Large-area ultrathin plastic part injection mould

A technology for injection molds and plastic parts, which is applied in the field of injection molds for large-area ultra-thin plastic parts, can solve problems such as the inability to meet the mass production molding requirements of large-area 0.18mm ultra-thin injection parts, achieve ideal molding conditions, avoid top wrapping or Deformation, the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

[0038] Through the description of the specific implementation mode, when the technical means and functions adopted by the present invention to achieve the predetermined purpose can be obtained a deeper and more specific understanding, but the accompanying drawings are only for reference and description, and are not used to explain the present invention be restricted.

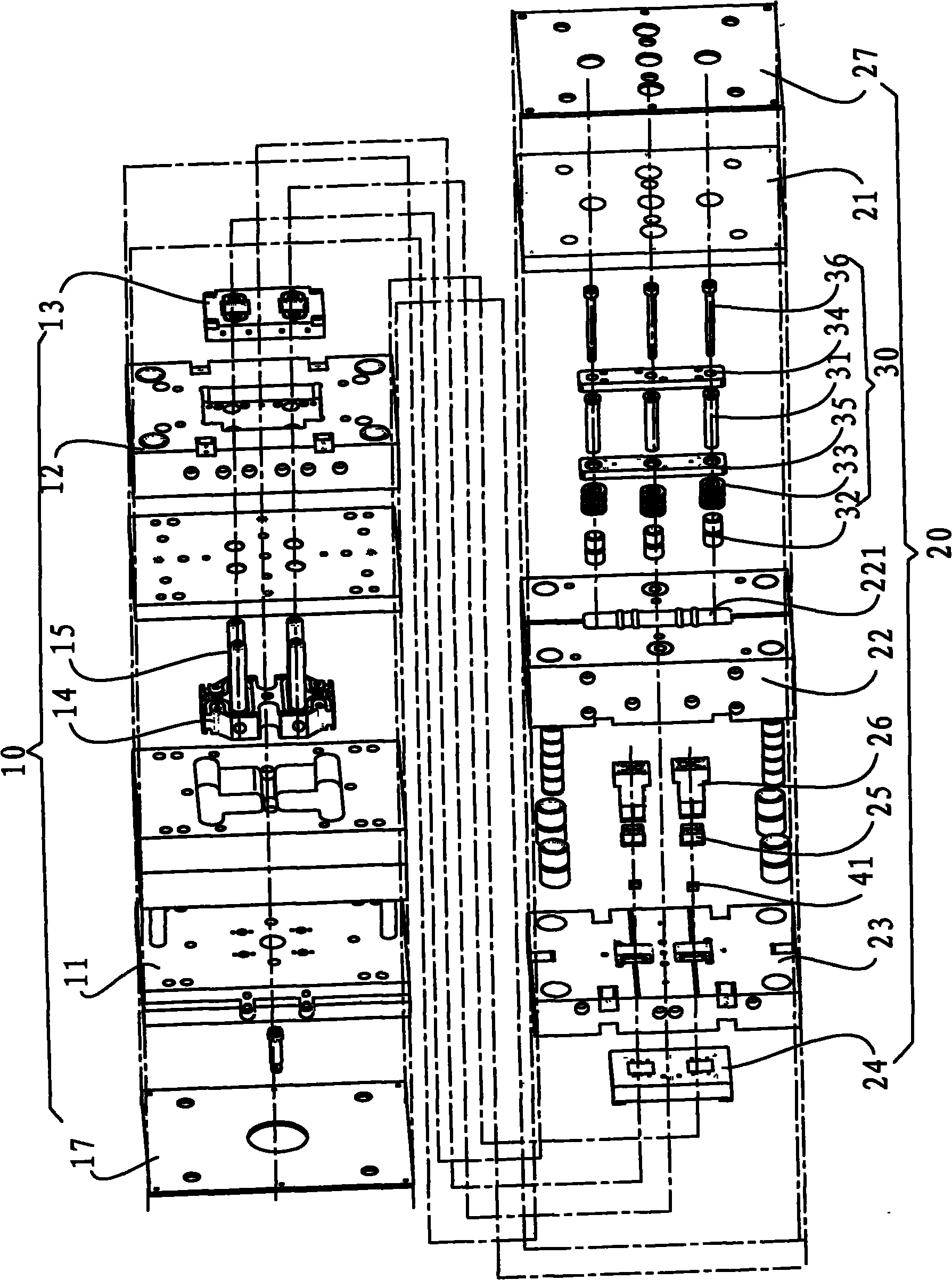

