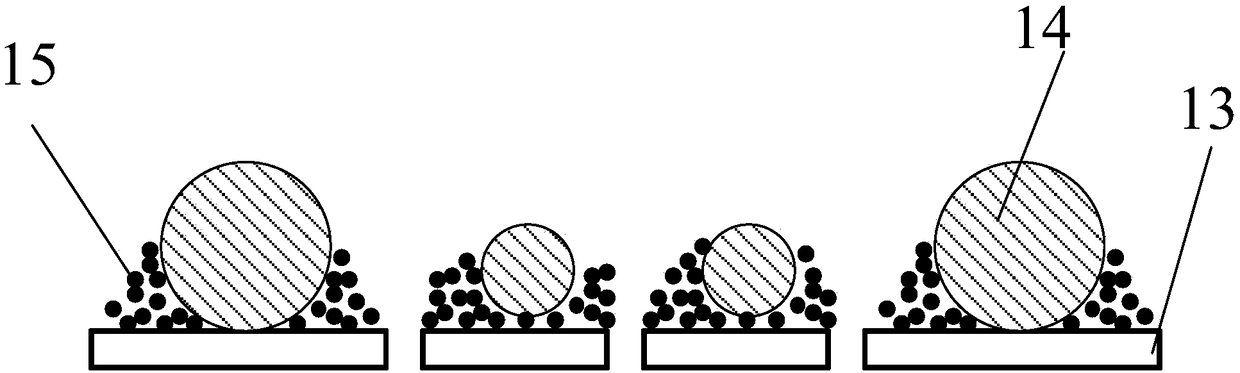

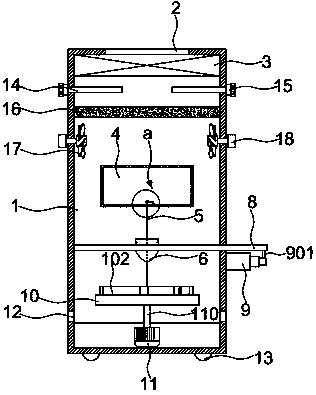

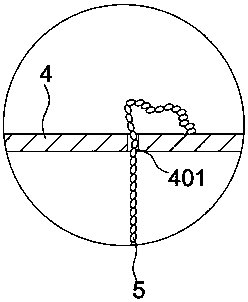

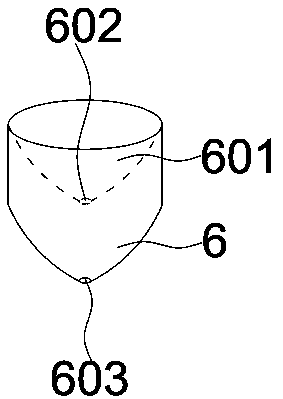

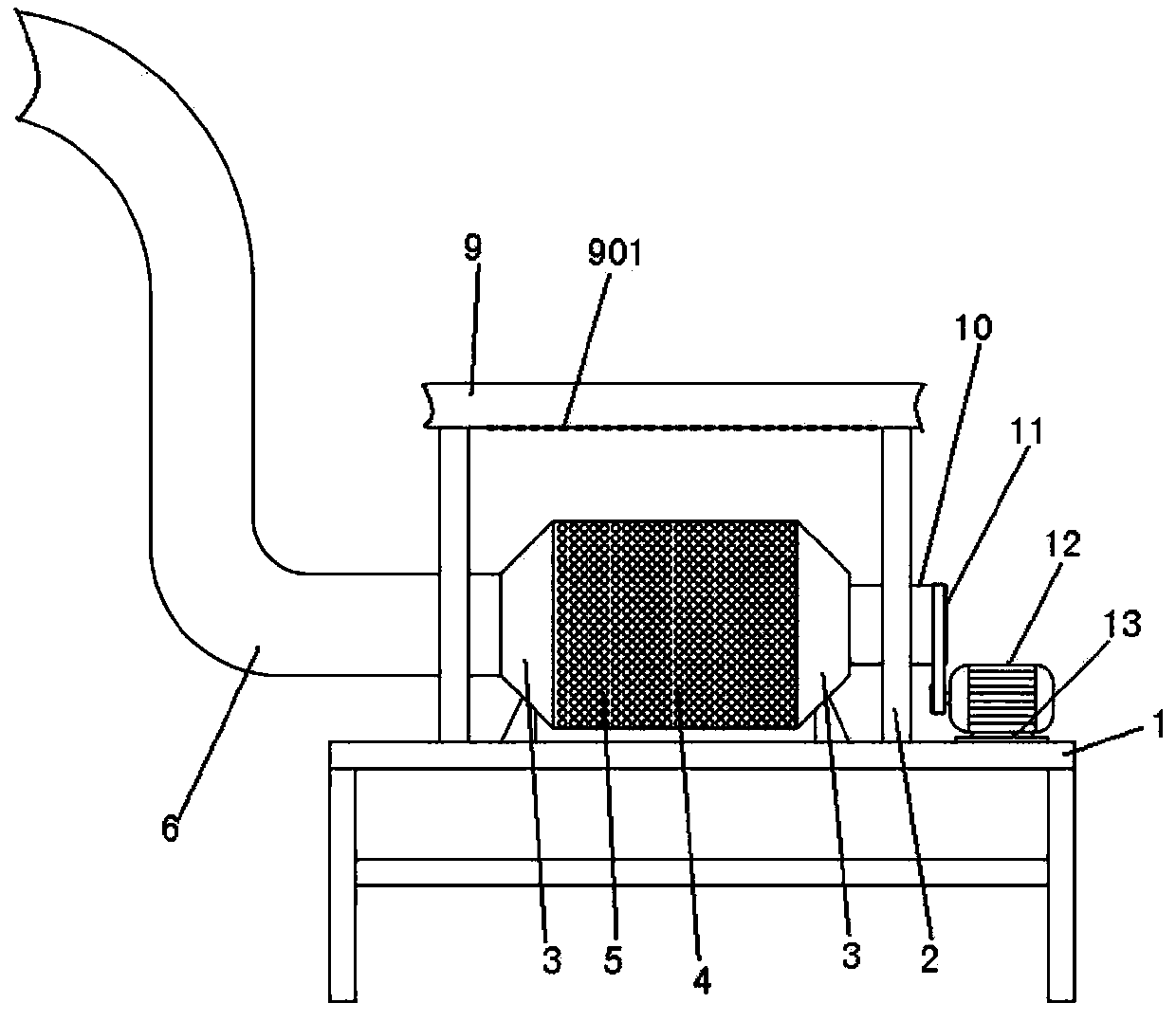

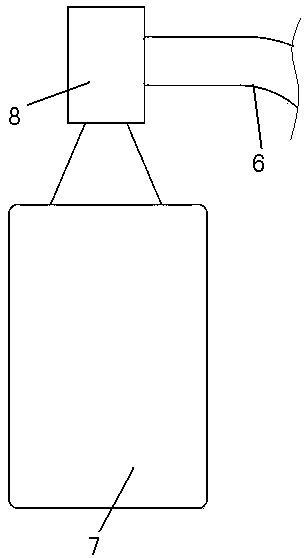

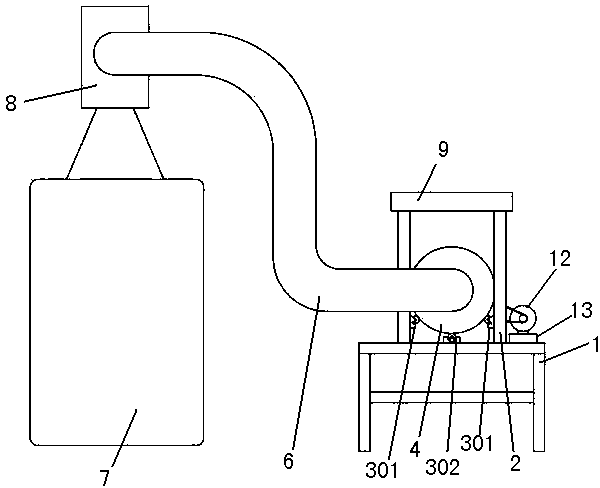

Method and device for cleaning sand gravel

The invention discloses a method and a device for cleaning sand gravel. The method for cleaning the sand gravel comprises the following steps of: allowing fine aggregate which is fed by primary sieving conveying equipment (6) to fall into a mortar mixer (1), injecting clean water from a water filling nozzle (4), rotating a stirring arm (2) under the drive of a drive motor (3) to stir and extrude the fine aggregate in water, and fully wetting and dissolving soil adhered to the sand gravel in water; and extruding from a discharge hole (5) when the fine aggregate is stacked to the height of the discharge hole (5), and allowing the fine aggregate to fall onto secondary sieving conveying equipment, and sieving and washing. In the device for cleaning the sand gravel, the primary sieving conveying equipment (6) is arranged above the left side of the mortar mixer (1), the water filling nozzle (4) is formed above the right side of the mortar mixer (1), the discharge hole (5) is formed on the right side of a machine body of the mortar mixer (1) and above the stirring arm (2), and the secondary sieving conveying equipment (7) is arranged below the discharge hole (5).

Owner:CHINA RAILWAY NO 5 ENG GRP +1

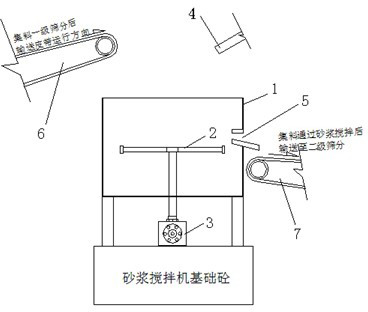

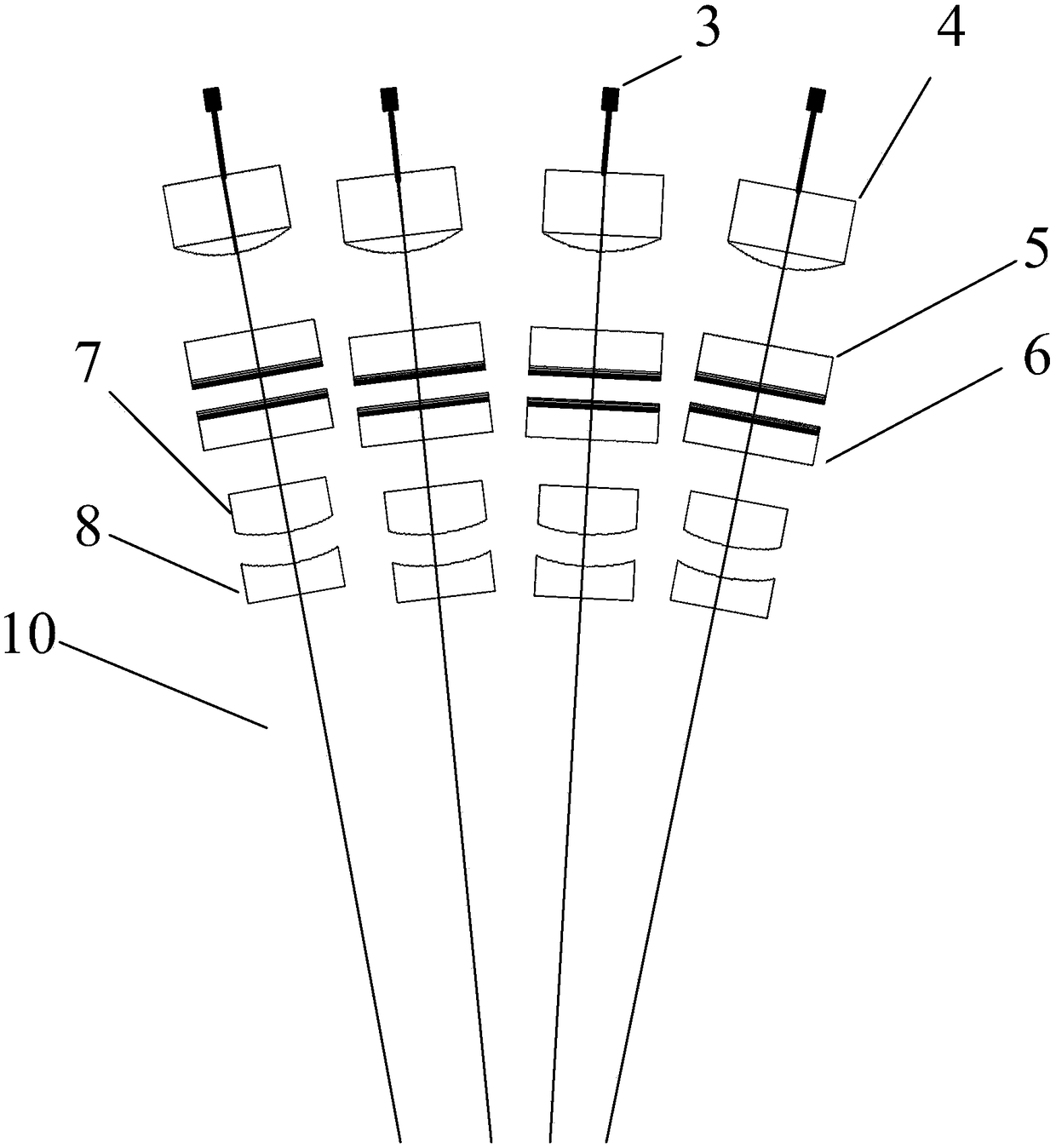

Laser output system and welding method for simultaneously welding multiple intensive points

ActiveCN108176922ASolve the compact layout problemImprove convenienceLaser beam welding apparatusLight beamLaser light

The invention relates to the technical field of laser welding, in particular to a laser output system and a welding method for simultaneously welding multiple intensive points. The laser output systemcomprises multiple light paths arranged in parallel, wherein each light path comprises a laser light source, a transmission fiber, a cylindrical mirror group and a wedge-shaped mirror; the multiple paralleled light paths form a convergence light path after passing through the wedge-shaped mirrors; each cylindrical mirror group comprises a Y-directional cylindrical mirror group and an X-directional cylindrical mirror group; each Y-directional cylindrical mirror group comprises a Y-directional plano-convex cylindrical mirror and a Y-directional plano-concave cylindrical mirror; each X-directional cylindrical mirror group comprises an X-directional plano-convex cylindrical mirror and an X-directional plano-concave cylindrical mirror; each cylindrical mirror group adjusts a laser beam in an Xdirection and a Y direction so as to form an elliptical beam; and the elliptical beams are converged through the wedge-shaped mirrors so as to form a working laser for welding the multiple intensivepoints. The invention provides the system for simultaneously welding the multiple points so as to be capable of simultaneously realizing setting of different welding pad sizes, different welding pad gaps and different welding point powers on the same equipment, and the system has higher efficiency and processing accuracy.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

