Electronic jacquard machine installation and weaving process of seamless wall covering with different patterns on the upper and lower sides

An electronic jacquard and seamless wall covering technology, which is applied in the direction of jacquard machines, embossed fabrics, digging fabrics, etc., can solve the problem of weaving single pattern jacquard seamless wall coverings, difficult to weave single pattern jacquard fabrics, and pattern layout in factories. Form rigidity and other problems, achieve beautiful appearance characteristics, improve aesthetics, and avoid high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

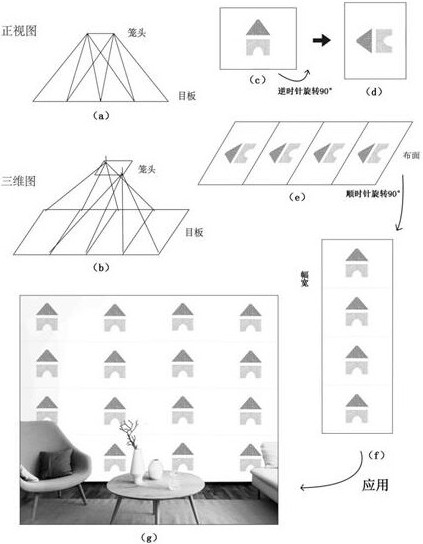

[0023] The invention provides a new electronic jacquard loom installation process aiming at the limitation of the pattern layout form of the seamless wall covering. The jacquard fabric woven by this decoration process has the appearance characteristics of two continuous patterns on the left, two continuous patterns on the right and four continuous patterns in the middle.

[0024] In this invention, by changing the manufacturing process of the electronic jacquard machine, the large-width jacquard fabric is designed with two continuous patterns on the left side, two continuous patterns on the right side and four continuous patterns in the middle. The installation process of the new electronic jacquard machine is as follows:

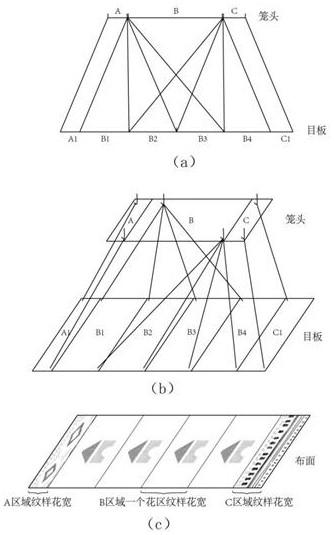

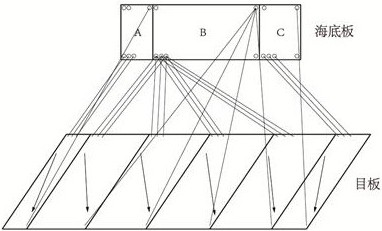

[0025] 1. Determination of the installation type of jacquard machine and the number of stitches

[0026] This invention mainly needs to divide the halter of the electronic jacquard machine into three areas A, B, and C from left to right, and design the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com