Shoe material hot-melt adhesive sheet and production process and equipment thereof

A hot-melt film and shoe material technology, applied in insoles, footwear, applications, etc., can solve problems such as insufficient hardness and elasticity, unfavorable automatic production, and environmental pollution of glue, so as to reduce hot pressure and solidification time, and improve the setting effect , The effect of simplifying the adhesion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

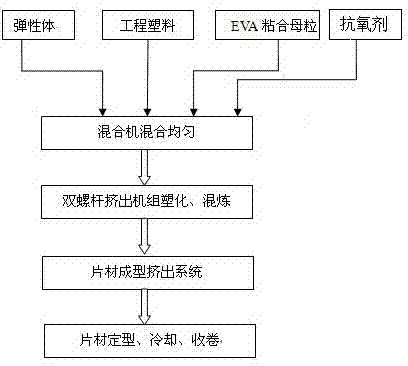

[0048] 1. Weigh the raw materials of each component according to the required ratio: TPU elastomer 38%, PC / ABS alloy 43%, PET 3%, EVA adhesive masterbatch 15%, antioxidant 1%. The EVA adhesive masterbatch is made of various materials, mainly including the following four substances: hot-melt grade EVA 25%, rosin resin 25%, PC / ABS alloy 25%, PU elastomer 25%, and the raw materials are mixed evenly Finally, it is pelletized by an extruder to make EVA adhesive masterbatch.

[0049] 2. Put the weighed raw materials of each component into the high mixer for mixing. The mixing time is 5 minutes, and the speed of the high mixer is 441r / min.

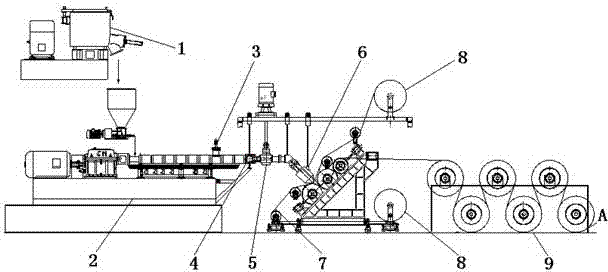

[0050] 3. The raw materials mixed evenly by the high mixer are put into the hopper of the twin-screw extruder, and the raw materials are plasticized and kneaded into a uniform melt in the twin-screw extruder. The barrel temperature of the extruder is set at 170-190°C.

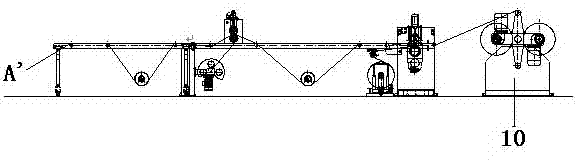

[0051] 4. The melt mixed by the twin-screws flows into the sheet forming ex...

Embodiment 2

[0054] 1. Weigh the raw materials of each component according to the required ratio: TPU elastomer 40%, PC / ABS alloy 45%, PET 4%, EVA adhesive masterbatch 10%, antioxidant 1%. The EVA adhesive masterbatch is made of various materials, mainly including the following four substances: hot-melt grade EVA 25%, rosin resin 20%, PC / ABS alloy 30%, PU elastomer 30%, and the raw materials are mixed evenly Finally, it is pelletized by an extruder to make EVA adhesive masterbatch.

[0055] 2. Put the weighed raw materials of each component into the high mixer for mixing. The mixing time is 5 minutes, and the speed of the high mixer is 441r / min.

[0056] 3. The raw materials mixed evenly by the high mixer are put into the hopper of the twin-screw extruder. The raw materials are plasticized in the twin-screw extruder and mixed into a uniform melt. The temperature of the extruder barrel is set at 170-190 ℃.

[0057] 4. The melt mixed by the twin-screws flows into the sheet forming extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com