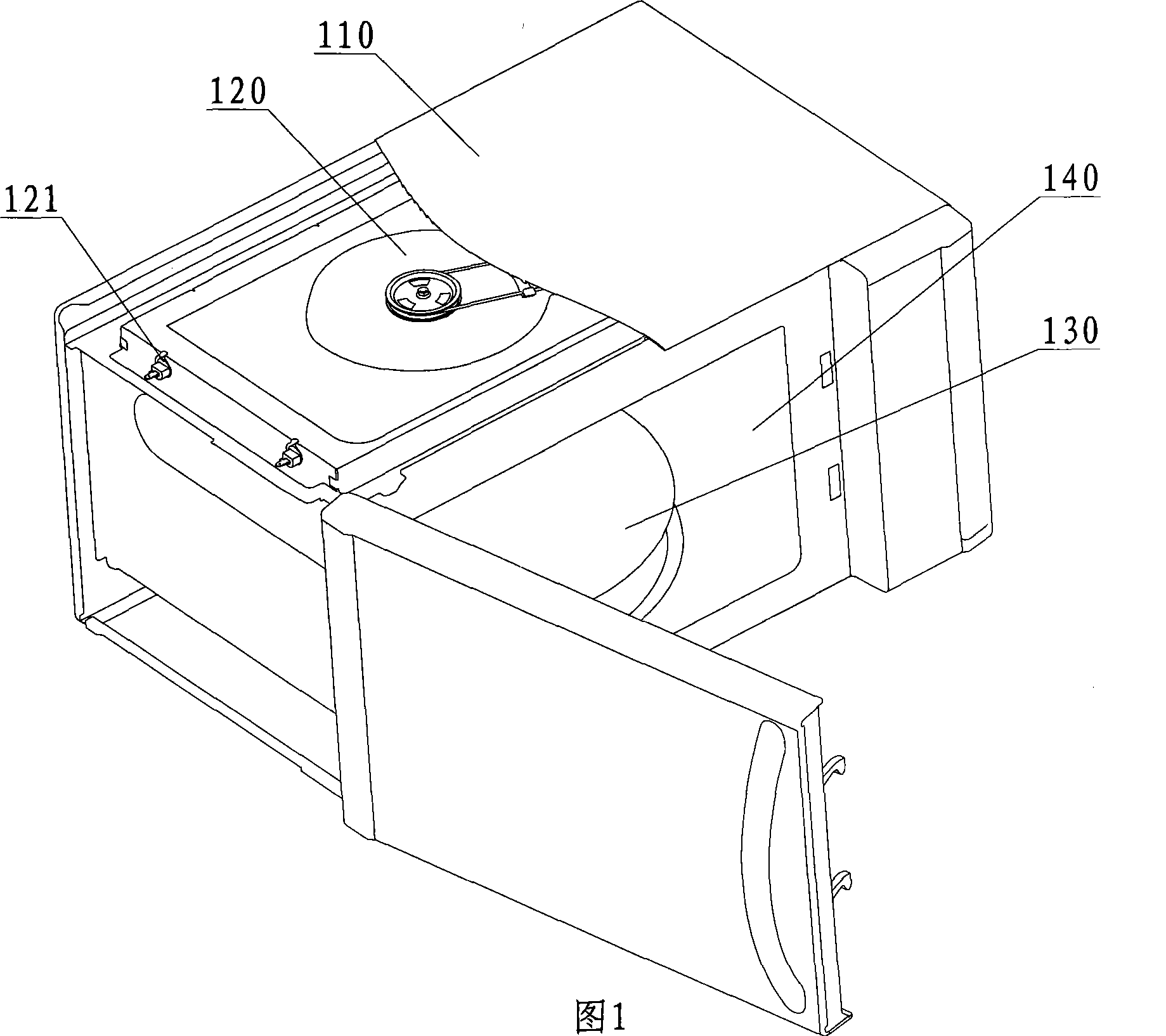

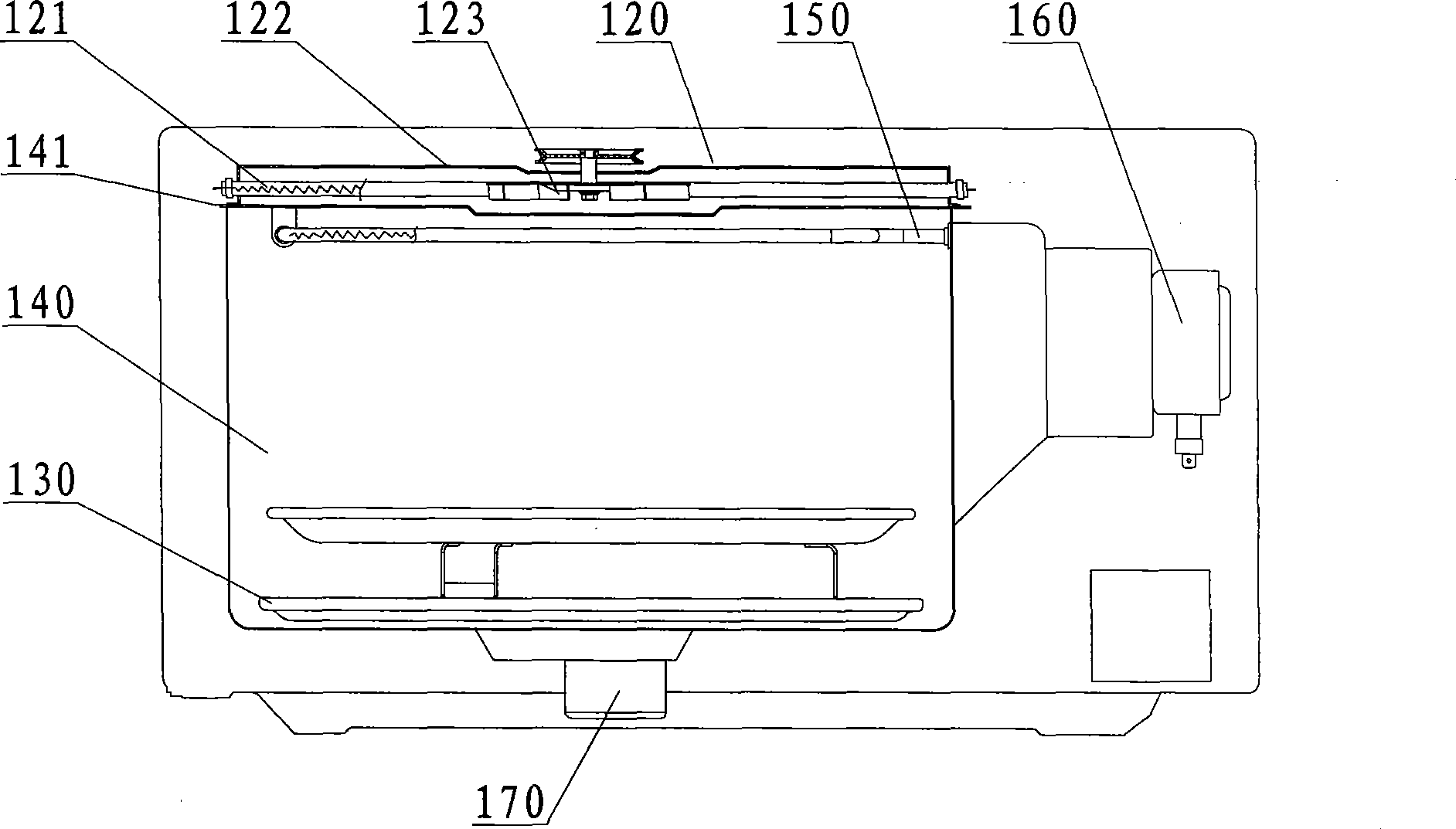

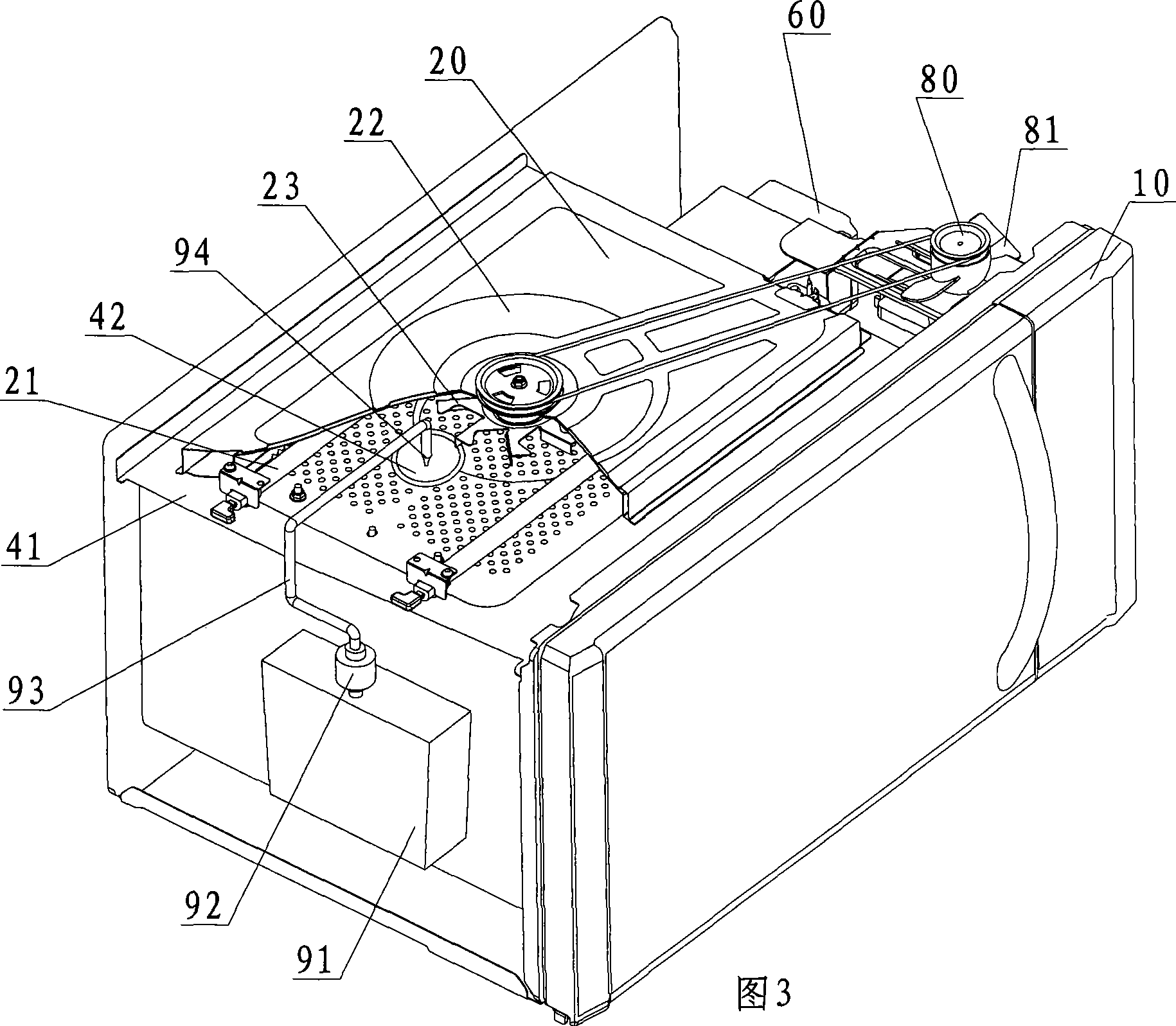

Hot blast convected circulation micro-wave oven with steam function

InactiveCN101451730AAvoid direct contactCook evenlyDomestic stoves or rangesLighting and heating apparatusMicrowave ovenLiquid water

A hot air convection type microwave oven with a steaming function comprises an oven body of which the top is provided with a hot air generator. A water tank is arranged in the oven body; one end of a pumping pipeline is connected with the water tank through a water pump and the other end reaches into a heating cavity of the hot air generator so as to generate high-temperature steam from liquid water directly running through the high-temperature heating cavity. The hot air generator comprises a heat collecting cover, a fan and a heating pipe. The bottom face of the heat collecting cover is connected with a roof plate of an oven cavity, and the inner bottom face of the heat collecting cover is provided with a fan. A shaft core of the fan reaches out the roof of the heat collecting cover and then is in transmission connection with a cooling motor. The heating pipe is arranged in the heating cavity between the heat collecting cover and the oven cavity. In order to better control water output, a nozzle is arranged at a water outlet end of a pumping pipeline; a concave face corresponding to the nozzle which contains and fully evaporates the liquid water is arranged on the roof plate of the oven cavity. The hot air convection type microwave oven has a simple and reasonable structure, high energy efficiency, a low manufacturing cost and a plurality of cooking functions, and uniformly heats and is easily cleaned.

Owner:GUANGDONG GALANZ GRP CO LTD

Flower and plant planting greenhouse

InactiveCN109121881ANovel structural designGood insulation effectClimate change adaptationSaving energy measuresAgricultural engineeringEngineering

The invention discloses a flower and plant planting greenhouse. The flower and plant planting greenhouse comprises a greenhouse body, wherein the top part of the greenhouse body is provided with a greenhouse ceiling; the exterior of the greenhouse ceiling is provided with a solar cell panel and a storage battery box; the bottom part of the inner chamber of the greenhouse body is provided with a plurality of flower and plant planting boxes; the side walls of the greenhouse body are respectively provided with a heat storage plate; the inner side of the greenhouse ceiling is provided with a waterspray pipe which is provided with a plurality of spray heads; an LED lamp is arranged between every two adjacent spray heads; LED lamps are electrically connected with a storage battery arranged in the storage battery box; the water spray pipe communicates with a water tank located at the exterior of the greenhouse body; and a high-pressure water pump is arranged in the water tank. The flower andplant planting greenhouse provided by the invention has novel structure design and good heat-preserving effect, can realize automatic spraying at the same time, and can improve the planting efficiency of flowers and plants.

