Method and device for cleaning sand gravel

A cleaning device and sand and gravel technology are applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve problems such as failure to meet construction and production requirements, unclean soil washing, etc., and achieve cost saving, Convenient, cost-effective, and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

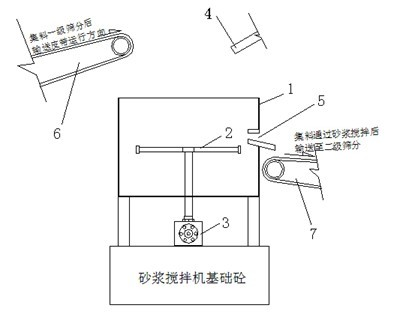

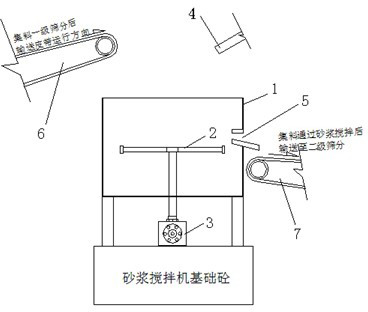

[0010] Embodiments of the present invention: the cleaning method of the present invention is as follows: the fine aggregate sent from the first-level screening conveying equipment 6 falls in the mortar mixer 1, and injects clear water by the water injection port 4 simultaneously, and the stirring arm 2 is in the position of the drive motor 3 Driven and rotated to stir and squeeze the fine aggregate in the water, the soil attached to the gravel is fully wetted and dissolved into the water; when the fine aggregate is piled up to the height of the discharge port 5, it is squeezed out, falls to the secondary screening conveying equipment for screening and washing.

[0011] Cleaning device of the present invention sees figure 1 , the upper left side of the mortar mixer 1 is provided with a primary screening conveying device 6, the upper right side is provided with a water injection port 4, the right side of the body of the mortar mixer 1, and the position above the stirring arm 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com