Novel light-emitting diode (LED) lamp

A technology of LED lamps and LED chips, applied in the field of lighting, can solve the problems of large power supply, constant color, difficulty in making special-shaped lamps, etc., and achieve the effect of flexible and changeable appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

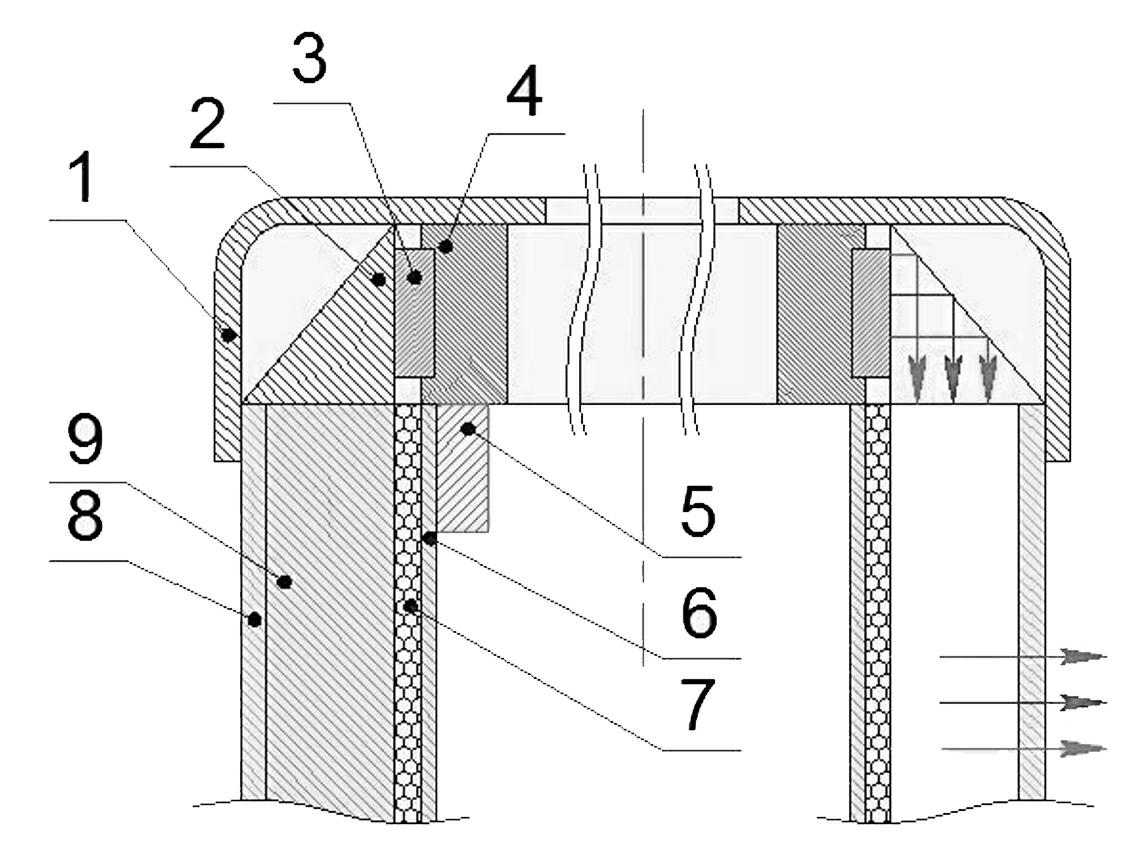

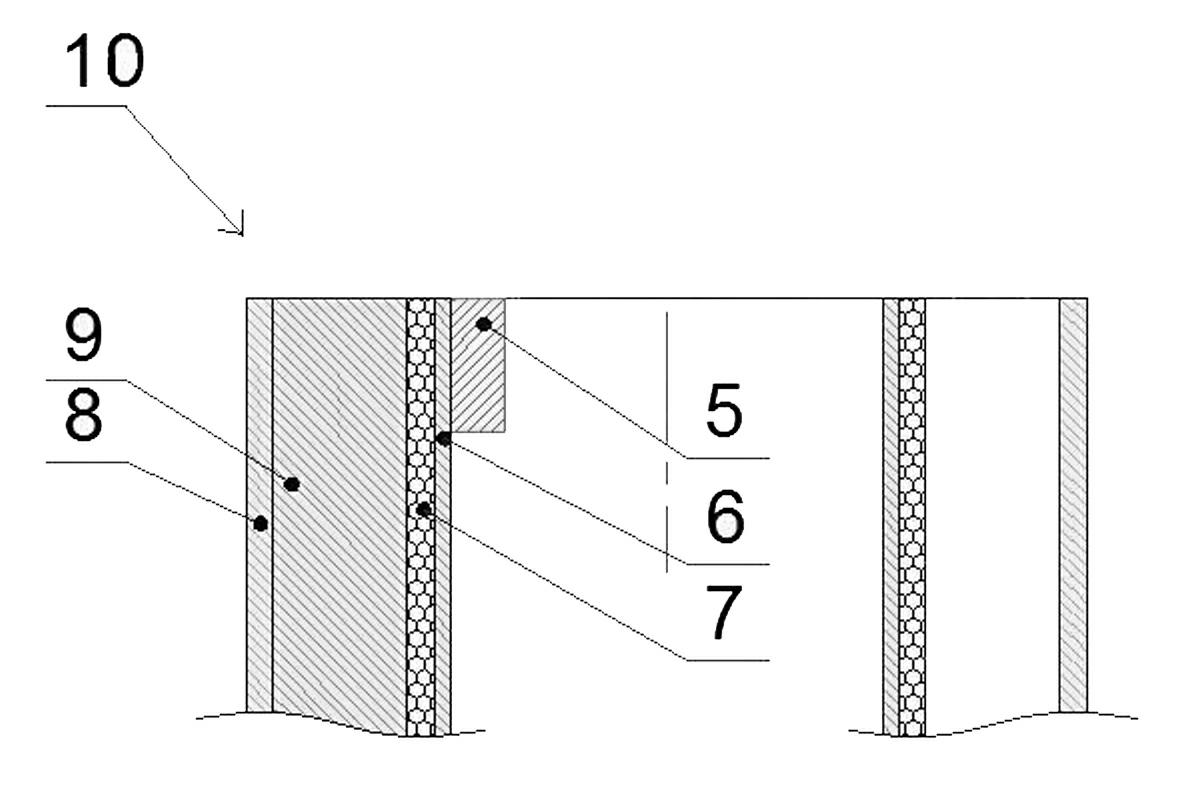

[0031] Such as figure 1 with 2 A new type of LED lamp is shown, which includes an LED chip 3 , a baseband 4 , a uniform light guide body 10 , and a prism 2 . The baseband 4 is an aluminum substrate or a soft copper-clad