Owner:胡新军

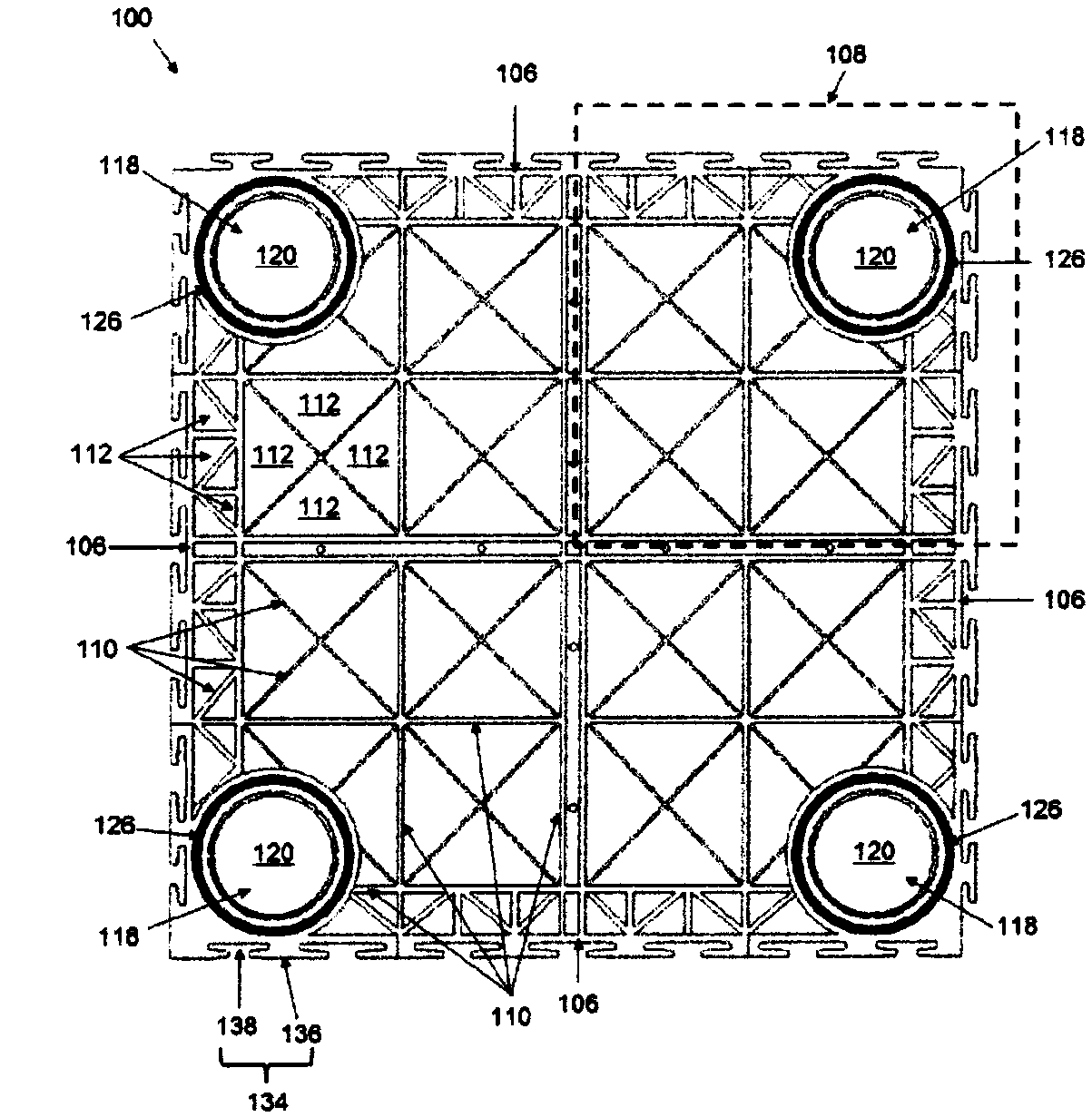

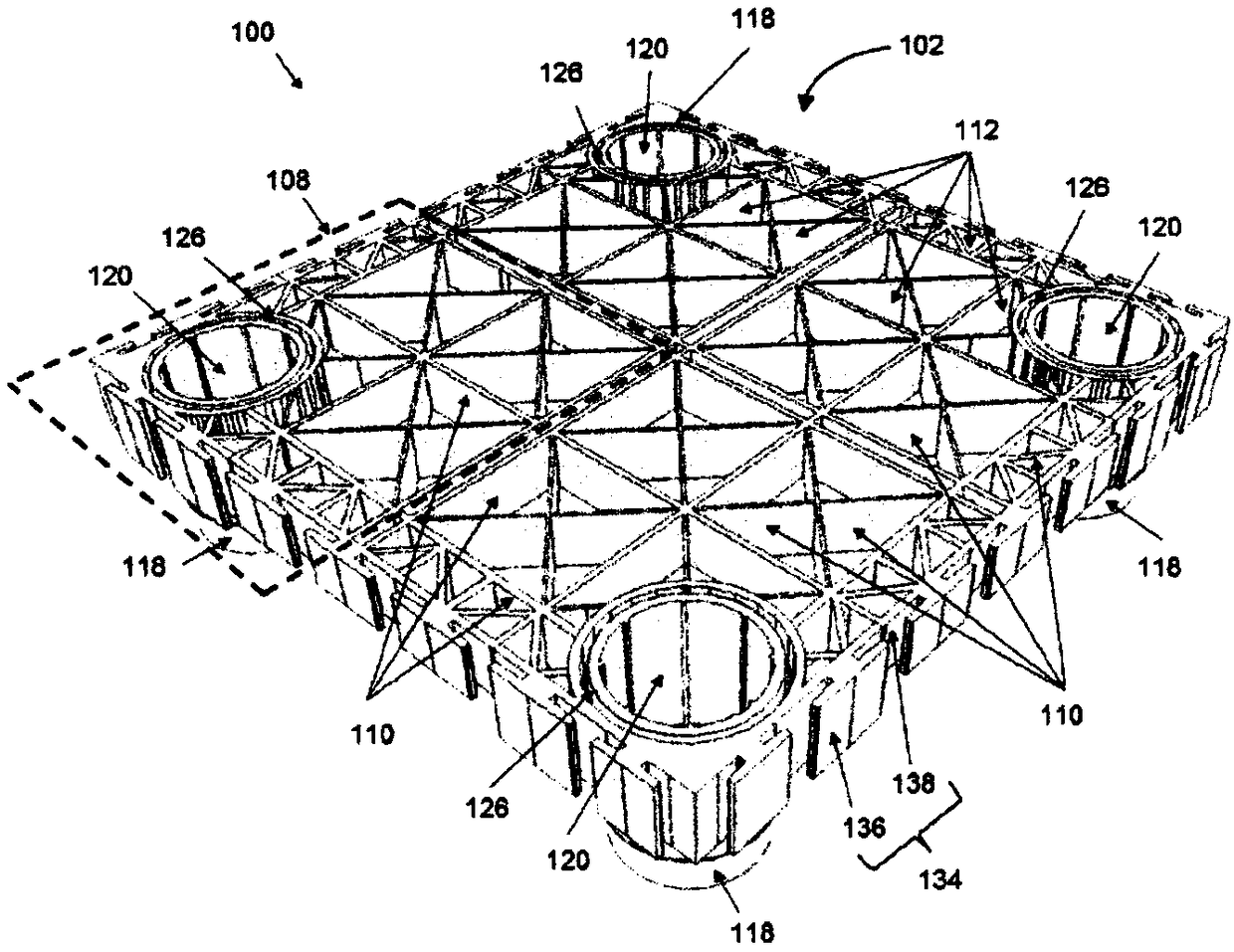

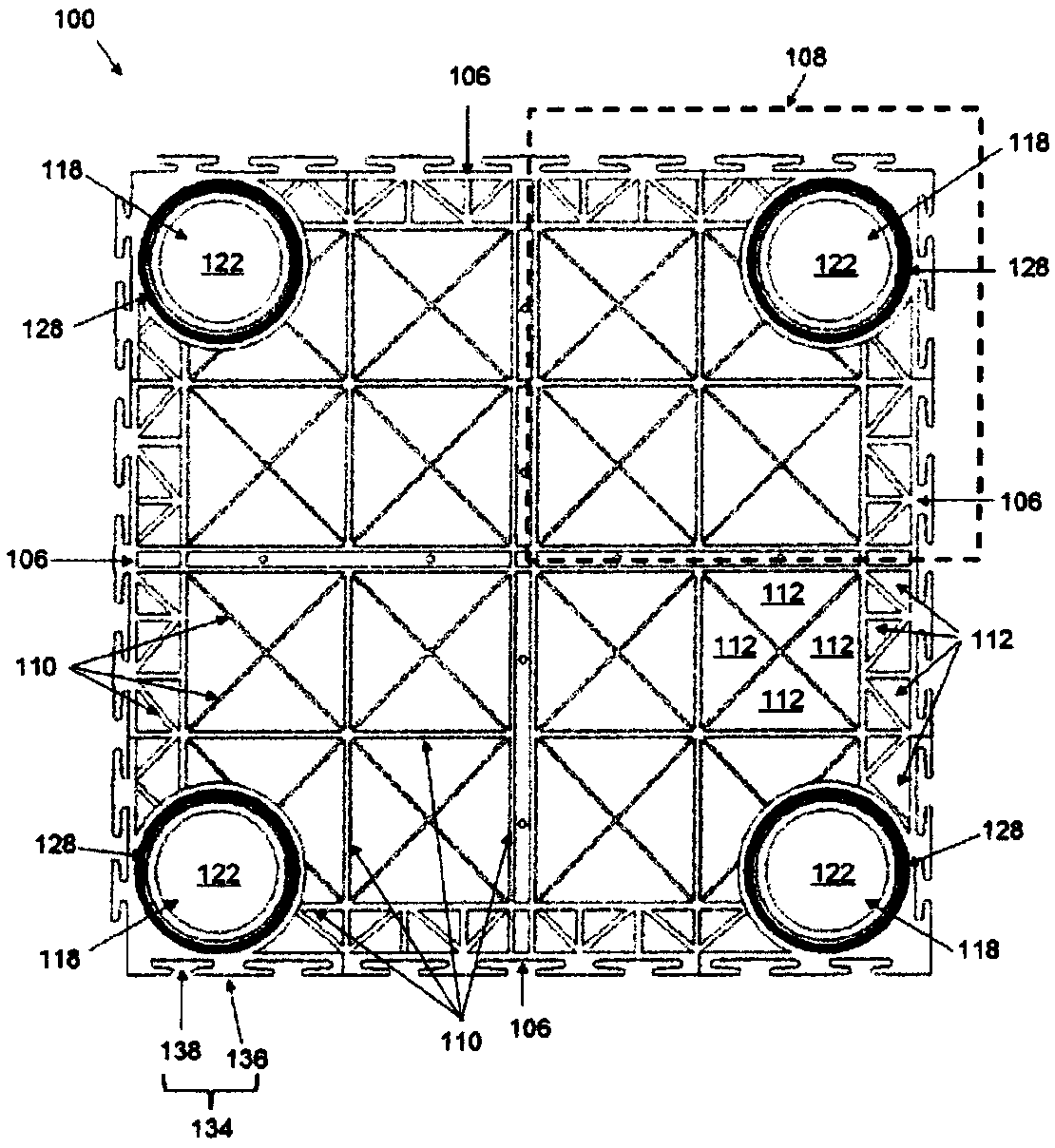

Modular pallet and multilayer support structure

A modular pallet for use in supporting and transporting goods. The modular pallet comprises a plurality of hollow legs integral to an inner side of the sidewall and a plurality of interlocking means integral to an outer side of the sidewall for coupling other modular pallets laterally, wherein each of the hollow legs comprises a top opening aligned with the top surface of the pallet and a bottom opening further away from the bottom surface of the pallet, and a top groove along a peripheral edge of the top opening and a bottom groove along a circumference of the hollow leg adjacent to the bottom surface. A multilayer support structure comprises at least two layers of the modular pallets separated by a plurality of hollow support columns for being positioned under the ground to support a hardscape / softscape disposed thereon while enable for tree roots growth, water drainage and storage of utilities.

