Patents

Literature

30results about How to "Appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

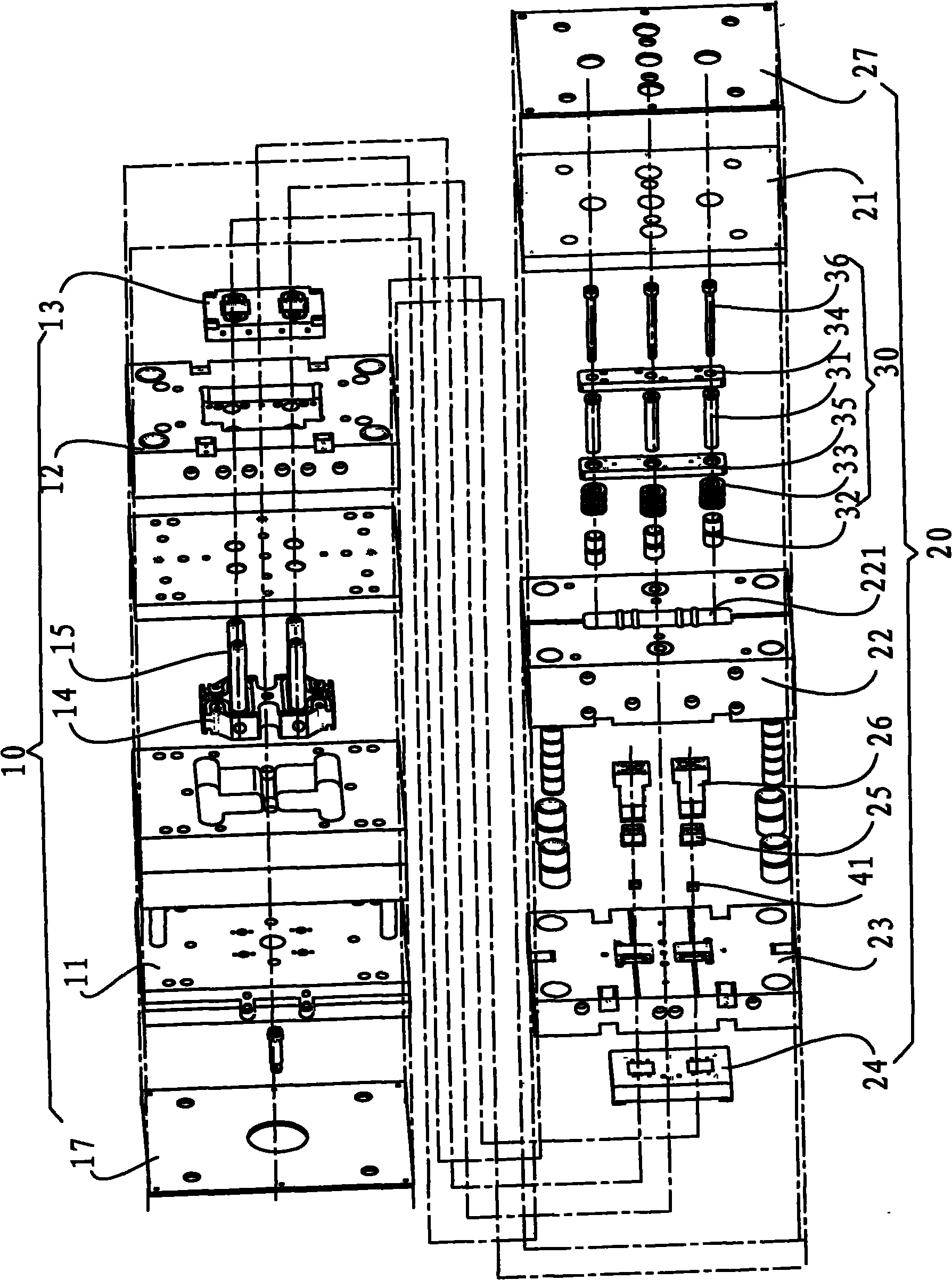

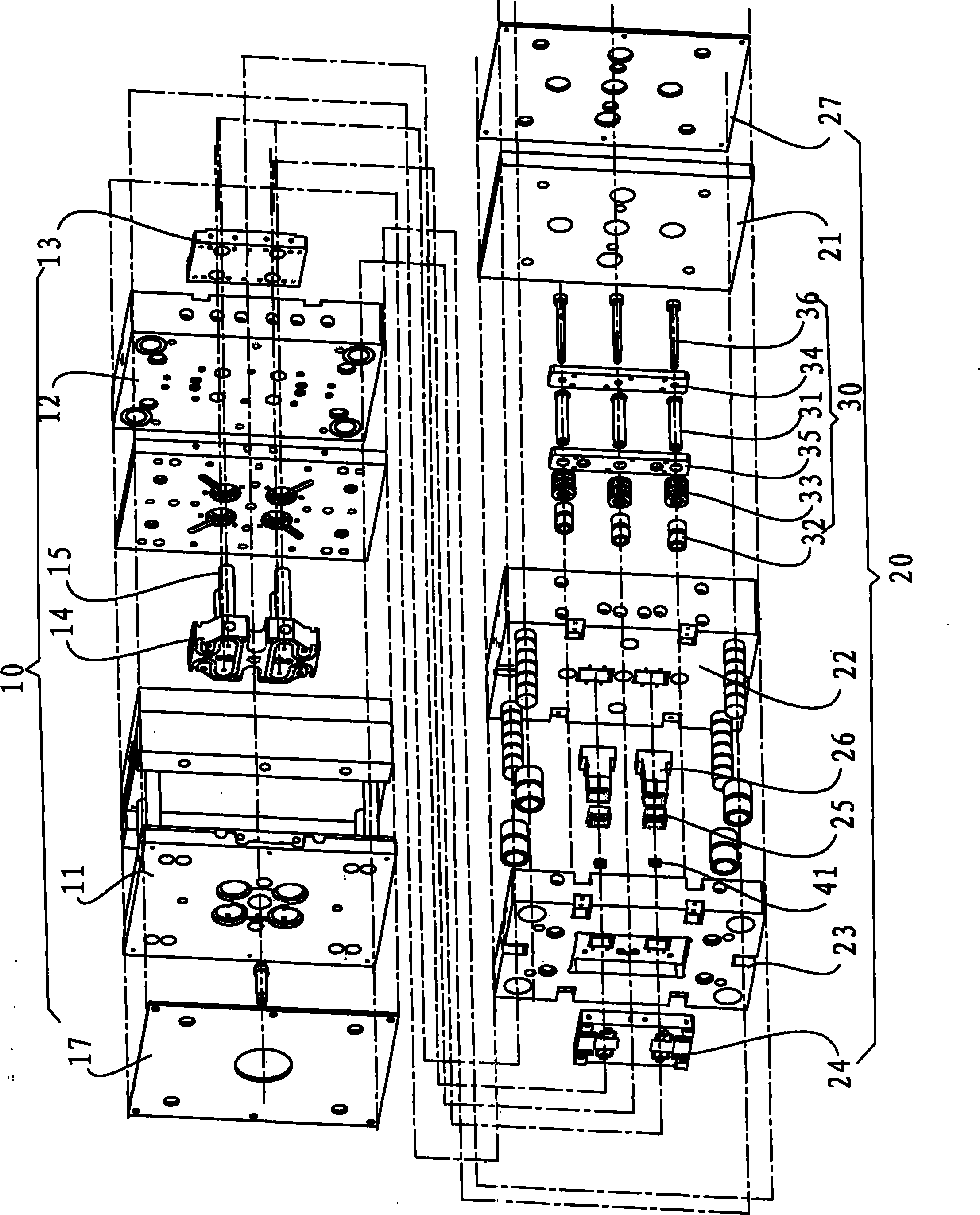

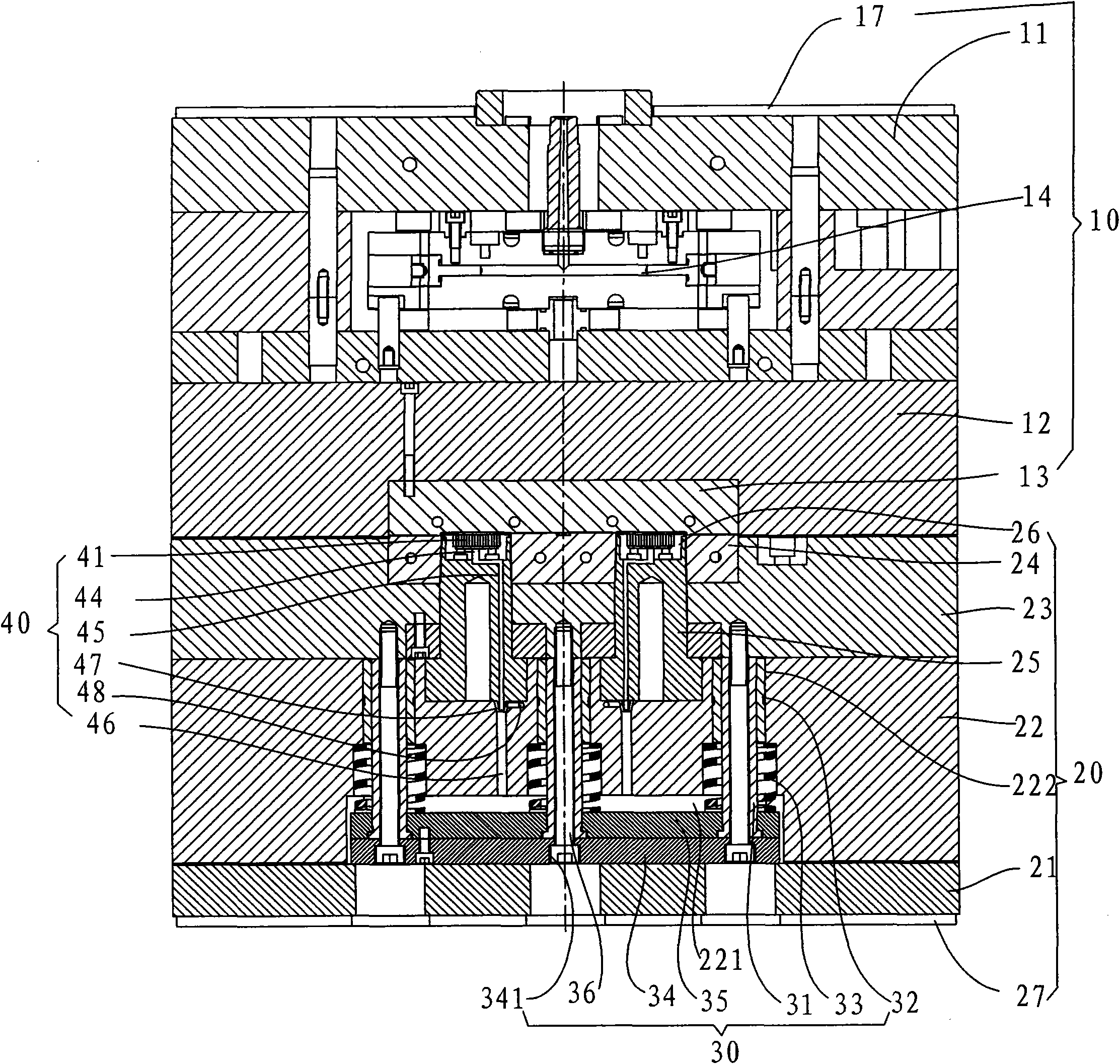

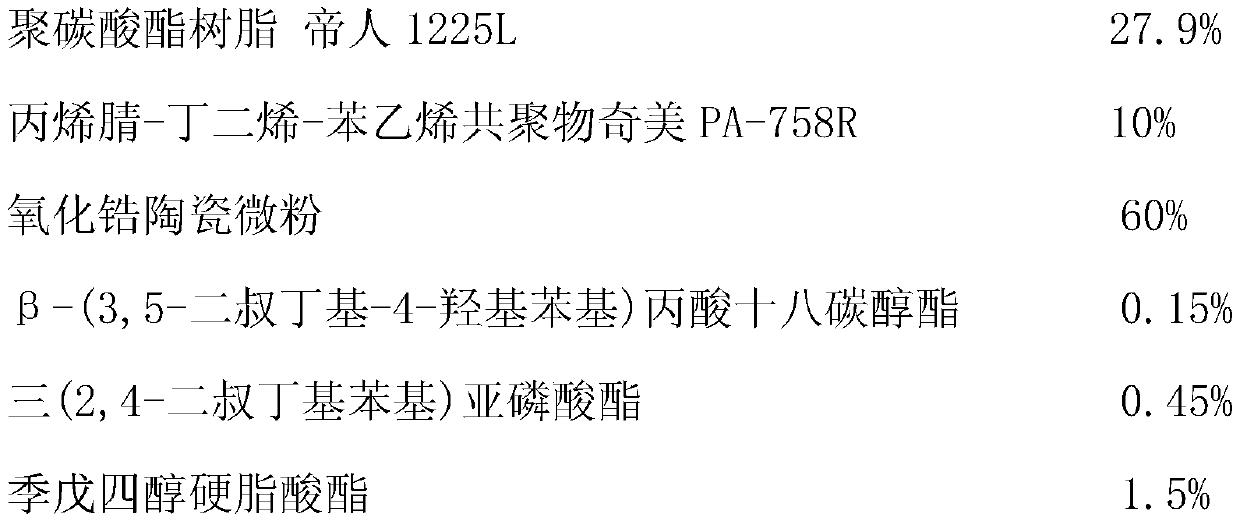

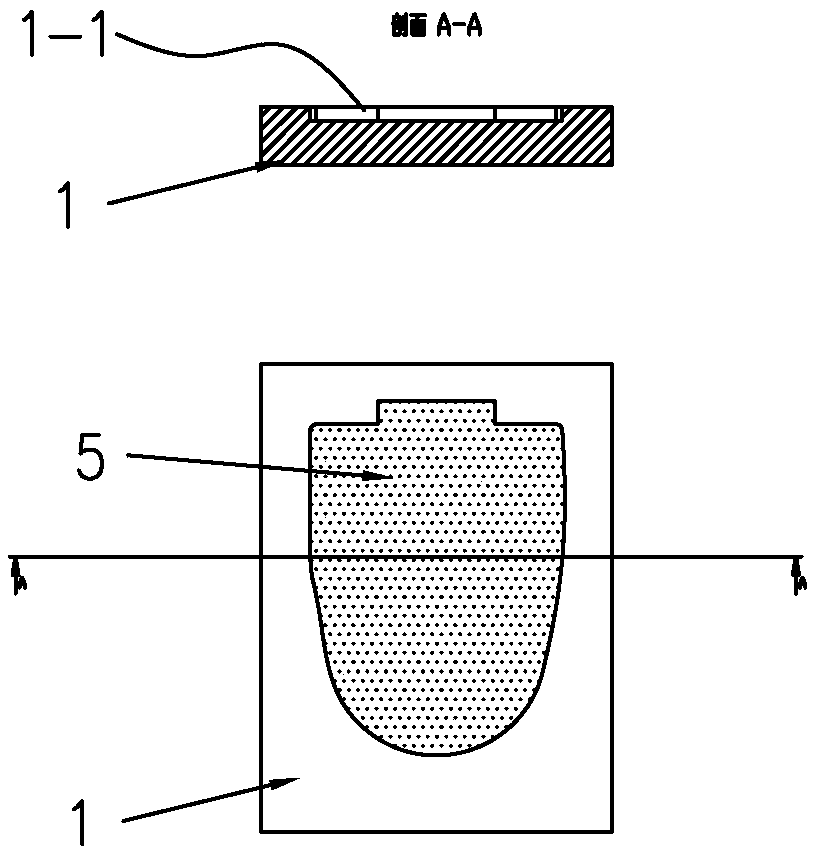

Large-area ultrathin plastic part injection mould

ActiveCN102120357AImprove pressure bearing capacityExtend your lifeAir trappingPlastic injection molding

The invention relates to the field of plastic injection molding moulds, and particularly relates to a large-area ultrathin plastic part injection mould. The mould comprises a static mould and a movable mould, wherein the static mould is composed of a static mould fixing plate, and the static template and a static mould core, a movable mould composed of a movable mould fixing plate, a pad, a movable template and a movable template core; the static template is a thickened static template; the pad is a whole square thick steel block; an ejection device is a push board ejection device; an exhaustsystem comprises a group of exhaust plates at the bottom of a mould cavity, an exhaust groove at the periphery of the mould cavity and an exhaust channel connected with the exhaust plates and the exhaust groove; and a compressed air blow pipe leading the exhaust channel to generate negative pressure is arranged on the exhaust channel. The mould has high strength, the service life is up to 2 million times; the exhaust is smooth, and adverse phenomena, such as insufficient filling, burning, air trapping, heavy fused connecting wire and the like, are prevented, so that the purpose of large area of 1,429mm<2> and ultrathin of 0.18mm molding is achieved; and the extrusion or deformation of a product is effectively avoided by adopting the push board ejection device.

Owner:DONGMING XINGYE SCI TECH CO LTD

Preparation method of spinning hairpiece by human hair and protein acrylic fibre

InactiveCN101037813AWith textureAppearanceWigsConjugated cellulose/protein artificial filamentsMean diameterAcrylic fibre

The invention relates to a preparation method for hairpiece formed by human hair and protein acrylon. The method comprises the following steps: human hairs being crushed into human hair powder at mean diameter of 1-10 micron, wherein the maximum size is not more than 30 micron; the human hair powder uniform distributing in polyacrylonitrile fibre, wherein the content of human hair powder is 1-30%(wt%) and the content of polyacrylonitrile is 70-99%(wt%); using wet-process acrylon spinning technique to finally obtain the protein acrylon hairpiece. The said human hair is crushed, no need of chemical extraction. The operation is simple, the souce of raw materianl is wide and the cost is low. The protein acrylon hairpiece has features of satia plump texture, good hand feeling, reality, similar burning property to human hair.

