Hot blast convected circulation micro-wave oven with steam function

A microwave oven and functional technology, applied in the field of microwave ovens, can solve the problems of increasing the difficulty of installation and increasing costs, and achieve the effects of easy cleaning, low cost and low cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

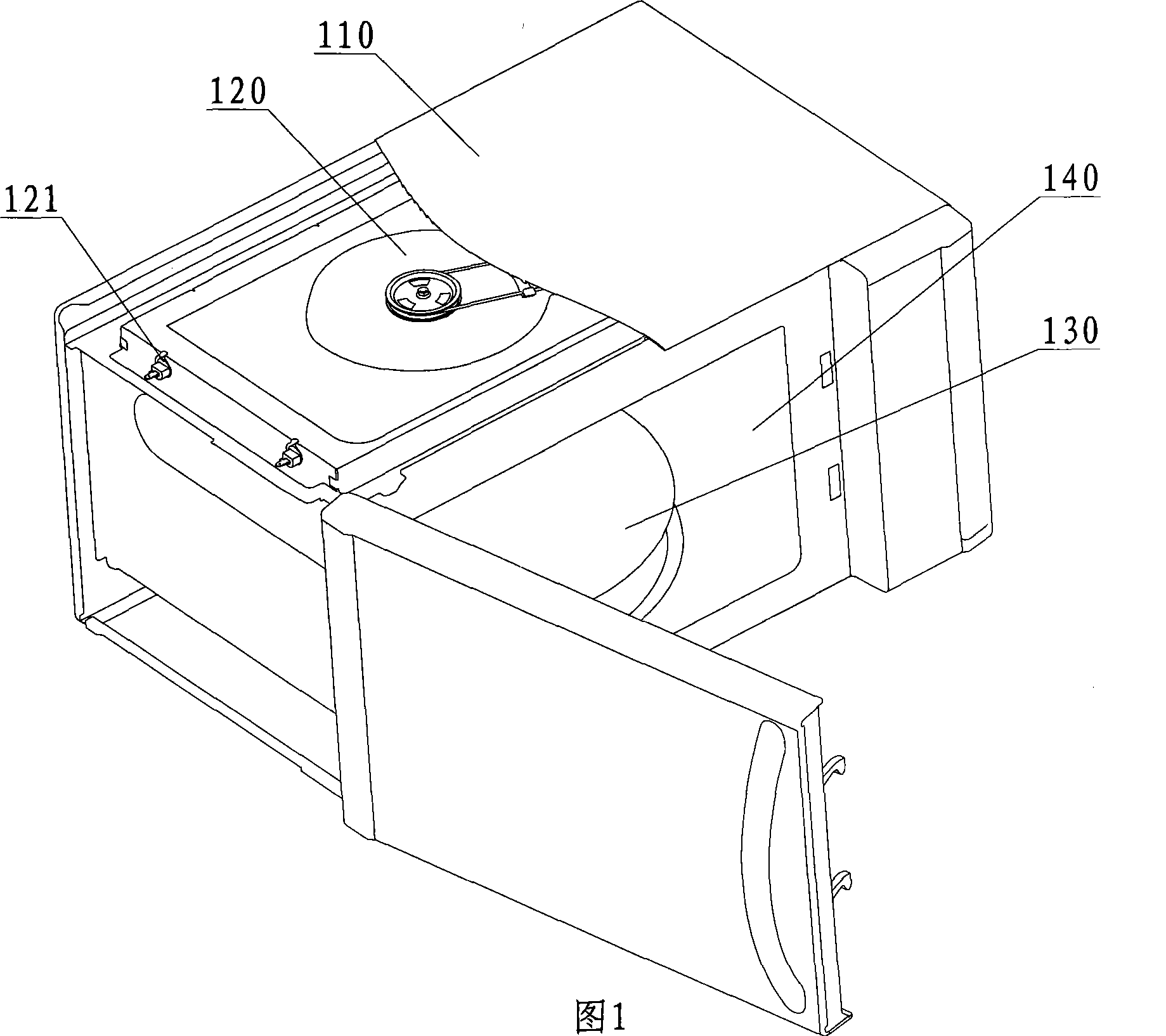

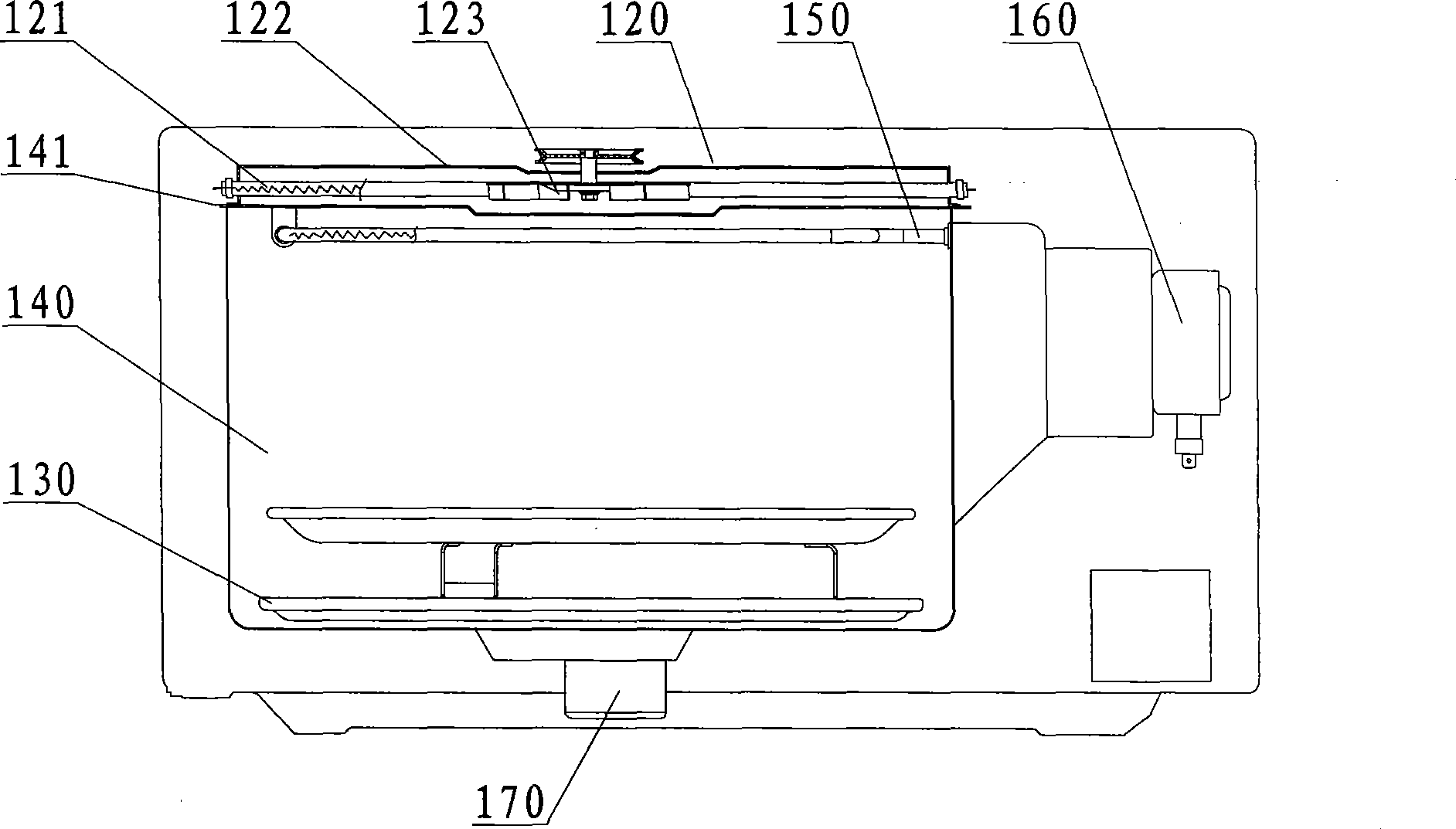

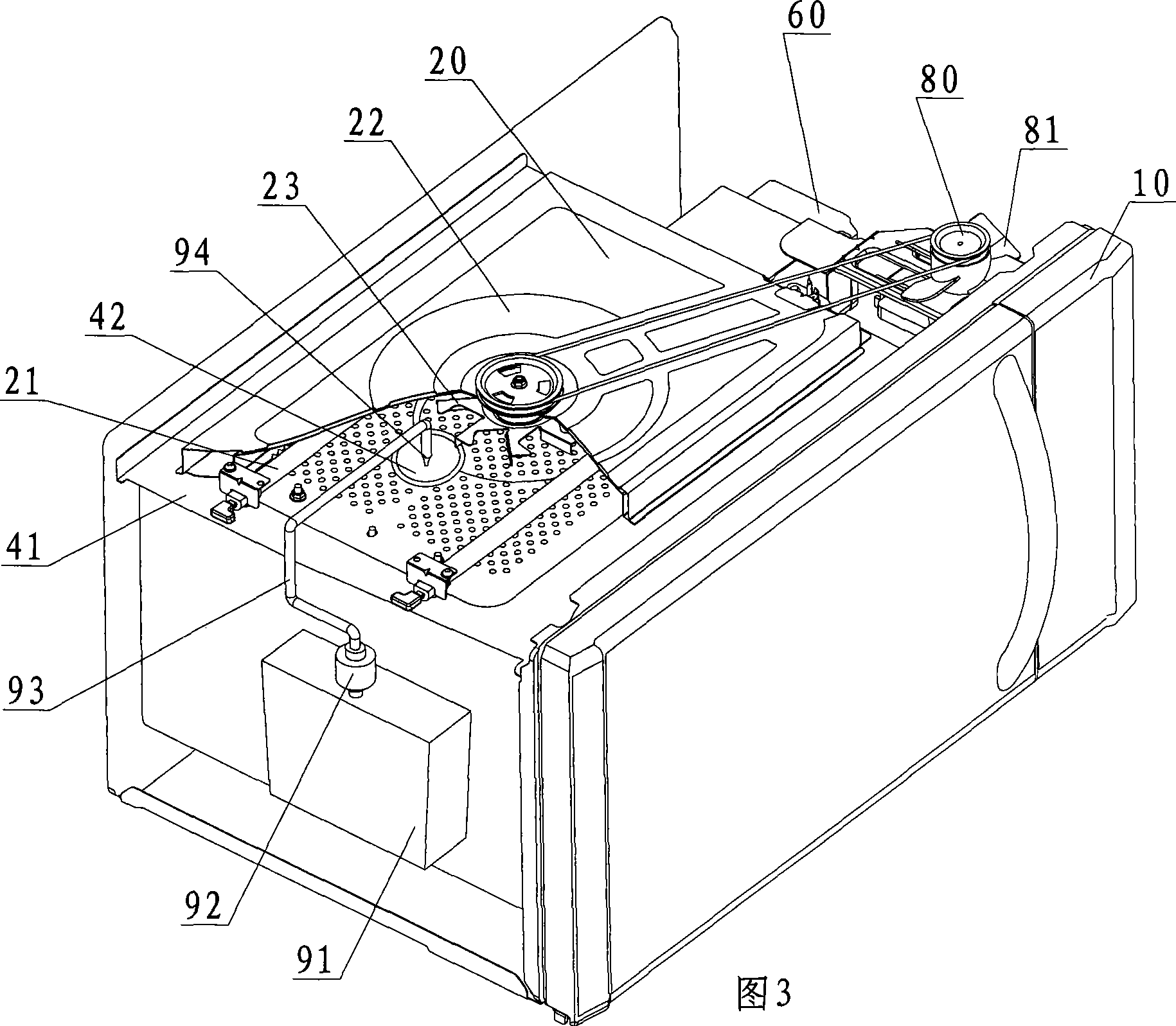

[0020] See Figure 3-- Figure 5 , This hot air convection microwave oven with steam function includes a body of heater 10, an oven cavity 40, a hot air generator 20, a water storage tank 91 and a water pumping pipeline 93. Furnace chamber 40 is arranged in furnace body 10, and hot blast generator 20 is arranged on the top of furnace chamber, and water storage tank 91 is arranged on the left side of furnace chamber, and is connected with suction pipe 93 by water pump 92, and the outlet end of suction pipe is provided with nozzle 94 and Extend vertically into the heating cavity of the hot air generator. The hot air generator 20 includes a heat collecting cover 22, a fan 23 and a heat pipe 21. The bottom surface of the heat collecting cover is connected to the top plate 41 of the furnace chamber, and the inner bottom surface is provided with a fan. Pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com