Preparation method of self-humidifying membrane electrode for fuel cell

A fuel cell and self-humidification technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of increasing charge transfer resistance, reducing electrode conductivity, complicated preparation procedures, etc., and reducing electrode conductivity and resistance. effect, excellent performance, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Pretreatment of proton exchange membrane

[0023] Take a 3×3cm Nafion212 proton exchange membrane, first place it in 5wt.% hydrogen peroxide and treat it at 80°C for 1 hour, wash it with distilled water, then treat it in 0.5mol / L sulfuric acid solution for 1 hour, and then use After washing with distilled water, place the treated proton exchange membrane at the center of two pieces of 10×10 cm plexiglass with 2×2 cm holes, and clamp them to prevent shrinkage and deformation during the process of loading the catalyst.

[0024] (2) Preparation of anode hydrophilic catalytic layer

[0025] According to the mass ratio of 6:3:1:500, weigh 4 mg of Pt / C catalyst (40 wt.%, Johnson Matthey), 40 mg of Nafion solution (5 wt.%, DuPont), and 0.67 mg of chitin (aladdin) 1. 0.5 g of isopropanol, ultrasonically oscillated for 30 minutes, sprayed on one side of the proton exchange membrane, and dried in an oven at 75° C. for 3 hours to obtain the anode hydrophilic catalytic layer. ...

Embodiment 2

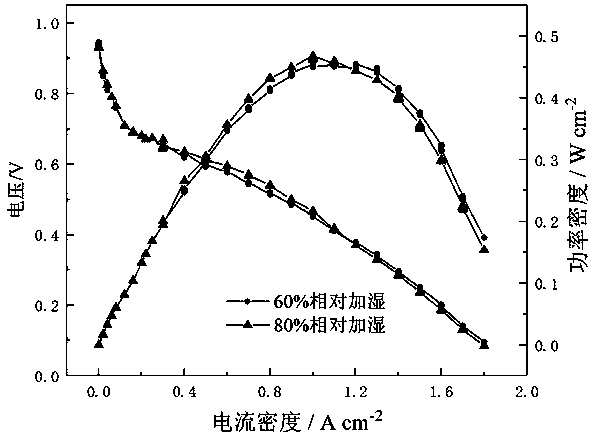

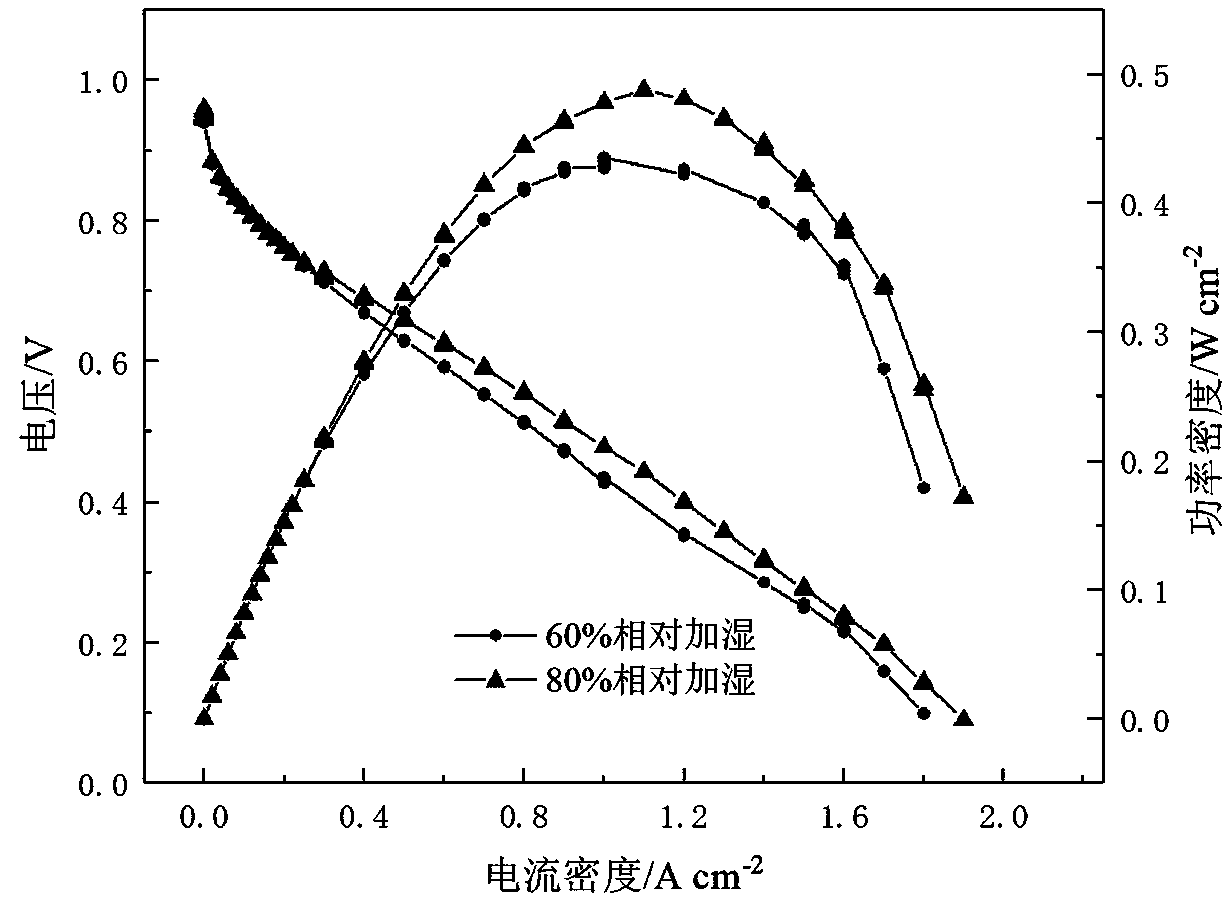

[0031] The amount of chitin added was changed to 30 wt.%, and the rest of the experimental steps and assembly test conditions were the same as in Example 1. Test results such as figure 2 , it can be seen that the highest power density of the battery reaches 435mW / cm when the relative humidity is 60%. 2 ,0.6V current density reaches 597 mA / cm 2 ;The highest power density reaches 480mW / cm at 80% relative humidity 2 , the current density reaches 707 mA / cm at 0.6V 2 .

Embodiment 3

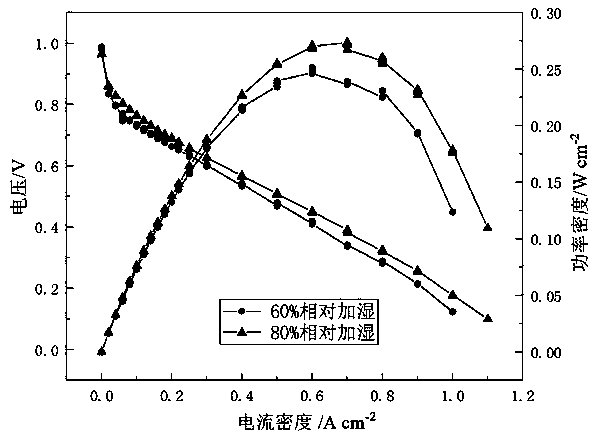

[0033]The amount of chitin added was changed to 20 wt.%, and the rest of the experimental steps and assembly test conditions were the same as in Example 1. The test results show that the highest power density of the battery reaches 459mW / cm when the relative humidity is 60%. 2 ,0.6V current density reaches 611 mA / cm 2 ;The highest power density reaches 469mW / cm at 80% relative humidity 2 ,0.6V current density reaches 628mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com