Owner:DONGHUA UNIV

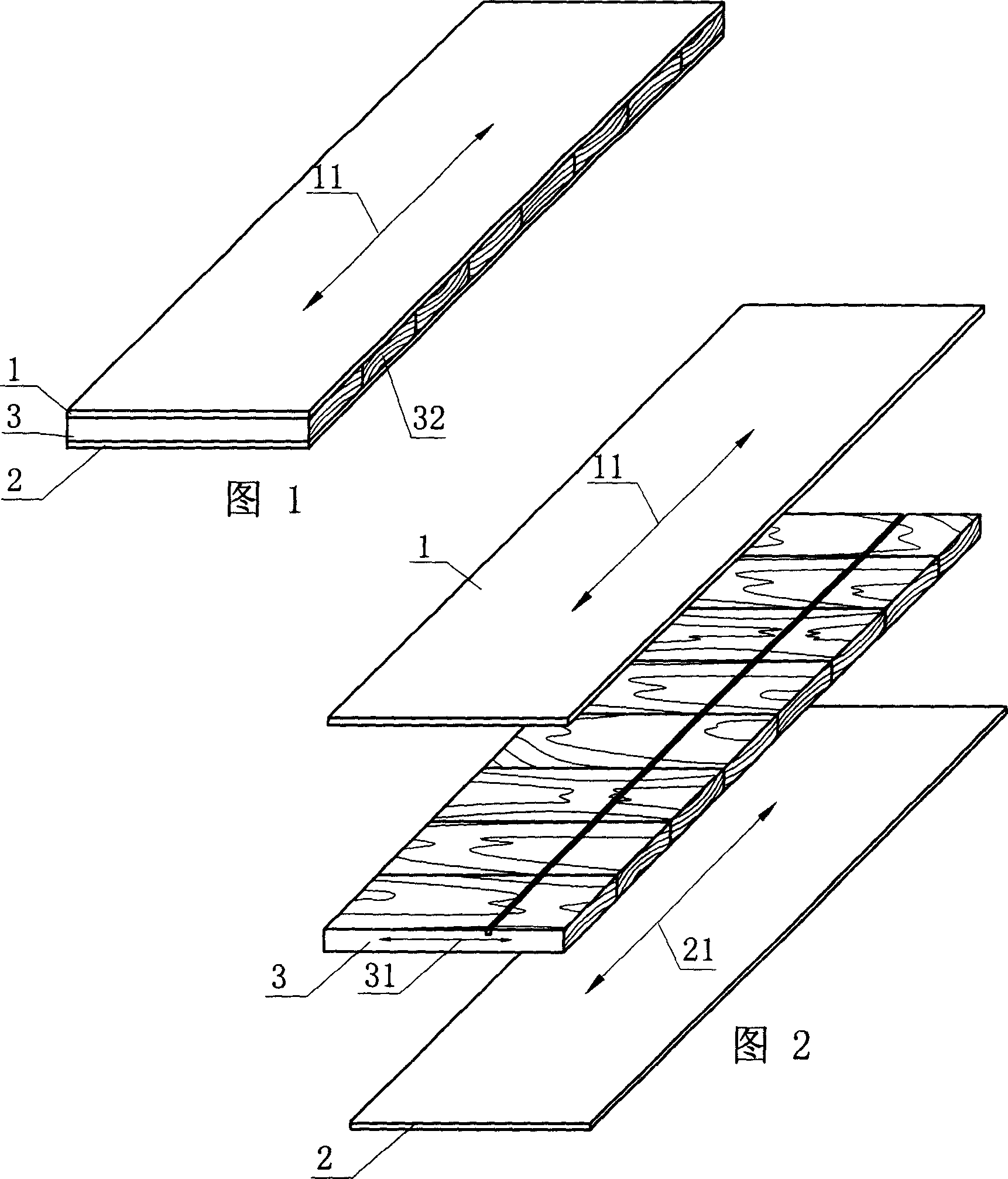

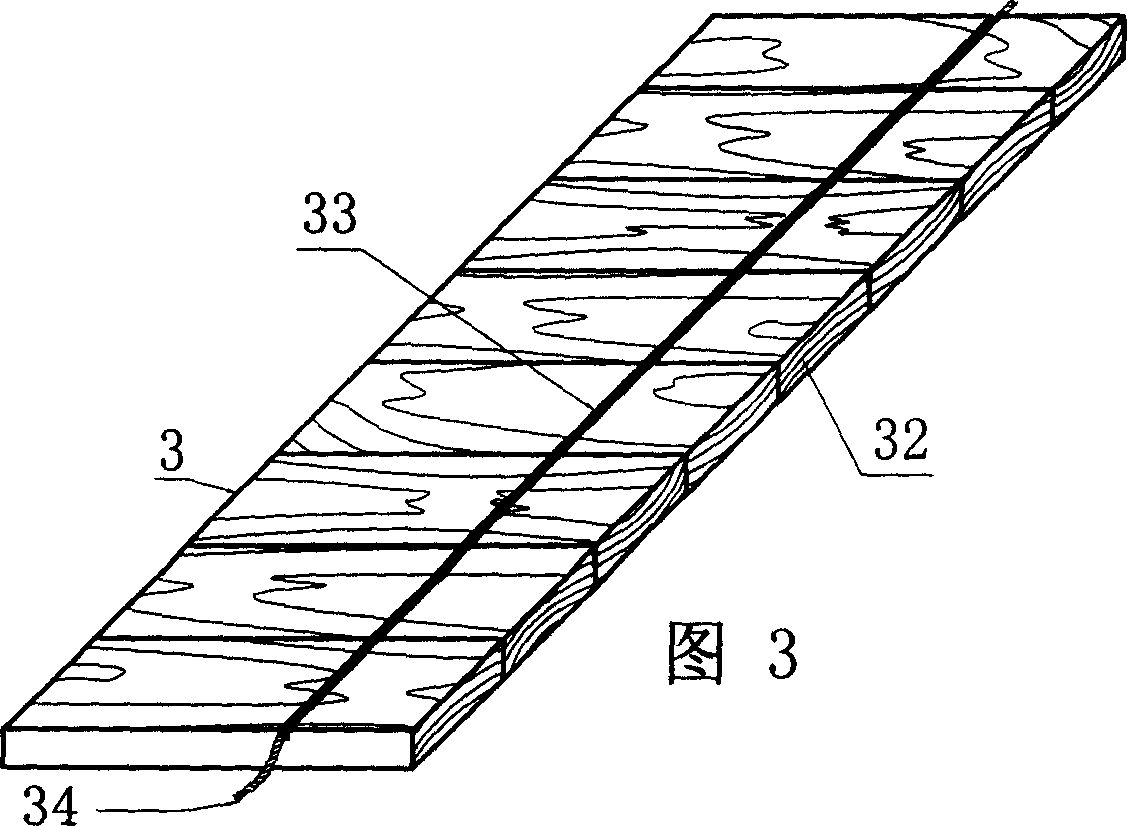

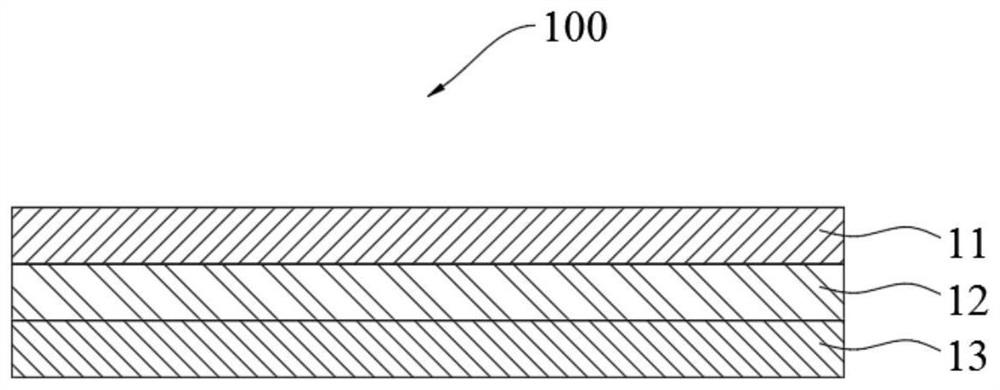

Bamboo wood compound floor board

InactiveCN1912311AHas surface hardnessImprove qualityWood layered productsFlooringSolid woodSurface layer

A bamboo-wood composite floor is prepared as using heavy bamboo material to prepare surface layer board and bottom layer board and using wood as intermediate layer board, crossing fiber orientation of adjacent layer and setting fiber orientations of surface layer board and bottom layer board to be identical, forming said bamboo material by mixing and high-pressure pressing bamboo filigree or bamboo splints.

Owner:浙江坚林林业股份有限公司

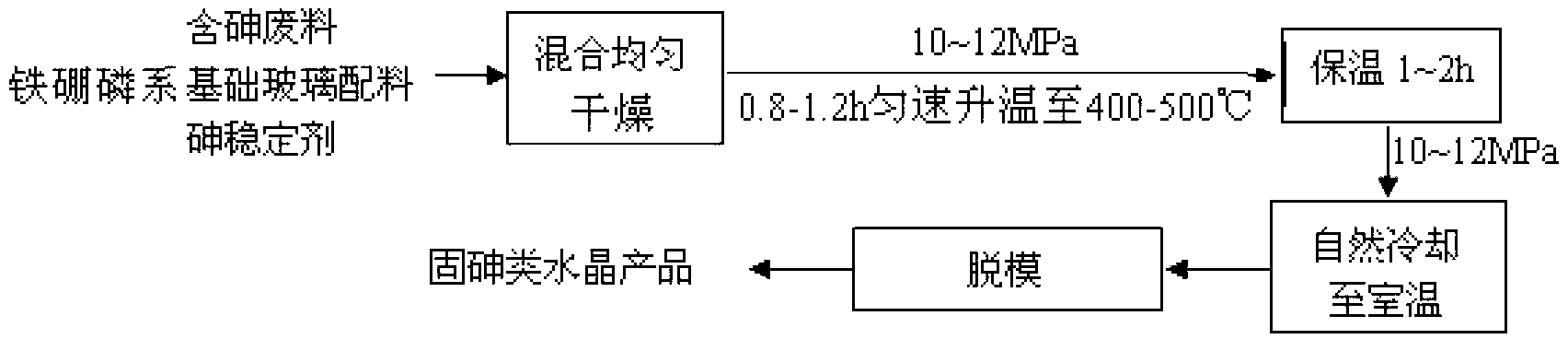

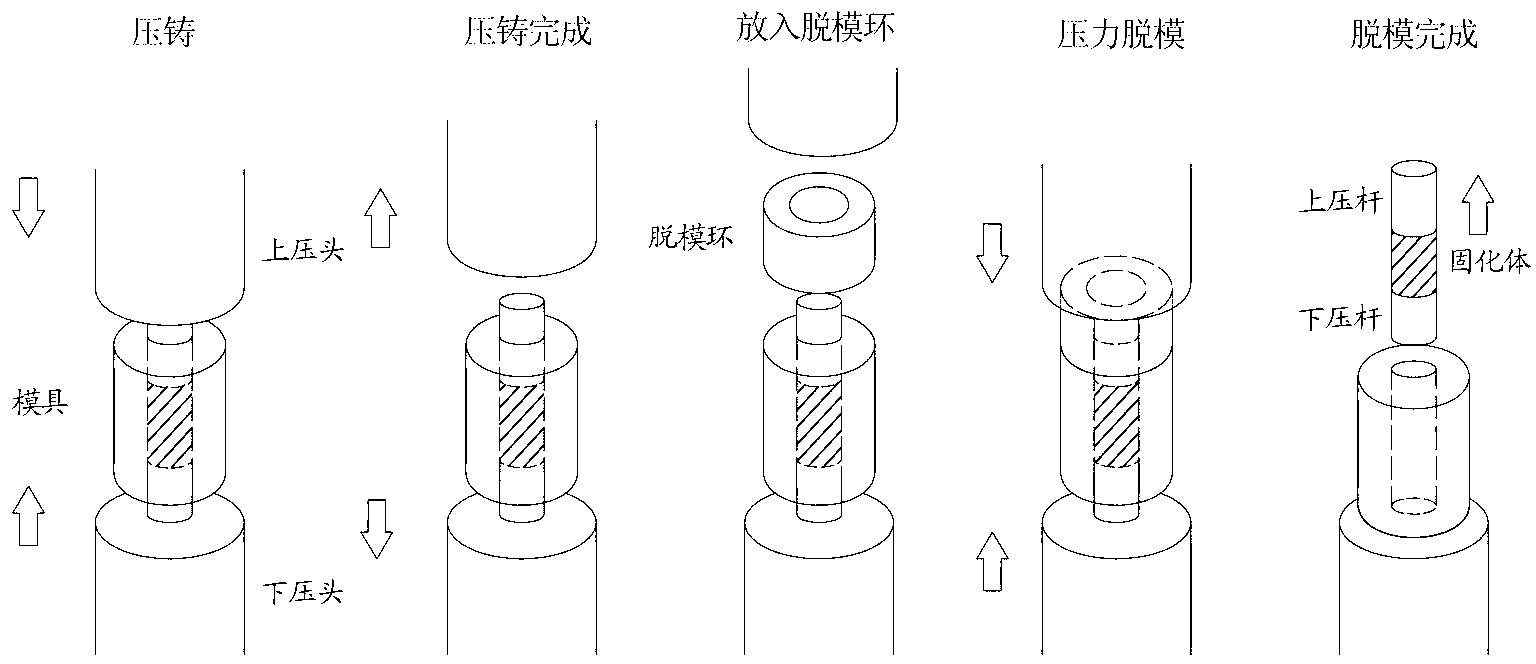

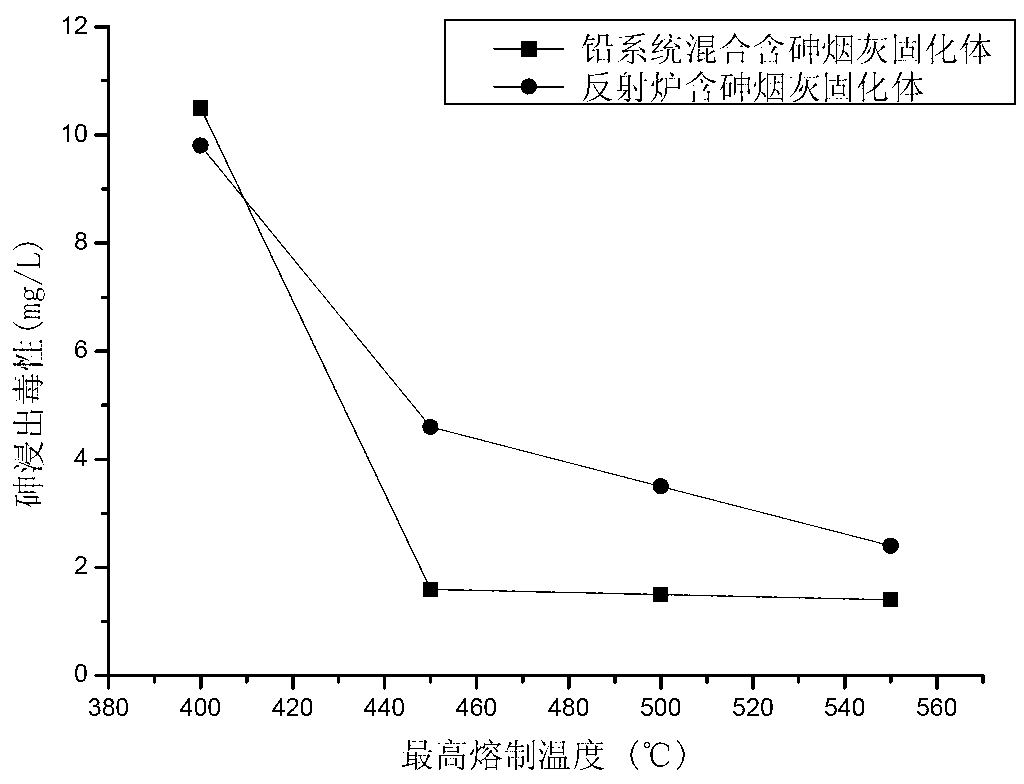

Arsenious waste curing method as well as generated solid arsenic crystal product and application thereof

The invention provides an arsenious waste curing method. The arsenious waste curing method comprises the following steps of: (1) grinding arsenious waste into powder, adding into iron, boron and phosphorous basic glass ingredients and a stabilizer, and uniformly mixing raw materials and drying; and (2) placing the dried raw materials into a stainless steel mould, heating to 400-500 DEG C at a constant speed within 0.8-1.2 hours, and insulating for 1-2 hours, wherein intensity of pressure in the stainless steel mould is maintained to be 10-12Mpa all the time in the heating process; and founding, homogenizing, then carrying out natural cooling to room temperature, taking out the mould, and demoulding, thus the solid arsenic crystal product is obtained. The invention also provides a solid arsenic crystal product generated by the arsenious waste curing method. Arsenic curing rate of the arsenious waste curing method is high, and the produced cured product can be used for making a building or decorative material.

Owner:CENT SOUTH UNIV

Concentrated laundry liquid suitable for machine washing, and preparation method thereof

InactiveCN104031756ASignificant compound antifoamSignificant foam breaking effectSurface-active detergent compositionsDetergent compounding agentsLaundryFatty alcohol

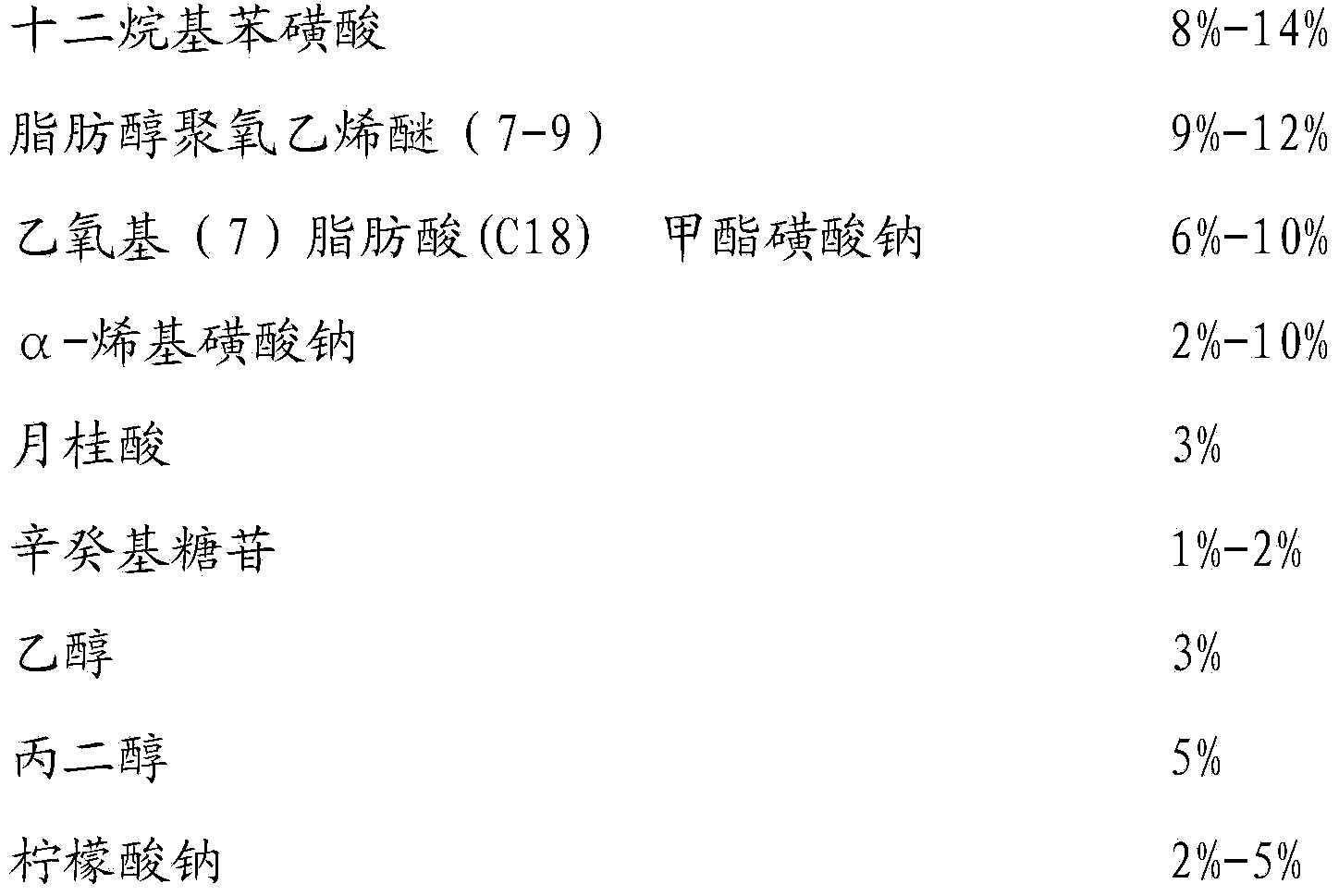

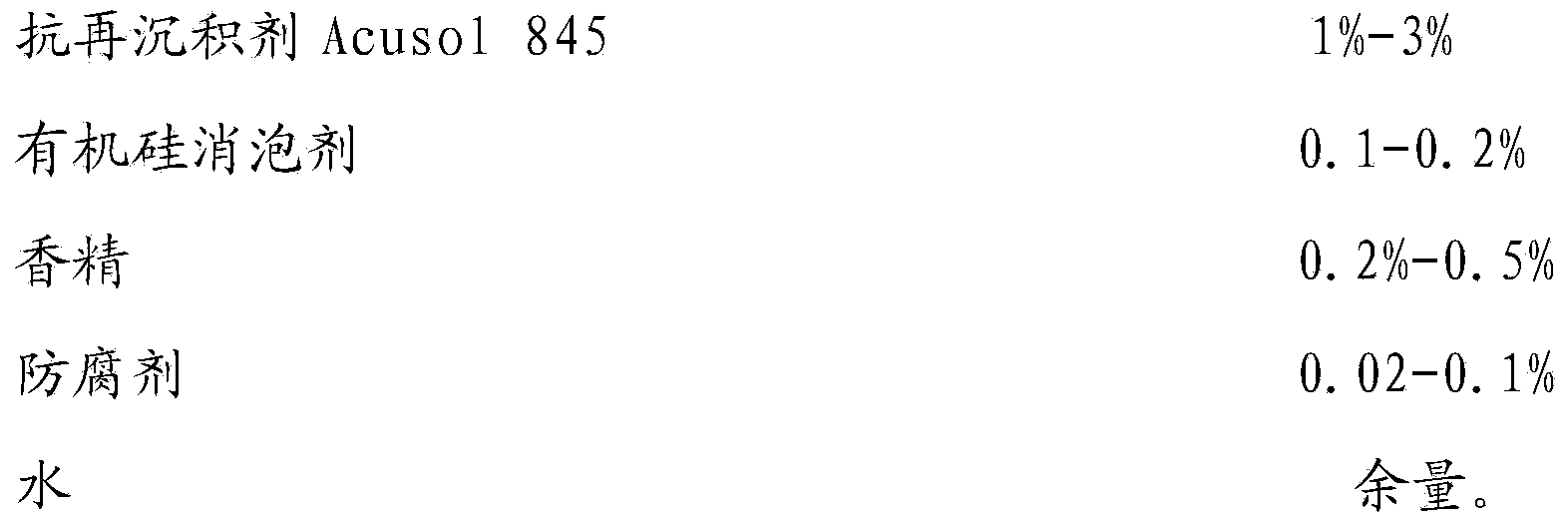

The invention relates to a concentrated laundry liquid suitable for machine washing, and a preparation method thereof. The above washing agent composition comprises 8-14wt% of dodecylbenzene sulfonic acid, 9-12wt% of fatty alcohol polyoxyethylene ether (7-9), 6-10wt% of sodium ethoxylated (7) fatty acid (C18) methyl ester sulfonate, 2-10wt% of sodium alpha-alkenyl sulfonate, 1-3wt% of lauric acid, 1-2wt% of caprylyl / capryl glucoside, 3wt% of ethanol, 5wt% of propylene glycol, 1-5wt% of sodium citrate, 1-3wt% of an anti-redeposition agent Acusol845, a small amount of an essence and an antiseptic, and the balance water. The concentrated laundry liquid is slightly alkaline, is suitable for the machine washing of fabrics comprising cottons, hemps, synthetic fibers and the like, and has the characteristics of low temperature stability, strong decontamination force, low foaming, easy rinsing high cost performance and the like; and the concentrated laundry liquid has the advantages of high enrichment, no phosphorus, no fluorescent brightening agent, good biodegradability and environmental protection.

