Cleaning device, scrubber and sweeper

A cleaning device and host technology, applied in the direction of carpet cleaning, floor cleaning, cleaning machinery, etc., can solve the problems of leaving traces and reducing the working efficiency of the host, and achieve the effect of good floor cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

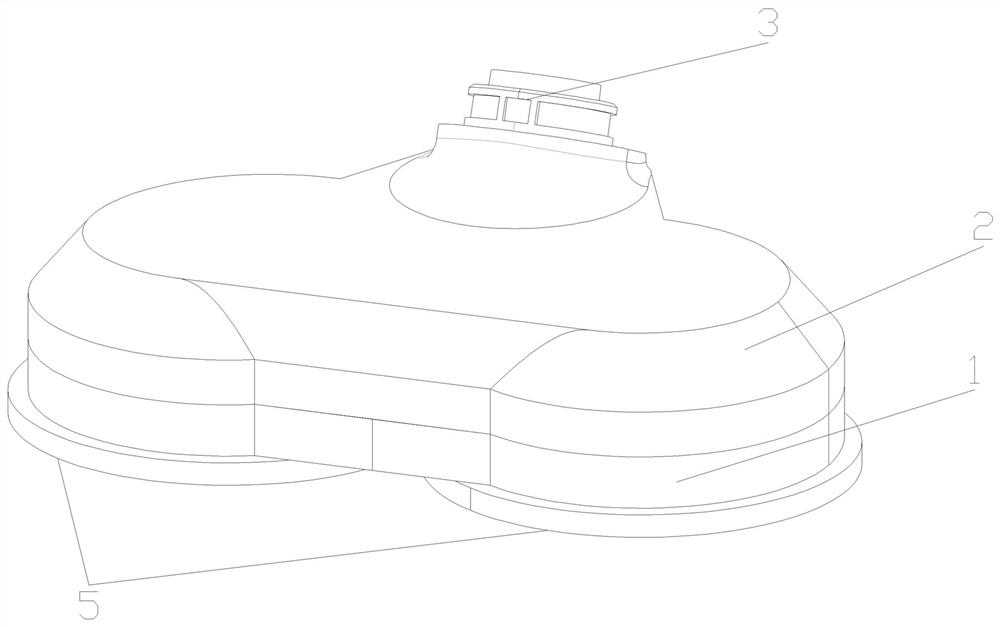

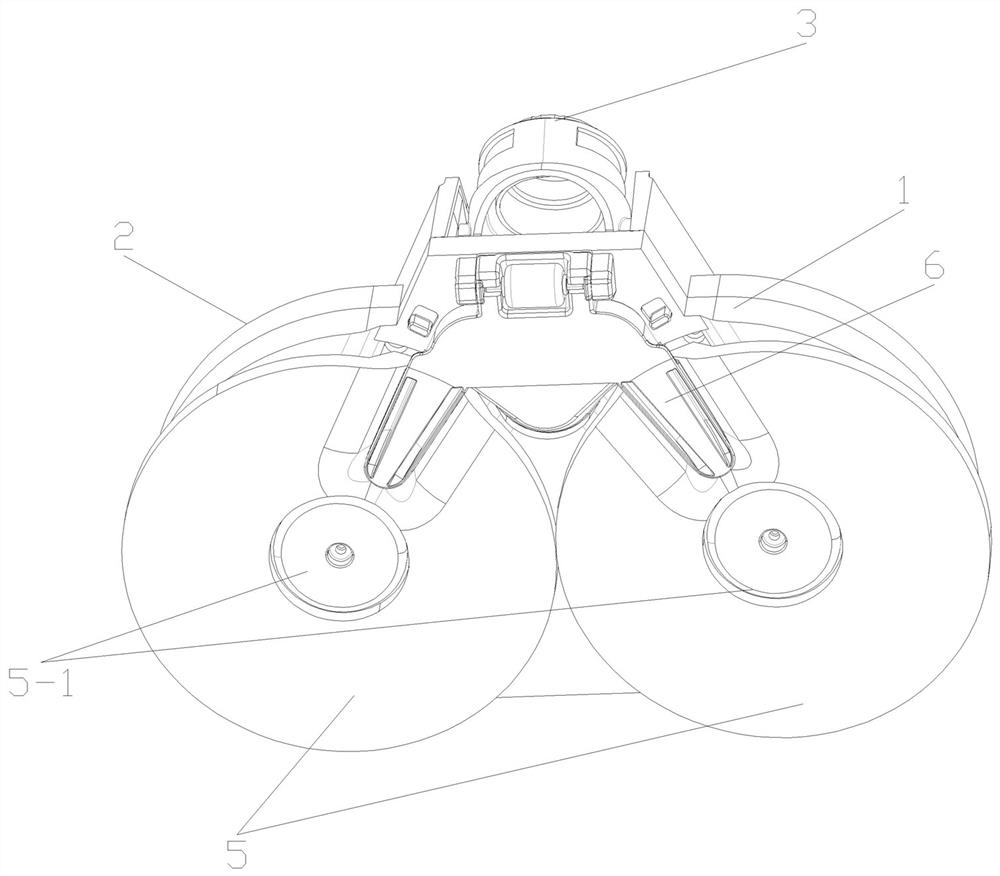

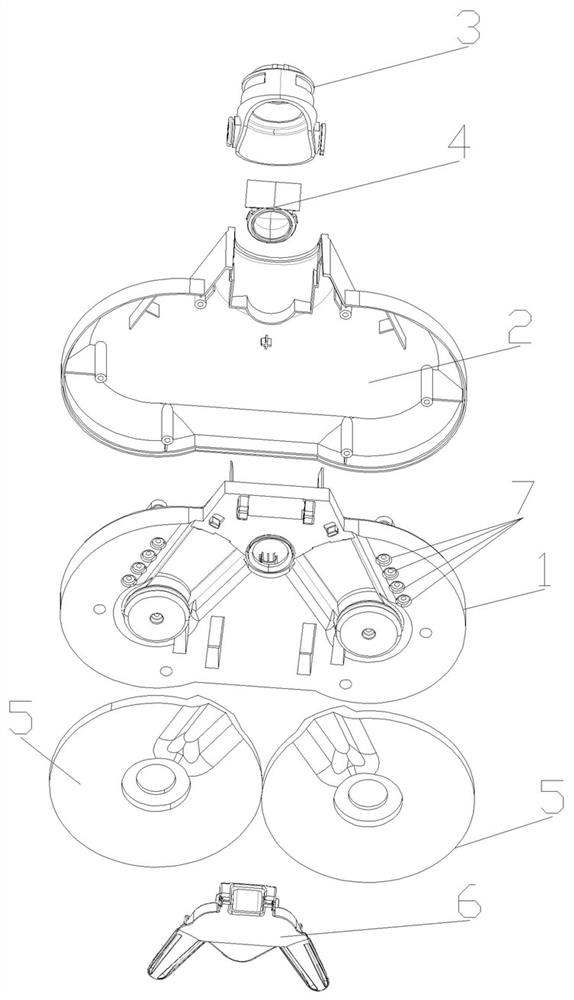

[0034] Such as Figures 1 to 4 As shown in , the cleaning device of the present invention includes a bracket 1, a motor 8 is arranged on the upper side of the bracket 1, and a transmission assembly 9 is arranged on the left and right sides of the motor 8, and the output shaft of the motor 8 is driven by the two left and right transmission assemblies 9. connection, the transmission assembly 9 adopts a worm gear transmission assembly, and an outer cover 2 is also arranged on the bracket 1, and the outer cover 2 is used to cover and protect the structure on the bracket 1; two circular rags 5 are arranged on the lower side of the bracket 1, The centers of the two rags 5 are provided with connecting parts, and the connecting parts are clamping parts 5-1, and the clamping parts 5-1 are clamped on the upper and lower sides of the center of the rags 5, so that the rags 5 are fixed, and the rags 5 The other parts of the other parts do not overlap with the clamping part 5-1, and the two...

Embodiment 2

[0038] The difference between the cleaning device in this embodiment and Embodiment 1 is that the rag rotates in a crawler type, and the position where the working surface 6-1 of the scraper 6 collides with the rag and the position where the water spray port 7 wets the rag are respectively