Preparation method of modified coating of carbon fiber surface

A surface modification, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, chemical instruments and methods, etc., can solve the problems of weak interface between carbon fiber and resin matrix, and achieve increased surface roughness and surface energy, fiber adsorption capacity improvement, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

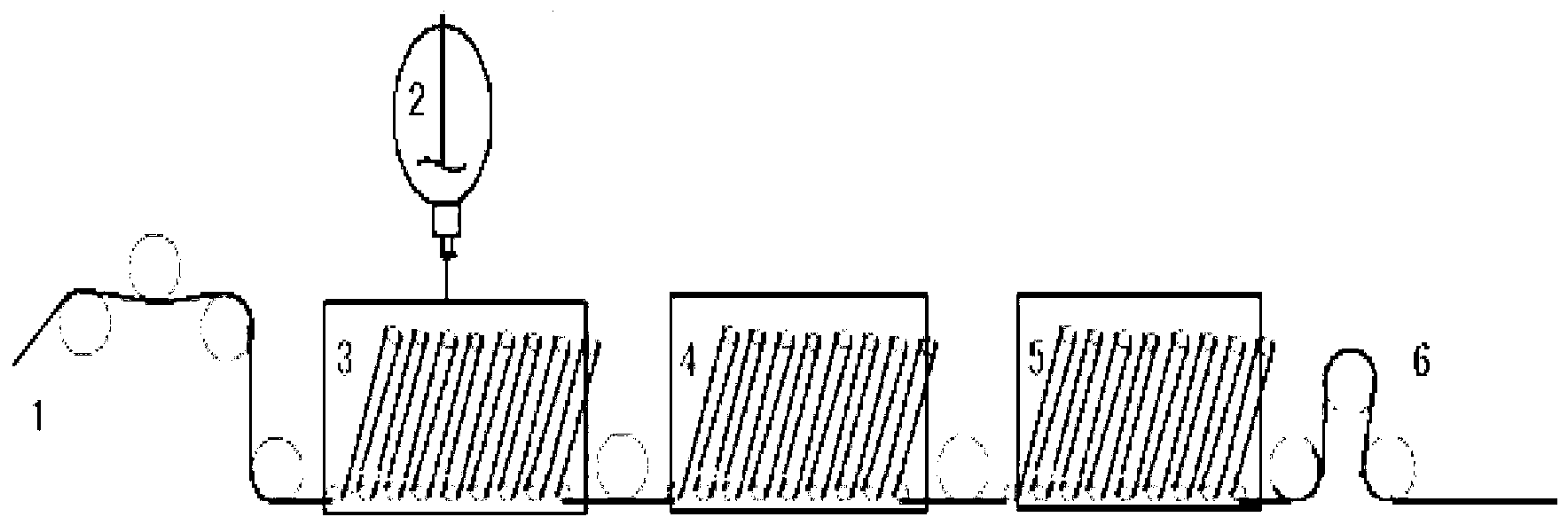

[0020] Specific embodiment one: the preparation method of the carbon fiber surface modification coating of the present embodiment is carried out according to the following steps:

[0021] 1. Pre-polymerization of phenolic resin: In the phenolic resin pre-polymerization reactor, 50 parts of monomeric phenolic compounds, 40-70 parts of aldehyde compounds and 0.5-5 parts of catalyst are mixed in parts by weight. React at 20°C~200°C for 0.01~600min to obtain phenolic resin slurry;

[0022] 2. Coating of phenolic resin slurry: inject the phenolic resin slurry obtained in step 1 into the dipping tank, and then soak the carbon fiber in the dipping tank for 0.01~300min to obtain carbon fiber coated with phenolic resin prepolymer on the surface;

[0023] 3. Curing of phenolic resin: put the carbon fiber coated with phenolic resin prepolymer obtained in step 2 into the high temperature curing reaction chamber, and react for 0.1~300min under the conditions of pressure 0.1~100MPa and temp...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the phenolic compound described in step one is phenol, o-cresol, m-cresol, p-cresol, o-chlorophenol, p-chlorophenol, 1 -A mixture of one or more of naphthol, p-aminophenol and o-aminophenol in any ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the aldehyde compounds described in step one are formaldehyde, n-propionaldehyde, isobutyraldehyde, acetaldehyde, o-phthalaldehyde, cinnamaldehyde, A mixture of one or more of glyoxal, benzaldehyde and o-chlorobenzaldehyde in any ratio. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com