Laser output system and welding method for simultaneously welding multiple intensive points

An output system and laser technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low welding efficiency, difficulty in spatial arrangement of dense multi-point spots, and difficulty in taking into account the effective welding of pads, etc., to achieve high Efficiency and processing accuracy, solve the problem of compact layout, and realize the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by specific embodiment the present invention is described in further detail:

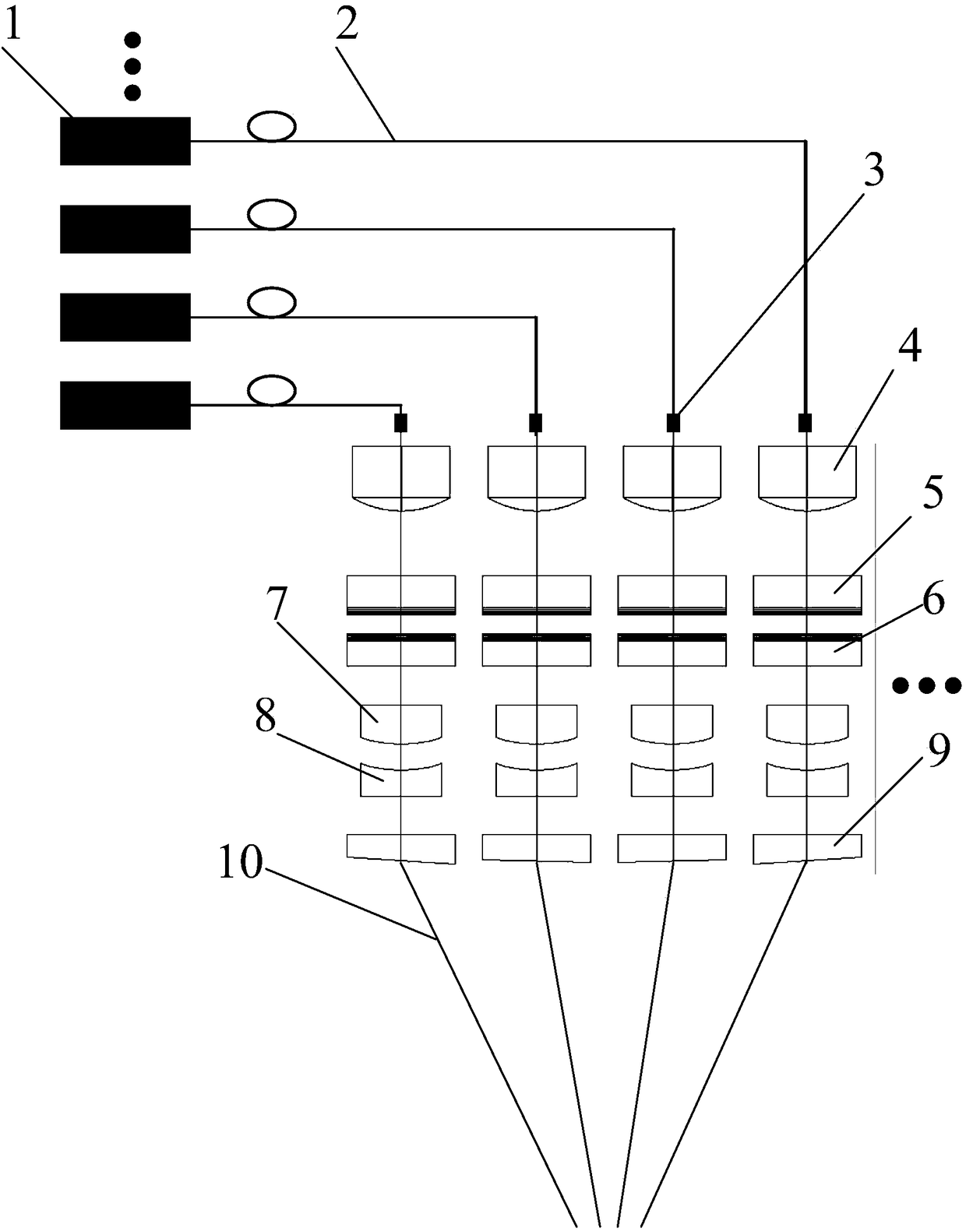

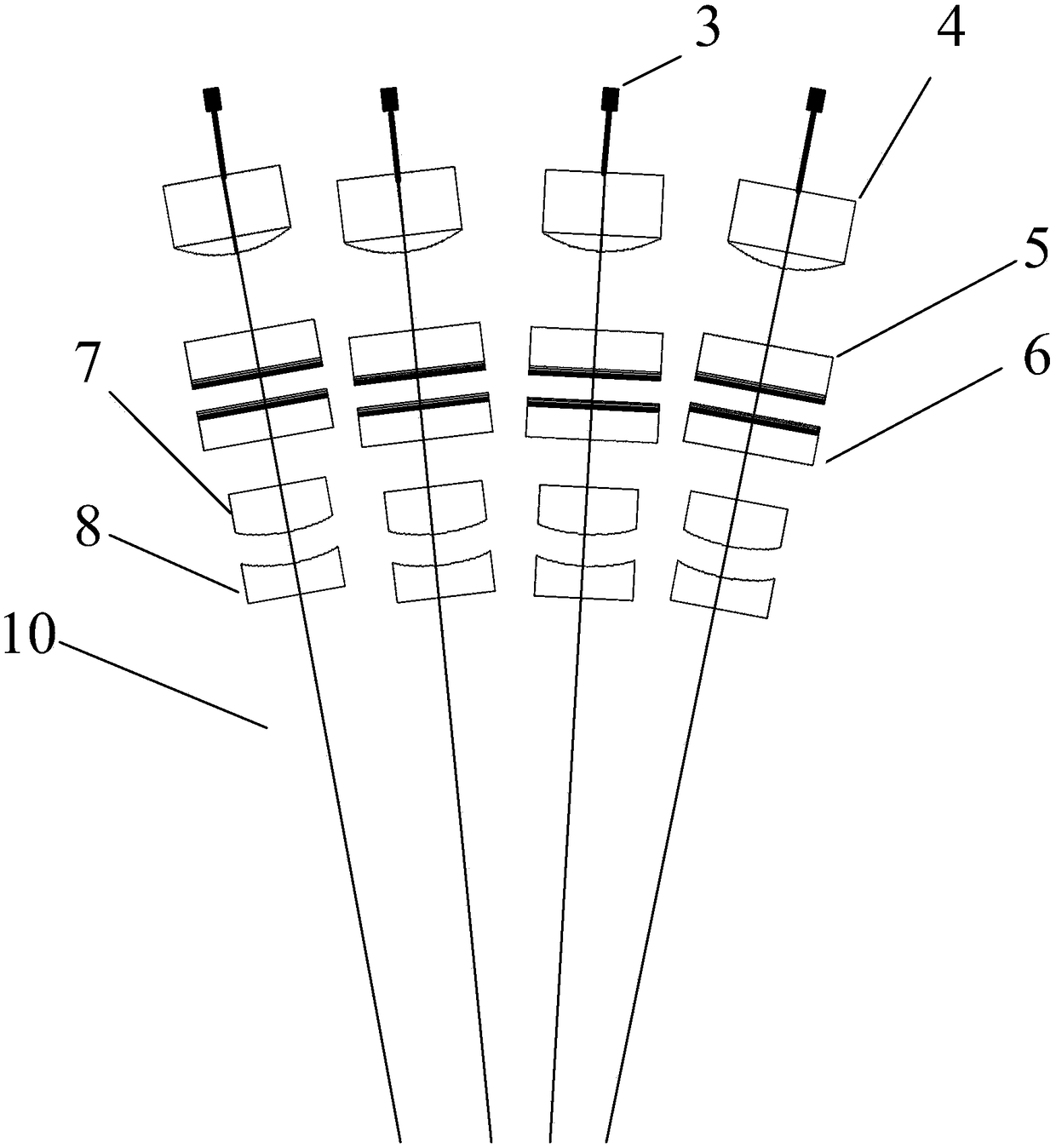

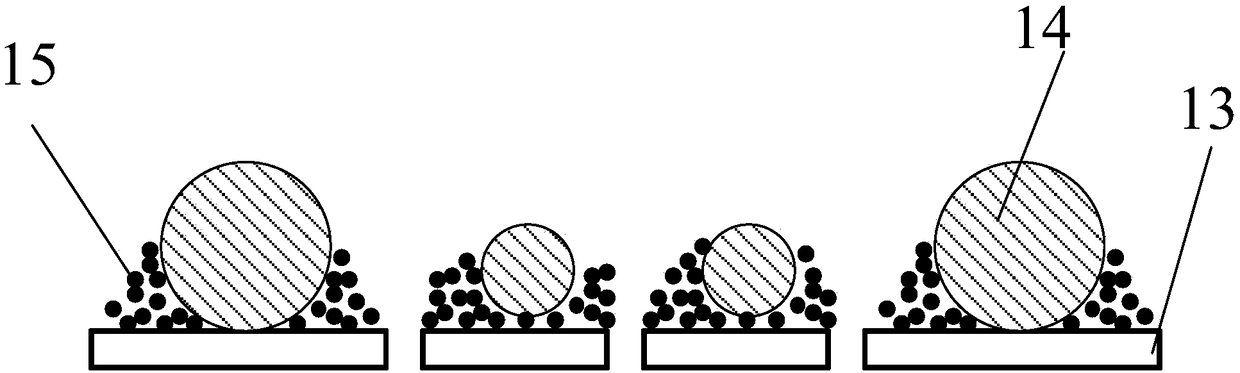

[0032] Such as figure 1 As shown, a laser output system for intensive multi-point simultaneous welding, which includes: multiple optical paths arranged in parallel with the same number of welding pads, wherein each optical path is sequentially provided with a laser light source 1, transmission Optical fiber 2, collimating mirror 4, cylindrical mirror group and wedge mirror 9. Among them, the cylindrical mirror group includes a Y-direction cylindrical mirror group and an X-direction cylindrical mirror group, and the Y-direction cylindrical mirror group includes a Y-direction plano-convex cylindrical mirror 5 and a Y-direction plano-concave cylindrical mirror 6. The mirror group includes an X-direction plano-convex cylindrical mirror 7 and an X-direction plano-concave cylindrical mirror 8 . The cylindrical mirror group in the Y direction is arranged at the front end of the cylindrical m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com