Owner:林儿庆

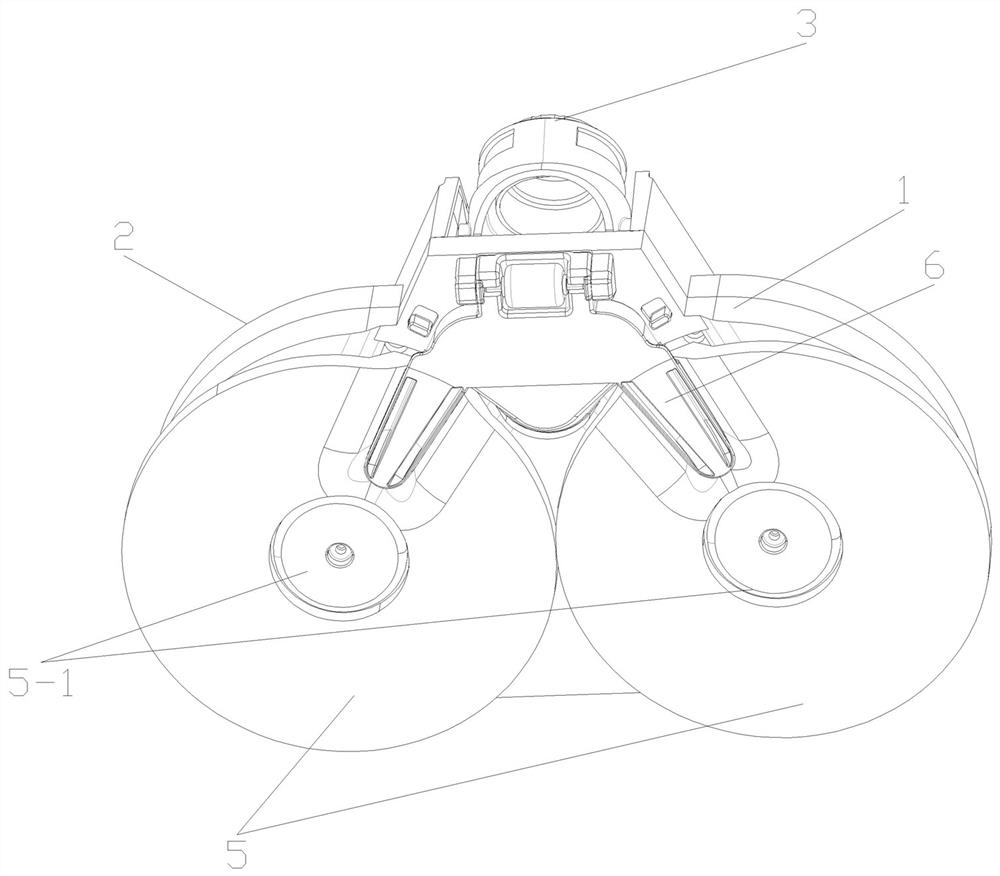

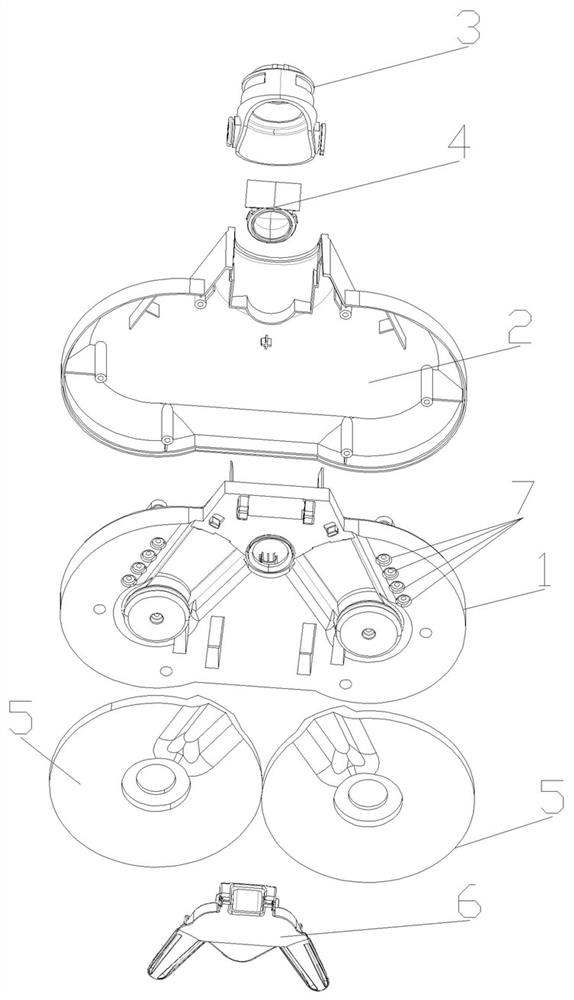

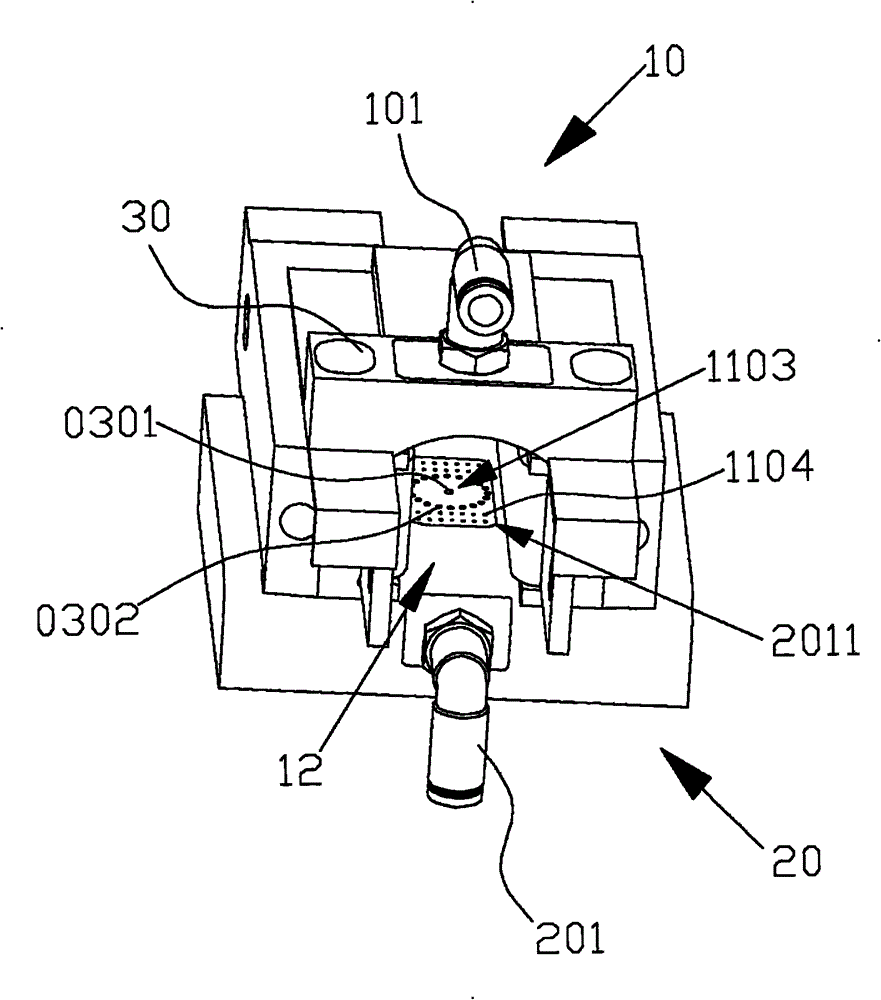

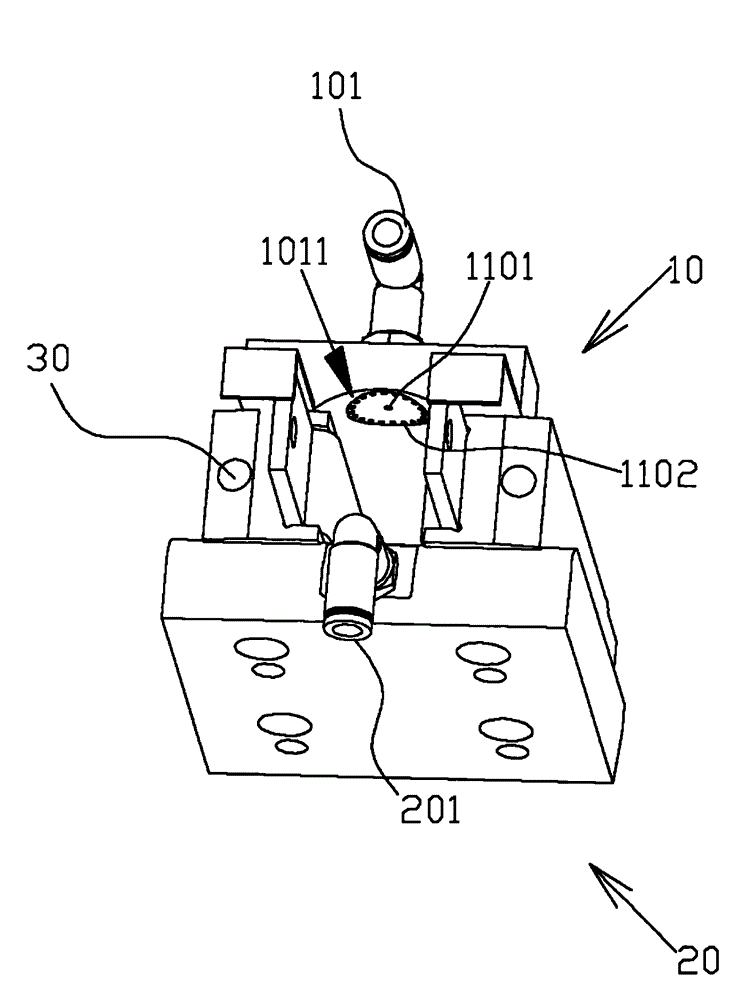

Cleaning device, scrubber and sweeper

The invention relates to a cleaning device, a scrubber and a sweeper. The cleaning device comprises a support, cleaning cloth, a scraper and a structure used for wetting the cleaning cloth, the support is used for supporting the cleaning cloth and the scraper, the working face of the scraper is arranged below the cleaning cloth and abuts against the cleaning cloth, the working face of the scraper is further provided with a suction port, the cleaning cloth is used for mopping the floor, the cleaning cloth can move relative to the scraper, the working face of the scraper is used for scraping the cleaning cloth and squeezing sewage on the cleaning cloth when the scraper and the cleaning cloth move relative to each other, the squeezed sewage and the scraped dirt fall into the suction port, and a sewage channel communicated with the suction port is further formed in the scraper. After the cleaning cloth is wetted, the ground can be mopped in a wet mode, after the cleaning cloth becomes dirty, dirt on the cleaning cloth can be scraped off through the scraper, sewage on the cleaning cloth is squeezed, the cleaning cloth can be cleaned in time, the sewage and the dirt fall into the suction port and can be treated in time through the sewage channel, no trace is left on the ground, and the ground cleaning effect is good.

Owner:NINGBO FUJIA IND

Intelligent indoor humidification and ventilation device

InactiveCN108954551AAvoid stickingFully moistMechanical apparatusLighting and heating apparatusWater storageAgricultural engineering

The invention discloses an intelligent indoor humidification and ventilation device. The intelligent indoor humidification and ventilation device comprises a shell, an air inlet is formed in the top wall of the shell, an exhaust fan is arranged below the air inlet, a water tank is arranged in the shell, air outlets are formed in the two sides of the bottom of the shell, and universal wheels are arranged at the bottom of the shell. The bottom of the water tank is provided with a water outlet, a water absorbing rope is arranged in the water outlet in a penetrating mode, and a water storage device is arranged below the water absorbing rope in a penetrated manner. The exterior of the water storage device is fixedly sleeved with a gear, a rack engaged with the gear is arranged on one side of the gear, and one end of the rack penetrates through the shell and is movably connected with the inner wall of the shell. The intelligent indoor humidification and ventilation device not only can effectively purify air but also can enable air to be filled with negative oxygen ions, so that a wet and clean environment is created around people, and human health is benefited.

Owner:金华市鸿讯机械工程技术有限公司

Coal water slurry dispersing stabilizer

InactiveCN104651002AReduce surface tensionFully moistLiquid carbonaceous fuelsCoal waterPoly(methyl acrylate)

The invention relates to a coal water slurry dispersing stabilizer, and belongs to the technical field of coal water slurry processing. The coal water slurry dispersing stabilizer is composed of the following raw materials by weight: 10 parts of sodium lignosulfonate, 3.2-3.5 parts of modified starch, 1.7-2.0 parts of hydroxymethyl cellulose, 2.3-2.7 parts of poly methyl acrylate, 1.8-2.3 parts of polyepoxysuccinic acid and 1.2-1.5 parts of methyl benzotriazole. According to the invention, the existing surface active agents are selected and combined according to a certain ratio, so that the surface active agents with different functions mutually coordinate to realize excellent dispersion effect. Specifically, the dispersing stabilizer can reduce the surface tension of water, increase the surface tension of coal, reduce the interfacial tension between the two liquid, so that the coal water slurry can be fully wet. The hydration film can separate the coal particles and reduce the resistance of the coal particles, so as to reduce the viscosity effect.

Owner:张晨

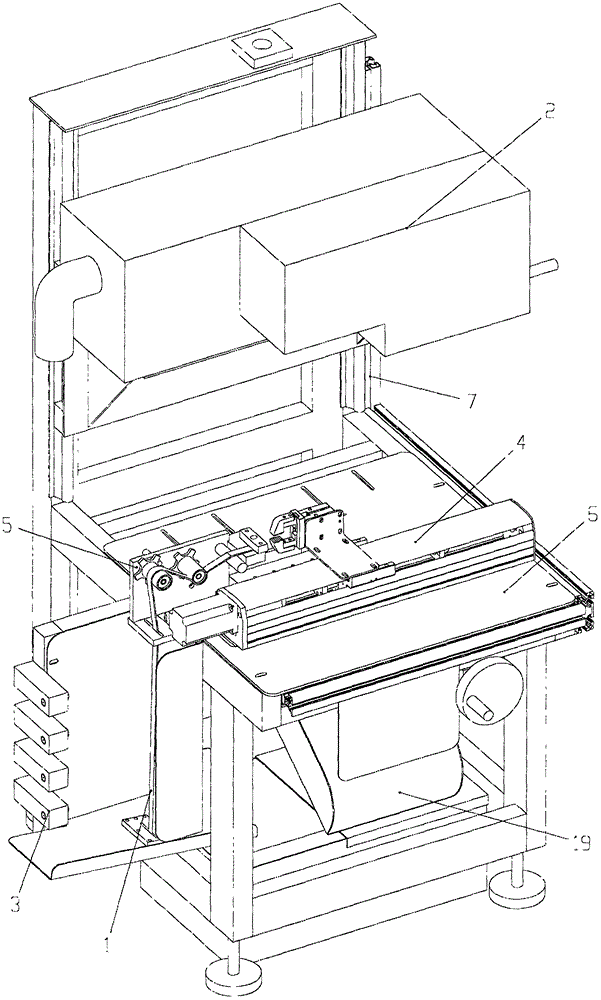

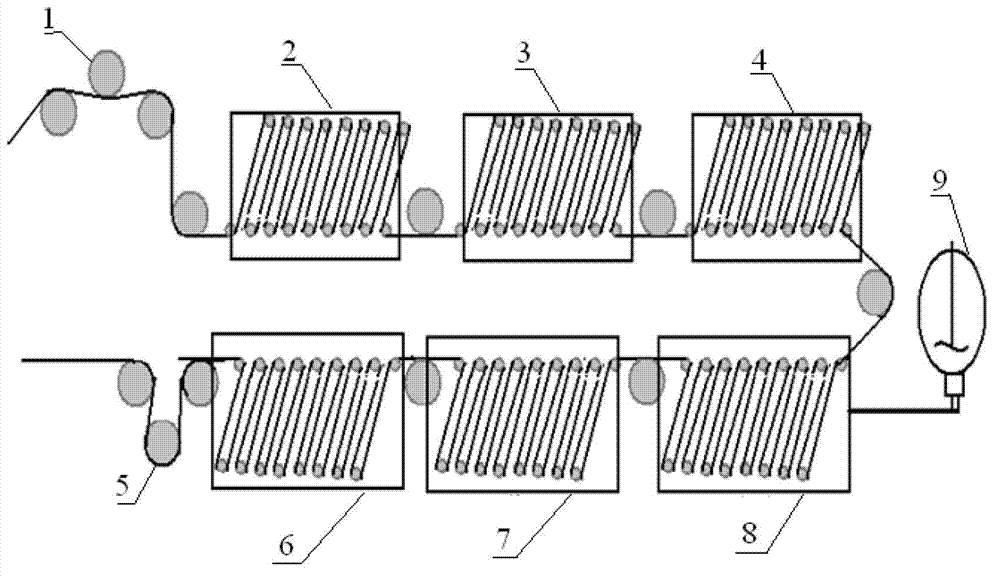

Fully automatic equipment for laser cutting of belt

ActiveCN106271112AIncrease productivityImprove product qualityWelding/soldering/cutting articlesMetal working apparatusLaser cuttingEngineering

The invention relates to automatic equipment, in particular to automatic equipment for laser cutting of a belt. The fully automatic equipment for the laser cutting of the belt comprises a laser device, a water spraying mechanism, a traction mechanism, a material conveying mechanism, a working table and a bracket, wherein the working table is fixedly connected to the bracket; the traction mechanism is fixedly connected to the working table; the material conveying mechanism is fixedly connected to the working table; the water spraying mechanism is fixedly connected to the bracket; the laser device is fixedly connected to the bracket; the laser device is located above the working table. Due to the cooperative operation of the water spraying mechanism, the traction mechanism and the material conveying mechanism, the operations such as stretching, cutting and material falling are repeatedly performed so as to fully automatically realize automatic laser cutting of the belt and control the laser cutting effect of the belt; and therefore, the production efficiency and the quality of a product are improved.