Owner:LAFANG CHINA CO LTD

Polypropylene material for automobile interior trimming parts and preparation method thereof

The invention discloses a polypropylene material for automobile interior trimming parts and a preparation method of the polypropylene material. The polypropylene material for automobile interior trimming parts comprises the following components in part by weight: 30-80 parts of polypropylene, 5-10 parts of ethylene propylene terpolymer and 10-25 parts of talcum powder. The polypropylene material can be prepared just through weighting each raw material in certain proportion; after the raw materials are uniformly mixed, carrying out fusing and mixing on the obtained mixture; and carrying out extruding and granulation to obtain the polypropylene material. Through mixing the polypropylene with the ethylene propylene terpolymer, the toughness and cold resistance of the polypropylene material can be improved, and the polypropylene material is good in ozone resistance, oxidation resistance and erosion resistance; meanwhile, the polypropylene material has a shockproof effect; and after the talcum powder is added, the friction coefficient of the polypropylene material can be reduced, and the self lubricity of the polypropylene material can be improved. The polypropylene material for automobile interior trimming parts disclosed by the invention has the appearance and performance of a rubber body; and the polypropylene material can be prepared into automobile interior trimming parts suchas outer side plates for driver seats, small cover lids, inner plates of side plates, plastic parts for inner side plates, outer side plates for passenger seats, door-sheet armrest frames and door trimming plates and the like through an injection molding process.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

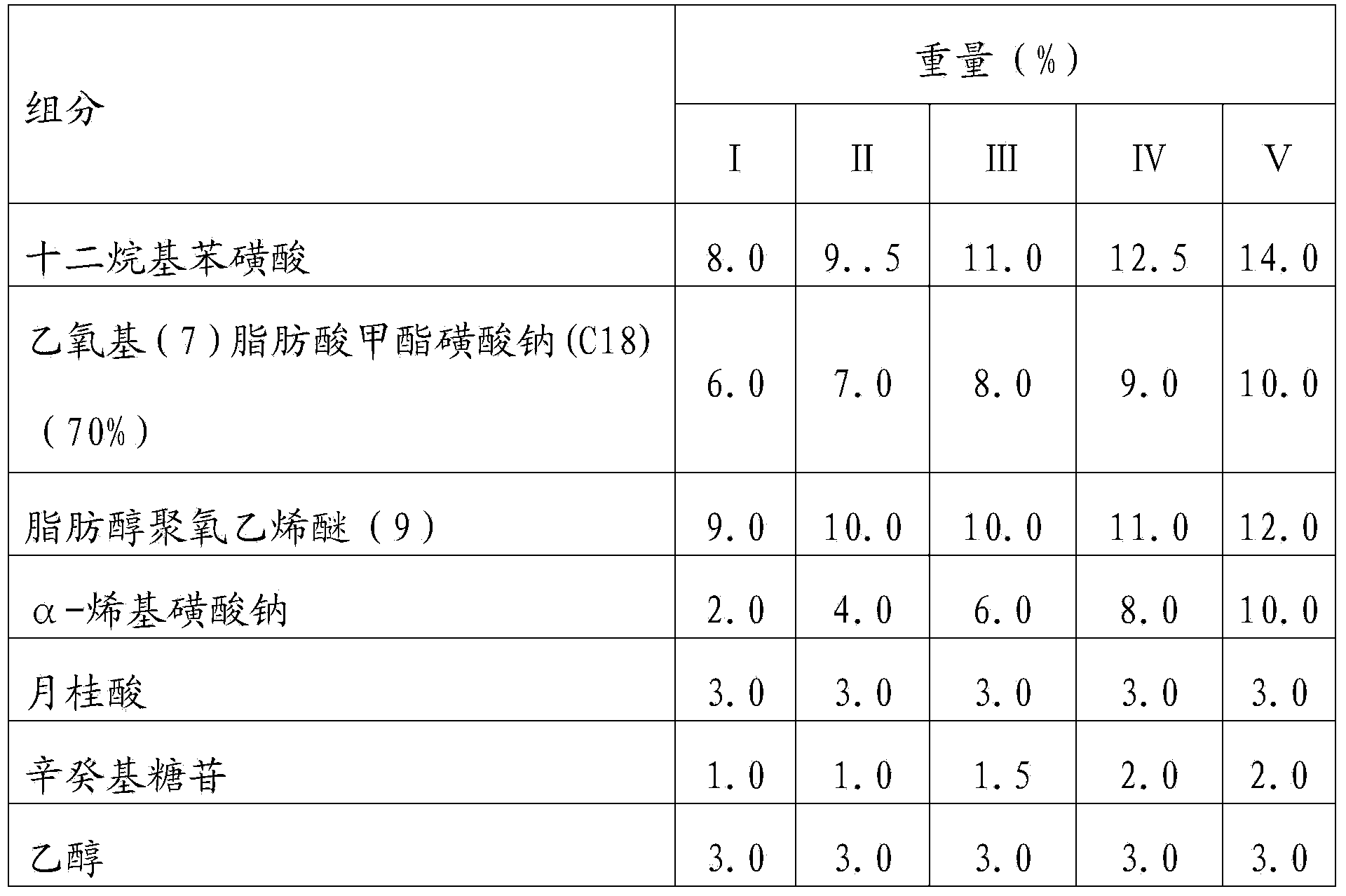

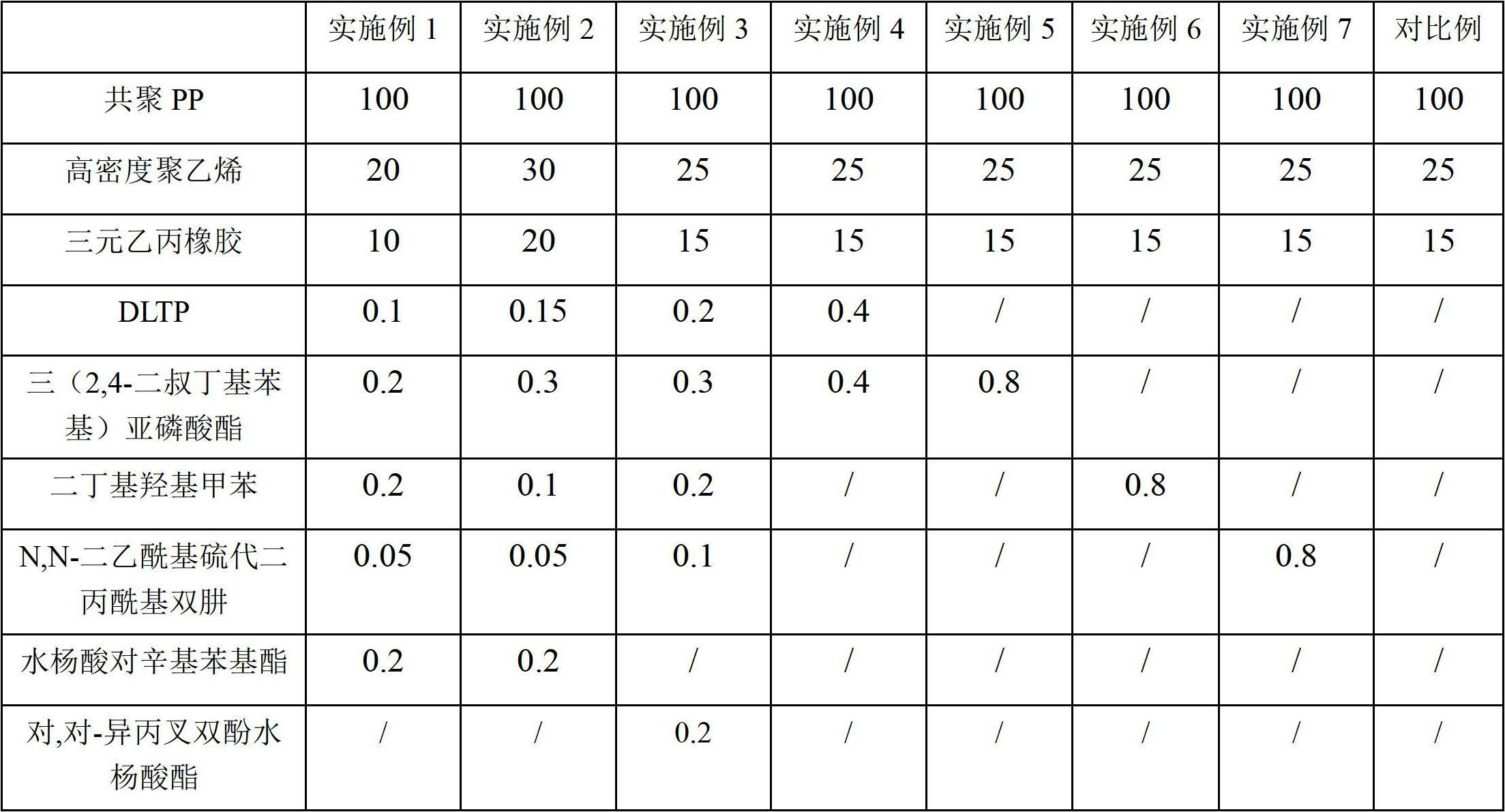

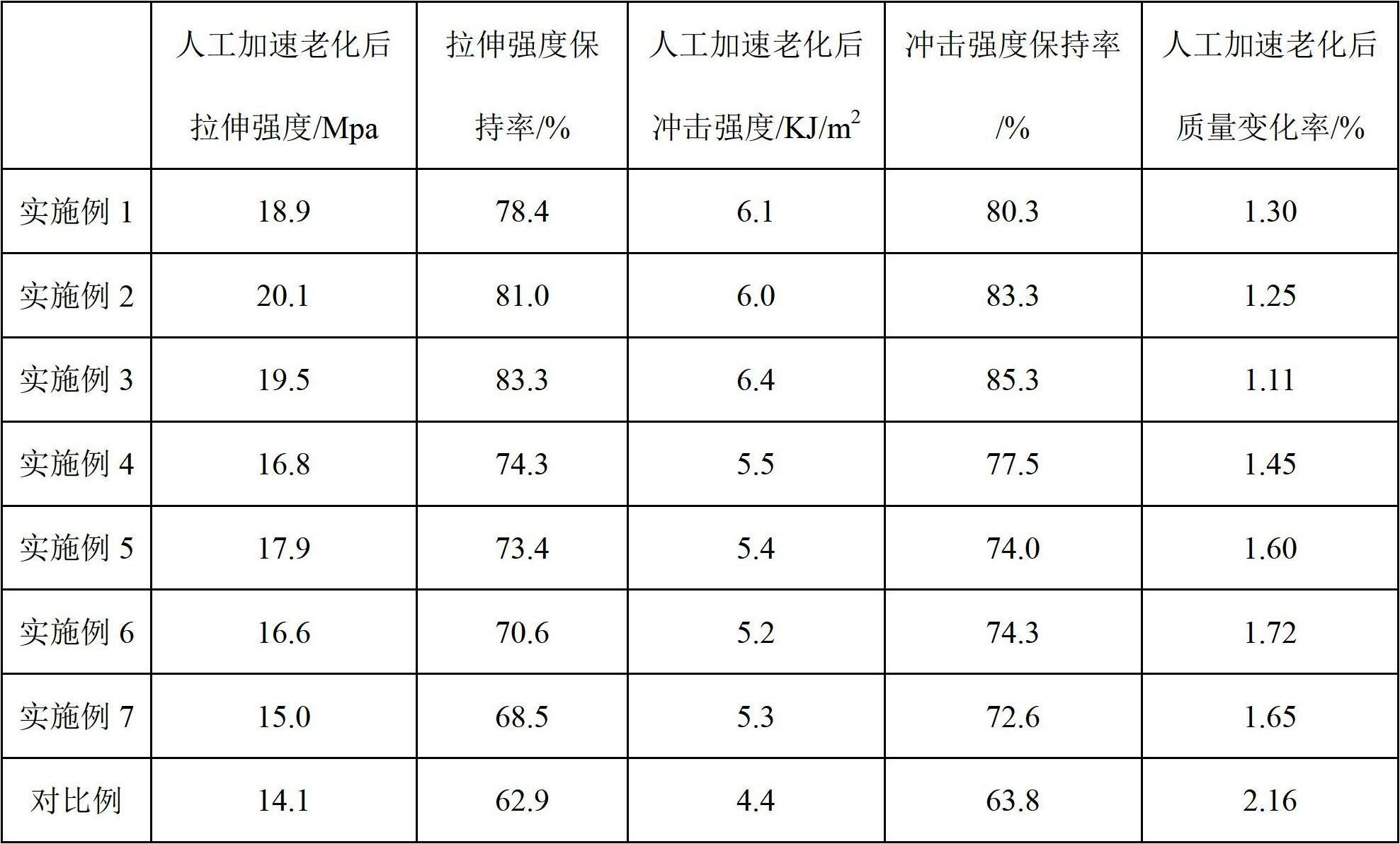

Anti-ageing PP/HDPE (Polypropylene/High-Density Polyethylene) plastic for automobile interior and preparation method thereof

The invention discloses anti-ageing PP / HDPE (Polypropylene / High-Density Polyethylene) plastic for an automobile interior and a preparation method thereof. The automobile interior is applied to PP / HDPE plastic, and comprises the following components in parts by weight: 100 parts of PP, 20-30 parts of HDPE, 10-20 parts of ethylene propylene diene monomer and 0.1-5 parts of anti-ageing agent. The method comprises the following steps of: weighing raw materials according to a certain proportion; mixing uniformly; melting and compounding; and extruding and pelletizing to obtain the PP / HDPE plastic. The anti-ageing PP / HDPE plastic for the automobile interior has rubber body appearance and performance, high tensile strength, high flexural modulus and high cantilever beam gap impact strength, and can be easily processed into automobile interiors of various shapes through an injection molding process such as glove box inner cover plates, glove box hoppers, auxiliary instrument board bodies, storage box liners and panel storage boxes.

Owner:克林斯曼新材料有限公司

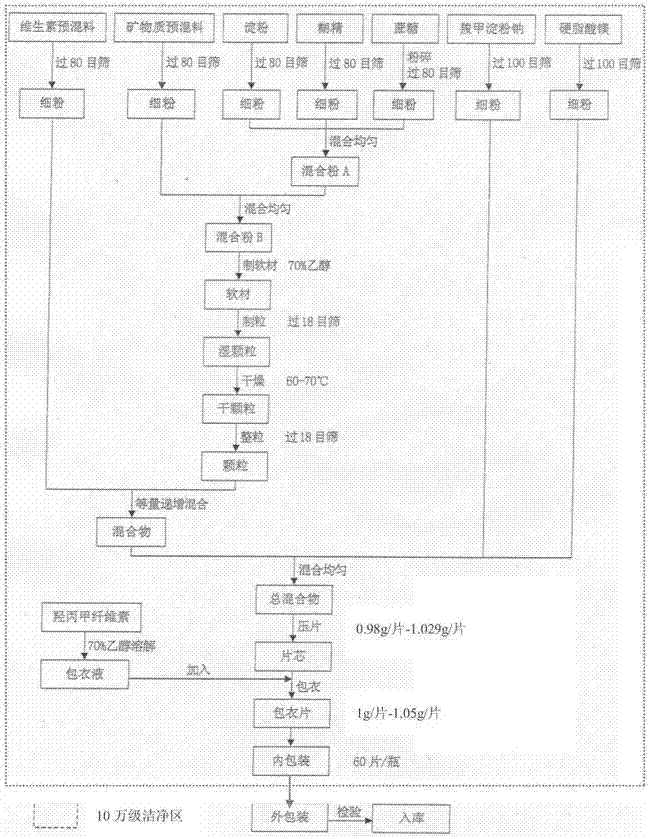

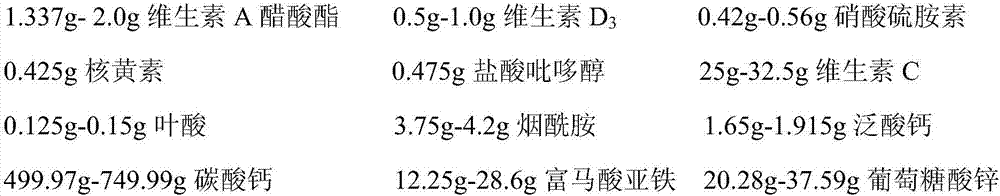

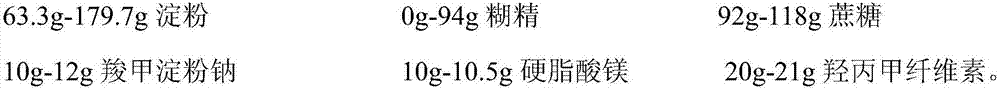

Health-care product for complementing multivitamins and mineral substances for pregnant women

InactiveCN107455758AStrong targetingPromote absorptionFood shapingFood ingredient functionsSucroseVitamin C

The invention discloses a health-care product for complementing multivitamins and mineral substances for pregnant women. 1000-1050g of the health-care product contains the following raw materials by weight: 1.337-2.0g of vitamin A acetic ester, 0.5-1.0g of vitamin D3, 0.42-0.56g of thiamine nitrate, 0.425g of lactoflavin, 0.475g of pyridoxine hydrochloride, 25-32.5g of vitamin C, 0.125-0.15g of folic acid, 3.75-4.2g of nicotinamide, 1.65-1.915g of calcium pantothenate, 499.97-749.99g of calcium carbonate, 12.25-28.6g of ferrous fumarate, 20.28-37.59g of zinc gluconate, 63.3-179.7g of starch, 0-94g of dextrin, 92-118g of cane sugar, 10-12g of carboxymethyl starch sodium, 10-10.5g of magnesium stearate and 20-21g of hydroxypropyl methylcellulose.

Owner:步源堂生物科技有限公司

Method for making colour-glazed porcelain plate

The invention discloses a glazed ceramic board making method, adopting the steps of: 1) applying glaze on a mud blank ceramic board; 2) simultaneously sintering the blank and glaze; 3) making glaze post- processing on the ceramic board sintered with glaze, such as colored drawing, or pasting decal paper, or tracing design in gold, etc; 4) decorating firing. And it can act as sign boards and other pendants, and as compared with the existing materials, such as wood, metal, plastics, and even white ceramic board, has characters of stainlessness, not decoloring, not rotting, not deforming, easy to care, etc, thus a new variety of porcelain.

