Plating auxiliary for hot dip aluminum plating and hot dip aluminum plating process for steel structural part

A technology for hot-dip aluminum plating and steel structural parts, which is applied in hot-dip plating process, metal material coating process, coating, etc. Uniformity and other problems, to achieve the effect of smooth coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

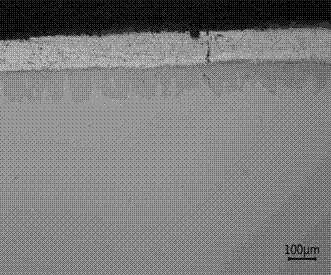

Image

Examples

Embodiment 1

[0036] The hot-dip aluminum plating on the surface of the hot-rolled 35CrMo material adopts the following process:

[0037] 1) Pretreatment: first soak the steel parts in acetone for 10-15 minutes for degreasing treatment and wash with water. Then soak the degreased steel parts in acid solution at 50-80°C for 2-5 minutes for derusting treatment, and then expose the clean surface after washing with water. The acid solution used is a 4:1 mixture of sulfuric acid with a concentration of 15% to 20% and hydrochloric acid with a concentration of 10% to 12%.

[0038] 2) Flux plating treatment: immerse the cleaned steel piece in the flux flux at 80°C for 12 minutes for flux flux treatment, and dry it; the flux flux consists of the following components by weight percentage, 2% NaCl, 4% KF, 2%ZnCl 2 , and the rest is water.

[0039] 3) Hot-dip aluminum plating: dip the dried steel piece into molten aluminum at 780°C for hot-dip aluminum plating, and pull out the steel piece after 6 m...

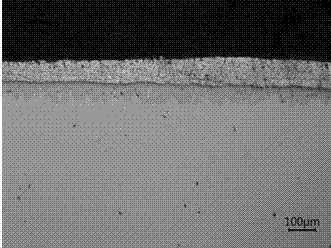

Embodiment 2

[0043] The hot-dip aluminum plating on the surface of the hot-rolled 35CrMo material adopts the following process:

[0044] 1) Pretreatment: first soak the steel parts in acetone for 10-15 minutes for degreasing treatment and wash with water. Then soak the degreased steel parts in acid solution at 50-80°C for 2-5 minutes for derusting treatment, and then expose the clean surface after washing with water. The acid solution used is a 4:1 mixture of sulfuric acid with a concentration of 15% to 20% and hydrochloric acid with a concentration of 10% to 12%.

[0045] 2) Flux treatment: immerse the cleaned steel piece in the flux at 78°C for 15 minutes for flux treatment, and dry it; the flux consists of the following components by weight percentage, 1.5% NaCl, 3.8% KF, 1.8%ZnCl 2 , and the rest is water.

[0046] 3) Hot-dip aluminizing: dip the dried steel piece into molten aluminum at 700°C for hot-dip aluminizing, and pull out the steel piece after 8 minutes; the pulling speed i...

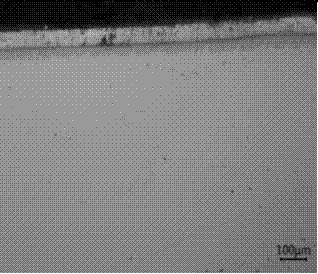

Embodiment 3

[0049] The hot-dip aluminum plating on the surface of the hot-rolled 35CrMo material adopts the following process:

[0050] 1) Pretreatment: first soak the steel parts in acetone for 10-15 minutes for degreasing treatment and wash with water. Then soak the degreased steel parts in acid solution at 50-80°C for 2-5 minutes for derusting treatment, and then expose the clean surface after washing with water. The acid solution used is a 4:1 mixture of sulfuric acid with a concentration of 15% to 20% and hydrochloric acid with a concentration of 10% to 12%.

[0051] 2) Flux treatment: immerse the cleaned steel piece in the flux at 82°C for 10 minutes for flux treatment, and dry it; the flux consists of the following components by weight percentage, 3% NaCl, 5.2% KF, 2.5%ZnCl 2 , and the rest is water.

[0052] 3) Hot-dip aluminizing: dip the dried steel piece into molten aluminum at 780°C for hot-dip aluminizing, and pull out the steel piece after 3 minutes; the pulling speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com