Owner:滁州辉煌无纺科技有限公司

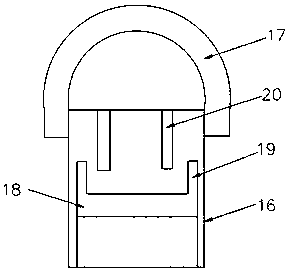

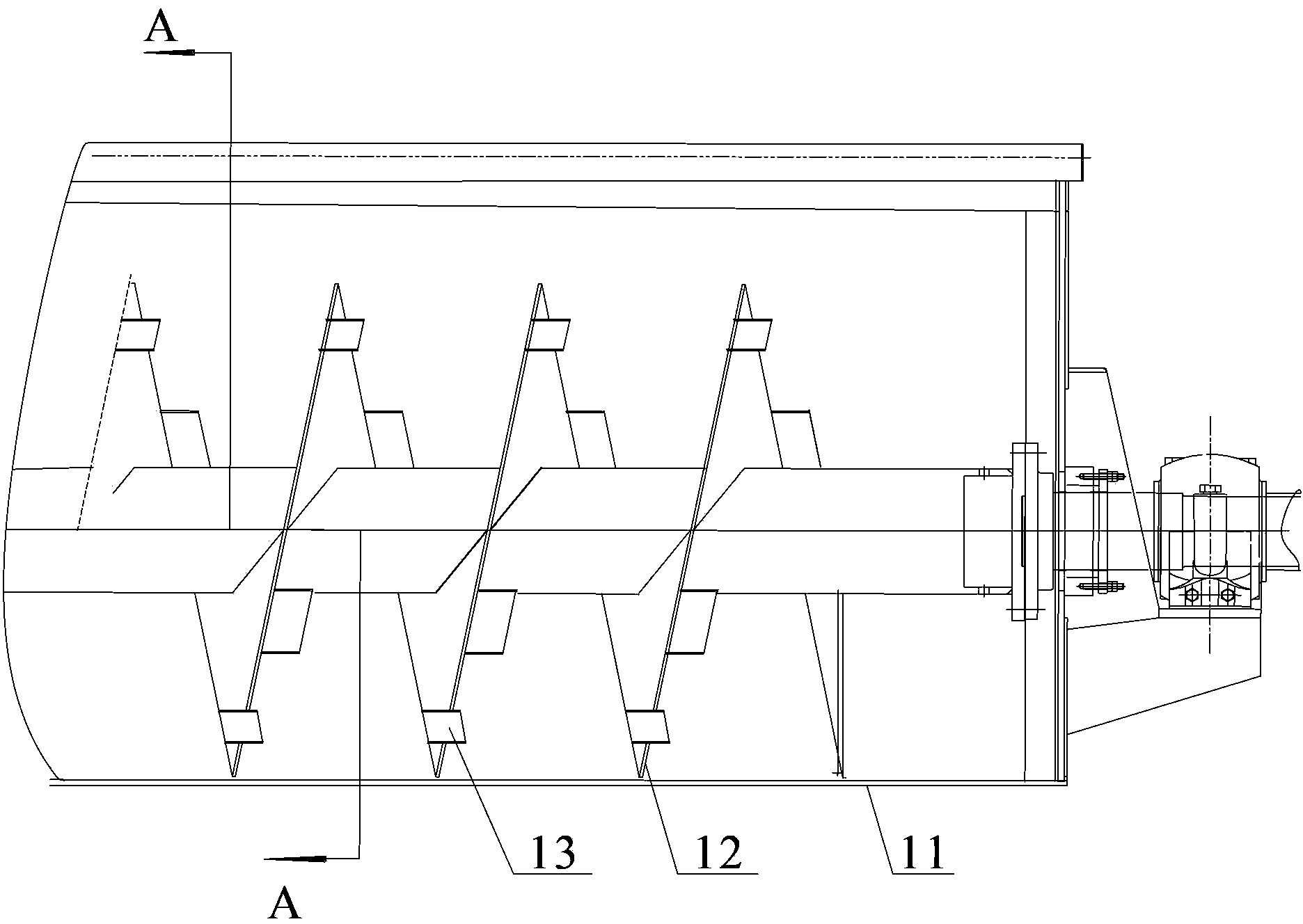

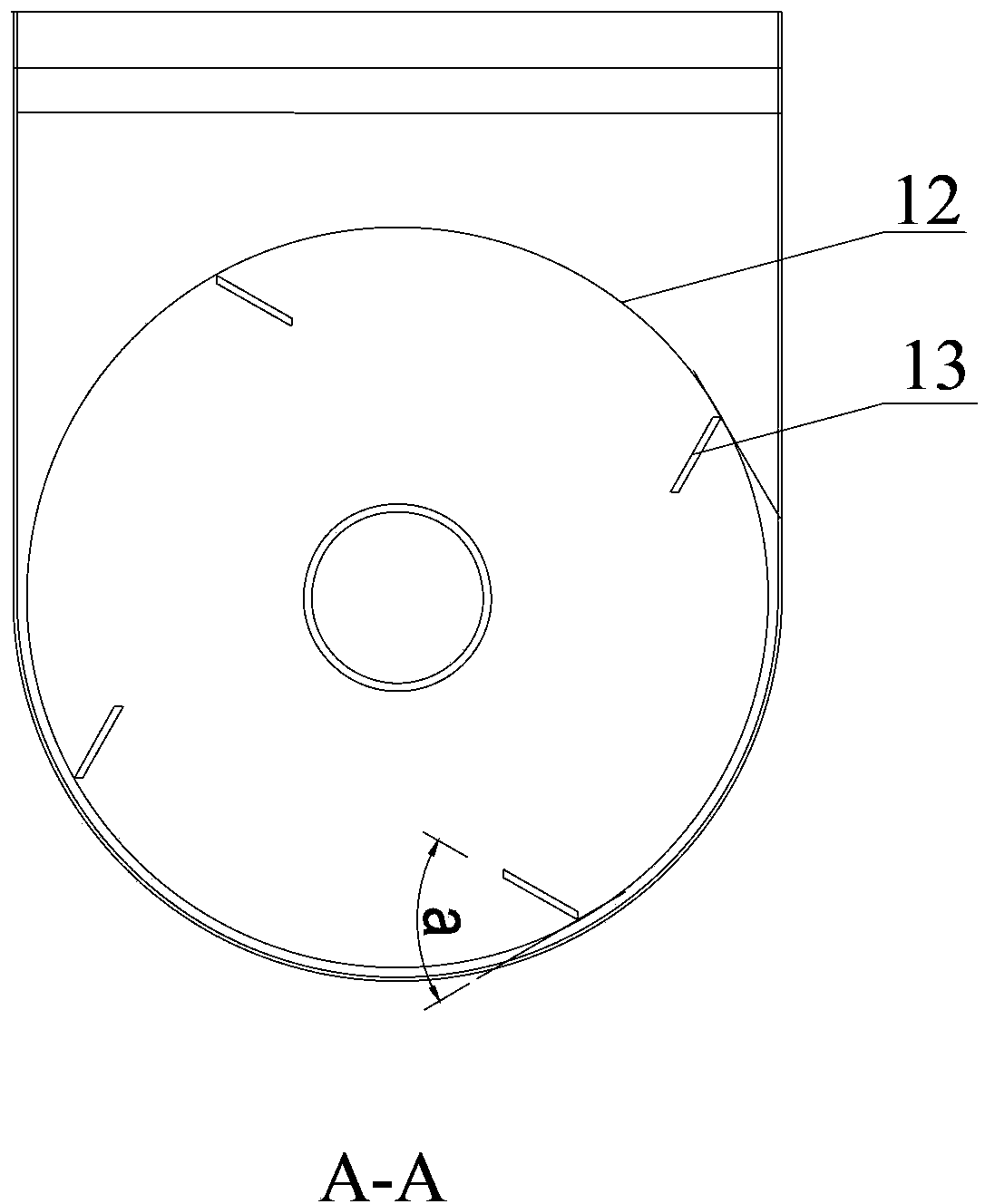

Spiral propelling device

InactiveCN103350874ASolve the problem of uneven humidityLow densityPackagingEngineeringMechanical engineering

The invention discloses a spiral propelling device which comprises an outer tube, a rotating shaft and a spiral conveying plate. The rotating shaft and the spiral conveying plate are arranged inside the outer tube, the spiral conveying plate is provided with a scraper blade which protrudes out of the spiral conveying plate. Thus, the spiral propelling device is capable of effectively solving the problems of unevenness of water moistening humidity caused by inconsistent density of materials needing to be transported.

Owner:FOSHAN HAIYING FOOD

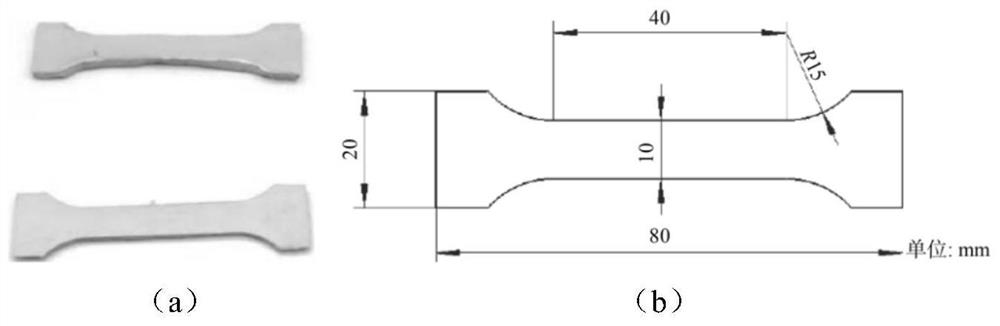

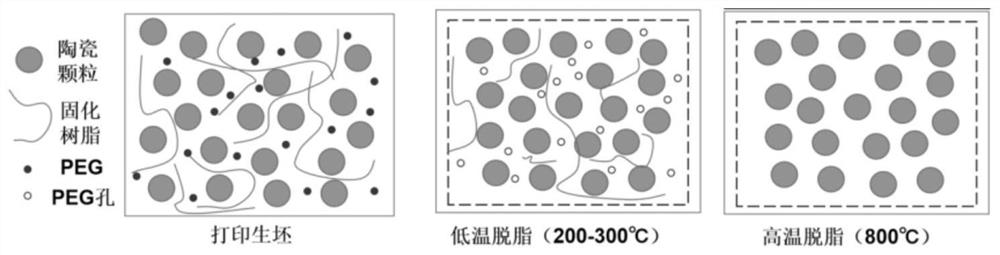

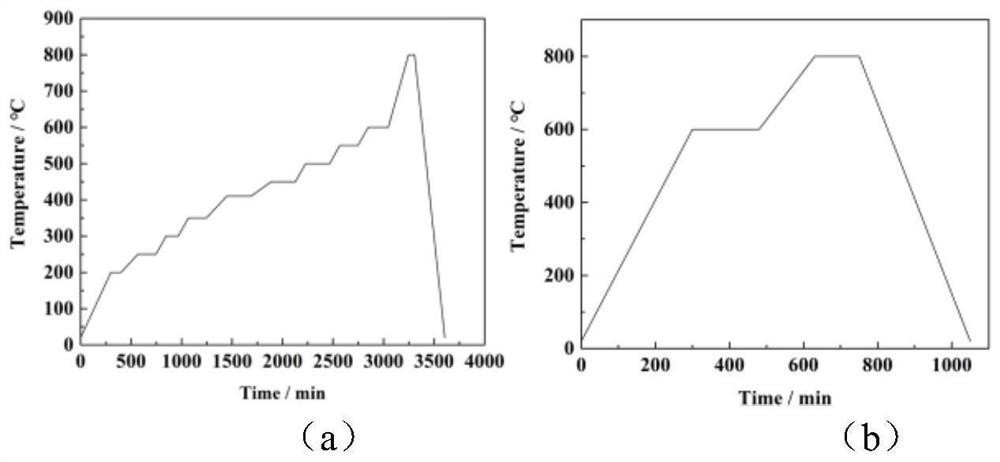

High-thickness high-strength light-cured silicon nitride ceramic and preparation method thereof

PendingCN114478049AIncreased maximum degreasing thicknessEasy to removeAdditive manufacturing apparatusCeramicwareArgon atmosphereSpherical pore

According to the high-thickness high-strength light-cured silicon nitride ceramic and the preparation method thereof, in the preparation process, a low-temperature pore-forming agent PEG is added into ceramic paste, so that in the later degreasing process, the maximum degreasing thickness of the silicon nitride ceramic is increased to 8 mm, the degreasing time is only 60 h, and the degreasing rate can reach 99% or above. According to the characteristics that PEG is volatilized at the temperature of 200-300 DEG C and spherical holes are left, firstly, macromolecular cracking and low-temperature pore-forming agent removal are carried out in an argon atmosphere, the low-temperature pore-forming agent can be almost completely removed at the temperature of 300 DEG C, and a channel is provided for follow-up escape of small molecules. In the process, a channel is reserved in a green body in advance in the ceramic green body degreasing process, so that subsequent high-temperature removal of photosensitive resin is facilitated (cracking deformation is avoided, and the limit degreasing thickness is increased).

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

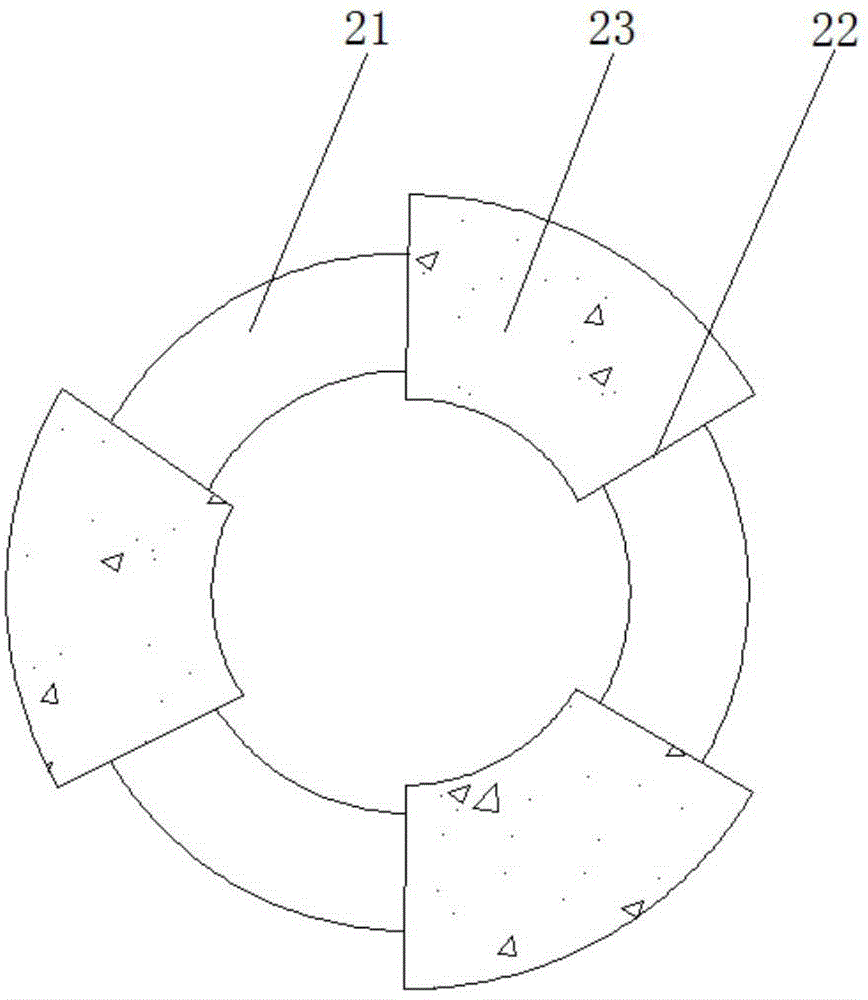

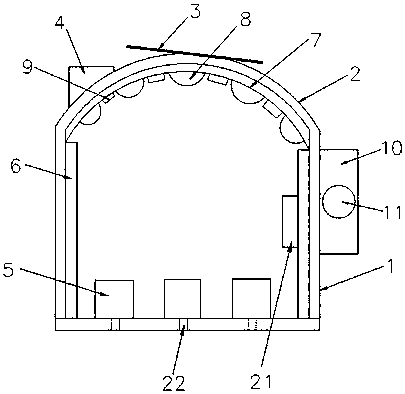

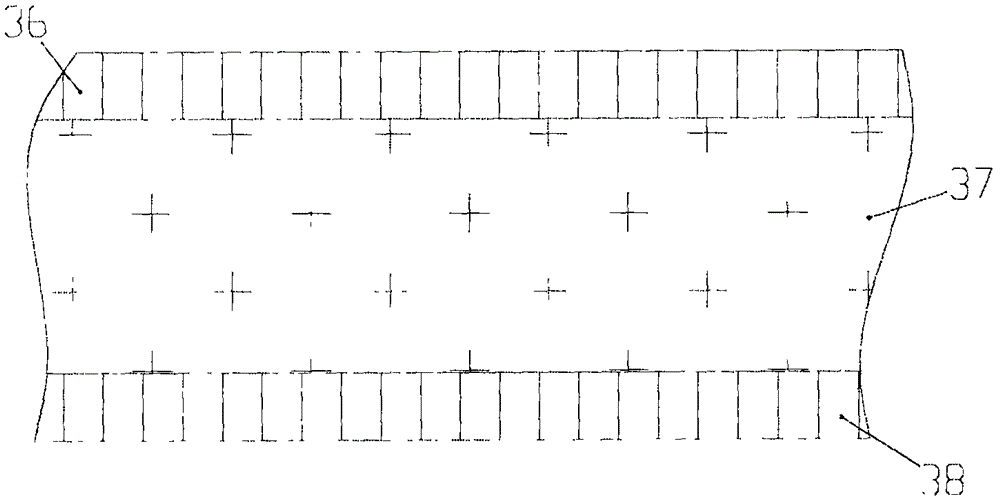

Circular-net humidifying device of wool top outlet rack

ActiveCN103993440AFully moistUniform humidityLiquid/gas/vapor textile treatmentDrive wheelElectric machinery

The invention discloses a circular-net humidifying device of a wool top outlet rack. The circular-net humidifying device comprises a fixing rack, a net cylinder and a suction fan. A steam humidifying pipeline supporting frame is fixed on the upper surface of the fixing rack. The net cylinder is arranged above the fixing rack, a plurality of humidifying air suction holes are evenly formed in the outer surface of the net cylinder, and supporting rollers are arranged at the two ends of the net cylinder. An air suction pipeline is arranged at one end of the net cylinder, a driving wheel is arranged at the other end of the net cylinder, and the driving wheel is driven by a motor to rotate. A steam humidifying pipeline is arranged above the net cylinder, and a plurality of humidifying air outlet holes are evenly formed in the outer surface, right opposite to the net cylinder, of the steam humidifying pipeline. The suction fan is connected to the other end of the air suction pipeline, and the lower end of the suction fan is connected with a drying oven. The circular-net humidifying device of the wool top outlet rack has the advantages of being reasonable in design, simple in structure, convenient to operate, good in humidity effect, even in dyeing, capable of saving cost and convenient to popularize.

