Manganese tailing water permeable brick and preparation method thereof

A technology of manganese tailings and permeable bricks is applied in the field of manganese tailings permeable bricks and their preparation, which can solve the problems of high cost and unfavorable environmental protection of sintered permeable bricks, and achieve the effects of avoiding high-temperature sintering process, improving the environment and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

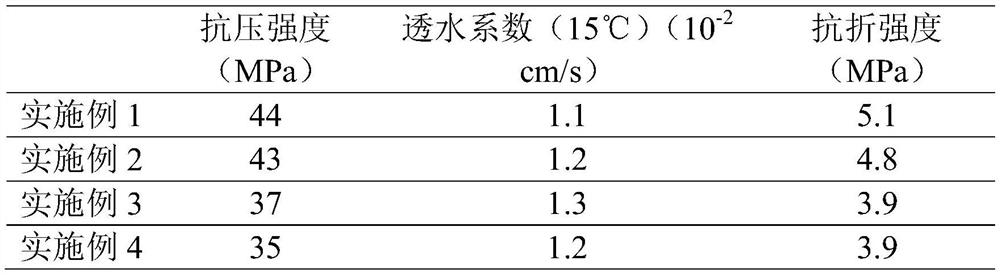

Embodiment 1

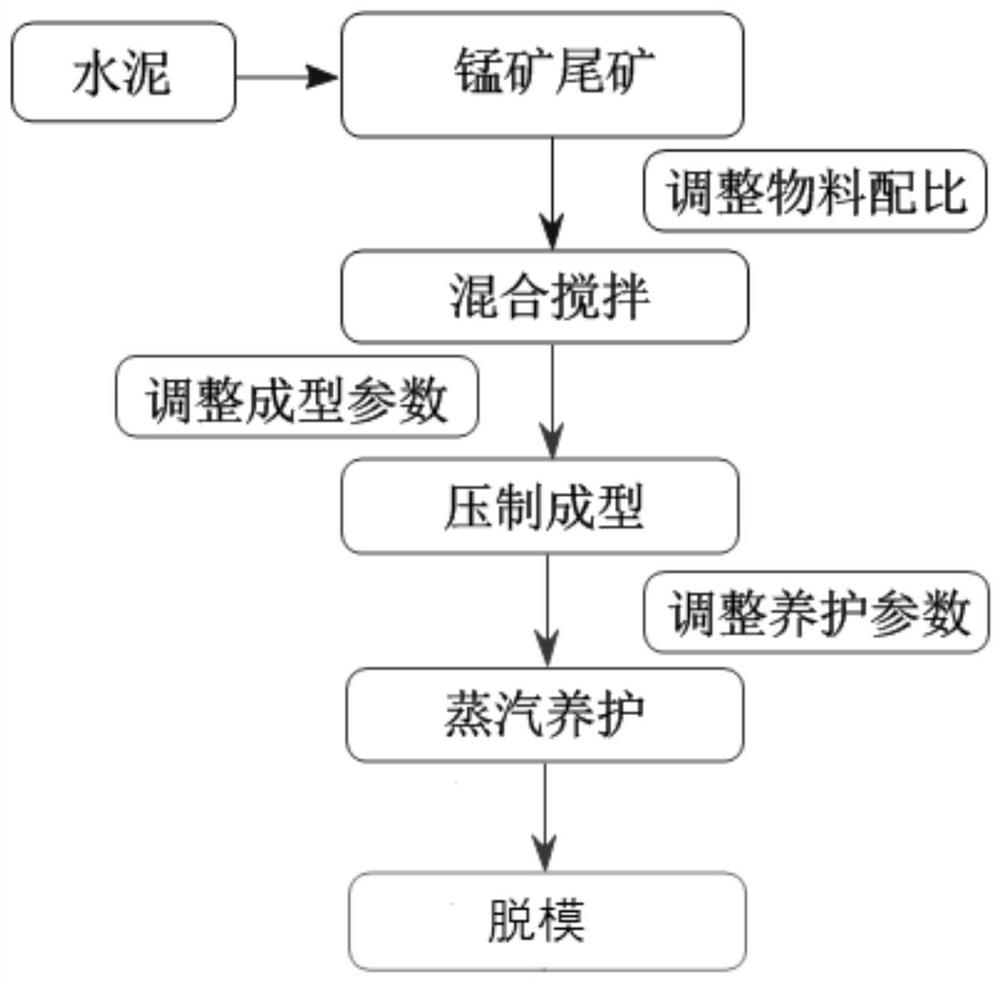

[0028] Such as figure 1 As shown, this embodiment relates to a manganese tailings permeable brick and its preparation method, which consists of the following steps:

[0029] 1) Preparation of the basic blank:

[0030] Select the manganese ore tailings with a particle size of 5mm-10mm (obtained by 3 times of crushing, and remove the part with a particle size smaller than 5mm) as raw materials. The mass parts of each raw material are: 40 parts of manganese tailings, 10 parts of cement, and 15 parts of water The pore-forming agent Al powder is 0.2% by weight of the total weight of each raw material; the manganese tailings, cement and water are mixed and stirred, and the pore-forming agent is added during the stirring process to make a permeable brick base material for subsequent use;

[0031] 2) Permeable brick facing layer blank:

[0032] Select the manganese ore tailings with a particle size of 20 mesh as raw materials, the mass parts of each raw material: 50 parts of mangane...

Embodiment 2

[0038] This embodiment relates to a manganese tailings permeable brick and its preparation method, which consists of the following steps:

[0039] 1) Preparation of base material of permeable brick:

[0040] Select the manganese ore tailings with a particle size of 5mm-10mm (obtained by 3 times of crushing, and remove the part with a particle size smaller than 5mm) as raw materials. The mass parts of each raw material are: 40 parts of manganese tailings, 10 parts of cement, and 15 parts of water The pore-forming agent Al powder is 0.2% by weight of the total weight of each raw material; the manganese tailings, cement and water are mixed and stirred, and the pore-forming agent is added during the stirring process to make a permeable brick base material for subsequent use;

[0041] 2) Permeable brick facing layer blank:

[0042] Select the manganese ore tailings with a particle size of 20 mesh as raw materials, the mass parts of each raw material: 42 parts of manganese tailings...

Embodiment 3

[0048] This embodiment relates to a manganese tailings permeable brick and its preparation method, which consists of the following steps:

[0049] 1) Preparation of base material of permeable brick:

[0050] Select the manganese ore tailings with a particle size of 5mm-10mm (obtained by 3 times of crushing, and remove the part with a particle size smaller than 5mm) as raw materials. The mass parts of each raw material are: 52 parts of manganese tailings, 14 parts of cement, and 19 parts of water The pore-forming agent Al powder is 0.3% by weight of the total weight of each raw material; the manganese tailings, cement and water are mixed and stirred, and the pore-forming agent is added during the stirring process to make a permeable brick base material for subsequent use;

[0051] 2) Permeable brick facing layer blank:

[0052] Select the manganese ore tailings with a particle size of 20 mesh as raw materials, the mass parts of each raw material: 38 parts of manganese tailings, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com