Owner:傅涛

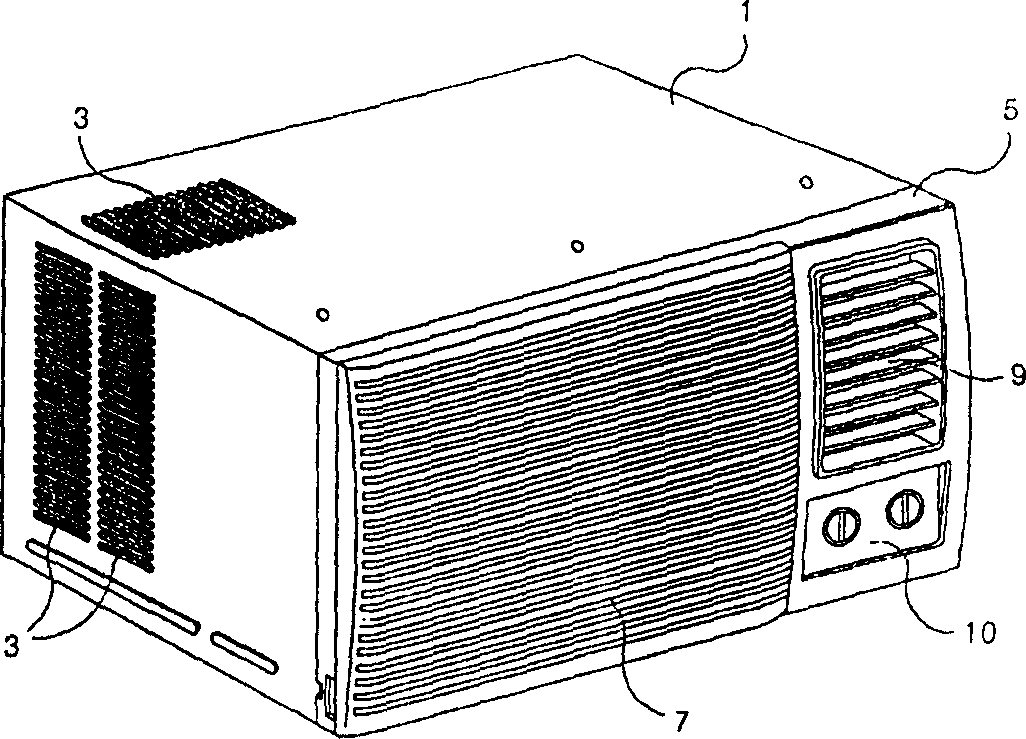

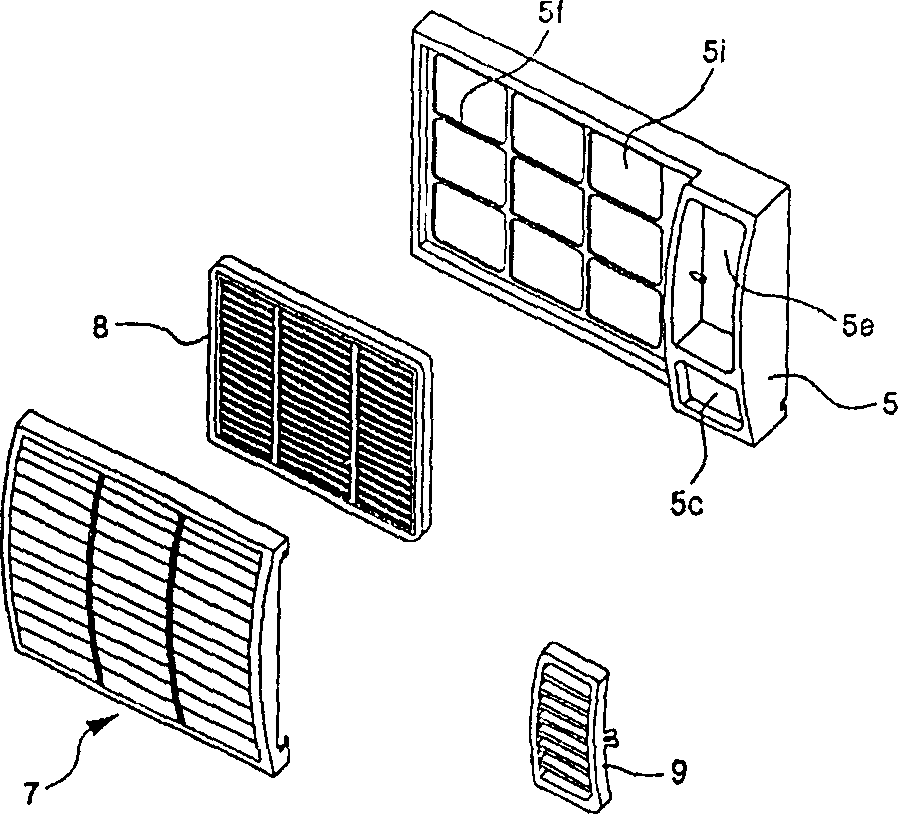

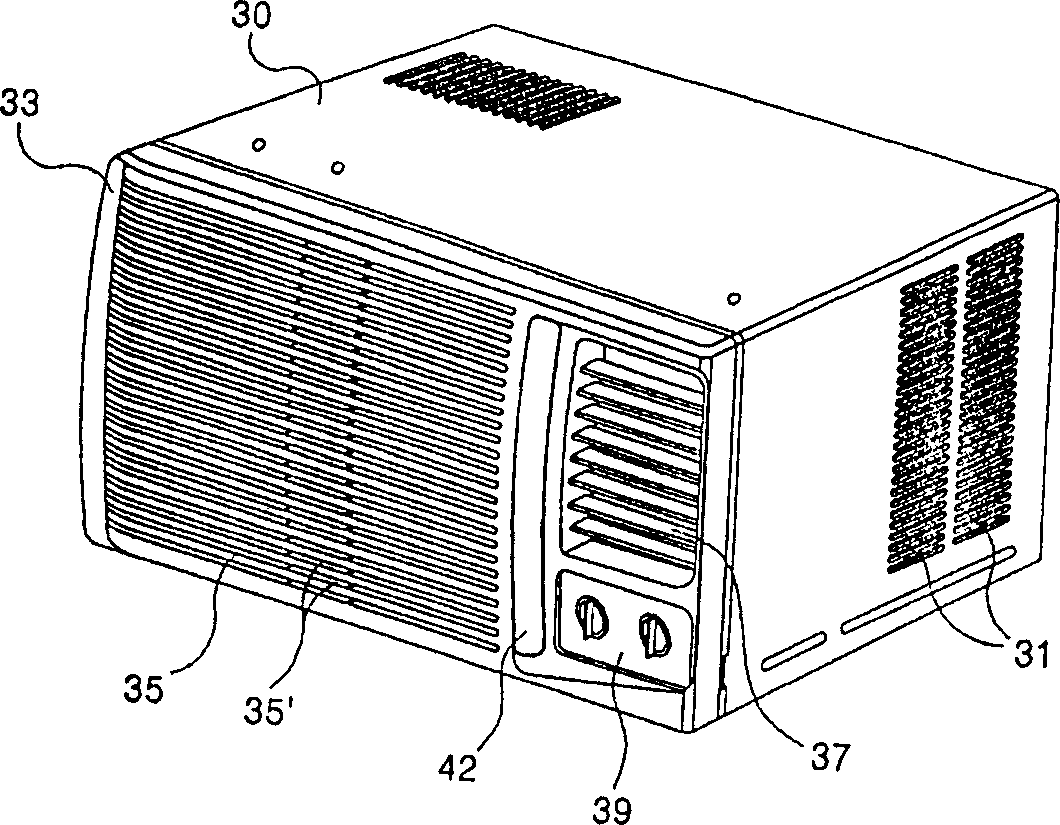

Integral air conditioner

InactiveCN1693800ASimple appearanceAppearanceLighting and heating apparatusHeating and ventilation casings/coversInterior spaceEngineering

The invention discloses an integral air conditioner. The inner space formed by base plate and carcass is separated into indoor side and outdoor side, and several components are installed in. At the front of the base plate and the carcass, the front panel is formed. Air flow channel is formed between indoor side and the space needed to regulate air. Suction grill is set at one side of the front panel, and the other side is set exhaust vane section. Filter accessing entrance is set at the panel. The invention could decrease the component on the front panel and increase the installation efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

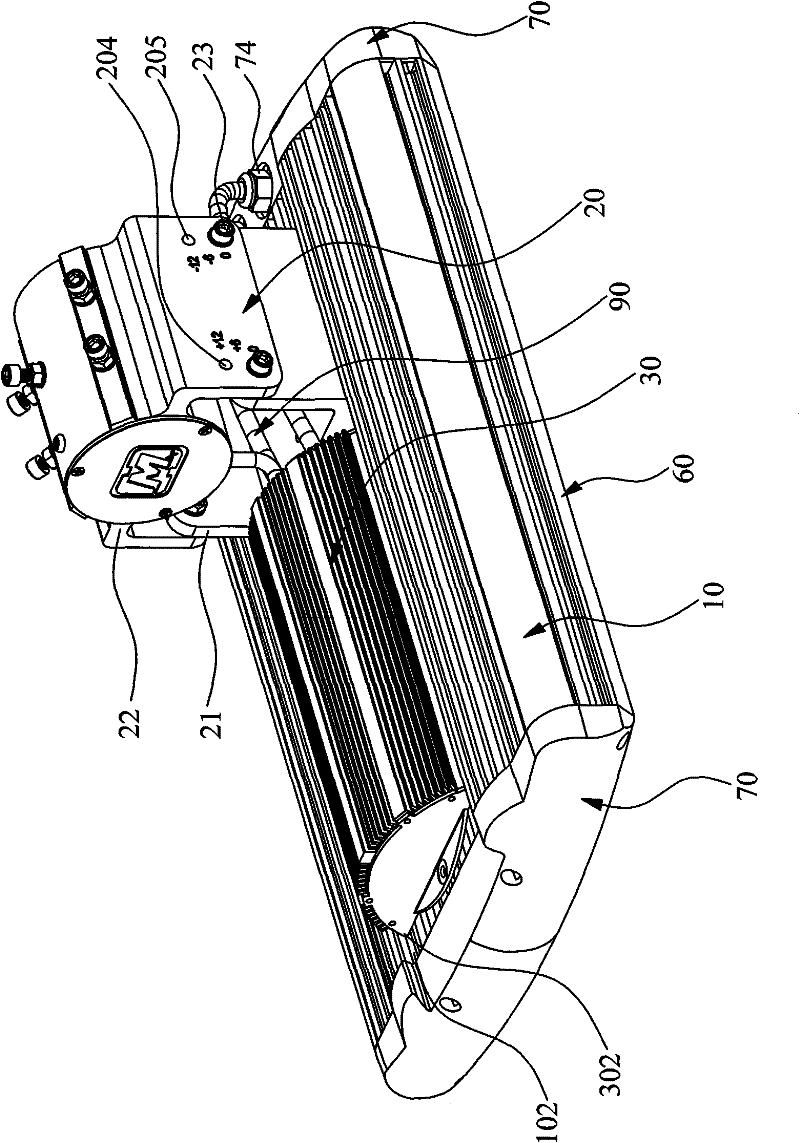

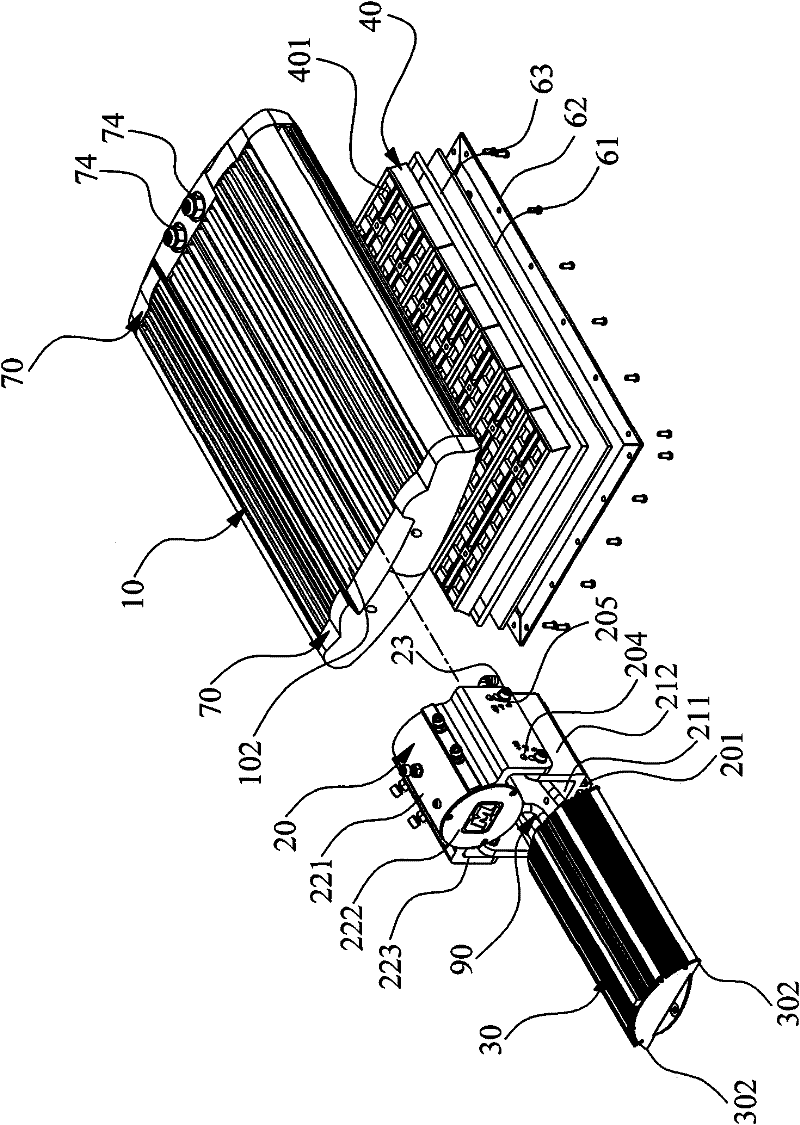

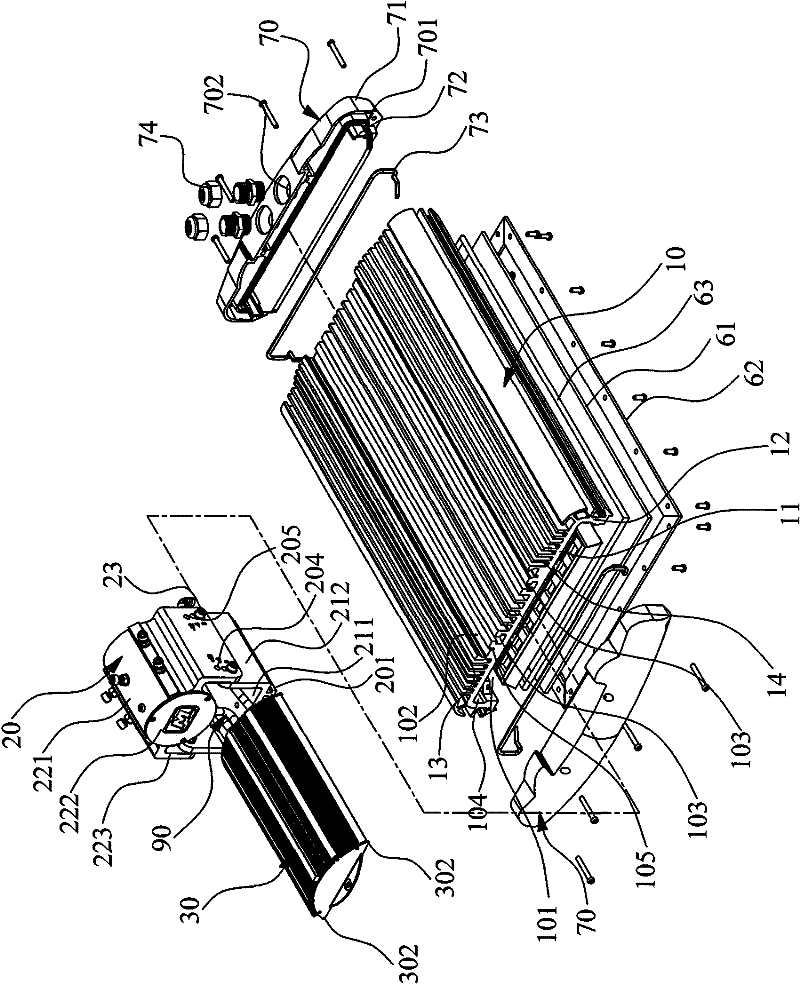

LED illuminating lamp

InactiveCN101943339BEasy to arrange reasonablyEasy to assemblePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight transmission

The invention discloses an LED illuminating lamp comprising a heat radiation base, a fixed support, a power supply box, a light enhancement shield, a light transmission shield and a fixed end cover, wherein the heat radiation base has a containing space; a dovetail groove and a T-shaped groove are arranged outside the heat radiation base; a positioning groove is arranged on the inner wall surfaceof the heat radiation base; a T-shaped block is arranged on the fixed support and inserted along the T-shaped groove; the fixed support is fixedly connected with the heat radiation base through screws; a dovetail inclined angle is arranged in the power supply box and inserted along the dovetail groove; the power supply box is fixedly connected with the heat radiation base through the screws; the light enhancement shield is arranged in the containing space; a plurality of grid grooves are arranged on the light enhancement shield; LED lamp bodies and lenses are arranged in the grid grooves; a positioning pillar is arranged on the fixed end cover and inserted along the positioning groove; and the fixed end cover is fixedly connected with the heat radiation base through the screws. The invention can ensure that the assembling of the parts is convenient by utilizing the bearing of the heat radiation base on the parts; the installation and the connection of the parts are more stable by utilizing the fixedly locking of the screws; and the LED illuminating lamp is suitable for popularization in markets.

Owner:东莞市光烨节能科技有限公司

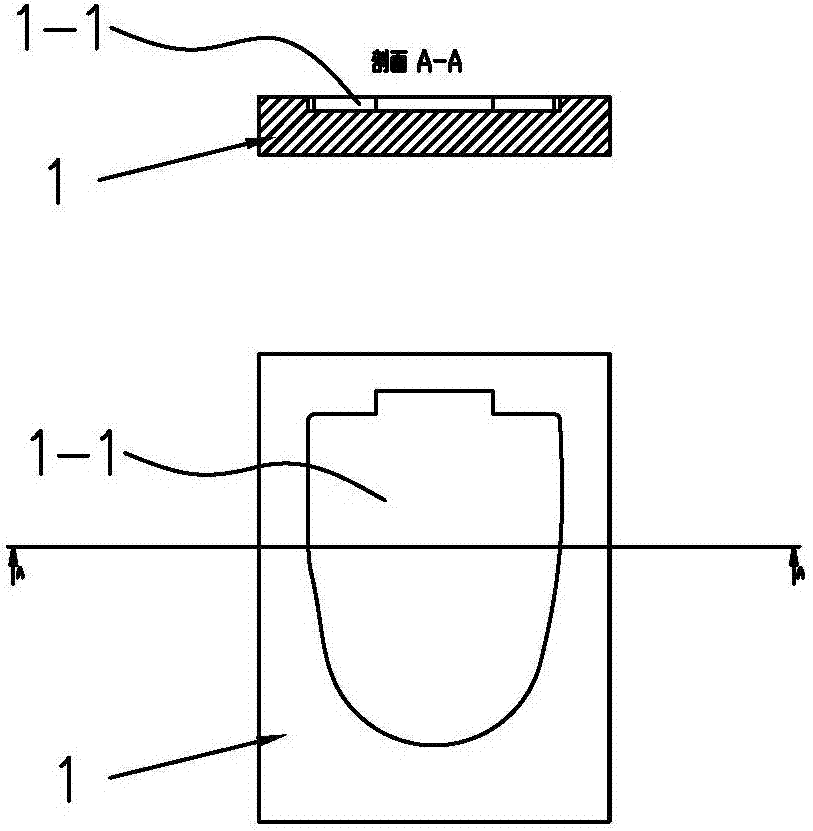

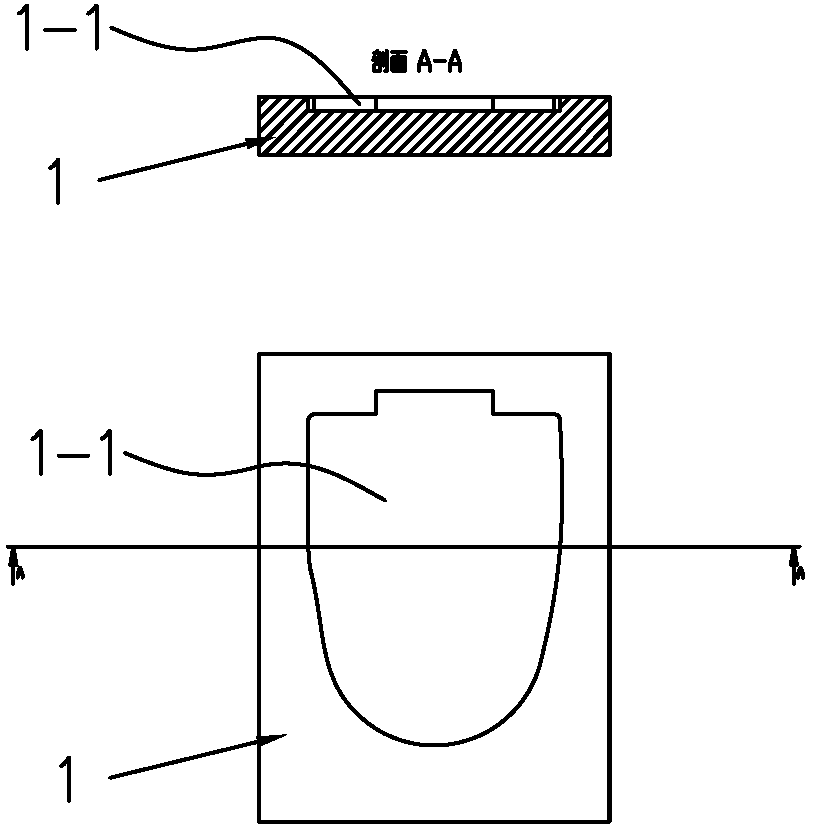

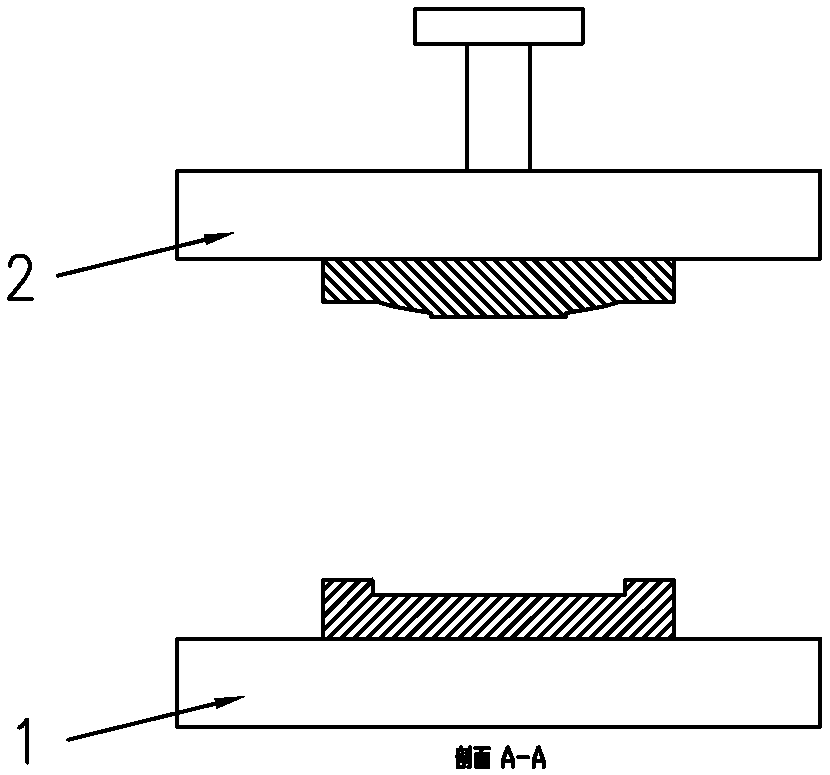

Toilet seat and preparation method thereof

The invention discloses a toilet seat and a preparation method thereof. The seat comprises a thermosetting resin seat body, and a heating assembly is embedded in the seat body. The method includes the following steps that 1, thermosetting particles and two mold sets with upper molds and a lower mold are provided, wherein the two mold sets share the lower mold; 2, the first layer of urea formaldehyde particles are laid in the first mold set of a compression molding machine, the first upper mold is closed for forming, and then the first upper mold is opened and moved away; 3, the heating assembly is laid on the seat with first forming; 4, the second layer of the urea formaldehyde particles are laid on the heating assembly and the seat with first forming; 5, the second upper mold is closed, and forming is conducted through compression molding. According to the toilet seat and the preparation method, the production method is simple, and the product is beautiful and safer.