Owner:张家港天宇精梳羊毛有限公司

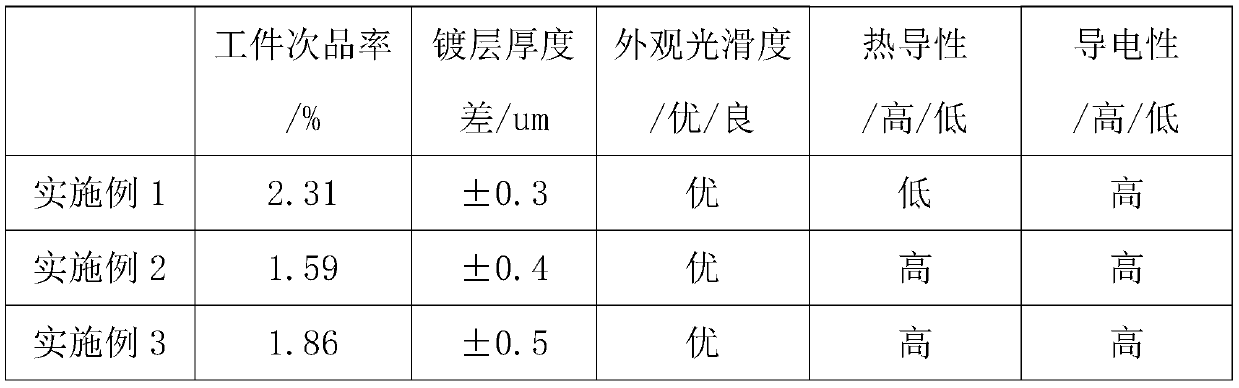

LED support electroplating method and LED support

ActiveCN110528036AImprove physical performanceMolecular density and uniformityJewelleryFree coolingEngineering

The invention discloses an LED support electroplating method and an LED support. The invention relates to the technical field of electroplating. The method comprises the following steps of: 1, performing electroplating pretreatment on an LED support, cleaning dust and impurities on the surface of an LED support material, performing smooth surface treatment, uniformly fixing the LED support material by using a hanger, flushing the surface of the LED support material by using clear water, and activating the surface of the LED support material by using a plating aid; 2, carrying out first-stage electroplating. According to the invention, after first-stage electroplating, second-stage electroplating, third-stage electroplating and fourth-stage electroplating are performed, the surface of eachcoating is uniformly sprayed by using a flame gun; the coatings are made to tend to be melted, homogenized and then naturally cooled to form a coating crystallization structure, molecules are compactand uniform, the coverage rate is good, good heat conductivity and heat conduction performance are guaranteed, the LED support is connected with a heat conduction rod, the LED support is integrally heated and annealed, all structural layers of the LED support are fused, the integration degree is high, and the overall physical performance of the support is improved.

Owner:崇辉半导体(深圳)有限公司

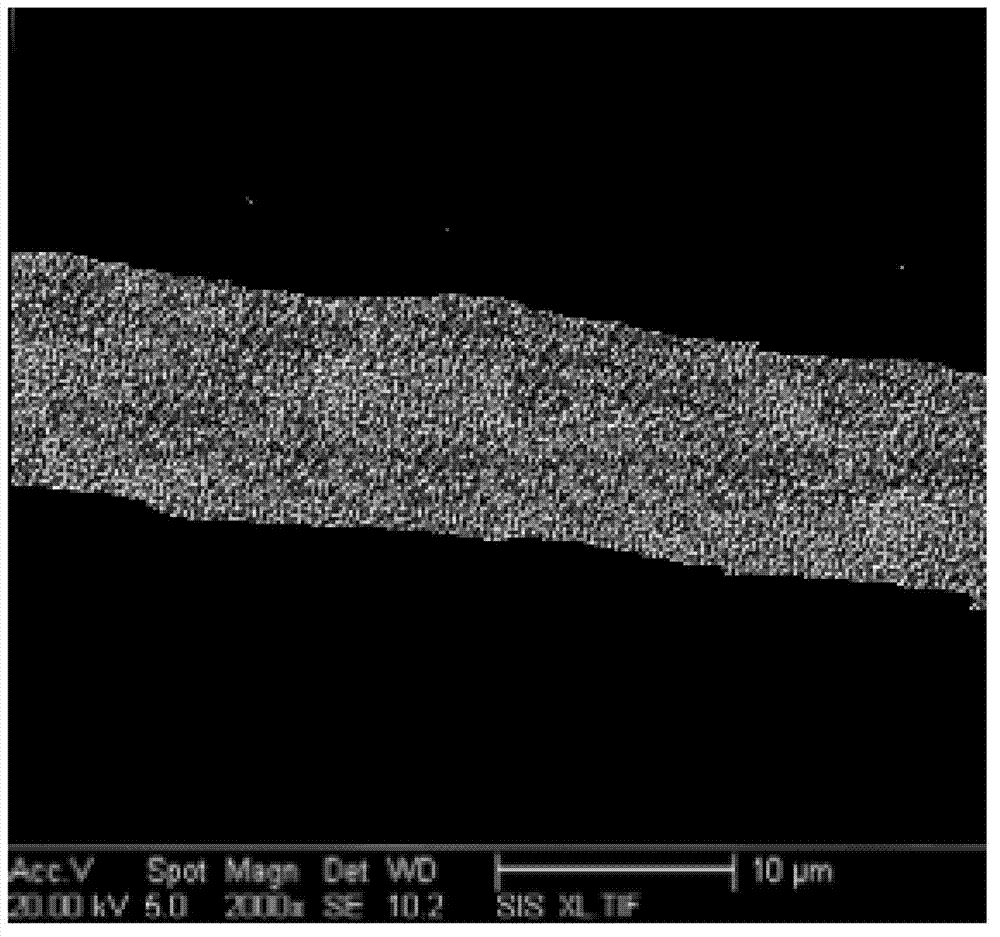

Preparation method of carbon fiber surface full-carbon coating

The invention relates to a preparation method of a carbon fiber surface full-carbon coating, relating to the field of preparation of carbon fibers and solving the problem of weak interface between the carbon fiber and a resin matrix in the existing carbon fiber composite material. The preparation method comprises the following steps of: 1, treating a carbon fiber; 2, pre-polymerizing phenolic resin; 3, coating phenolic resin slurry; 4, curing the phenolic resin; and 5, carbonizing the phenolic resin. The interlaminar shear strength of the prepared carbon fiber surface full-carbon coating is respectively improved by 12-53 percent; and the fiber adsorption capacity is remarkably improved; and the carbon fiber surface full-carbon coating is a good catalyst carrier. The carbon fiber surface full-carbon coating is controllable in structure; different functions can be endowed on the carbon fiber or the carbon fiber can be applied to different kinds of resin matrix composite materials through regulating the chemical composition and the component proportioning of phenolic aldehyde. The preparation method has the advantages of simplicity in operation, high efficiency and good effect; and the industrialized production is easily realized. The carbon fiber surface full-carbon coating is applied to the fields such as aviation, aerospace, military and building.

Owner:HARBIN INST OF TECH

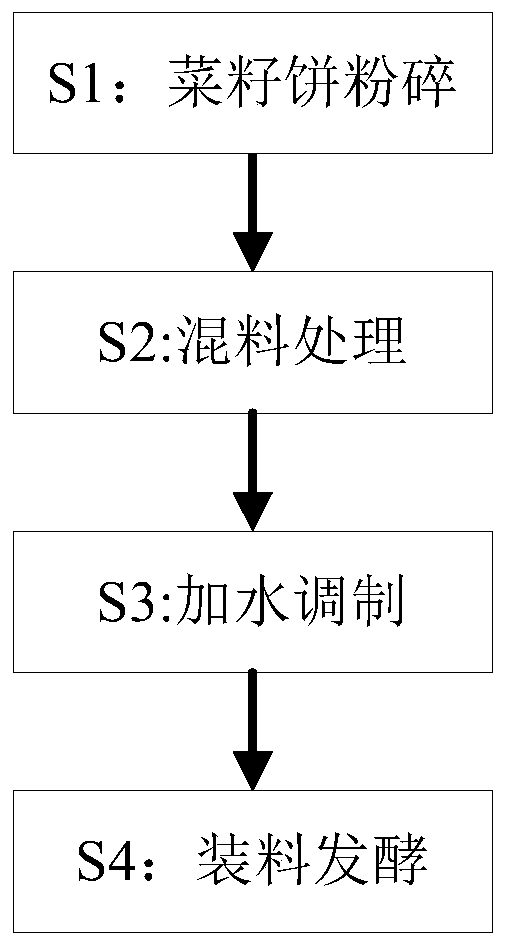

Method for preparing feed from by-product rapeseed cakes after rapeseed oil expression

