Mosquito-preventing and insect-expelling PVC composite material and preparation method thereof

A composite material and anti-mosquito technology, which is applied in the field of anti-mosquito and insect repellent PVC composite materials and its preparation, can solve the problems of inability to be applied on a large scale and low structural strength, so as to improve the performance of anti-mosquito and insect repellent, overcome perishability, prevent Excellent mosquito repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

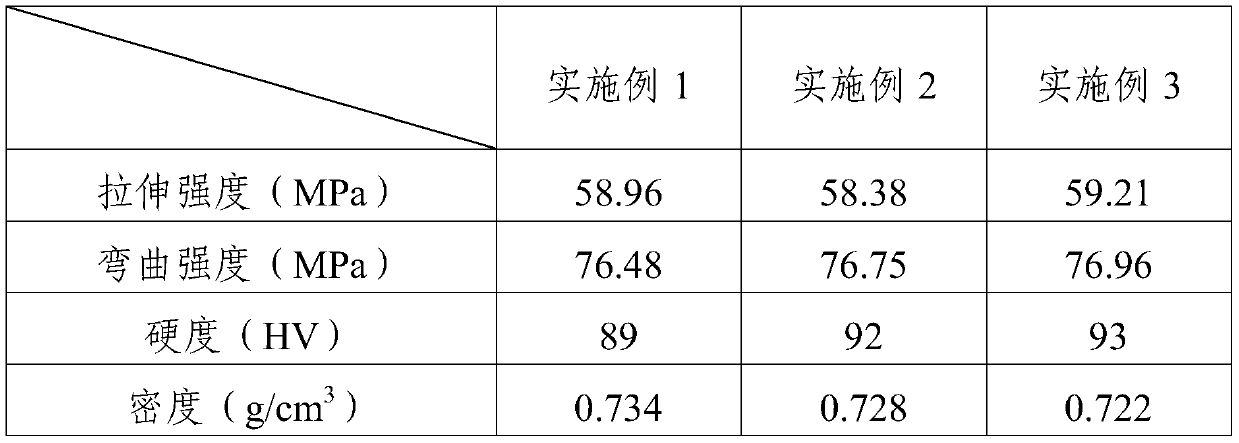

Embodiment 1

[0030] A kind of anti-mosquito and repellent PVC composite material, comprising the following components in parts by weight: 180 parts of wood powder (formed by mixing camphor wood powder and eucalyptus wood powder in a mass ratio of 3:2), 35 parts of camphor leaf extract , 35 parts of nano-graphene, 105 parts of vinyl chloride monomer, 0.8 parts of LPO, 25 parts of DOA, 4 parts of ammonium bicarbonate, 15 parts of MAPE, 18 parts of dicumyl peroxide, 6 parts of maleic anhydride, 18 parts of KH5501, 80 parts of chlorinated paraffin, 140 parts of high-density polyethylene, and 450 parts of water.