Owner:BESTTER XIAMEN TECH

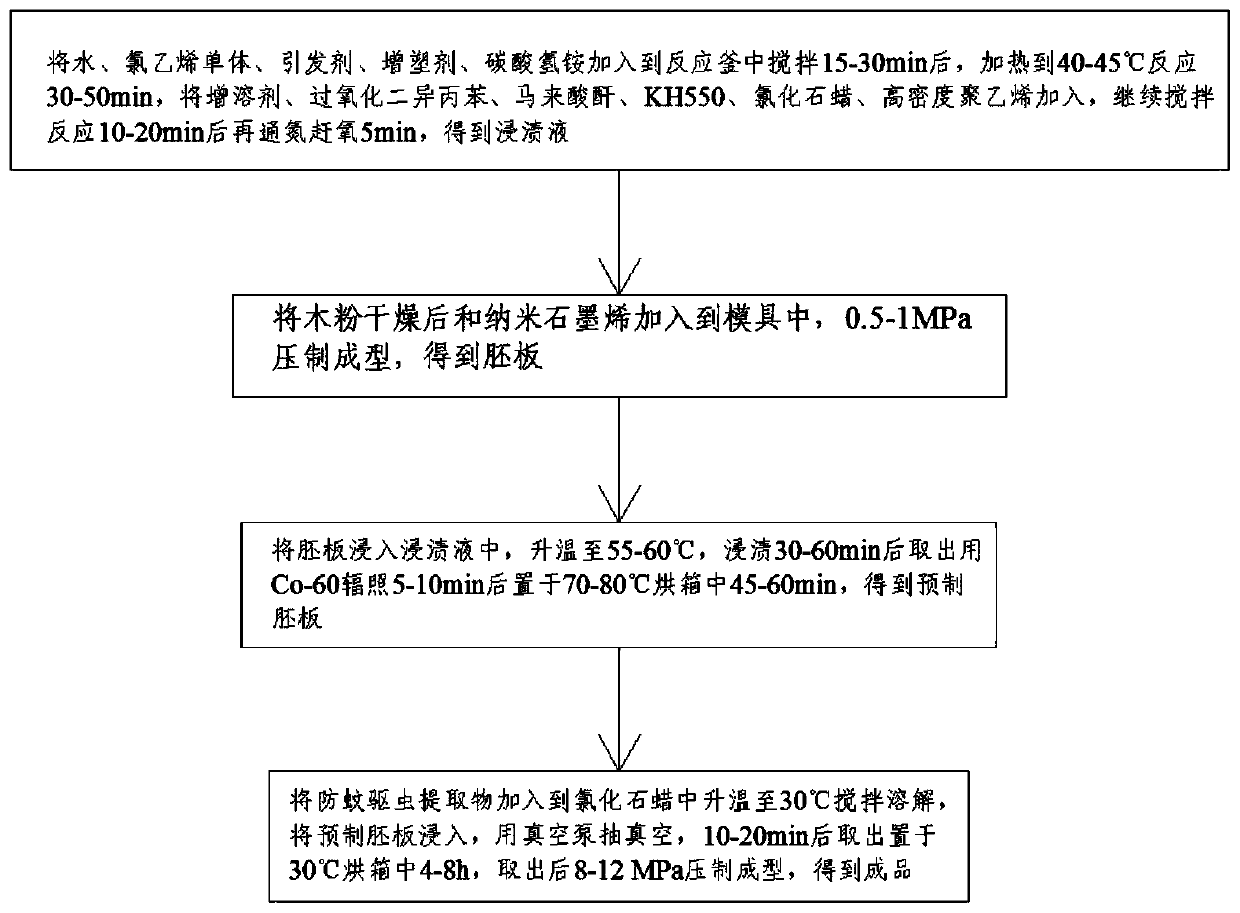

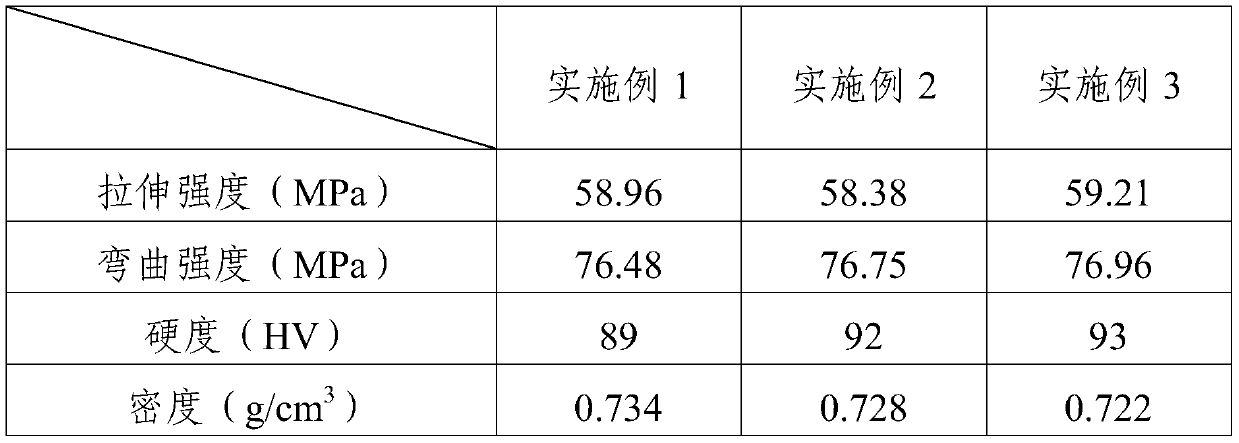

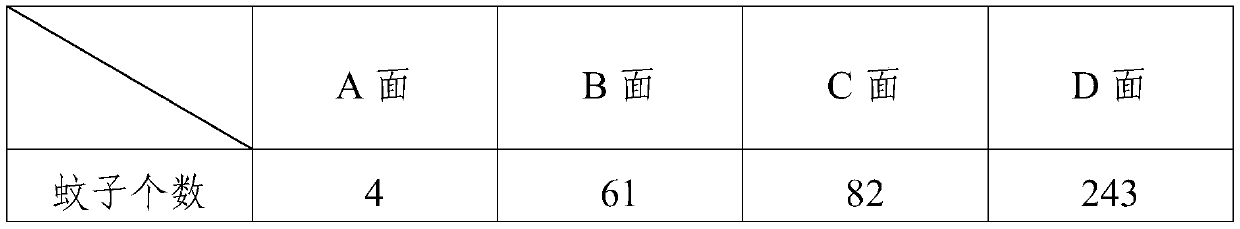

Mosquito-preventing and insect-expelling PVC composite material and preparation method thereof

InactiveCN111073108AImprove toughnessImprove mosquito repellent performanceChlorinated paraffinsZoology

The invention provides a mosquito-preventing and insect-expelling PVC composite material and a preparation method thereof, and relates to the field of polymer composites. The composition comprises thefollowing components in parts by weight: 160-200 parts of wood powder, 30-50 parts of anti-mosquito and insect-expelling extract, 20-40 parts of nano graphene, 100-120 parts of vinyl chloride monomer, 0.1-1 parts of an initiator, 20-30 parts of a plasticizer, 1-5 parts of ammonium bicarbonate, 10-30 parts of a solubilizer, 10-20 parts of dicumyl peroxide, 5-10 parts of maleic anhydride, 10-20 parts of KH550, 60-100 parts of chlorinated paraffin, 120-150 parts of high-density polyethylene and 400-500 parts of water. The composite material disclosed by the invention has anti-mosquito and insect-expelling properties, has quite excellent mechanical properties, and is suitable for large-scale use.

Owner:安徽亿脉通讯科技有限公司

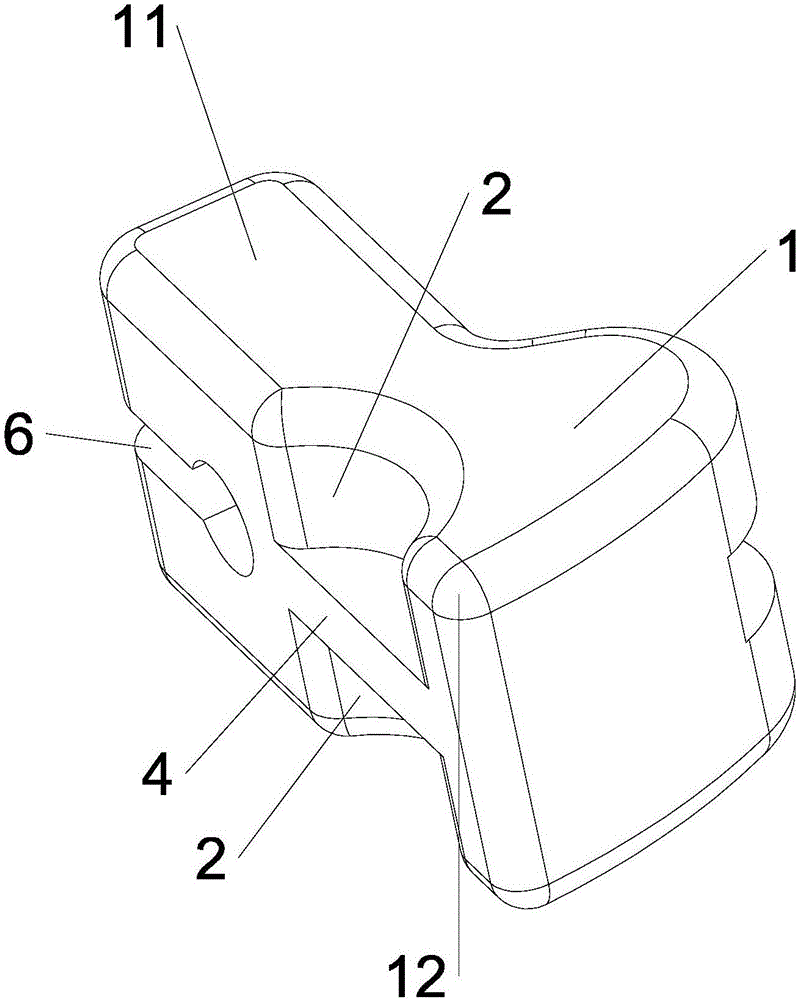

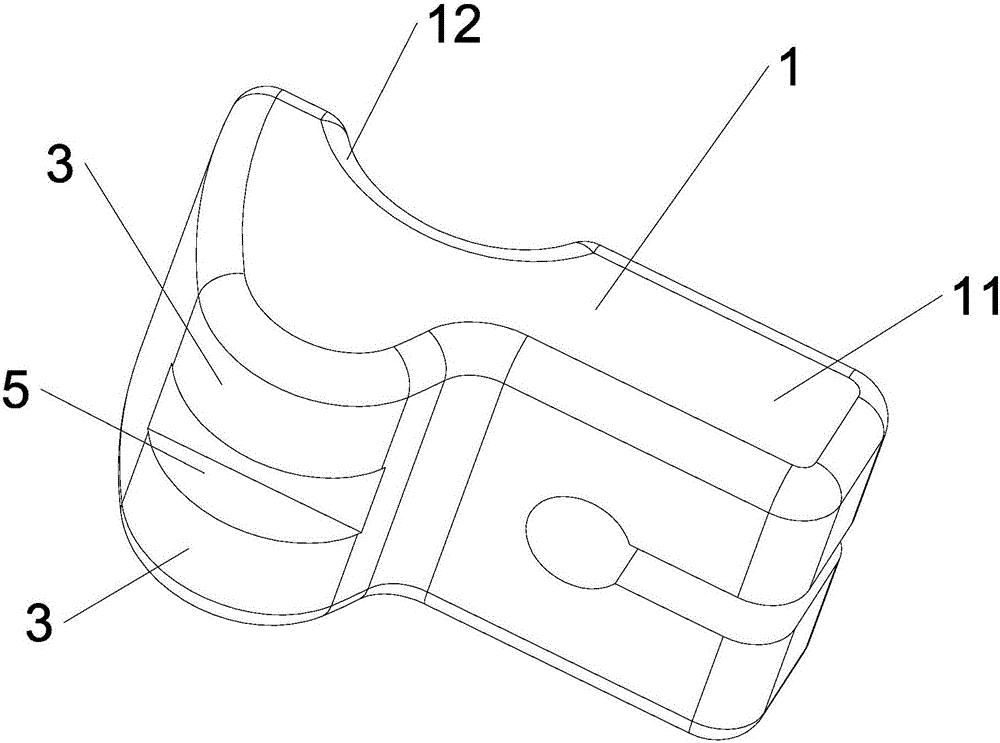

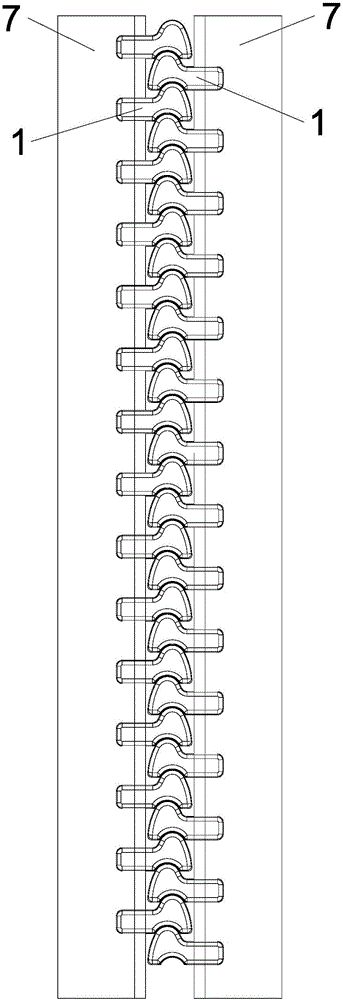

Novel plastic steel zipper tooth and zipper with zipper tooth

The invention discloses a novel plastic steel zipper tooth and a zipper with the zipper tooth. The novel zipper tooth comprises a zipper tooth body, a meshing concave portion, a meshing convex portion, a limiting projection, a limiting groove and a cloth tape containing groove, the meshing concave portion is separated from the middle by the limiting projection, and the meshing convex portion is disconnected from the middle by the limiting groove. When meshing is achieved, the meshing convex portion is inserted into the meshing concave portion, and the limiting groove is inserted into the limiting projection to position. The zipper with the novel zipper tooth comprises a pull head and zipper tapes, the novel zipper teeth for meshing are fixed on the zipper tapes, and the pull head is arranged on the zipper tapes in a penetrating manner and can be mutually connected with the zipper teeth. When two mutually meshed novel zipper teeth are meshed, the meshing convex portion is inserted into the meshing concave portion, and the limiting groove is inserted into the limiting projection to position in a clamping manner. The invention provides a new plastic steel zipper tooth structure, so that the novel plastic steel zipper tooth has appearance and texture of a metal zipper tooth and is low in production cost.

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

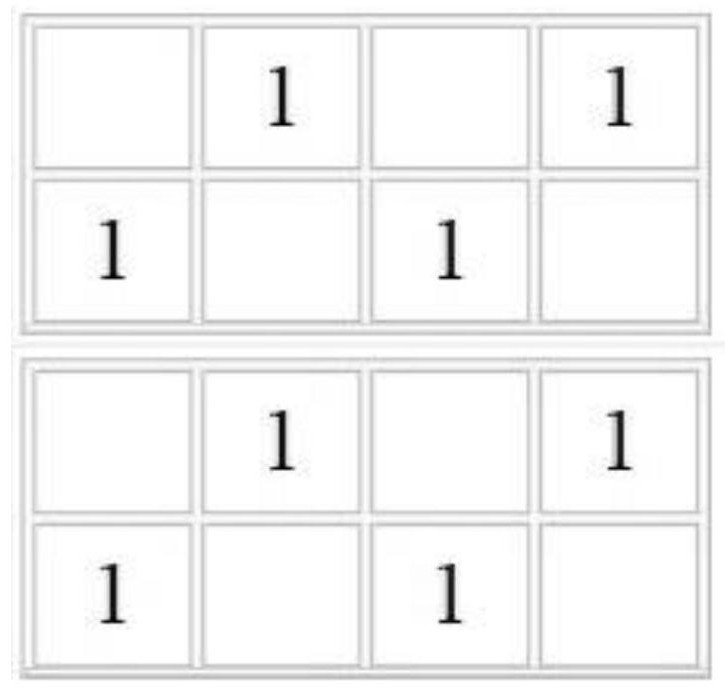

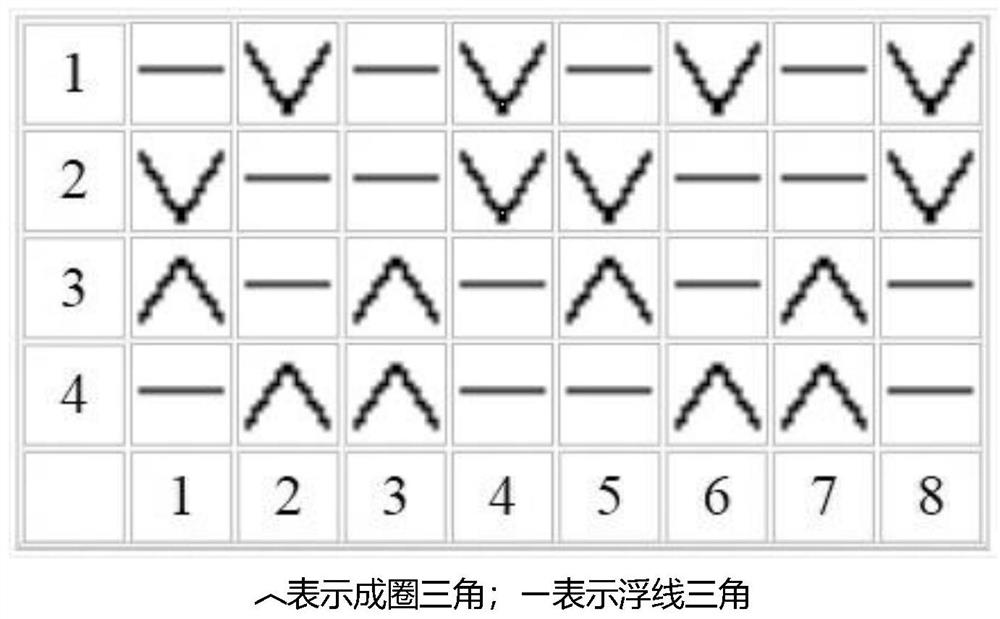

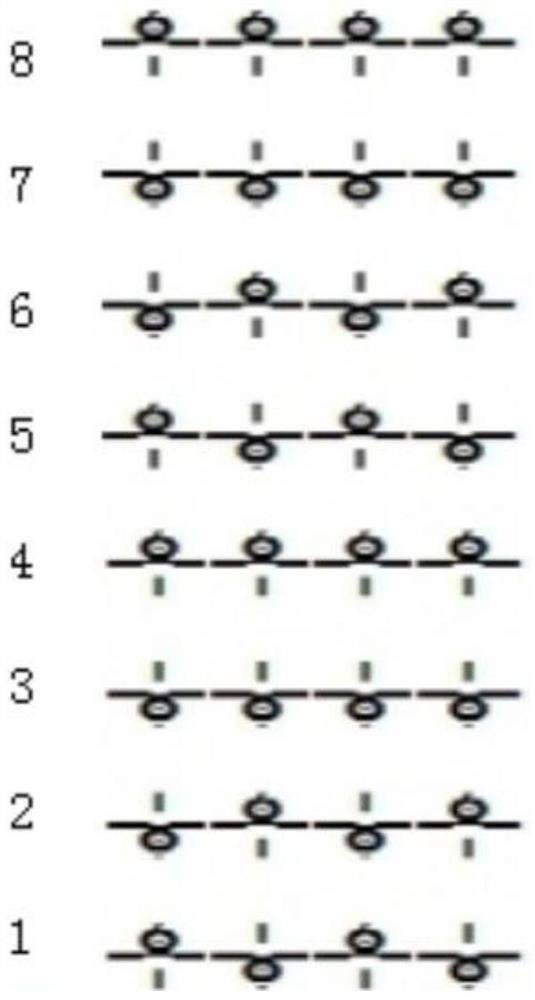

Bi-component polyester cotton-like elastic knitted fabric and preparation method thereof

The invention provides a bi-component polyester cotton-like elastic knitted fabric and a preparation method thereof. The fabric weave of the fabric is a variable Roman cloth weave; the fabric is formed by interweaving bi-component cotton-like elastic composite filaments and polyester filaments; and the bi-component cotton-like elastic composite filaments are draw-textured yarns formed by processing PTT / PET composite filaments and full-dull common polyester POYs (Polyester Pre-Oriented Yarns). According to the bi-component polyester cotton-like elastic knitted fabric and the preparation method thereof provided by the invention, the bi-component cotton-like elastic composite filaments and the conventional polyester are interwoven, so that the surface of the fabric presents unique stripe texture combining roughness and fineness; meanwhile, the fabric has excellent dimensional stability, pollution resistance, wrinkle resistance, wear resistance and easy-to-dye property due to the characteristics of the raw materials; and through the fabric containing the bi-component cotton-like elastic composite filaments and the open-width washing procedure and the sanding procedure which are added in the production process, the fabric is closer to the fluffy and soft touch feeling of a cotton material, and the appearance of the fabric is also closer to the appearance of the cotton material.

