Silver copper oxide/copper composite electrical contact material and preparation process thereof

An electric contact material, silver copper oxide technology, applied in the direction of contacts, circuits, electric switches, etc., can solve the problems of high silver content in the contact material and high production cost, and achieve the improvement and reduction of physical and electrical properties Material cost, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

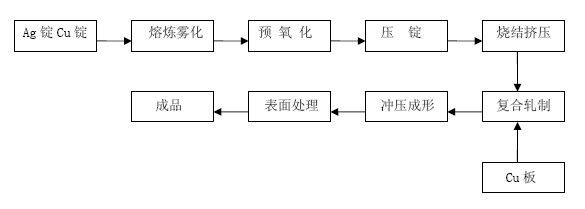

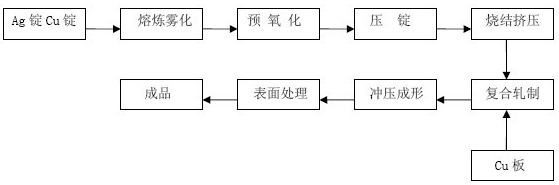

Method used

Image

Examples

Embodiment 1

[0032] The silver oxide copper working layer of this embodiment is as follows through the mechanical industry electrical material product quality supervision and inspection center performance index detection: density: 9.86g / cm3,

[0033] Hardness (HB): 82.3,

[0034] Resistivity: 2.29μΩcm,

[0035] Metallographic structure: The distribution of particles in the silver matrix is mainly uniform, without aggregates, inclusions, and pores, the composite working layer is evenly distributed, and there is no leakage of copper matrix materials around the surface.

[0036] Embodiment two:

Embodiment 2

[0038] Adopt the silver copper oxide / copper composite electrical contact that the present invention makes, its silver copper oxide working layer performance index is as follows:

[0039] 1. Density ≥ 9.6g / cm3;

[0040] 2. Hardness (HB) ≥ 70;

[0041] 3. Resistivity ≤ 3.3μΩcm;

[0042] 4. Metallographic structure: uniform particles;

[0043] 5. Bonding strength: There is no gap between the silver copper oxide working layer and the substrate copper bonding surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com