Garland X joint for steel structure building and mounting process of joint

A steel structure and node technology, applied in the direction of building and building structure, can solve problems such as high weather requirements, increased construction costs, building constraints, etc., to improve firmness and stability, prevent deformation, and improve support performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

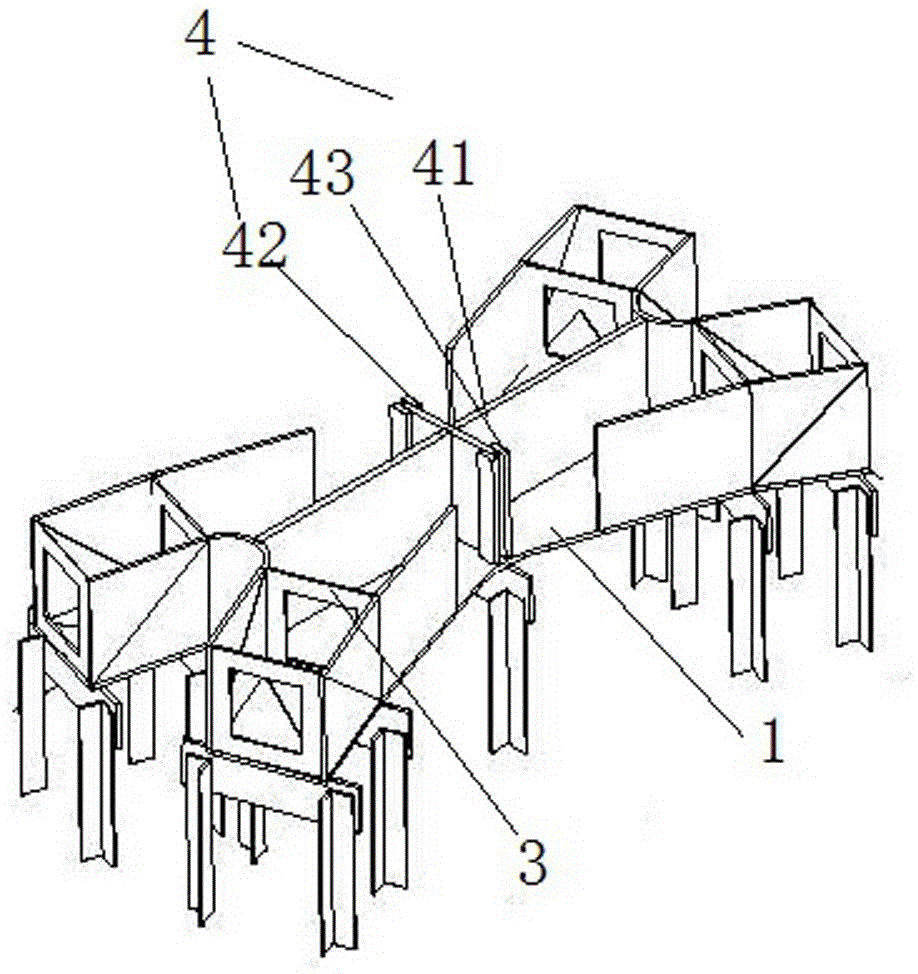

[0036] like figure 1 and figure 2 A garland X joint used in steel structure buildings shown is characterized in that it includes: a lower flange plate 1 and an upper flange plate 2, and the upper flange plate 2 is arranged on the bottom of the lower flange plate 1 above;

[0037] The relationship between the above components is as follows:

[0038] A stiffening plate 3 is provided between the upper flange plate 2 and the lower flange plate 1, a partition plate 4 is arranged in the middle of the stiffening plate 2, and the edge between the upper flange plate 2 and the lower flange plate 1 passes through The web 5 is connected.

[0039] Further, the stiffener 3 is polygonal, and an opening is provided in the middle.

[0040] Further, the stiffener 3 adopts a quadrangular shape, and it cooperates with the lower flange plate 1 and the upper flange plate 2 .

[0041] Further, the partition 4 is composed of a transverse partition 41 and a longitudinal partition 42, and the tra...

Embodiment 2

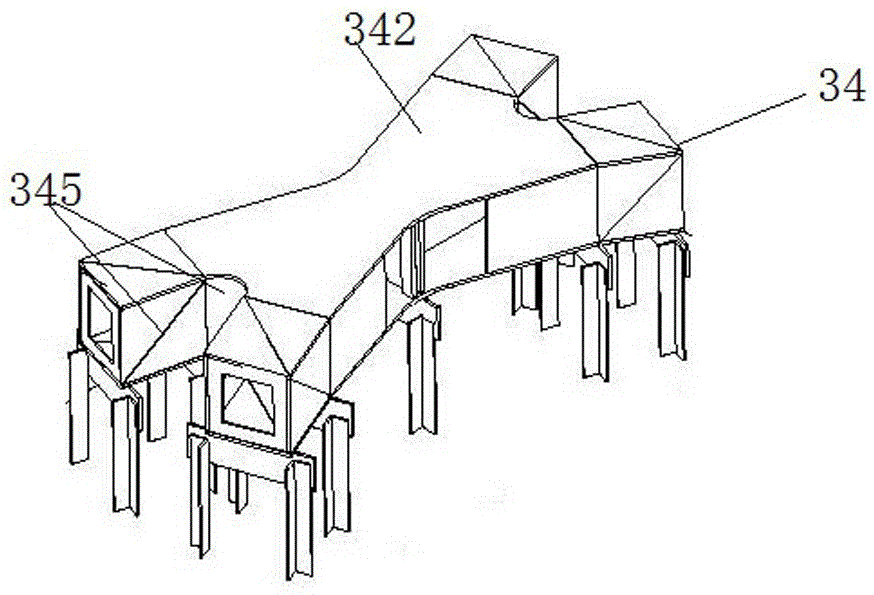

[0046] like figure 1 and figure 2A garland X joint used in steel structure buildings shown is characterized in that it includes: a lower flange plate 1 and an upper flange plate 2, and the upper flange plate 2 is arranged on the bottom of the lower flange plate 1 above;

[0047] The relationship between the above components is as follows:

[0048] A stiffening plate 3 is provided between the upper flange plate 2 and the lower flange plate 1, a partition plate 4 is arranged in the middle of the stiffening plate 2, and the edge between the upper flange plate 2 and the lower flange plate 1 passes through The web 5 is connected.

[0049] Further, the stiffener 3 is polygonal, and an opening is provided in the middle.

[0050] Further, the stiffener 3 adopts a quadrangular shape, and it cooperates with the lower flange plate 1 and the upper flange plate 2 .

[0051] Further, the partition 4 is composed of a transverse partition 41 and a longitudinal partition 42, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com