Owner:NINGBO DAQIAN TEXTILE

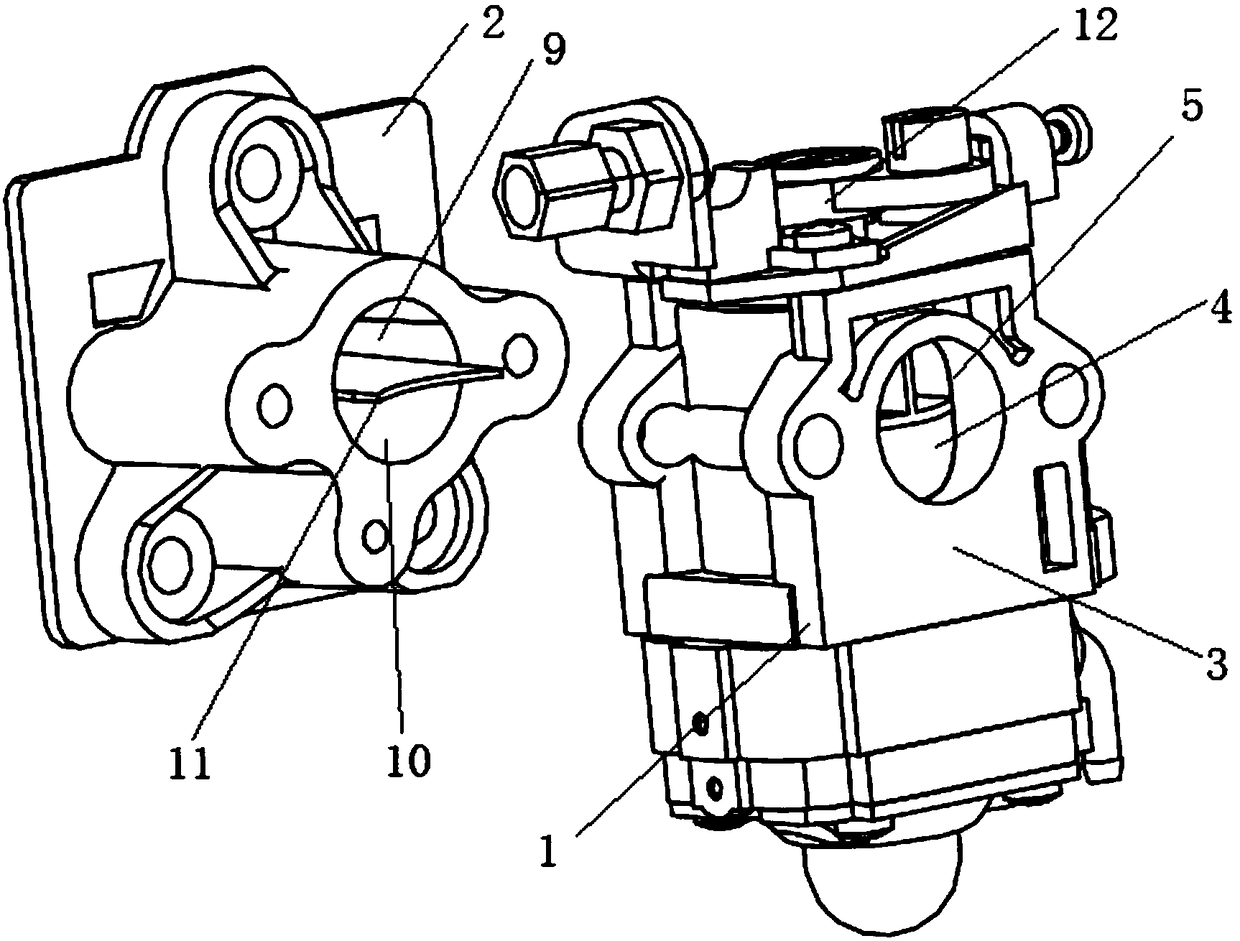

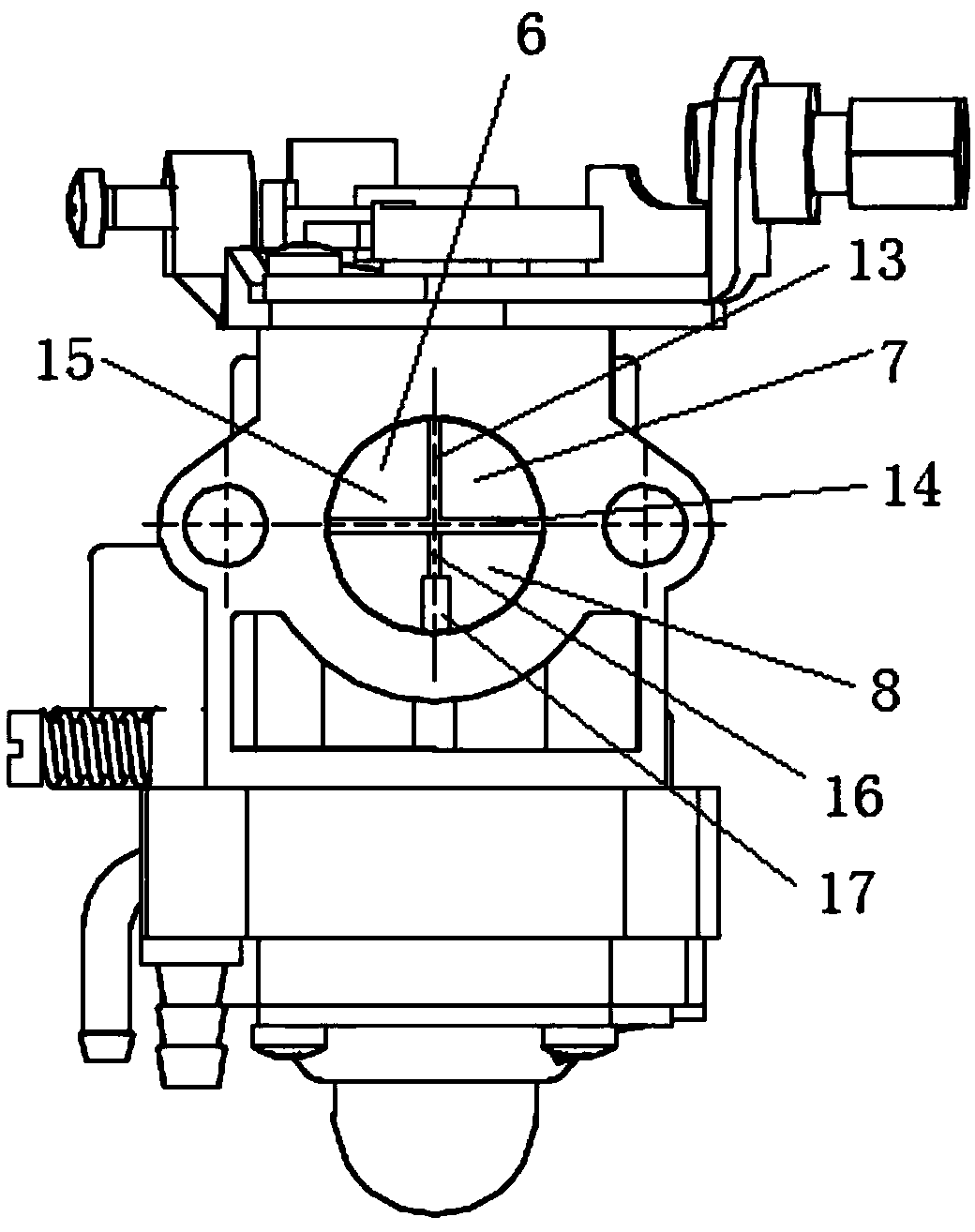

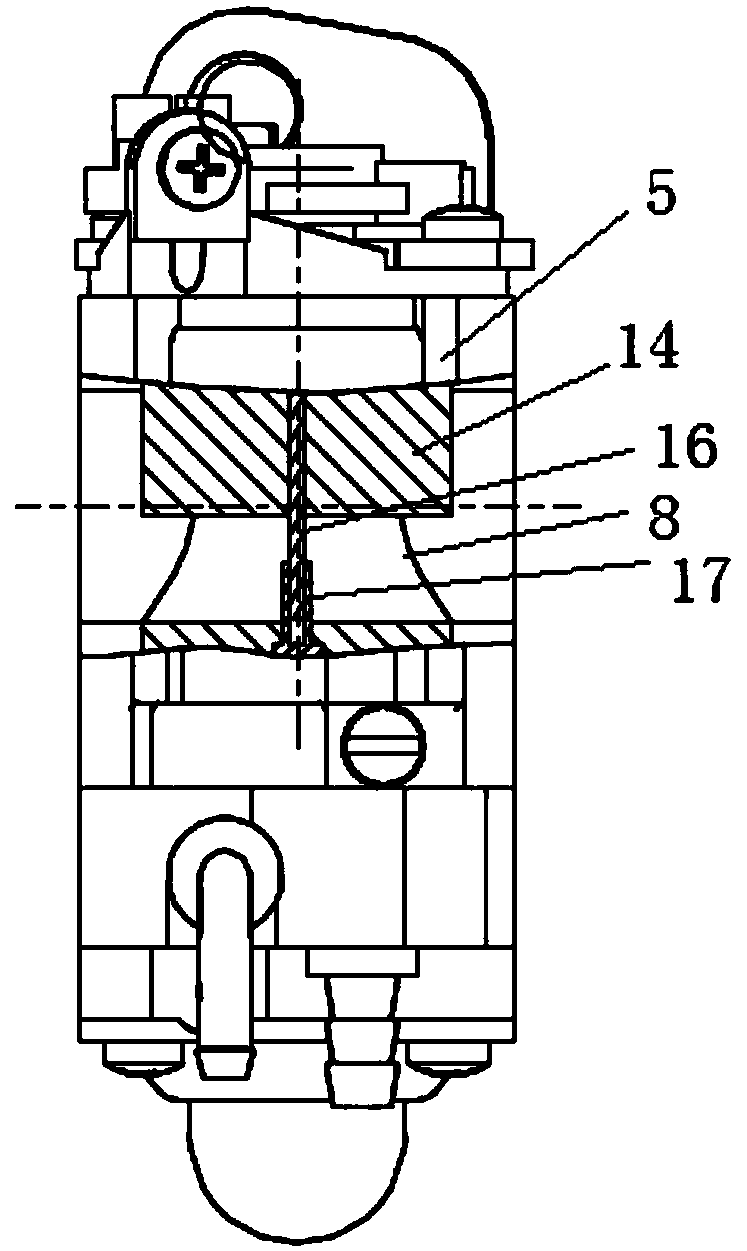

Two-stroke air-guided engine air inlet system

PendingCN108571405AWith the function of layered scavengingAppearanceMachines/enginesAir intakes for fuelRotary valveEngineering

The invention discloses a two-stroke air-guided engine air inlet system. The system comprises a carburetor, wherein the carburetor is connected with an air inlet pipe, the carburetor comprises a carburetor body and an air inlet passage arranged on the carburetor body, the air inlet passage is divided into a separate carburetor pure air first passage, a carburetor pure air second passage and a carburetor combustible mixed gas passage through a rotary valve; the air inlet pipe is internally provided with an air inlet pipe pure air passage communicated with the carburetor pure air first passage and the carburetor pure air second passage and an air inlet pipe combustible mixed gas passage communicated with the carburetor combustible mixed gas passage. The two-stroke air-guided engine air inletsystem has the advantages that the appearance and connection mode of a common carburetor are provided, so that the appearance of the whole machine and a throttle operating mechanism do not need to bechanged, and compared with the whole machine adopting a conventional stratified scavenging engine air inlet system, the structure is simpler, and the reliability is higher.