sheet, and the LED chips 3 are welded on the baseband 4 by reflow soldering. The LED chips 3 on the baseband 4 are closely connected and connected in series or in parallel. Arrows in the figure indicate the direction of light.

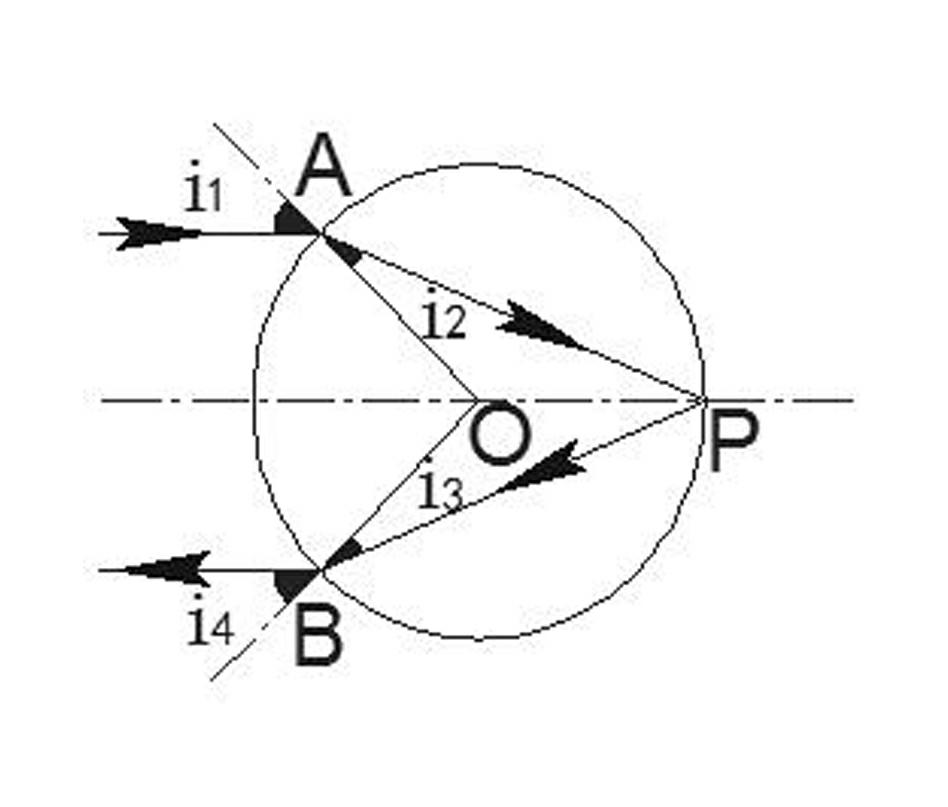

[0032] The uniform light guide body 10 is composed of a light guide body 9, a bead layer 7, and a reflective layer 6. The light guide body 9 is made of a transparent material with high light transmittance, and the bead layer 7 with high reflectivity is bonded to the light guide body 9. The inner side of the microbead laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com