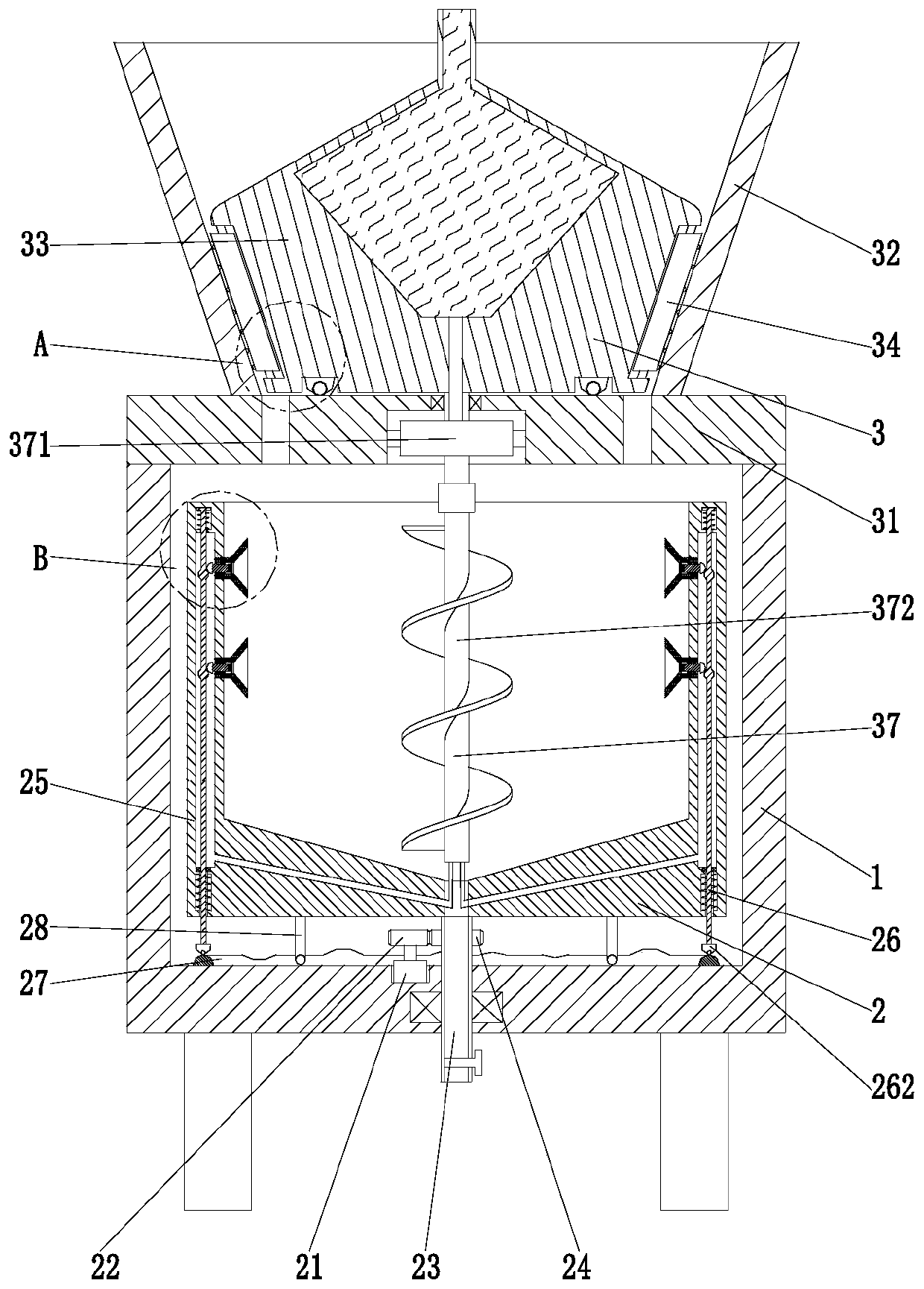

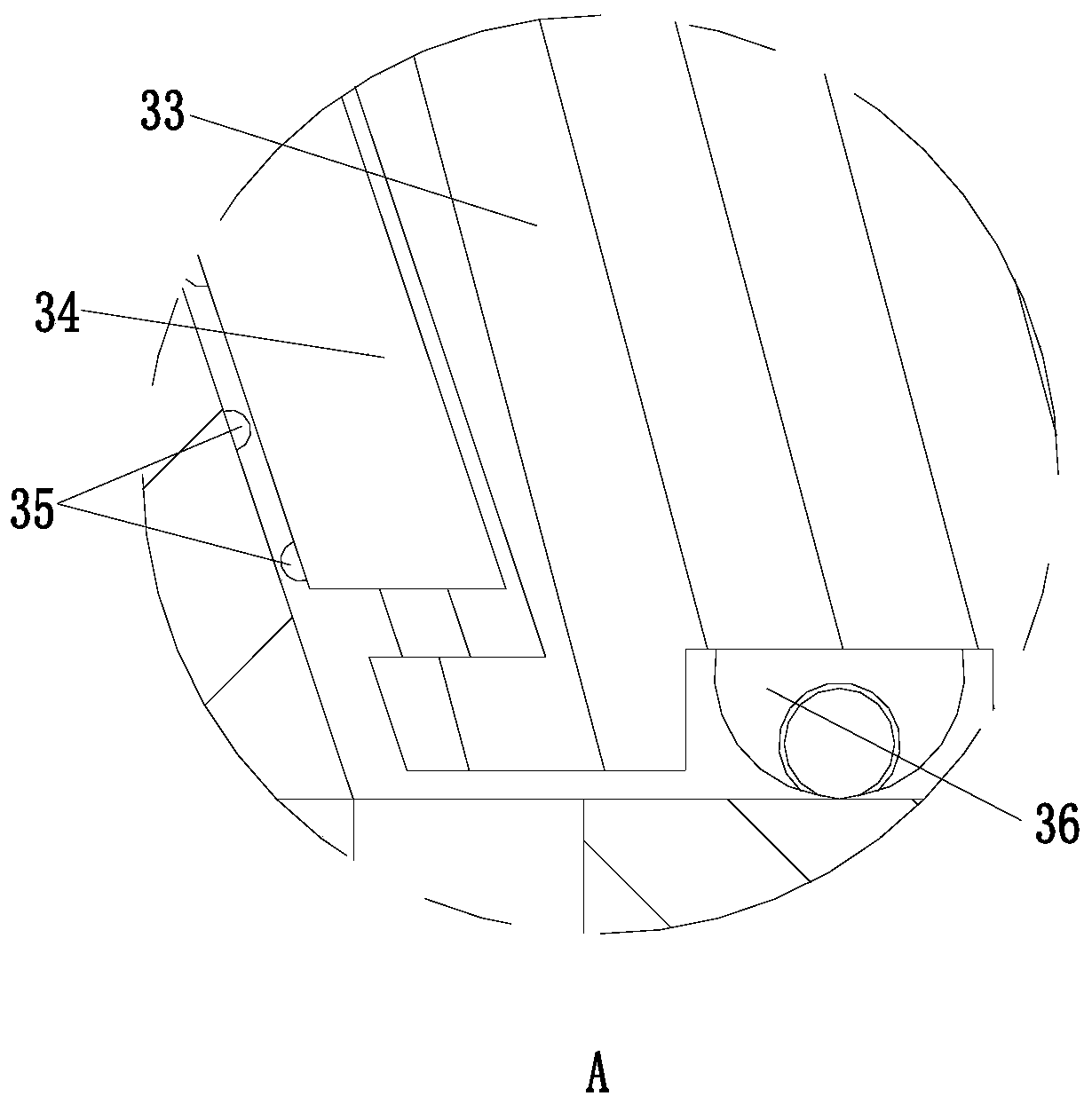

The invention provides a method for preparing feed from by-product rapeseed cakes after rapeseed oil expression. A limiting cylinder, a water injection unit, a feeding stirring unit and the like are matched to complete preparation of the rapeseed cake feed. The main difficult problems that as for existing rapeseed cake feed, in the stirring process of a mixture, a: the rapeseed cakes are blocky coagulations after pressing, and in the stirring process, the blocky coagulations are difficult to crush and are fully evenly mixed with auxiliary materials such as corn flour, wheat bran and a leavening agent difficultly; and b: as for existing stirring, the rapeseed cakes, the corn flour and the like are mixed in a concentrated mode and stirred by adding water, stirring by adding the water is prone to being uneven, the water is difficultly absorbed by the rapeseed cakes, the corn flour and the like, consequently, the caking phenomenon is prone to being caused, and the production quality of therapeseed cakes is affected are solved.

Owner:朱运霞

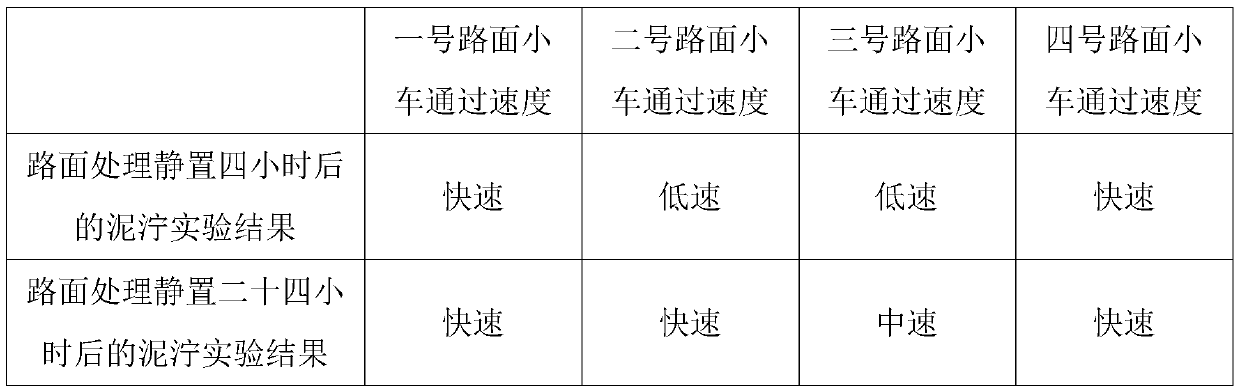

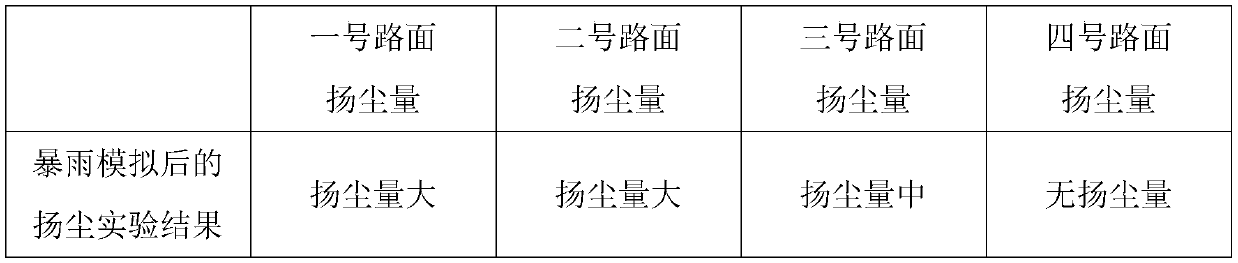

Dust suppressant for non-hardened pavement as well as preparation and application methods of dust suppressant

InactiveCN110028935ASuppress dustImprove liquidityOther chemical processesRoad cleaningHexadecaneBoiling point

The invention discloses a dust suppressant for a non-hardened pavement. The dust suppressant is prepared from the following raw materials in parts by weight: 160-165 parts of polypropylene glycol, 15-18 parts of hexadecane, 9-11 parts of octadecanol, 9-11 parts of an antifreezing solution and 1-2 parts of a preservative. Materials with water absorption capability are mostly used for preparing thedust suppressant in the current market or patents. As a result of hydrophilcity of soil, the pavement is muddy and is easily scoured by rainwater or evaporated by using the dust suppressant, so that the dust suppressant prepared with the method is not suitable for the non-hardened pavement. The dust suppressant in the patent is prepared from a hydrophobic material. After being constructed onto thesurface of soil, the dust suppressant achieves a purpose of inhibiting flying dust by increasing the proportion of fine soil particles. When vehicles pass, a dust cloud is avoided. As a result of excellent hydrophobicity and immiscibility to water, the dust suppressant is not scoured by rainwater easily. The material is relatively high in boiling point and is hard to evaporate to disappear, so that a dust suppression effect can be achieved effectively for a long time.

Owner:淮南中科盛联环保科技股份有限公司

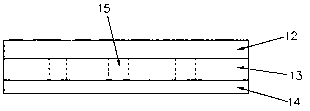

Special fiber humidifier with combined function

ActiveCN103556415AReduce the amount of dust absorbedKeep healthyTextile treatment by spraying/projectingFiberEngineering

The invention provides a special fiber humidifier with a combined function. The special fiber humidifier comprises an upper humidifying mechanism and a lower humidifying mechanism, wherein a product channel is arranged between the upper humidifying mechanism and the lower humidifying mechanism; the upper humidifying mechanism is provided with an upper humidifying channel, the upper humidifying channel is provided with an upper humidifying port which is arranged on the lower surface of the upper humidifying mechanism; the lower humidifying mechanism is provided with a lower humidifying channel which is provided with a lower humidifying port; the lower humidifying port is arranged on the upper surface of the lower humidifying mechanism; the upper humidifying mechanism and the lower humidifying mechanism are respectively provided with a part installing position. The special fiber humidifier provided by the invention has the advantages that not only are the part installing positions arranged for installing parts, but also the humidifying mechanisms are arranged for fully humidifying a product, so that the amount of dust inhaled by a human body is reduced, the operating environment is improved, the body health of an operator is guaranteed, and the purpose of multiple functions with one part is achieved.

Owner:NANTONG CELLULOSE FIBERS CO LTD

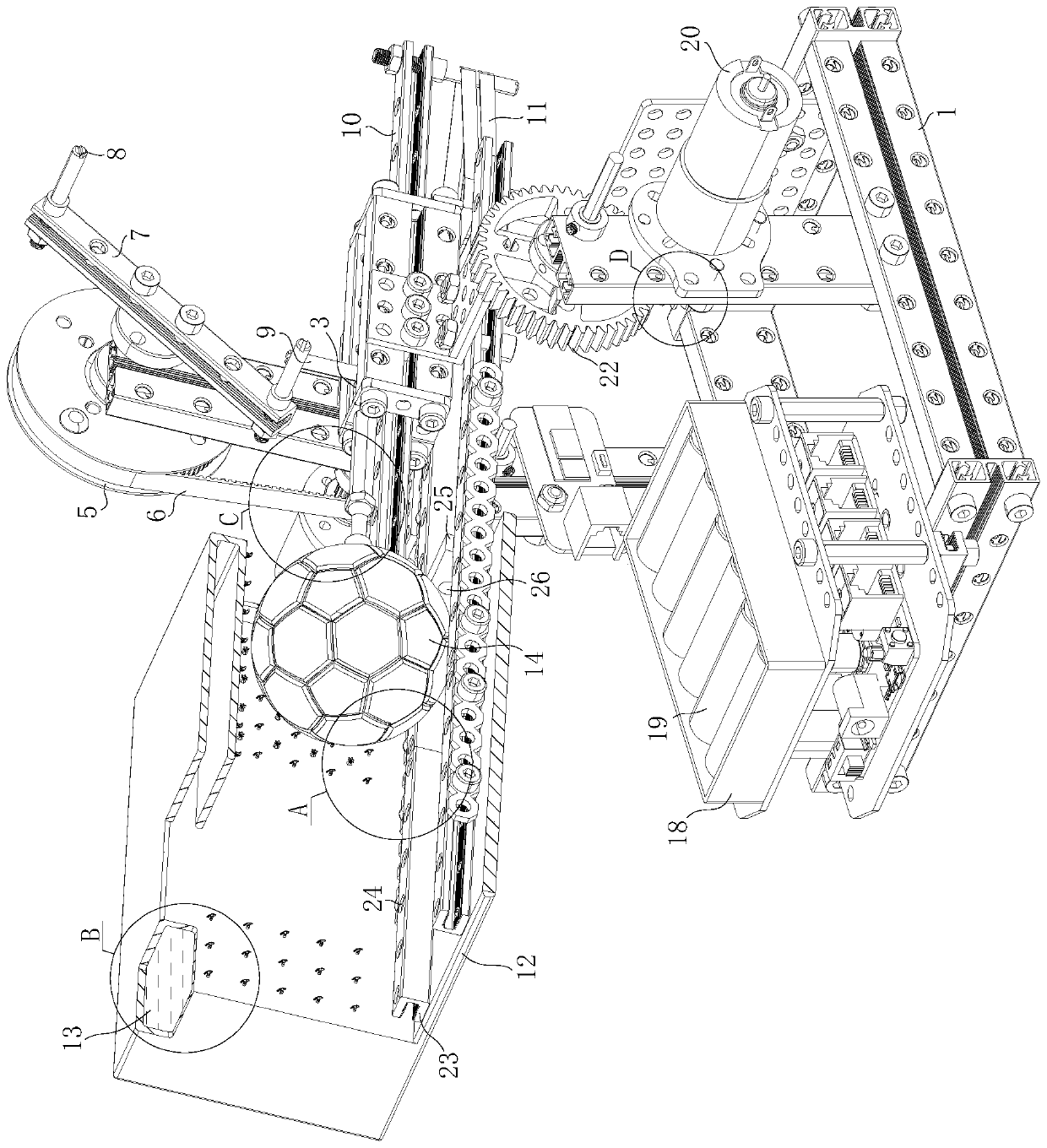

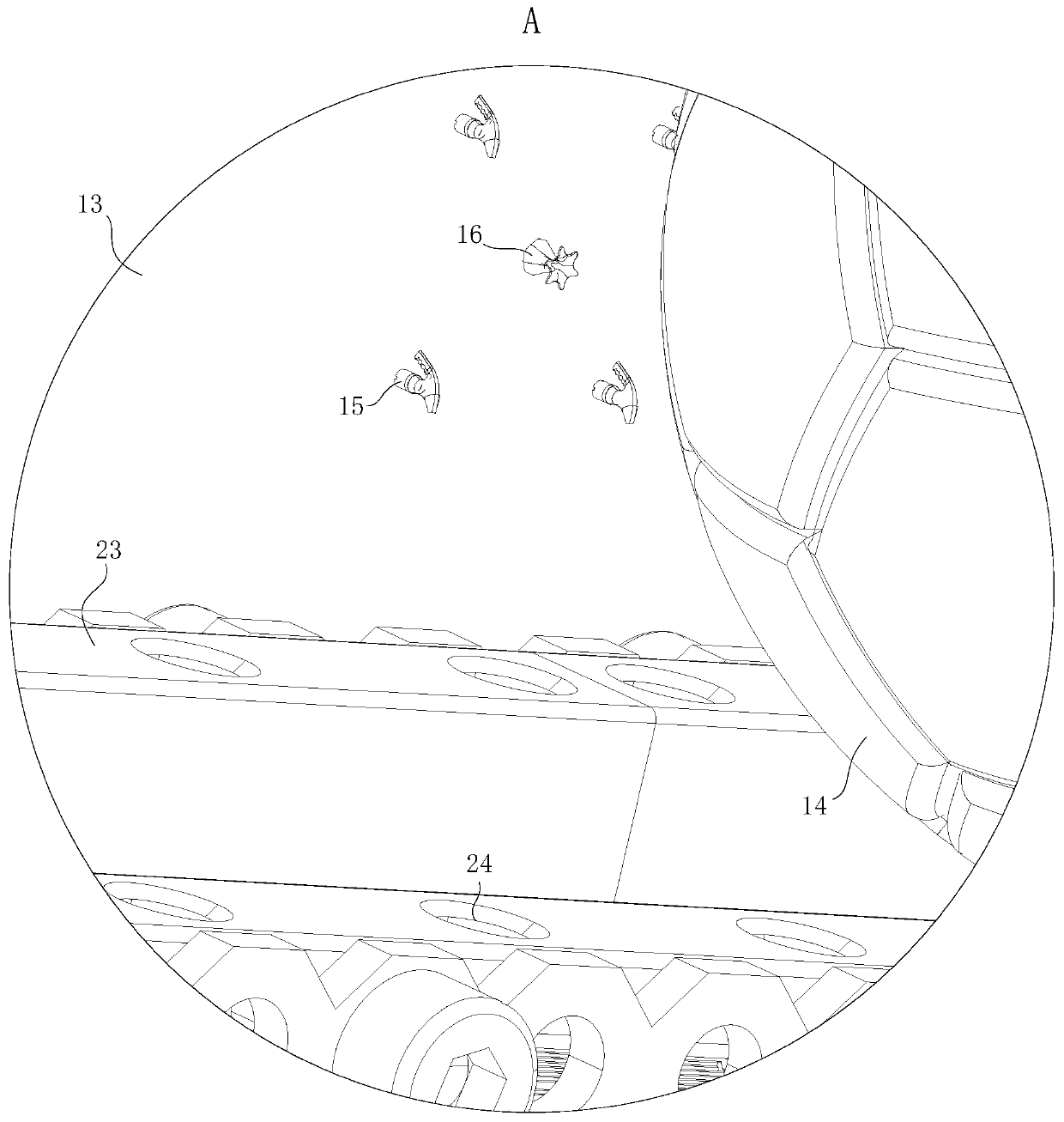

Soccer shooting training equipment for sports

The invention belongs to the technical field of sports equipment, and particularly relates to soccer shooting training equipment for sports. The soccer shooting training equipment comprises a support;one side of the support is fixedly connected with a shooting motor, and a push rod is slidably connected to the support; a driving synchronizing wheel is fixedly connected to the shooting motor, a driven synchronizing wheel is arranged above the driving synchronizing wheel, and the driving synchronizing wheel and the driven synchronizing wheel are connected through a synchronous belt; the drivensynchronizing wheel is rotationally connected to the support, and a rotary plate is fixedly connected to the driven synchronizing wheel; shifting rods are symmetrically arranged on the rotary plate; atop column is fixedly connected to the upper end face of the push rod, and the lower end face of the push rod is fixedly connected with a top plate; a pull rope is fixedly connected between the top plate and the support, and one side of the top plate is provided with a shooting tube; and a water tank is arranged in the shooting tube, and a soccer is arranged in the shooting tube. The soccer can be wetted by the water tank in the shooting tube, thus the scene of shooting in rainy days can be simulated, the situations that a soccer player practices shooting in the rainy days and consequently catches a cold and is accidentally injured can be avoided, and physical safety of the player is ensured.

