Method for preparing aggregates special for pavement asphalt from construction wastes and waste plastics

A technology for waste plastics and construction waste, applied in buildings, roads, roads, etc., can solve the problems of not being able to maximize the utilization of construction waste, achieve good environmental and social benefits, good environmental protection, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

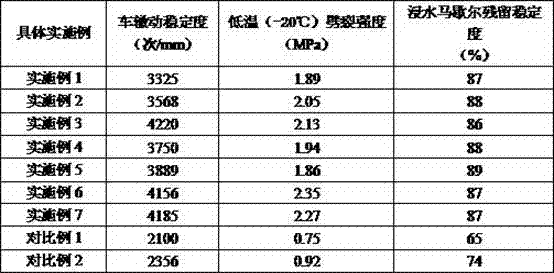

Examples

Embodiment 1

[0031] A method for preparing pavement asphalt special aggregate by using construction waste and waste plastics, the specific process of preparing recycled aggregate is as follows:

[0032] Crush the construction waste so that its outer diameter is not greater than 300mm, and use a metal separator with a sensitivity of not less than 0.5mm for iron, not less than 0.8mm for stainless steel, and not less than 1mm for other metals to separate and remove the metal components. . Then wash it with water for at least 3 times, remove the soil, and obtain construction waste that retains components such as masonry, concrete, wood, and plastic products; then dry it until the moisture content does not exceed 80%, and place it in a special recoil for construction waste In the type pulverizer, double-rotor upper and lower stages are used to pulverize, and the initial recycled aggregate with a particle size of no more than 5mm is obtained; then it is placed in a vertical eccentric device, and...

Embodiment 2

[0035] A method for preparing pavement asphalt special aggregate by using construction waste and waste plastics, the specific process of preparing recycled aggregate is as follows:

[0036] Crush the construction waste so that its outer diameter is not greater than 300mm, and use a metal separator with a sensitivity of not less than 0.5mm for iron, not less than 0.8mm for stainless steel, and not less than 1mm for other metals to separate and remove the metal components. . Then wash it with water for at least 3 times, remove the soil, and obtain construction waste that retains components such as masonry, concrete, wood, and plastic products; then dry it until the moisture content does not exceed 80%, and place it in a special impact machine for construction waste In the pulverizer, the upper and lower stages of double rotors are used to crush to obtain the initial recycled aggregate with a particle size of no more than 5mm; then it is placed in a vertical eccentric device, and...

Embodiment 3

[0039] A method for preparing pavement asphalt special aggregate by using construction waste and waste plastics, the specific process of preparing recycled aggregate is as follows:

[0040] Crush the construction waste so that its outer diameter is not greater than 300mm, and use a metal separator with a sensitivity of not less than 0.5mm for iron, not less than 0.8mm for stainless steel, and not less than 1mm for other metals to separate and remove the metal components. . Then wash it with water for at least 3 times, remove the soil, and obtain construction waste that retains components such as masonry, concrete, wood, and plastic products; then dry it until the moisture content does not exceed 80%, and place it in a special recoil for construction waste In the type pulverizer, double-rotor upper and lower two-stage crushing is used to obtain the initial recycled aggregate with a particle size of no more than 5mm; then it is placed in a vertical eccentric device, which adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com