Owner:王廷高

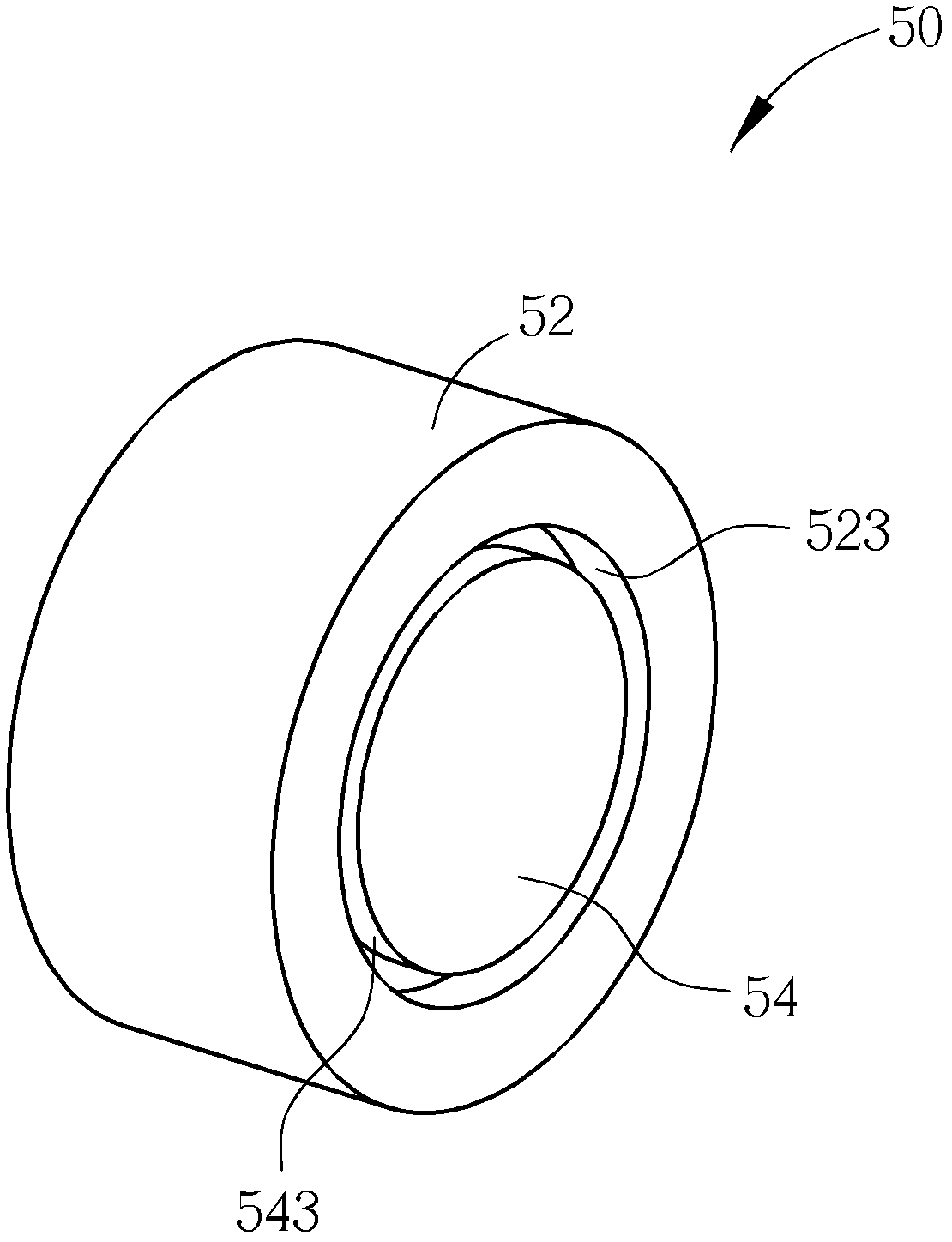

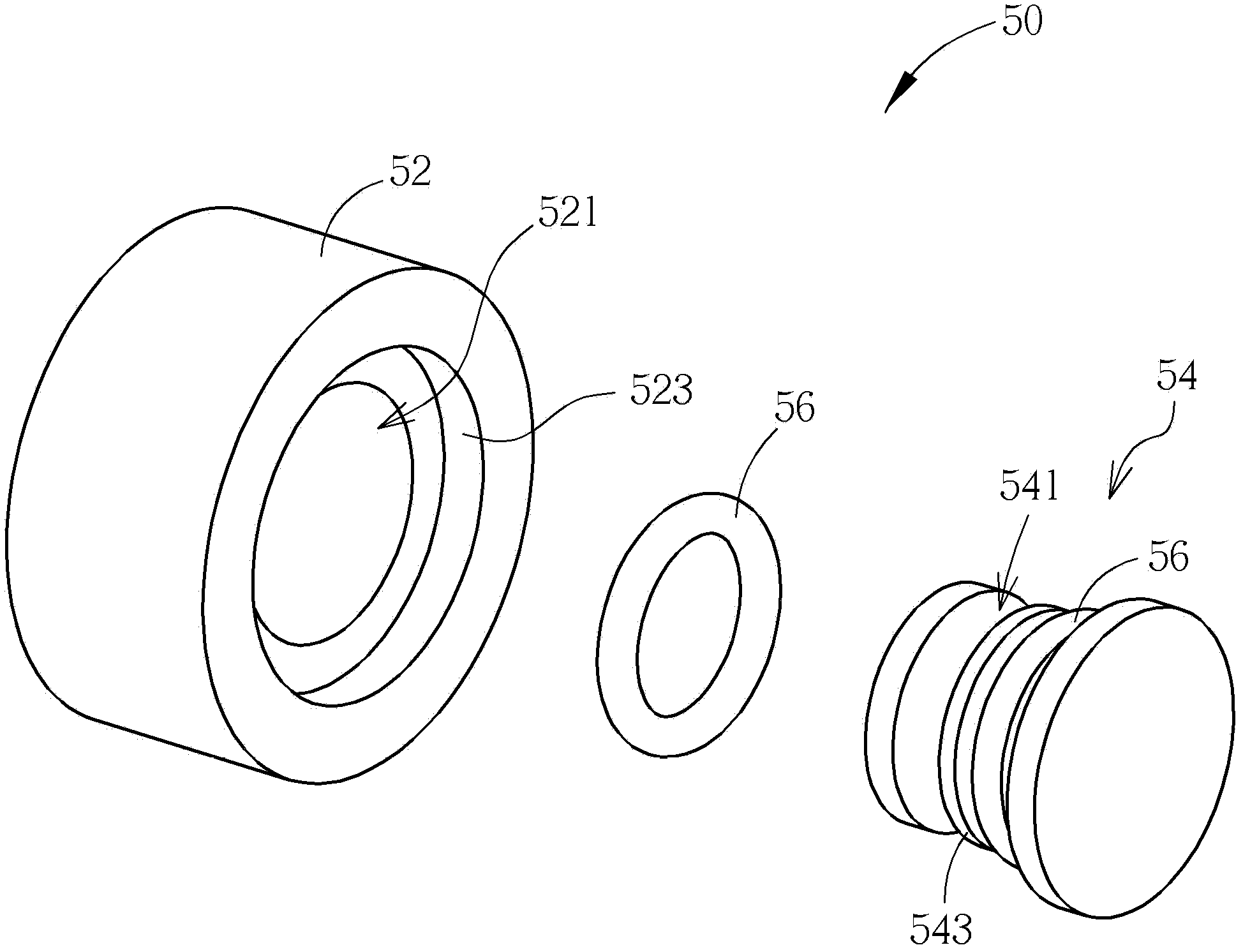

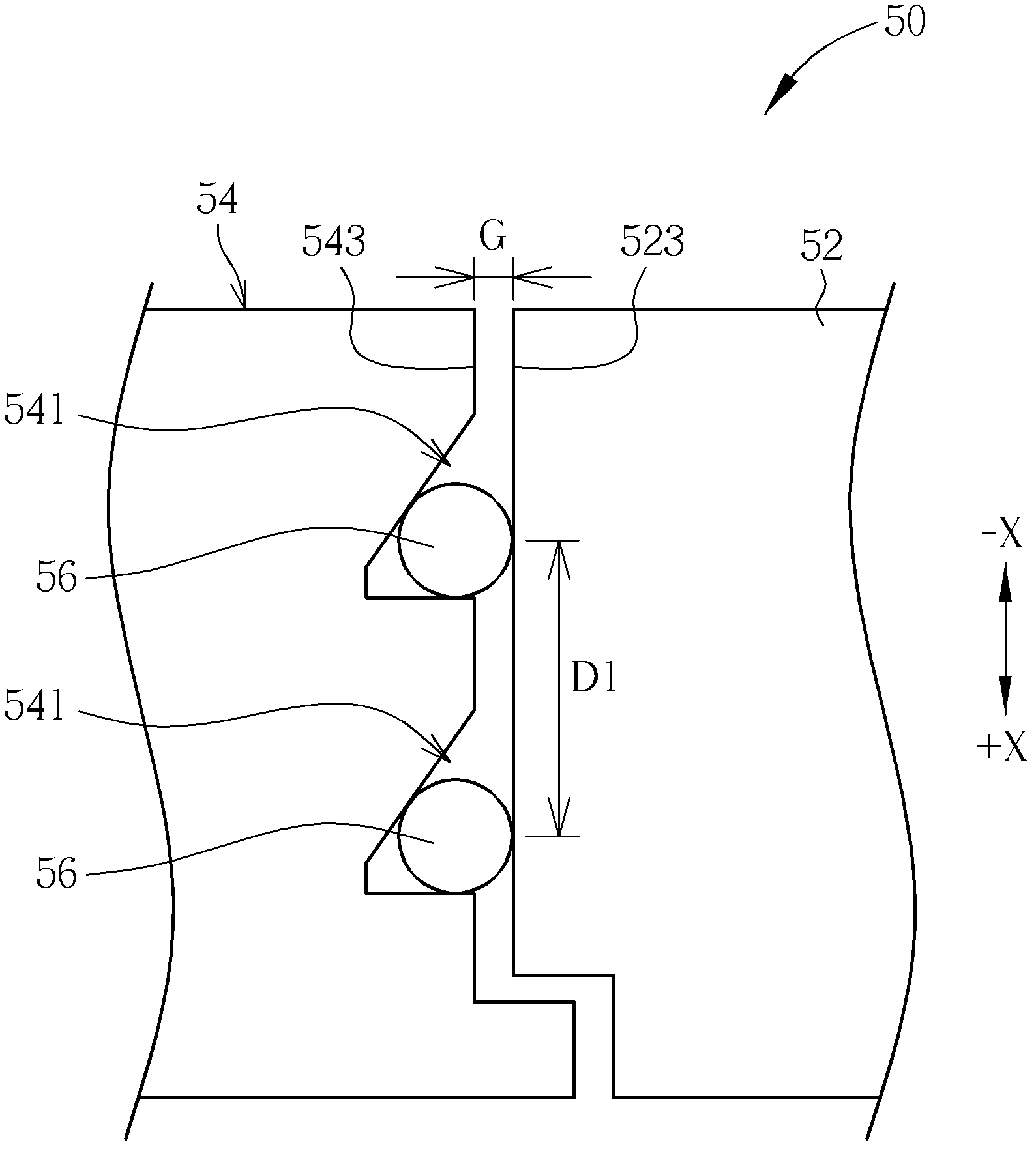

Press button device having waterproof function

InactiveCN103187192AExtend assembly hoursAppearanceElectric switchesEngineeringMechanical engineering

The invention provides a press button device having a waterproof function. The press button device having a waterproof function includes a first press button shell, a press button body and at least one elastic element. A hollow accommodation chamber is formed in the press button shell. The press button body can be installed in the hollow accommodation chamber in a manner of moving in a first direction. At least one groove is formed in the press button body. A gap is formed between an outer edge of the press button body and an inner wall of the press button shell. The elastic element is installed in the groove and the gap is enclosed. When the press button body is pressed in the first direction and moves relative to the press button shell, the elastic element is pressed elastically by the elastic element for providing elastic returning force to the press button body, so that the press button body is driven to move in a direction opposite to the first direction relative to the press button shell.

Owner:WISTRON CORP

Method for preparing contraposition aramid fiber dissolving pulp from contraposition aramid fiber waste silk chopped fiber

ActiveCN101440589BSolve the problem of resource utilizationWill not increase investmentPulp beating methodsSynthetic cellulose/non-cellulose material pulp/paperDissolving pulpBody fluid

The invention discloses a method for preparing p-phenylene terephalamide pulp from short cut p-phenylene terephalamide waste fibers through pre-treatment and combined beating. The method comprises: pretreating the short cut p-phenylene terephalamide waste fibers with a 2 to 50 percent swelling agent at 20 to 60 DEG C for 1 to 24 hours first, wherein the bath ratio is (5-50):1; and then subjectingthe pretreated short cut p-phenylene terephalamide waste fibers to body fluid exhaustion and washing, preparing a suspension of fibers with a pulp mass concentration of 0.25 to 3 percent with the short cut p-phenylene terephalamide waste fibers, and beating by a two-stage combined bearing process of a trough-style pulp beater to obtain the p-phenylene terephalamide pulp. The method is characterized by taking the short cut p-phenylene terephalamide waste fibers as a raw material, using the swelling agent to pretreat the short cut p-phenylene terephalamide waste fibers, preparing the p-phenylene terephalamide pulp by the two-stage beating process, shortening time for beating, improving the added value of p-phenylene terephalamide waste fibers and preparing the p-phenylene terephalamide pulpwith excellent performance.

Owner:SINOPEC OILFIELD SERVICE CORPORATION +1

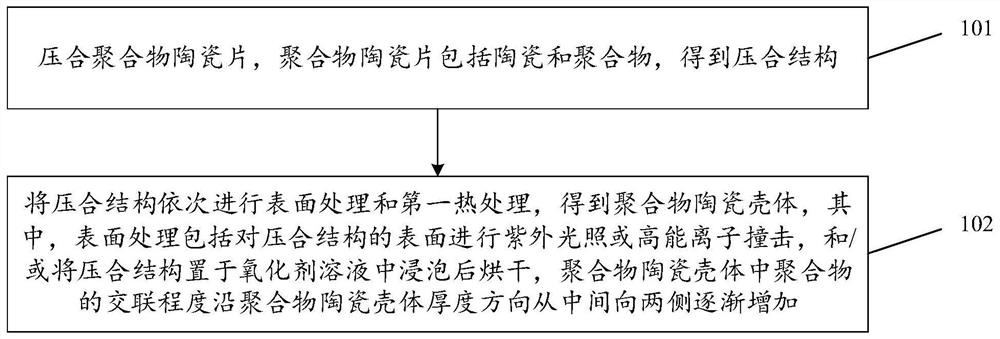

Polymer ceramic shell and electronic equipment

ActiveCN113347828AReduce the degree of crosslinkingImprove toughnessCasings/cabinets/drawers detailsWear resistancePolymer

The invention provides a polymer ceramic shell, and the shell comprises ceramic and a polymer, wherein the crosslinking degree of the polymer in the polymer ceramic shell is gradually increased from the middle to the two sides in the thickness direction of the polymer ceramic shell. The polymer in the polymer ceramic shell is small in crosslinking degree and good in toughness, the impact resistance of the polymer ceramic shell is improved, the outside of the polymer ceramic shell is large in crosslinking degree, high in surface density, low in surface energy, large in hardness and excellent in wear resistance, meanwhile, the polymer ceramic shell further has ceramic texture and appearance, and application of the polymer ceramic shell is better facilitated. The invention further provides electronic equipment with the polymer ceramic shell.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

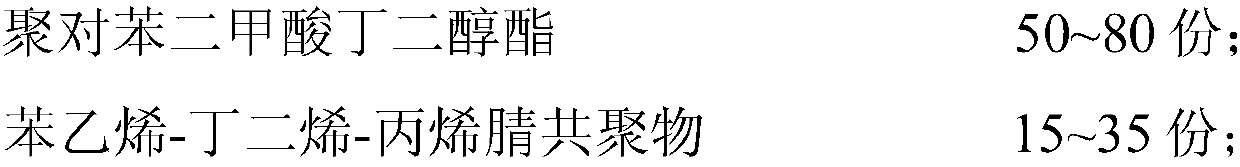

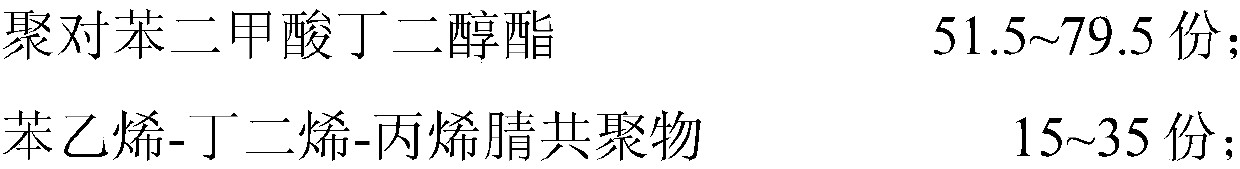

PBT (polybutylene terephthalate) zipper material with high modulus and washability and application of PBT zipper material

ActiveCN109679302AHigh modulusImprove washing resistancePolytetramethylene terephthalateAcrylonitrile

The invention discloses a PBT (polybutylene terephthalate) zipper material with high modulus and washability and an application of the PBT zipper material in preparation of gold stamped zippers. The PBT zipper material is prepared from raw materials in parts by weight as follows: 50-80 parts of PBT, 15-35 parts of a styrene-butadiene-acrylonitrile copolymer, 1-8 parts of a modified nucleating agent, 1-5 parts of a compatilizer, 1-5 parts of a toughening agent and 0.1-2 parts of a processing aid; the modified nucleating agent comprises a coating structure taking titanium dioxide as a shell andminerals as a core, and the minerals are selected from at least one of talc powder, barium sulfate and sheet mica. The special PBT zipper material has the advantages of high modulus and washability, has excellent processability and cloth adhesion, has appearance and texture of metal zippers and is particularly suitable for preparation of high-end gold stamped zippers.

Owner:CGN JUNER NEW MATERIALS +1

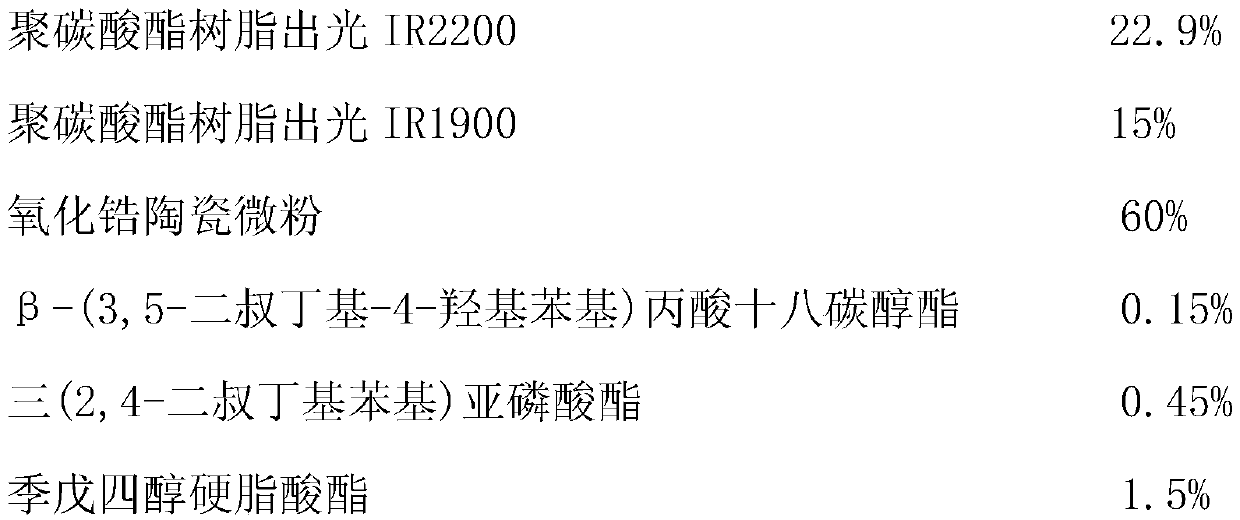

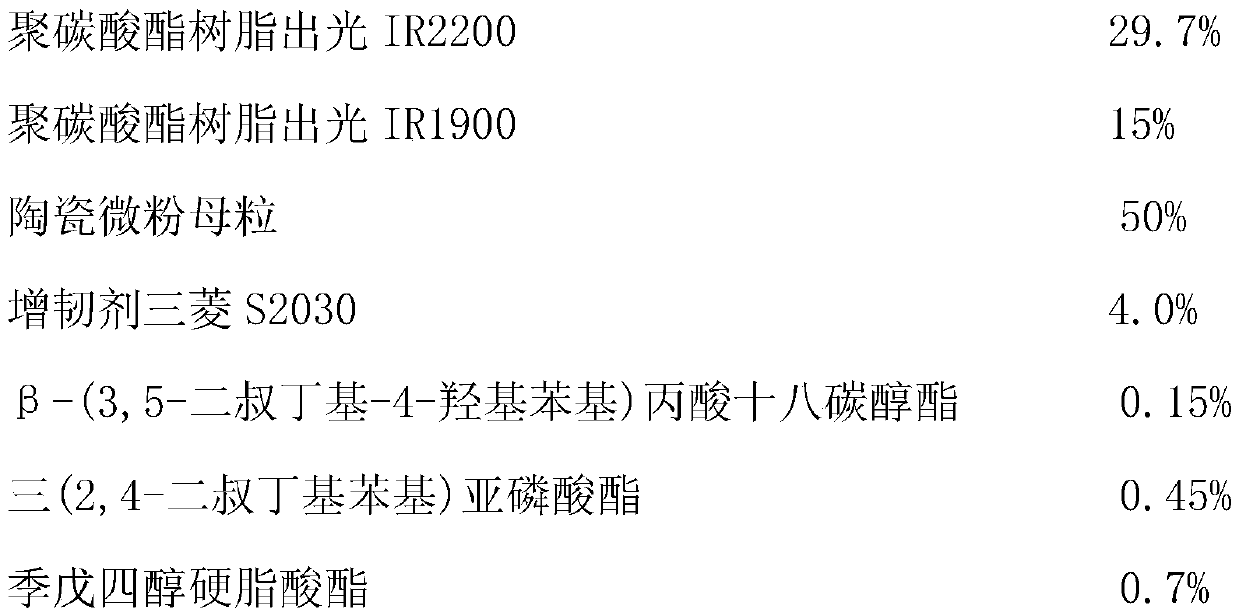

Ceramic micro-powder master batch, polymer composite material with ceramic texture and preparation methods of ceramic micro-powder master batch and polymer composite material

The invention discloses a ceramic micro-powder master batch, a polymer composite material with ceramic texture and preparation methods of the ceramic micro-powder master batch and the polymer composite material. According to the formula of ceramic micro-powder master batch, the weight percentage of the high-molecular polymer is 40%-58.5%; the weight percentage of the ceramic micro powder is 40%-58.5%; the weight percentage of the antioxidant is 0.5%-1%; the weight percentage of the lubricant is 1%-3%. According to the formula of the polymer composite material with ceramic texture, the weight percentage of the high-molecular polymer is 20%-47%; the weight percentage of the ceramic micro-powder master batch is 50%-77%; the weight percentage of the toughening agent is 2%-6%; the weight percentage of the antioxidant is 0.5%-1.0%; the polymer composite material with ceramic texture is prepared from the ceramic micro-powder master batch, the ceramic micro-powder is dispersed and mixed more uniformly through secondary processing, and the polymer composite material has the advantages of being stable in performance, good in heat dissipation effect, good in appearance and hand feeling and has the ceramic texture.

Owner:DONGGUAN BAILIXING NEW MATERIAL CO LTD

Smoking oil cream for treating herpes zoster and method for preparing smoking oil cream

InactiveCN105267424ANo pollutionEasy to get dirtyAerosol deliveryOintment deliveryParaffin waxSweet flavor

The invention discloses smoking oil cream for treating herpes zoster and a method for preparing the smoking oil cream. The smoking oil cream comprises, in parts by weight, 8-12 parts of thick tobacco smoking oil extract, 15-19 parts of stearic acid, 1-3 parts of lanolin, 7-12 parts of liquid paraffin, 0.08-0.12 part of ethylparaben, 3-8 parts of glycerin, 4-8 parts of triethanolamine, 3-7 parts of menthol and 55-75 parts of distilled water. The smoking oil cream and the method have the advantages that the smoking oil cream mainly comprises the thick tobacco smoking oil extract, tobaccos are warm in nature and have sweet flavor, and effects of diminishing swelling, removing toxicity, killing insects and the like can be realized by the tobaccos; tobacco extract is completely extracted by the aid of the distilled water, accordingly, the method is simple and convenient, the smoking oil cream is low in cost, and environmental pollution and residual solvents can be prevented; the prepared cream is attractive and is easy to apply and wash, users feel comfortable, and clothes can be prevented from being contaminated by the smoking oil cream.

Owner:田友清

Light-weight stainless steel water meter shell

The invention discloses a light-weight stainless steel water meter shell which consists of an upper shell, a lower shell and a movement, wherein the upper shell comprises a metal wrapping housing, an inner plastic cavity, O-shaped rings and a tempered glass panel, the metal wrapping housing is arranged outside the upper shell, the inner plastic cavity is formed in the upper shell, the O-shaped rings sleeve the tempered glass panel, and the tempered glass panel is arranged on the top surface of the upper shell; the lower shell comprises a metal wrapping housing, an inner plastic cavity and two knurling connection pipes, the metal wrapping housing is arranged outside the lower shell, the inner plastic cavity is formed in the lower shell, the two knurling connection pipes are arranged on two sides of the lower shell, and the movement is arranged on the lower shell; plastic rubber is injected into a groove of the inner plastic cavity of the lower shell; an opening of the inner plastic cavity of the upper shell is inserted into the groove of the inner plastic cavity of the lower shell; the upper shell and the lower shell are in sealing adhesion. The light-weight stainless steel water meter shell has the beneficial effects of high quality and low cost.

Owner:中安中合(宁波)科技有限公司

Producing method of rayon knitting composite fabric

InactiveCN103862804AComfortable to wearHas a silk feelWeft knittingSynthetic resin layered productsYarnSteam pressure

The invention discloses a producing method of rayon knitting composite fabric. Artificial viscose rayon with a size of 13.3 tex and combed cotton yarn with a size of 14.5 tex are adopted as raw materials. The method includes: interweaving by adopting a single-jersey 4-track circular machine with a machine gauge of 18 needle / 2.54 cm, heating water to 40 DEG C, adding grey fabric and a cleansing agent, washing to remove dirt on the surfaces of the fabric, drying at a low temperature, stentering and setting the dried grey fabric by a combined heat finishing machine at a temperature of 190-220 DEG C and under a steam pressure of 2.5-3.5 kg / cm<2>, naturally cooling the set grey fabric for 24 h, coating thermoplastic polyurethane (TPU) film with glue, preheating the film, subjecting the film and the obtained fabric to thermocompression bonding, and cooling to obtain a finished product. The method is simple in processing process and low in producing cost. The fabric has hygroscopicity similar to that of natural fiber and is comfortable to wear. The fabric has handfeel and appearance like silk, and is bright and clean. In addition, the fabric has good waterproofness, good moisture penetrability, and good antibacterial and bacteriostatic performances.

Owner:QINGDAO TONGGUANWANG IND

Cuiya tea shaping technology

InactiveCN106070743AImprove integrityConsistent shape and flatnessPre-extraction tea treatmentEngineeringTea leaf

The invention discloses a Cuiya tea shaping technology in the tea processing technical field. The invention includes the steps of primary shaping, secondary shaping, tertiary shaping and fourth shaping. In the primary shaping step, tidied tea leaves are placed into a first pot of a continuous tea flatting machine, pressed for 2-2.5 min and put into a second pot, wherein the temperature is 110-115 DEG C, the tea leaf input amount is 200-250 g, and the gap between a pot body of the first pot and a pressing plate is 3-3.5 mm. In the second shaping step, the gap between a pot body of the second pot and the pressing plate is adjusted to be 2-2.5 mm, and the tea leaves are pressed for 1.5-2 min at the temperature of 95-100 DEG C and put into a third pot. In the tertiary shaping step, the gap between a pot body of the third pot and the pressing plate is 1.5-2 mm, and the tea leaves are pressed for 1.2-1.5 min at the temperature of 85-90 DEG C and put into a fourth pot. In the fourth shaping step, the gap between a pot body of the fourth pot and the pressing plate is adjusted to be 1.5 mm, the tea leaves are pressed for 1-1.5 min at the temperature of 80-85 DEG C and discharged, and shaping of Cuiya tea is finished. By means of the shaping technology, the pressing plate is stressed by tea leaves, so the tea leaves rub the pot bodies back and forth, the technology has the advantages of manual frying, quality of tea is effectively improved, Meitan Cuiya tea good in smell and mellow in taste, uniform and complete is produced, and grand positioning of Meitan Cuiya tea is expected to be improved.