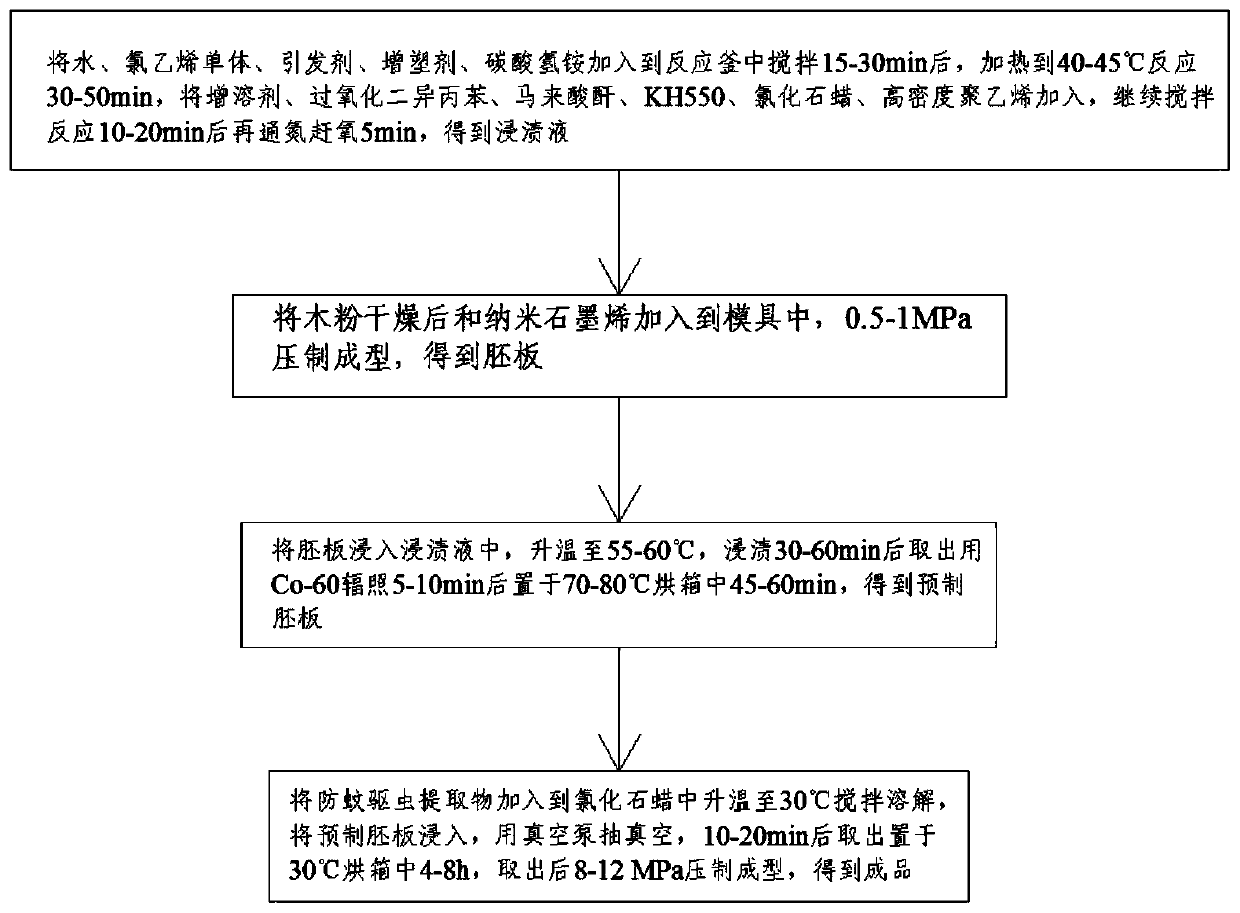

[0031] The preparation method of the above-mentioned anti-mosquito and insect repellent PVC composite material comprises the following steps:

[0032] Add water, vinyl chloride monomer, LPO, DOA, and ammonium bicarbonate into the reaction kettle and stir for 25 minutes, then heat to 42°C and react for 40 minutes, add MAPE, dicumyl peroxide, maleic anhydride, KH550, and chlorinated par...

Embodiment 2

[0034] An anti-mosquito and insect-repelling PVC composite material, comprising the following components in parts by weight: 160 parts of wood powder (made by mixing camphor wood powder and eucalyptus wood powder at a mass ratio of 3:2), 40 parts of anti-mosquito and insect repellent extract 30 parts of camphor leaf extract, peppermint extract, and borneol extract in a mass ratio of 1:1:1, 30 parts of nano-graphene, 120 parts of vinyl chloride monomer, 0.1 part of BPO, 20 parts of DIDA, carbonic acid 4 parts of ammonium hydrogen, 20 parts of MAPOE, 10 parts of dicumyl peroxide, 10 parts of maleic anhydride, 20 parts of KH550, 80 parts of chlorinated paraffin, 150 parts of high-density polyethylene, and 500 parts of water.

[0035] The preparation method of the above-mentioned anti-mosquito and insect repellent PVC composite material comprises the following steps:

[0036] Add water, vinyl chloride monomer, BPO, DIDA, ammonium bicarbonate into the reaction kettle, stir for 15 min...

Embodiment 3

[0038] An anti-mosquito and insect-repellent PVC composite material, comprising the following components in parts by weight: 200 parts of wood powder (made by mixing camphor wood powder and eucalyptus wood powder at a mass ratio of 3:2), 50 parts of anti-mosquito and insect-repellent extract Parts (made from camphor leaf extract, peppermint extract, borneol extract, and lavender extract in a mass ratio of 1:1:1:1), 25 parts of nano-graphene, 105 parts of vinyl chloride monomer, OPO 0.2 20 parts of DBS, 2 parts of ammonium bicarbonate, 15 parts of EAA, 16 parts of dicumyl peroxide, 6 parts of maleic anhydride, 12 parts of KH55012, 80 parts of chlorinated paraffin, 130 parts of high-density polyethylene, 450 parts of water .

[0039] The preparation method of the above-mentioned anti-mosquito and insect repellent PVC composite material comprises the following steps:

[0040] Add water, vinyl chloride monomer, OPO, DBS, ammonium bicarbonate into the reaction kettle and stir for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com