Variable roughness texture ornamental porcelain brick and method for producing the same

A technology of porcelain tiles and concave-convex surface, which is applied in manufacturing tools, ceramic molding machines, metal processing equipment, etc., can solve the problems of rigid fixation of concave-convex surface, expensive manufacturing cost, inability to randomly change concave-convex surface, etc., and achieves good antifouling performance. , low cost, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

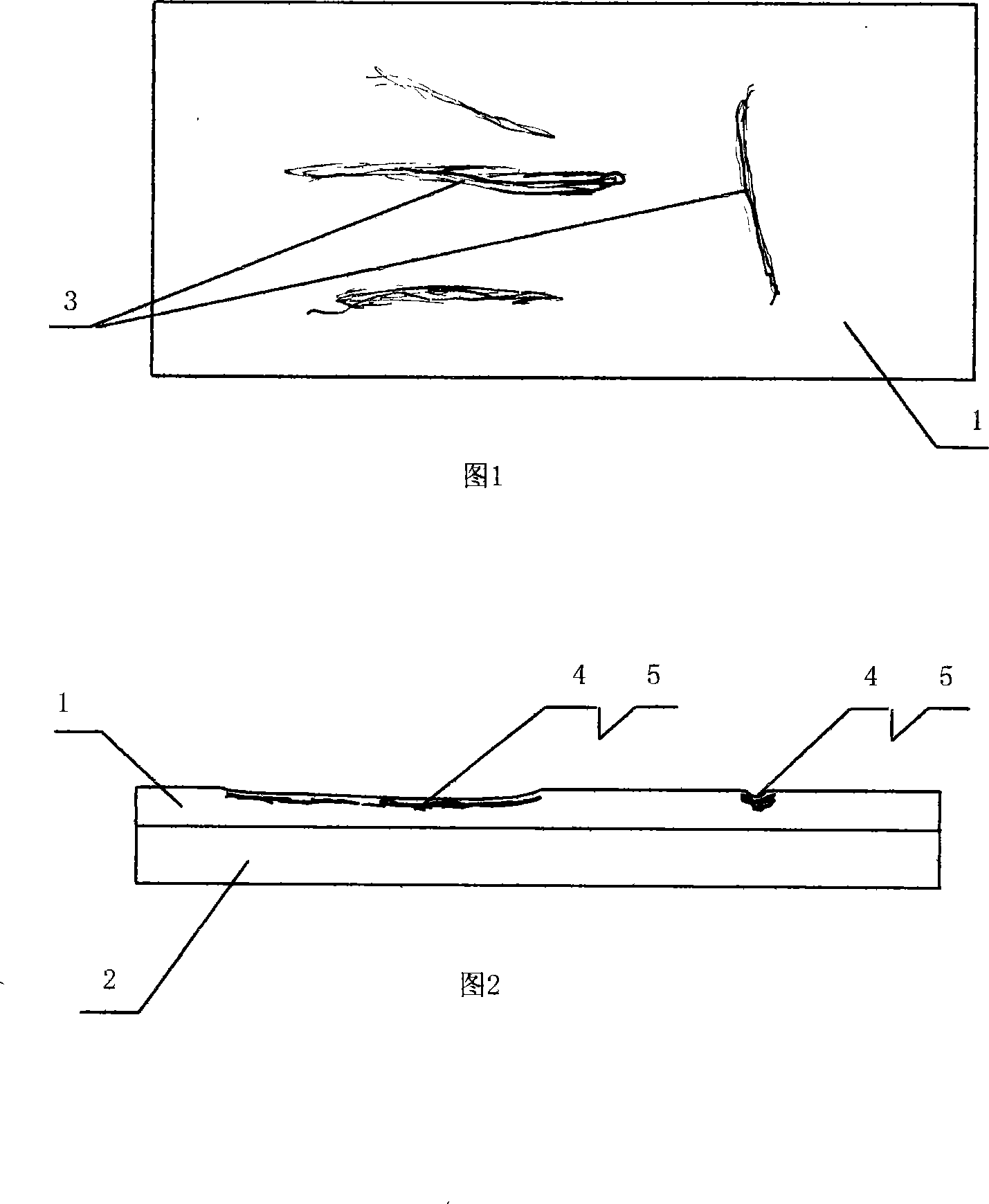

[0025] As shown in Figure 1 and Figure 2, the variable concave-convex surface texture decorative porcelain tile of the present invention includes a surface layer 1 and a base layer 2, and the surface layer 1 is set to have a cloth texture 3 and a concave-convex surface with ravines or pits 4 The ravines or pits 4 on the concave-convex surface vary naturally with the cloth texture 3, and the depth of the ravines or dents 4 is 0-1.5mm. The grooves or depressions are produced by the depression material 5 . The dry wear resistance of the depressed material 5 is lower than that of other patterned fabrics, and the firing shrinkage of the depressed material is higher than that of other patterned fabrics. The formula composition (parts by weight) of the depression material is: mud 8%, potassium feldspar 15%, sodium feldspar 25%, talc 6%, limestone 15%, wollastonite 15%, quartz sand 16%. The mud content in the powder formula composition of the surface layer 1 and the bottom base layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com