Owner:JIUJIANG UNIVERSITY

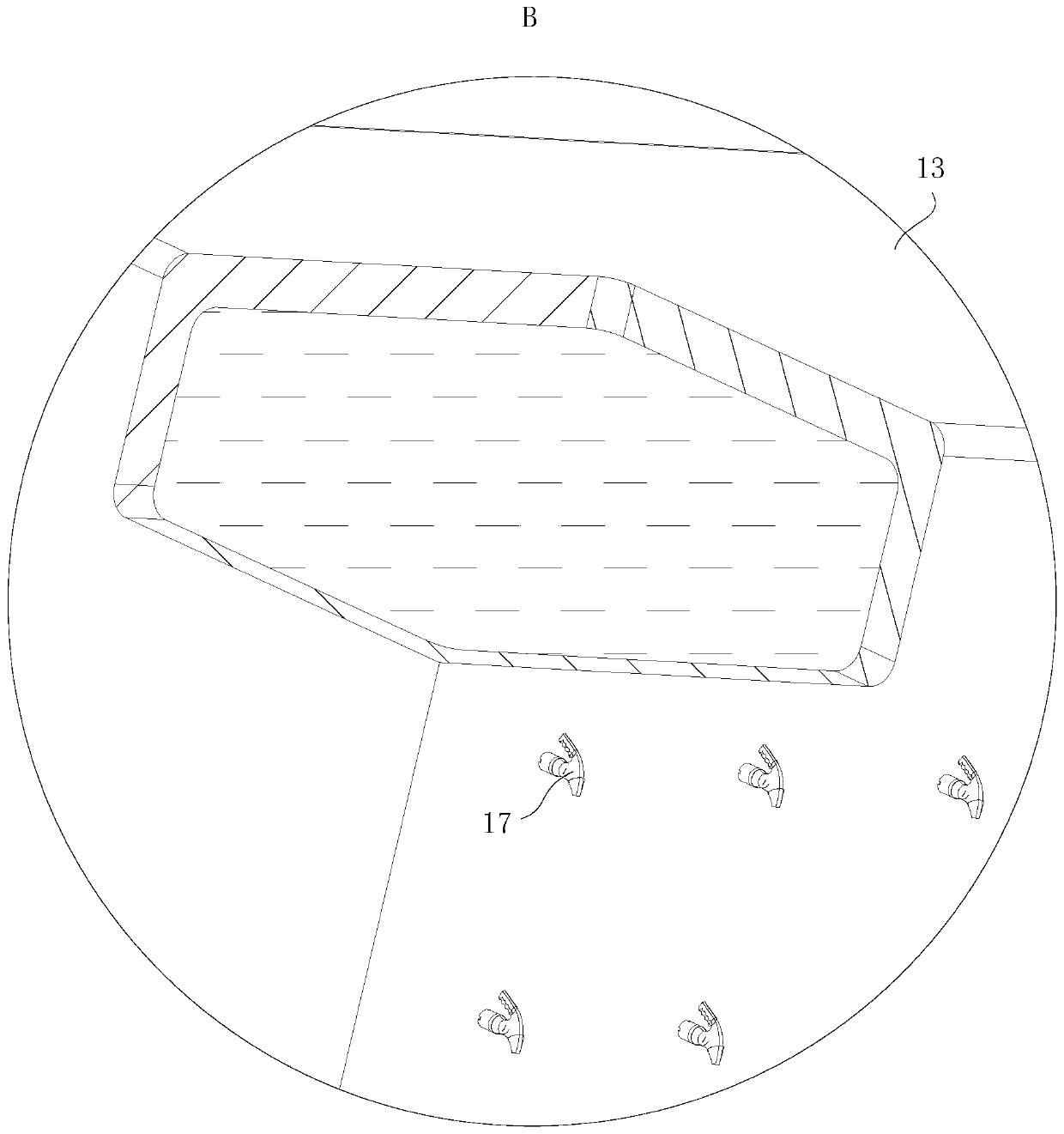

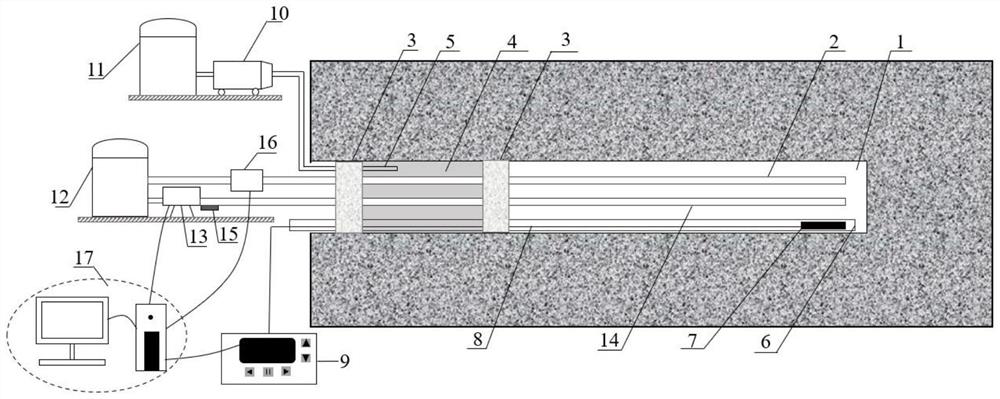

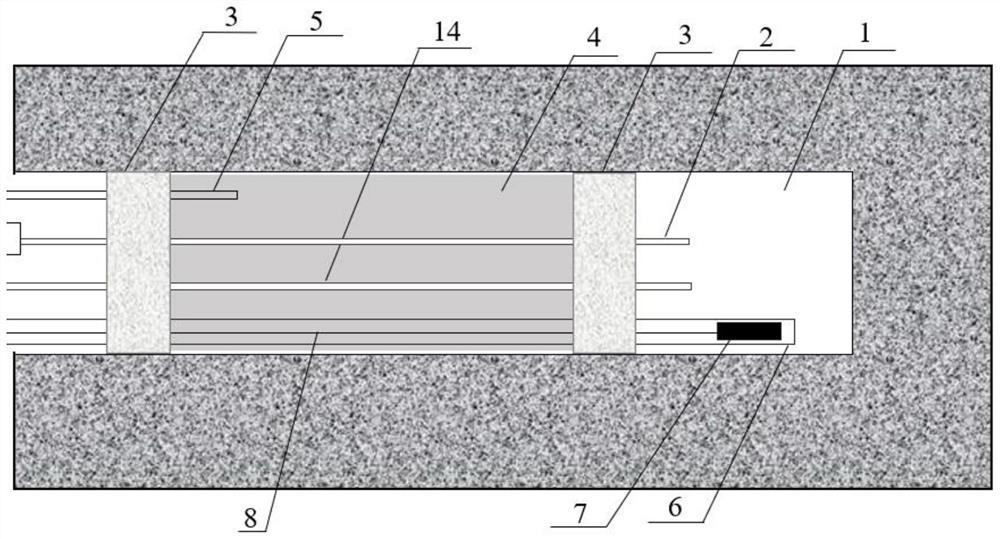

Coal seam water injection system based on integration of fracturing and ultrasonic excitation and operation method thereof

PendingCN114542071AFully moistIncrease moisture contentSurveyDisloding machinesThermodynamicsControl cell

The invention relates to a coal seam water injection system based on integration of fracturing and ultrasonic excitation and an operation method thereof, and the system comprises a hole sealing subsystem, a fracturing subsystem, an ultrasonic excitation subsystem and a control unit, the hole sealing assembly is arranged in a fracturing drill hole of a coal seam to seal the fracturing drill hole and enable the inner side of the fracturing drill hole to form a closed fracturing space. The fracturing subsystem comprises a fracturing pipe, a fracturing pump, a reflux pipe, a reflux pump, a fracturing flow-back fluid treatment station and a pressure monitoring device; the ultrasonic excitation subsystem comprises an ultrasonic generating power supply, an ultrasonic connecting wire and an ultrasonic transducer, and the ultrasonic generating power supply is arranged outside the fracturing drill hole; and the control unit is electrically connected with the pressure monitoring device, the fracturing pump, the reflux pump and the ultrasonic generation power supply. The device is reasonable and compact in structure, fracturing and ultrasonic excitation are combined, water can be effectively driven to enter finer micropores along a fracture network generated by coal fracturing, and therefore the water injection efficiency and the water injection effect are improved.

Owner:SHANDONG UNIV OF SCI & TECH

A method for selectively enriching scandium from Bayer process red mud

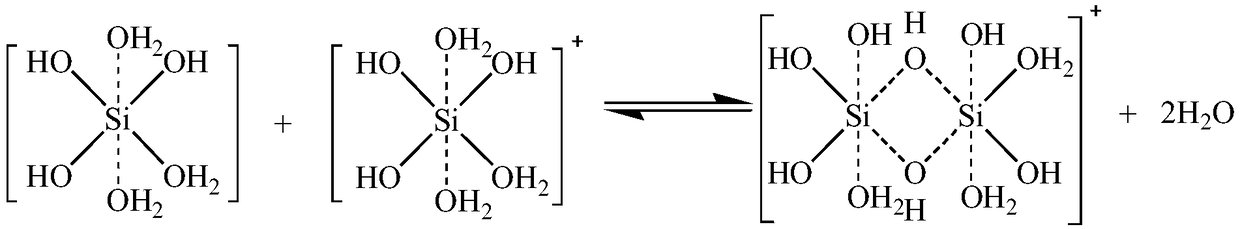

ActiveCN109112293BImprove leaching rateAvoid adsorptionProcess efficiency improvementRed mudSilicic acid

The invention discloses a method for selectively enriching scandium from Bayer process red mud. The method is characterized in that the Bayer process red mud is used as a raw material, the red mud isfully wet by adding an appropriate amount of water, the red mud is sulphated by using concentrated sulfuric acid and is then calcined at a high temperature, the solid calcined product is mechanicallyactivated by grinding and is then subjected to four-stage water immersion and washing, so that a scandium-rich leaching solution, scandium-rich washing liquid and low-alkali iron-rich slag are obtained. The method enables most of scandium to be leached, but the leaching rates of impurity iron and aluminum are low, and silicon and titanium are not leached substantially, so that the formation of colloidal silicate in the leaching solution is avoided, and the selective absorption and extraction of the scandium in the subsequent leaching solution are facilitated; the generated sulfur dioxide and sulfur trioxide can be reused in the preparation of sulfuric acid, so that the production of a large amount of waste acid is avoided; the pH of the low-alkali iron-rich slag is close to neutral, and can be used in the industries such as iron making, adsorbents, ceramics, construction and the like, so that a new way is provided for the extraction of the scandium and the comprehensive utilization ofthe red mud.

Owner:GUANGXI UNIV

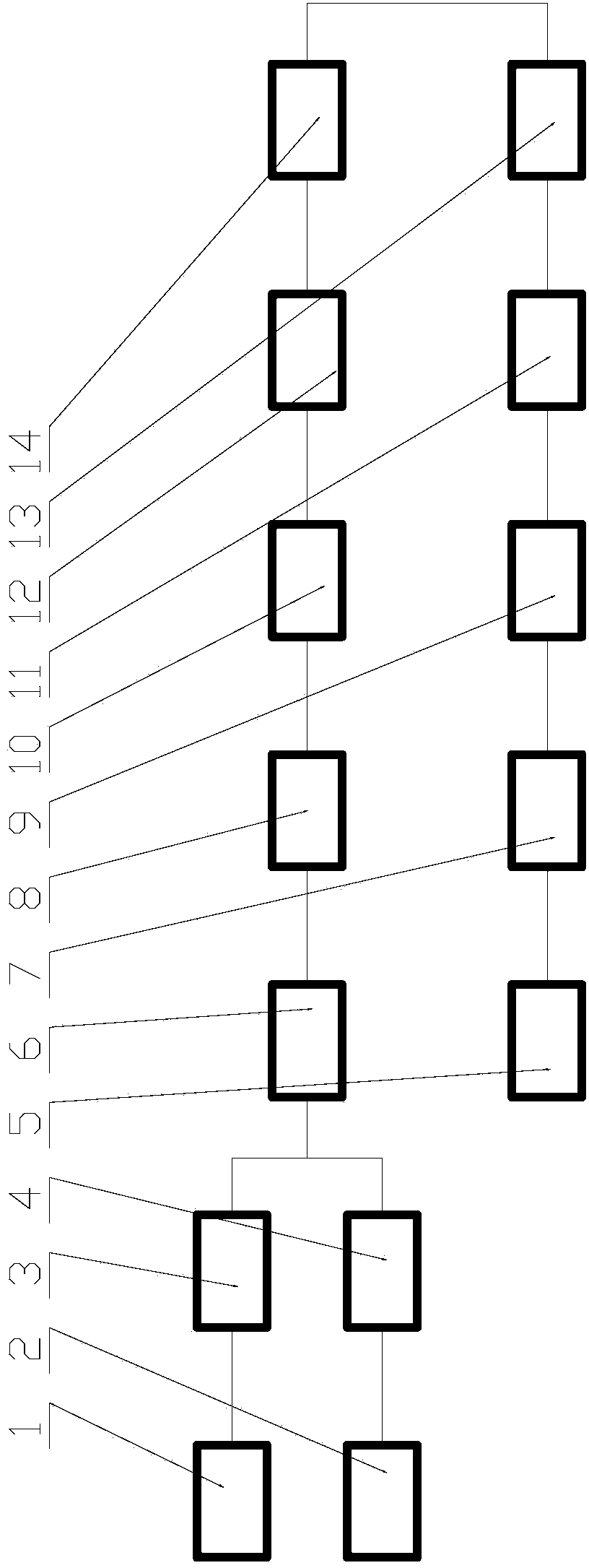

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com