Dust suppressant for non-hardened pavement as well as preparation and application methods of dust suppressant

An application method and technology of dust suppressant, which is applied in the field of dust suppressant for non-hardened road surfaces, can solve problems such as easy to be washed off by rain or evaporate, hidden safety hazards, muddy road surface, etc., and achieve excellent water-repellent performance and the effect of suppressing dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A dust suppressant for non-hardened pavement, in parts by weight, the raw materials of the dust suppressant include: 163 parts of polypropylene glycol, 16 parts of cetyl alcohol, 10 parts of stearyl alcohol, 10 parts of ethylene glycol 1 part, 1 part of sodium benzoate.

[0033] The preparation method of above-mentioned dust suppressant comprises the following steps:

[0034] The first step, pour the weighed polypropylene glycol, cetyl alcohol, stearyl alcohol, ethylene glycol, and sodium benzoate into the sealed mixing bucket at the same time to form a mixed solution;

[0035] The second step is to raise the temperature of the mixed solution in the mixing tank to 100-110°C, and continue to stir the mixed solution at this temperature for at least four hours until the components in the mixed solution are mutually soluble, and any of the mixed solution The properties of the partial liquid are the same as those of the rest of the mixture;

[0036] The third step is to fi...

experiment Embodiment 1

[0038] The dust suppression effect experiment of the dust suppressant of the present invention sprayed to the non-hardened road surface atomization of one square meter under normal temperature state:

[0039] 1. Select four one-square-meter non-hardened pavements with the same amount of dust, and number each pavement in turn;

[0040] 2. Do not do any treatment on No. 1 road surface; atomize and spray 2.5L clear water on No. 2 road surface; atomize and spray 0.5L dust suppressant prepared according to the method of Example 1 on No. 3 road surface; The dust suppressant prepared according to the method of Example 1 of L;

[0041] 3. After the treatment of the four pavements is completed, after standing for four hours, use the same air volume to blow the four pavements respectively; record the dust effect of each pavement;

[0042] 4. After the four pavements after a dust test, after standing still for 20 hours, use the same air volume to blow the four pavements respectively; re...

experiment Embodiment 2

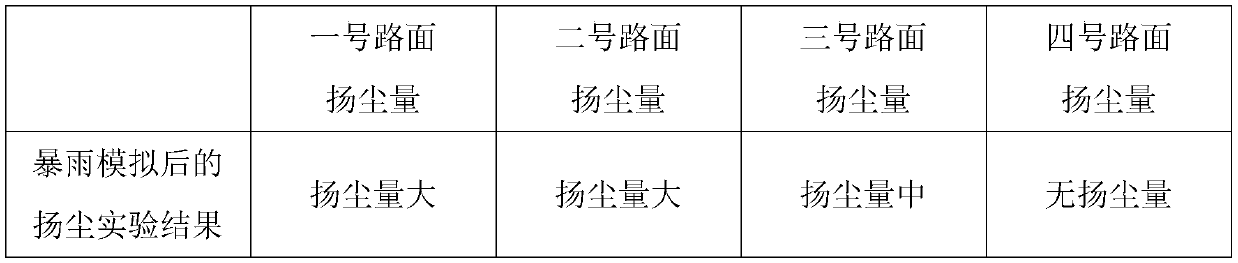

[0052] Dust suppressant of the present invention is sprayed to the muddy effect experiment of one square meter of non-hardened road surface atomization under normal temperature state:

[0053] 1. Select four one-square-meter non-hardened pavements with the same amount of dust, and number each pavement in turn;

[0054]2. Do not do any treatment on No. 1 road surface; atomize and spray 2.5L clear water on No. 2 road surface; atomize and spray 2.5L ordinary dust suppressant on No. 3 road surface; atomize and spray 2.5L on No. 4 road surface according to Example 1 The dust suppressant prepared by the method;

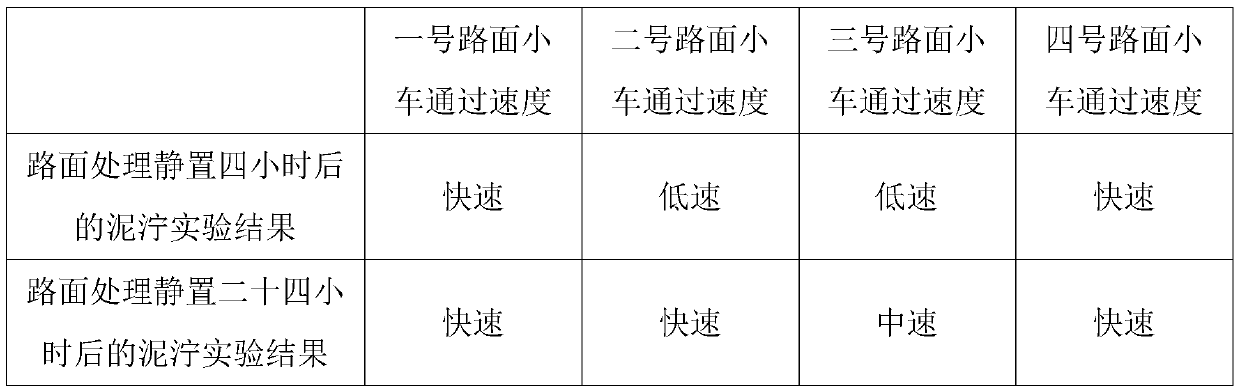

[0055] 3. After the treatment of the four road surfaces is completed, after standing still for four hours, use the toy car to pass through the four road surfaces at the lowest speed on the same path, and record the passing time of the toy car;

[0056] 4. After a mud test, let the four roads stand still for another 20 hours, use the toy car to pass through the four roads a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com