Concrete prefabricated pile and production method thereof

A technology of concrete prefabricated piles and production methods, applied in the field of concrete prefabricated piles and their production, can solve the problems of unqualified product quality and performance, poor fluidity, high viscosity of concrete, etc., achieve controllable stone powder content, improve work performance, contain The effect of low mud volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

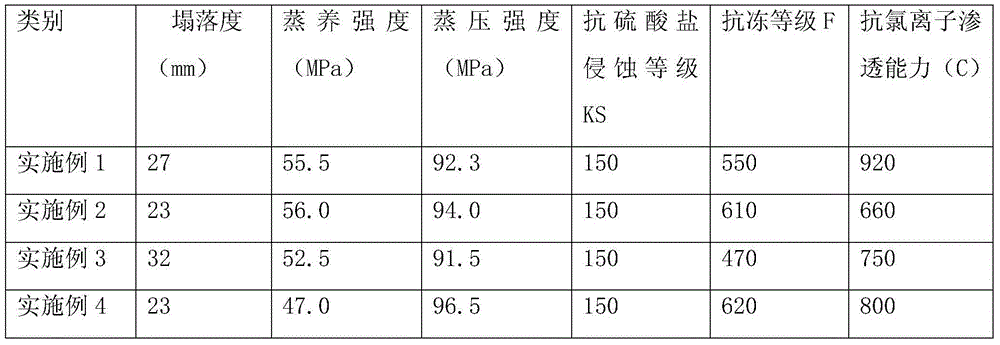

Examples

Embodiment 1

[0024] A concrete prefabricated pile, which is prepared by filling concrete into a mold equipped with a steel cage skeleton, closing the mold, stretching, centrifugal forming, curing with atmospheric pressure steam, demoulding, and curing with high-pressure steam. The raw materials of the concrete include glue cementitious material, fine aggregate, coarse aggregate, admixture and water, the content of said cementitious material is 350㎏ / m 3 , the cementitious material is composed of 55wt% cement and 45wt% admixture, the admixture is silica sand powder; the fine aggregate is machine-made sand or its mixture with natural sand, the fine aggregate The weight percentage of the machine-made sand is 20wt%. The machine-made sand is made from stone materials such as mine tailings and industrial waste slag through mechanical crushing, grading screening and dust removal, and the fineness modulus is 2.5.

[0025] The content of stone powder in the machine-made sand is 3wt%.

[0026] The s...

Embodiment 2

[0039] A concrete prefabricated pile, which is prepared by filling concrete into a mold equipped with a steel cage skeleton, closing the mold, stretching, centrifugal forming, curing with atmospheric pressure steam, demoulding, and curing with high-pressure steam. The raw materials of the concrete include glue cementitious material, fine aggregate, coarse aggregate, admixture and water, the content of said cementitious material is 400㎏ / m 3 , the cementitious material consists of 60wt% cement and 40wt% admixture, the admixture is silica sand powder; the fine aggregate is machine-made sand or its mixture with natural sand, the fine aggregate The weight percentage of the machine-made sand is 40wt%. The machine-made sand is made from stone materials such as mine tailings and industrial waste slag through mechanical crushing, grading screening and dust removal, and the fineness modulus is 3.0.

[0040] The content of stone powder in the machine-made sand is 5wt%.

[0041] The spec...

Embodiment 3

[0054] A concrete prefabricated pile, which is prepared by filling concrete into a mold equipped with a steel cage skeleton, closing the mold, stretching, centrifugal forming, curing with atmospheric pressure steam, demoulding, and curing with high-pressure steam. The raw materials of the concrete include glue cementitious material, fine aggregate, coarse aggregate, admixture and water, the content of said cementitious material is 450㎏ / m 3 , the cementitious material is made up of 80wt% cement and 20wt% admixture, and the admixture is silica sand powder; the fine aggregate is machine-made sand or its mixture with natural sand, and the fine aggregate The weight percentage of the machine-made sand is 60wt%. The machine-made sand is made from stone materials such as mine tailings and industrial waste slag through mechanical crushing, grading screening and dust removal, and the fineness modulus is 3.5.

[0055] The content of stone powder in the machine-made sand is 6wt%.

[0056...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com