located on the mopping surface of the rag. The two ends of the working surface, the mopping working surface of the rag refers to the plane in contact with the ground on the rag, when the cleaning device in this embodiment works, any point on the rag 5 is wetted by the water spray port 7 at one end of the mopping working surface , and then gradually become dirty during the mopping process. When it moves to the other end of the mopping surface, it is scraped off by the working surface 6-1 of the scraper and squeezed out the sewage, and then leaves the mopping surface, and so on. , to ensure that the rag can be cleaned in time before leaving the ground, and the sewage and solid dirt on the rag w...

Embodiment 3

[0040] The difference between the cleaning device in this embodiment and Embodiment 1 is that the rag moves reciprocatingly relative to the scraper, and the position where the water jet 7 wets the rag is on both sides of the position where the working surface 6-1 of the scraper 6 collides with the rag. , when the cleaning device in the present embodiment works, any point on the rag 5 is scraped off by the working surface 6-1 of the scraper 6 after mopping the floor and squeezed out the sewage, and then immediately wetted by the water spray port 7, After the rag is cleaned, it can better mop the ground, and then the point is cleaned by the scraper during the reverse movement. This cycle ensures that the rag can be cleaned in time, and the sewage and solid dirt on the rag will not fall on the ground. If any point on the rag can be wetted before being squeezed by the scraper, it will help to wash away the dirt on the rag and dilute the sewage on the rag, making the rag easier to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com