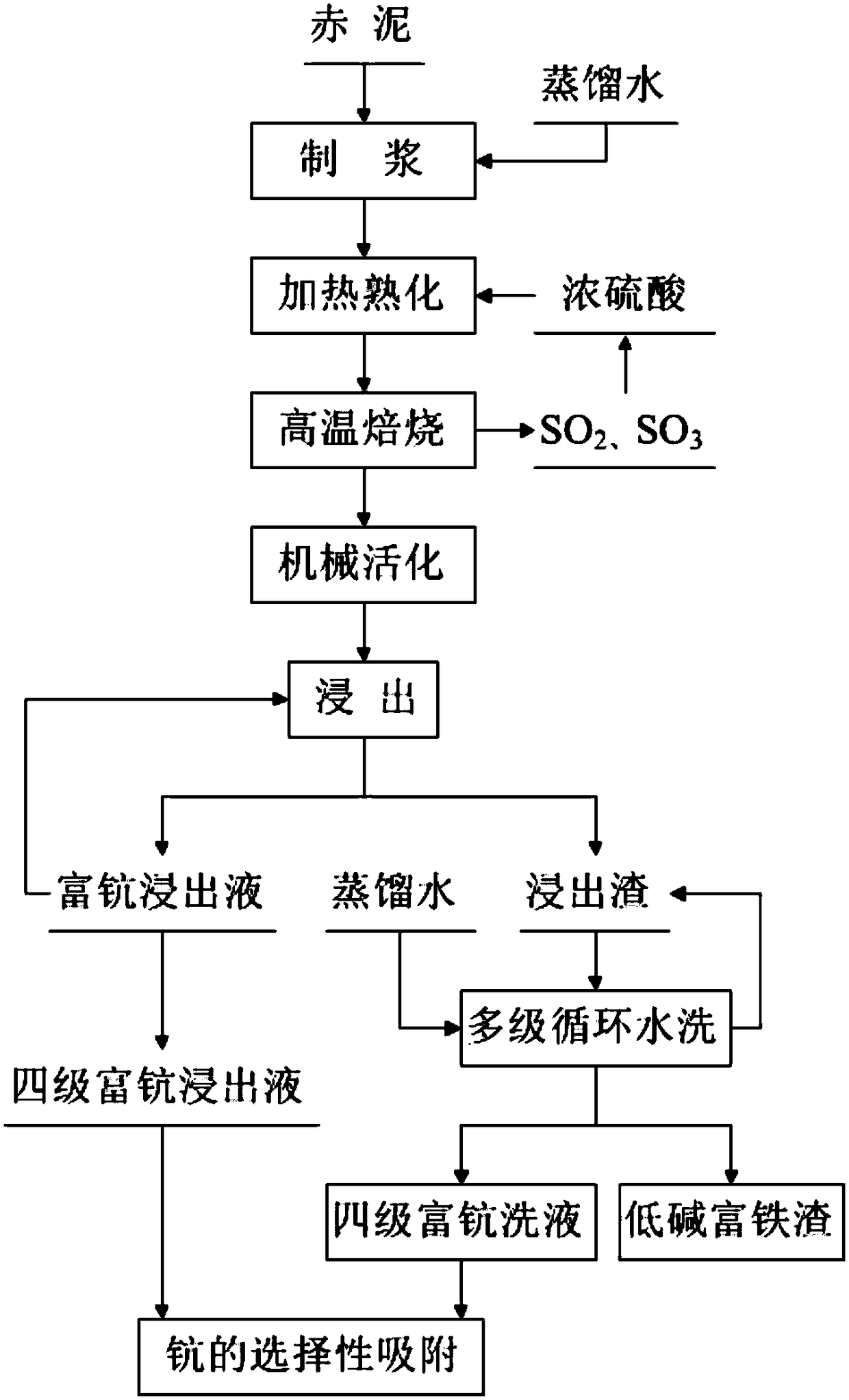

Method for selectively enriching scandium from Bayer process red mud

A Bayer red mud and selective technology, applied in the direction of improving process efficiency, can solve the problems of affecting scandium recovery, increasing costs, and large acid and alkali consumption, so as to reduce the use of sulfuric acid and increase the probability of combination. Effect of adsorption effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The raw material is Bayer red mud, and the main component and mass percentage of red mud are Fe 2 o 3 26.70%, Al 2 o 3 23.46%, CaO 14.66%, SiO 2 11.09%, TiO 2 5.75%, Na 2 O 5.41%, Sc 0.008%.

[0055] ① Dry and finely grind the Bayer process red mud until it is passed through a sample sieve to obtain a solid powder with a particle size of less than 74 μm; add water according to the ratio of water to red mud at 0.5mL / g to fully wet the red mud;

[0056] ②Add concentrated sulfuric acid to the slurry obtained in step ① according to the ratio of concentrated sulfuric acid (95-98% by mass) to red mud at a ratio of 1.0mL / g, and ripen at 100°C for 30 minutes to make the red mud sulphate;

[0057] ③ The red mud sulfation product obtained in step ② is subjected to high-temperature roasting, and the roasting conditions are: roasting temperature 850 ° C, roasting time 60 minutes; obtain a solid roasted product and generate sulfur dioxide and sulfur trioxide;

[0058] ④ Fu...

Embodiment 2

[0068] The raw material is Bayer red mud, and the main component and mass percentage of red mud are Fe 2 o 3 26.70%, Al 2 o 3 23.46%, CaO 14.66%, SiO2 11.09%, TiO 2 5.75%, Na 2 O 5.41%, Sc 0.008%.

[0069] ① Dry and finely grind the Bayer red mud until it passes through a sample sieve to obtain a solid powder with a particle size of less than 74 μm; add water according to the ratio of water to red mud at 0.4 mL / g to fully wet the red mud;

[0070] ②Add concentrated sulfuric acid to the slurry obtained in step ① according to the ratio of concentrated sulfuric acid (95-98%) to red mud at a ratio of 1.5mL / g, and mature at 80°C for 60 minutes to make the red mud sulphate;

[0071] ③ The red mud sulfation product obtained in step ② is subjected to high-temperature roasting, and the roasting conditions are: roasting temperature 825 ° C, roasting time 20 minutes; obtain a solid roasted product and generate sulfur dioxide and sulfur trioxide;

[0072] ④ Fully grind the solid ...

Embodiment 3

[0082] The raw material is Bayer red mud, and the main component and mass percentage of red mud are Fe 2 o 3 26.70%, Al 2 o 3 23.46%, CaO 14.66%, SiO 2 11.09%, TiO 2 5.75%, Na 2 O 5.41%, Sc 0.008%.

[0083] ① Dry and finely grind the Bayer process red mud until it passes through a sample sieve to obtain a solid powder with a particle size of less than 74 μm; add water to fully wet the red mud according to the ratio of water to red mud at 0.8mL / g;

[0084] ②Add concentrated sulfuric acid to the slurry obtained in step ① according to the ratio of concentrated sulfuric acid (95-98%) and red mud at a ratio of 0.75mL / g, and mature at 150°C for 20 minutes to make the red mud sulphate;

[0085] ③ The red mud sulfation product obtained in step ② is subjected to high-temperature roasting, and the roasting conditions are: roasting temperature 800 ° C, roasting time 75 minutes; obtain a solid roasted product and generate sulfur dioxide and sulfur trioxide;

[0086] ④ Fully grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com