LED support electroplating method and LED support

A technology of LED bracket and coating, which is applied in the direction of jewelry, etc., can solve the problems that affect the overall performance of the coating installed on the LED bracket, the coating thickness is not equal, and the ion replacement speed is uneven, so as to achieve good coverage, molecular density and uniformity, and improve plating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

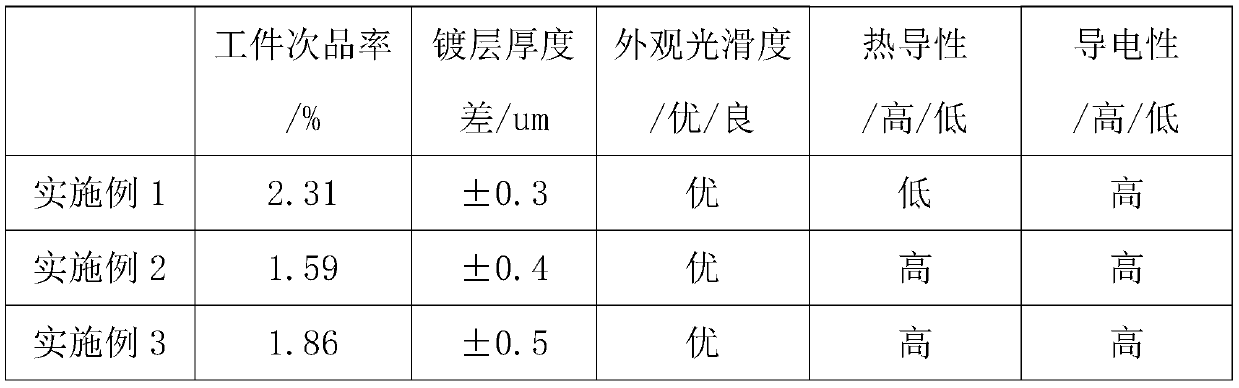

Embodiment 1

[0031] The invention provides a LED bracket electroplating method, the specific steps are as follows:

[0032] Step 1: LED bracket electroplating pretreatment, followed by electrolytic degreasing to remove oil stains and dirt on the surface of the LED bracket substrate, pickling to remove oxides, polishing treatment, high-pressure washing impurities and surface activation Five processes, cleaning the surface of the LED bracket material Dust and impurities, and do a smooth surface treatment, use the hanger to evenly fix the LED bracket material, use the plating flux to activate the surface of the LED bracket material, and set the plating flux to electrolytic activation flux;

[0033] Step 2: First-level electroplating, put the cleaned LED bracket material into the first-level electrolytic pool, and plate the first copper coating in an alkaline environment. After air drying, use a flame gun to evenly spray the surface of the first copper coating to make it tend to melt , after h...

Embodiment 2

[0049] The invention provides a LED bracket electroplating method, the specific steps are as follows:

[0050] Step 1: LED bracket electroplating pretreatment, followed by electrolytic degreasing to remove oil stains and dirt on the surface of the LED bracket substrate, pickling to remove oxides, polishing treatment, high-pressure washing impurities and surface activation Five processes, cleaning the surface of the LED bracket material Dust and impurities, and do a smooth surface treatment, use the hanger to evenly fix the LED bracket material, use the plating flux to activate the surface of the LED bracket material, and set the plating flux to electrolytic activation flux;

[0051] Step 2: First-level electroplating, put the cleaned LED bracket material into the first-level electrolytic pool, and plate the first copper coating in an alkaline environment. After air drying, use a flame gun to evenly spray the surface of the first copper coating to make it tend to melt , after h...

Embodiment 3

[0067] The invention provides a LED bracket electroplating method, the specific steps are as follows:

[0068] Step 1: LED bracket electroplating pretreatment, followed by electrolytic degreasing to remove oil stains and dirt on the surface of the LED bracket substrate, pickling to remove oxides, polishing treatment, high-pressure washing impurities and surface activation Five processes, cleaning the surface of the LED bracket material Dust and impurities, and do a smooth surface treatment, use the hanger to evenly fix the LED bracket material, use the plating flux to activate the surface of the LED bracket material, and set the plating flux to electrolytic activation flux;

[0069] Step 2: First-level electroplating, put the cleaned LED bracket material into the first-level electrolytic pool, and plate the first copper coating in an alkaline environment. After air drying, use a flame gun to evenly spray the surface of the first copper coating to make it tend to melt , after h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com