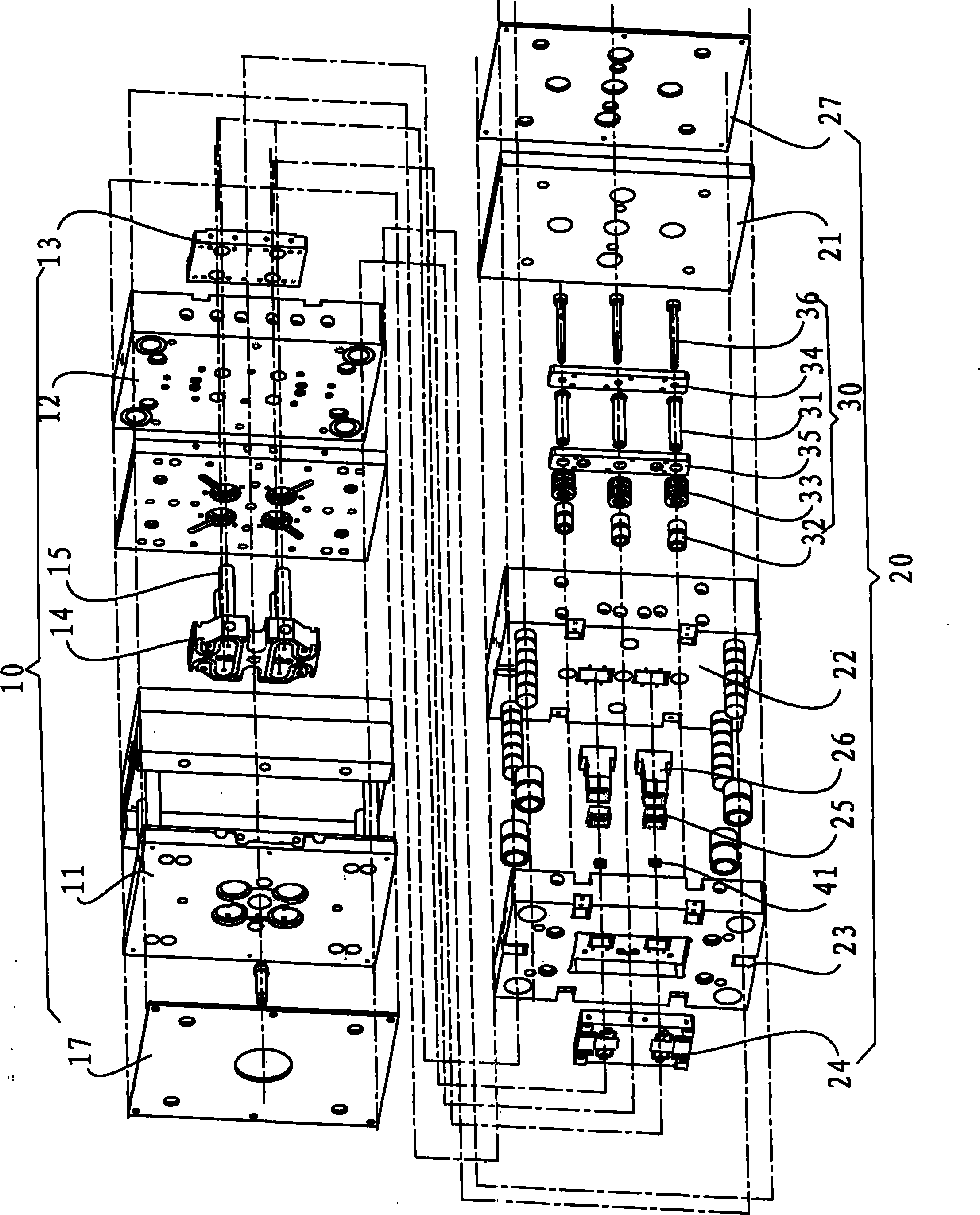

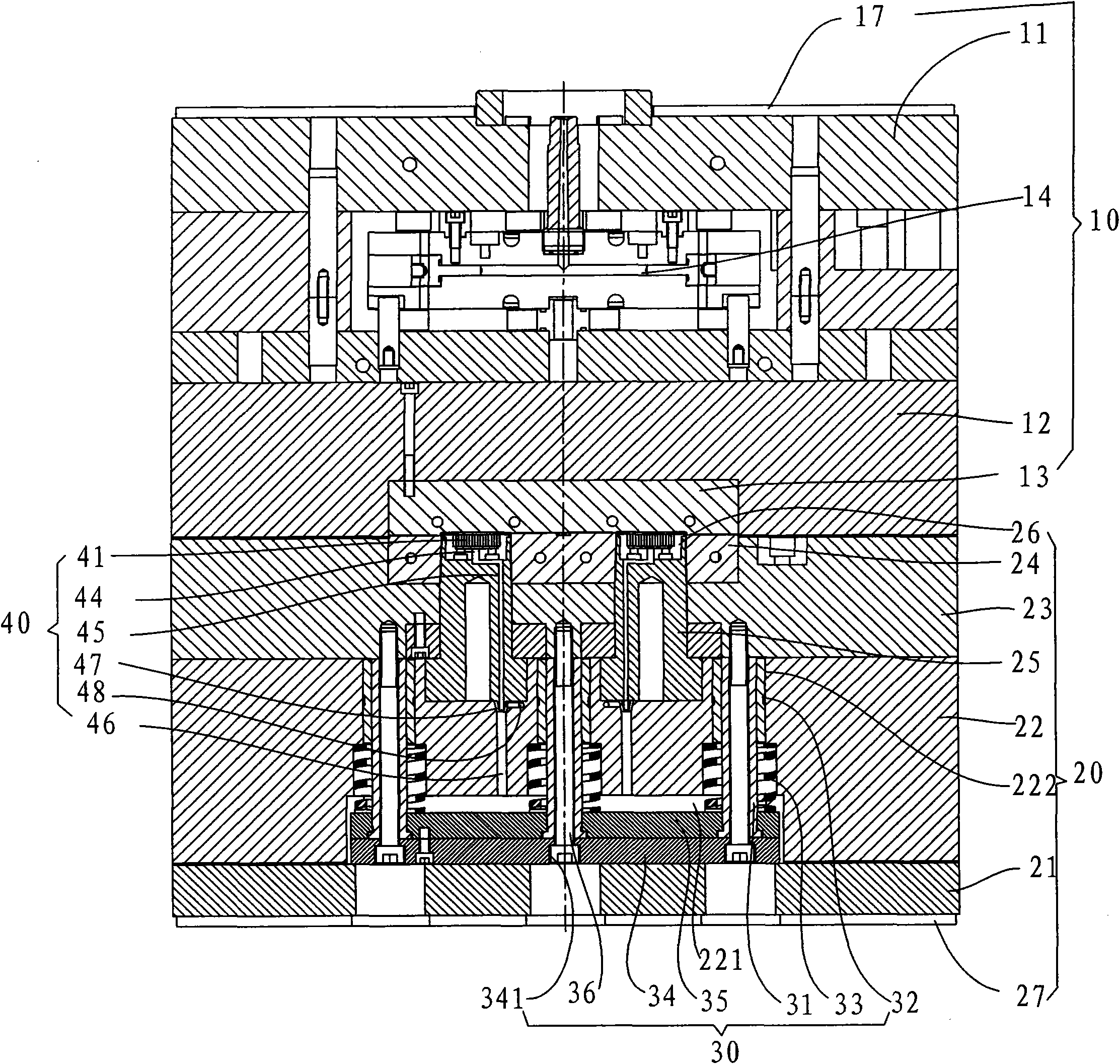

[0039] see figure 1 , figure 2 , image 3 , Figure 4 As shown, the large-area ultra-thin plastic injection mold of the preferred embodiment of the present invention mainly includes: a static mold 10 composed of a static mold fixing plate 11, a static template 12 and a static mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com