Owner:GUIZHOU YANGCHUNBAIXUE TEA IND

Toilet seat and manufacturing method thereof

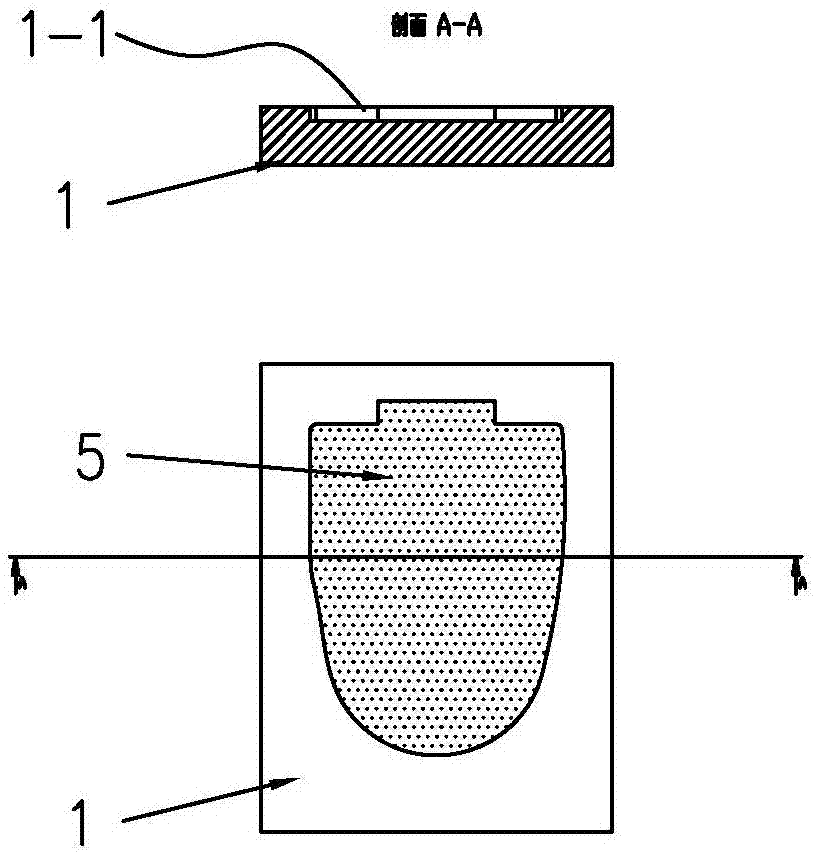

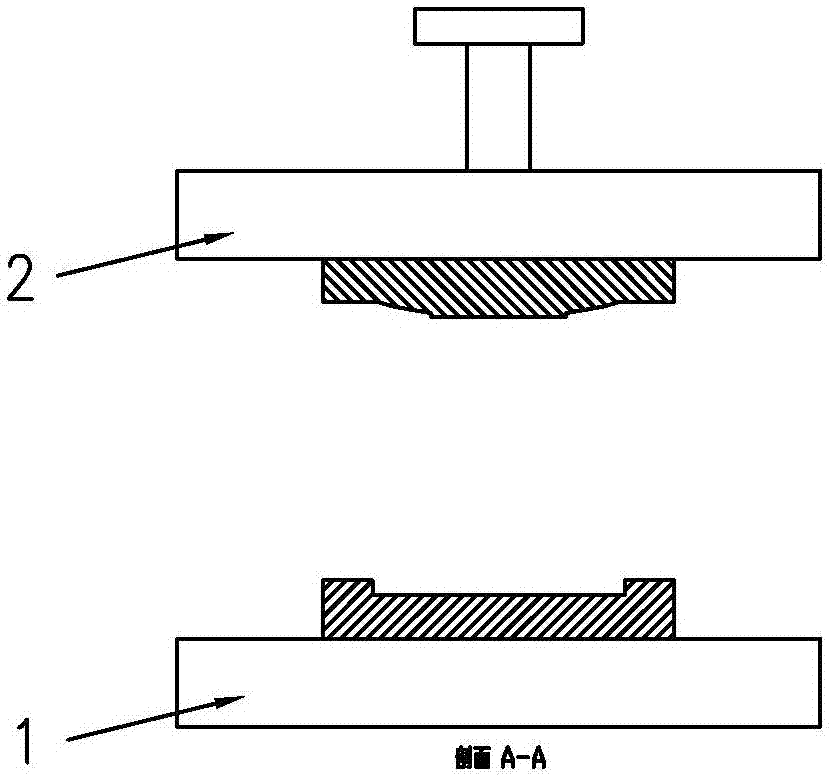

PendingCN107627518ALow priceEasy to operateBathroom coversDomestic articlesCompression moldingEngineering

The invention discloses a toilet seat and a manufacturing method of the toilet seat. The toilet seat comprises a thermosetting resin seat body. A heating component is embedded into the body. The method comprises the following steps that 1), thermosetting resin particles are provided; and two molds with upper mold bodies and a lower mold body are arranged, wherein the two molds share the same lowermold body; 2), a first layer of urea-formaldehyde particles is laid in the first mold of a compression molding machine; the first upper mold body is combined, and forming is performed; and the firstupper mold body is opened and moved away; 3), the heating component is laid on the preliminarily-formed seat; 4), a second layer of urea-formaldehyde particles is laid on the heating component and thepreliminarily-formed seat; and 5), the second upper mold body is combined, and compression forming is performed. The manufacturing method is simple, the product is attractive in appearance, and the higher safety is achieved.

Owner:BESTTER XIAMEN TECH

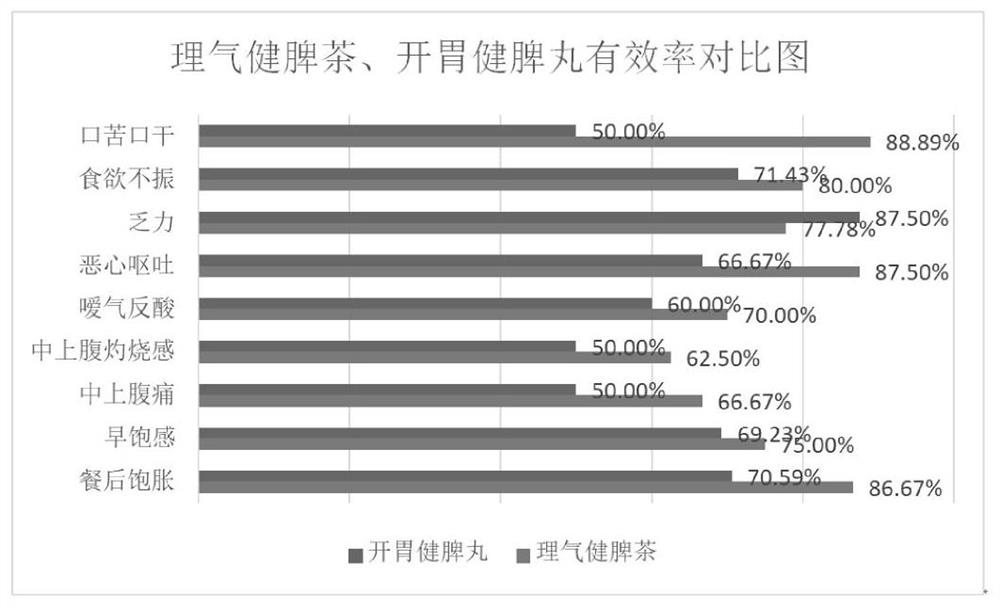

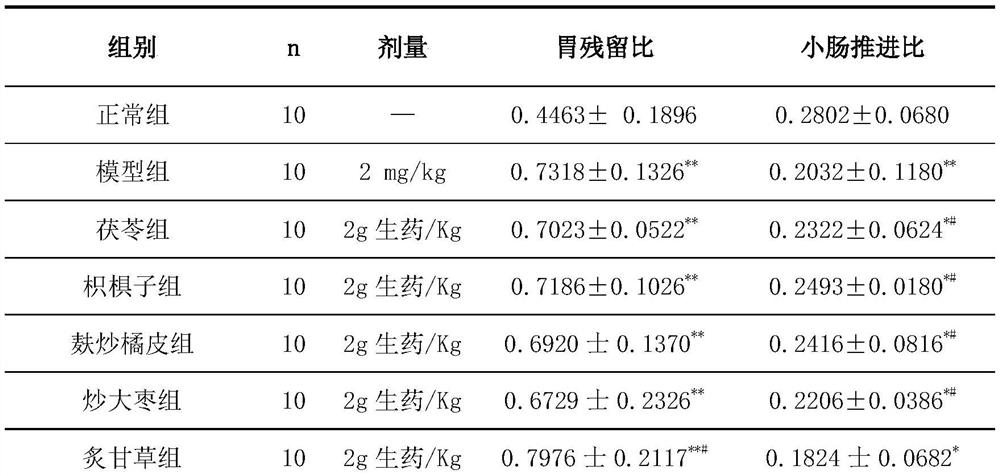

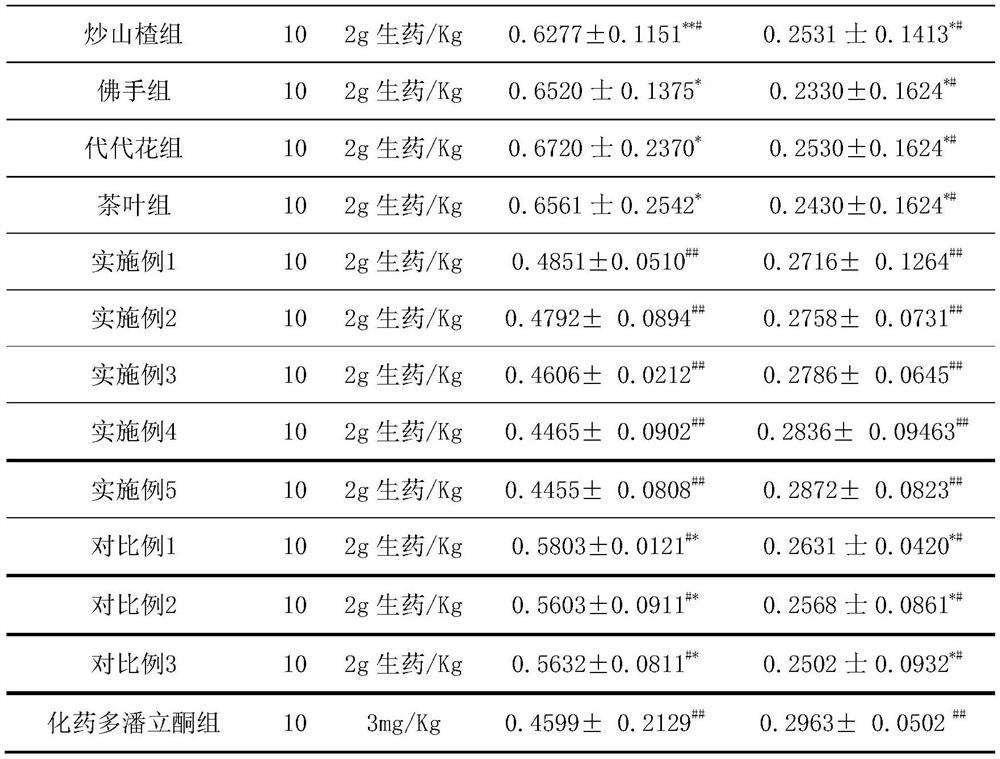

Health-care tea for regulating qi-flowing for strengthening spleen

PendingCN111670977AIncrease appetiteEasy to drinkPre-extraction tea treatmentMetabolism disorderBiotechnologyMedicinal herbs

The invention relates to a health-care beverage, in particular to health-care tea for regulating qi-flowing for strengthening spleen and a preparation method of the health-care tea. The health-care tea disclosed by the invention consists of medicinal and edible medicinal material extracts and tea leaves in a weight ratio of (1: 10)-(10: 1), wherein the tea leaves are 1-50 parts, and the medicinalmaterial extracts are prepared from the following raw material in parts by weight: 1-5 parts of poria cocos, 1-4 parts of hovenia dulcis thumb, 1-4 parts of pericarpium citri tangerinae, 0.1-1 part offructus auranti, 0.1-1 part of liquorice, 1-4 parts of fructus ziziphi jujubae, 0.1-1 part of fructus crataegi and 0.1-1 part of fructus citri sarcodactylis.

Owner:JIANGXI HUIREN PHARMA CO LTD

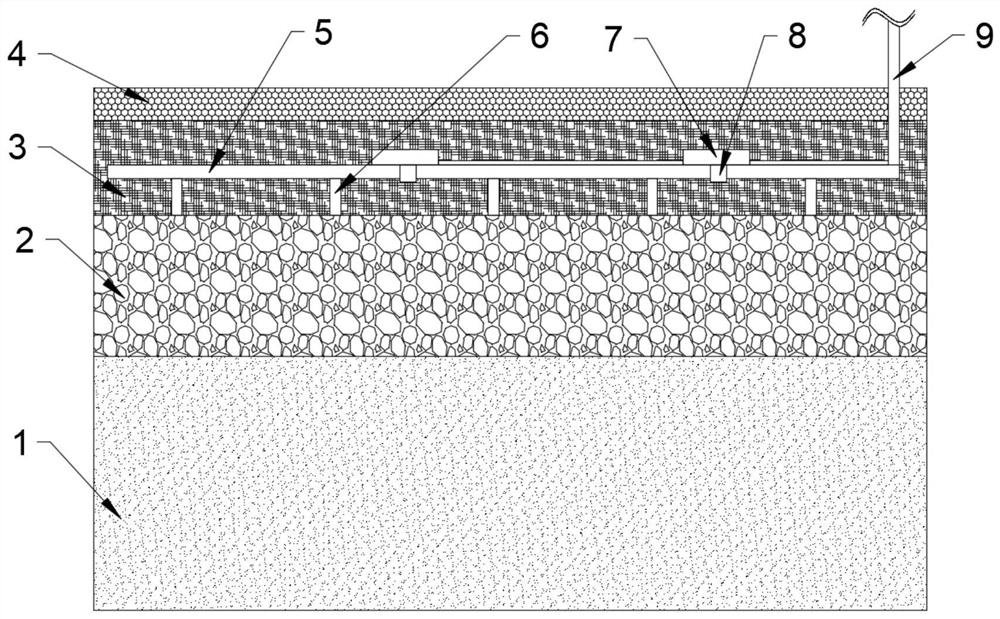

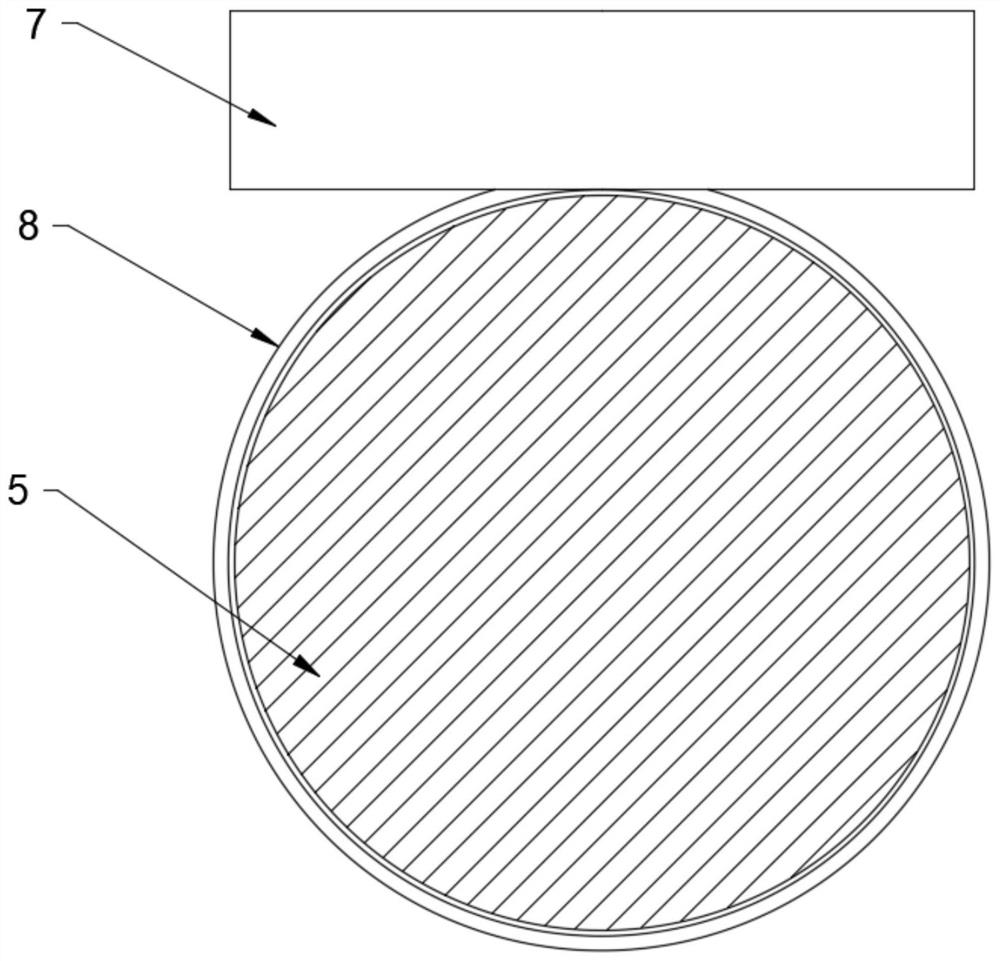

Multifunctional colored concrete structure and preparation process

ActiveCN114263075AHigh strengthMonitor permeabilitySolid waste managementMacromolecular adhesive additivesPhotopigmentRebar

The invention belongs to the technical field of concrete, and provides a multifunctional color concrete structure which comprises a color layer, a color layer, a concrete layer, a gravel layer and a foundation soil layer which are sequentially arranged, steel bars are arranged in the concrete layer in a staggered mode, and a plurality of detection elements are installed on the steel bars at intervals; the color layer is prepared from the following raw materials in parts by weight: 10 to 20 parts of cementing agent, 1 to 3 parts of pigment, 2 to 4 parts of sulfide series light-storing self-luminous material, 80 to 100 parts of filler with the particle size of 1 to 2mm, 3 to 8 parts of auxiliary agent and 15 to 25 parts of water; the reinforcing steel bars are arranged in the concrete layer, the strength of the concrete layer can be improved, the multiple detection elements are installed on the reinforcing steel bars at different points, the permeability and the pressure resistance of the concrete layer can be monitored, and the multifunctional effect is provided for the concrete structure; the problem that traditional concrete cannot meet the requirements of the modern society for diversification of roads or grounds is solved.

Owner:上海拜石实业发展有限公司

Ciprofloxacin lactate gel for ears and preparation method of ciprofloxacin lactate gel

InactiveCN105560164ASimple preparation processAppearanceAntibacterial agentsOrganic active ingredientsIsopropylene glycolPropylene glycol

The invention relates to the technical field of medicine preparation, in particular to ciprofloxacin lactate gel for the ears and a preparation method of the ciprofloxacin lactate gel. The ciprofloxacin lactate gel comprises 0.5-1g of ciprofloxacin lactate, 10-15mL of propylene glycol, 20-25mL of ethanol, 0.5-1.0g of CMC-Na, 0.5-1g of Carbomer 940 and 100g of purified water. The ciprofloxacin lactate gel for the ears is simple in preparation process, attractive in property, easy in coating, easy to absorb after local administration, capable of avoiding clothes contamination and good in stability.

Owner:SHAANXI SHENGMAI PETROLEUM

Plant straw reinforced polyolefin composite material and manufacturing method thereof

The invention discloses a plant straw reinforced polyolefin composite material and a preparation method thereof. The composite material is composed of natural plant straw, polyolefin plastic and processing aids, wherein the plant straw is 50% to 70%, and the polyolefin plastic is 30%. % to 50%, the total is 100%, and the processing aid is 2% to 5% of the total weight of plant straw and recycled polyolefin plastics. For plant straw, use wheat straw or rapeseed stalk or a mixture of the two; for polyolefin plastics, use recycled waste polyvinyl chloride or polyethylene, or a mixture of the two; processing aids include coupling agents, compatibilizers, and lubricants. Any combination of two or three. The preparation method of the present invention is that the plant straw is crushed and dried, mixed with a processing aid, then blended with polyolefin pellets, pelletized, extruded, cooled and shaped, dragged and cut into a plastic wood material of a certain specification. The composite material prepared by the invention has the appearance of wooden products and the processing characteristics of plastic-wood materials, and has a wide range of applications.

Owner:蒋寿悟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com